3D Bioprinting Revolution: How Nanoparticle Bioinks Are Advancing Tissue Engineering and Drug Development

This article provides a comprehensive overview of 3D bioprinting utilizing nanoparticle-laden bioinks, tailored for researchers and drug development professionals.

3D Bioprinting Revolution: How Nanoparticle Bioinks Are Advancing Tissue Engineering and Drug Development

Abstract

This article provides a comprehensive overview of 3D bioprinting utilizing nanoparticle-laden bioinks, tailored for researchers and drug development professionals. It explores the foundational principles of nanoparticle-enhanced hydrogels, detailing the methodological integration of metallic, polymeric, and ceramic nanoparticles for improved printability, mechanical strength, and bioactivity. The content addresses key challenges in rheology, cell viability, and sterilization, while offering optimization strategies for ink formulation and printing parameters. A critical evaluation covers the validation techniques, comparative performance against traditional bioinks, and the translational potential of these advanced constructs in creating physiologically relevant tissue models, drug screening platforms, and regenerative implants.

Nanoparticle Bioinks Explained: Core Concepts, Components, and Rationale for 3D Bioprinting

Nanoparticle bioinks represent an advanced class of materials for 3D bioprinting, engineered by incorporating functional nanoparticles (NPs) into traditional hydrogel-based bioinks. These composites are designed to enhance the physicochemical, biological, and mechanical properties of the printed constructs, thereby addressing critical challenges in tissue engineering and regenerative medicine. Within the broader thesis of 3D bioprinting research, nanoparticle bioinks are pivotal for creating biomimetic, bioactive, and structurally stable living tissues for applications in disease modeling, drug screening, and organ regeneration.

Composition and Key Functions

Nanoparticle bioinks typically consist of a hydrogel matrix (e.g., alginate, gelatin methacryloyl (GelMA), hyaluronic acid) infused with nanoparticles such as ceramic NPs (e.g., hydroxyapatite), polymeric NPs, metallic NPs (e.g., gold, silver), carbon-based NPs (e.g., graphene oxide), or drug-loaded liposomes. The nanoparticles confer multifunctionality.

Table 1: Primary Nanoparticle Types, Properties, and Functions in Bioinks

| Nanoparticle Type | Example Materials | Key Properties Imparted | Primary Function in Bioprinted Construct |

|---|---|---|---|

| Ceramic | Hydroxyapatite, Bioglass | Enhanced osteoconductivity, mechanical stiffness | Bone and cartilage tissue engineering |

| Metallic | Gold NPs, Silver NPs | Electrical conductivity, antimicrobial activity | Neural/ cardiac tissue interfaces, infection control |

| Polymeric | PLGA, Chitosan NPs | Controlled drug/protein delivery, improved shear-thinning | Sustained growth factor release, printability |

| Carbon-Based | Graphene Oxide, CNTs | High electrical conductivity, tensile strength | Electrically active tissues (muscle, nerve) |

| Lipid-Based | Liposomes, Extracellular Vesicles | High biocompatibility, efficient cell signaling molecule delivery | Enhanced cell-cell communication, wound healing |

Application Notes: Enhancing Bioink Performance

Note 1: Mechanical Reinforcement

Hydrogels alone often lack the mechanical integrity for printing load-bearing tissues. The incorporation of rigid nanoparticles like hydroxyapatite or cellulose nanocrystals creates nanocomposite networks. Recent studies show that adding 2% (w/v) cellulose nanocrystals to alginate bioinks increased compressive modulus by approximately 300%, from ~15 kPa to ~60 kPa.

Table 2: Quantitative Impact of Nanoparticles on Bioink Properties

| Bioink Formulation | Nanoparticle Load (wt%) | Key Outcome Measurement | Result (Mean ± SD) | Reference Year |

|---|---|---|---|---|

| GelMA + Graphene Oxide | 0.1% | Electrical Conductivity (S/m) | 0.18 ± 0.02 | 2023 |

| Alginate + HAp | 1.5% | Compressive Modulus (kPa) | 85 ± 7 | 2024 |

| Hyaluronic Acid + PLGA NPs | 3.0% | Sustained VEGF Release Duration (days) | 28 | 2023 |

| Collagen + Gold NPs | 0.05% | Printability Fidelity Score (%) | 94 ± 3 | 2024 |

Note 2: Biofunctionalization and Stimuli-Responsiveness

Nanoparticles can be surface-functionalized with peptides (e.g., RGD) to improve cell adhesion. Furthermore, magnetic nanoparticles (e.g., Fe₃O₄) enable non-contact manipulation of printed constructs or remote stimulation of cells. A 2023 protocol demonstrated that MNPs aligned endothelial cells in printed vessels under a magnetic field, increasing angiogenesis marker expression (CD31) by 2.5-fold.

Note 3: Controlled Therapeutic Delivery

Nanoparticles act as reservoirs for growth factors, antibiotics, or siRNA, protecting them from degradation and enabling localized, sustained release. This is crucial for creating instructive microenvironments. For instance, bioinks containing vascular endothelial growth factor (VEGF)-loaded mesoporous silica nanoparticles showed a sustained, linear release profile over 21 days, significantly enhancing vascular network formation in printed dermal grafts.

Experimental Protocols

Protocol 1: Synthesis and Characterization of a Nanocomposite Bioink for Bone Tissue Engineering

Title: Preparation and Rheological Assessment of GelMA-Hydroxyapatite Nanocomposite Bioink. Objective: To synthesize a osteogenic bioink by incorporating hydroxyapatite nanoparticles (nHAp) into GelMA hydrogel and characterize its printability and mechanical properties. Materials:

- GelMA polymer

- Photoinitiator (Lithium phenyl-2,4,6-trimethylbenzoylphosphinate, LAP)

- Hydroxyapatite nanoparticles (<200 nm)

- Phosphate Buffered Saline (PBS)

- UV light source (365 nm, 5-10 mW/cm²)

- Rheometer

- Extrusion bioprinter

Methodology:

- GelMA Solution Preparation: Dissolve GelMA in PBS at 10% (w/v) concentration at 37°C. Add LAP photoinitiator at 0.25% (w/v).

- Nanoparticle Incorporation: Gradually add nHAp powder to the GelMA solution to achieve a final concentration of 2% (w/v). Use probe sonication (5 cycles of 30s ON, 30s OFF, 40% amplitude) to ensure homogeneous dispersion. Avoid bubble formation.

- Rheological Characterization:

- Shear-thinning: Perform a steady-state flow sweep test from 0.1 to 100 s⁻¹ shear rate. The viscosity should decrease with increasing shear rate.

- Recovery Test: Apply high shear (100 s⁻¹ for 30s), then switch to low shear (0.1 s⁻¹ for 60s) to measure structural recovery (G' and G'' moduli).

- Printability Assessment: Load bioink into a sterile syringe. Print a 15x15 mm grid structure (22G nozzle, 150 kPa pressure, 8 mm/s speed). Assess filament uniformity, fusion, and strand diameter consistency.

- Crosslinking & Mechanical Testing: Expose printed structures to UV light (365 nm, 10 mW/cm², 60s). Perform unconfined compression tests on cylindrical samples (n=5) to determine compressive modulus.

Protocol 2: Bioprinting a Vascularized Construct with Drug-Releasing Nanoparticles

Title: Bioprinting a Vasculogenic Construct Using Bioinks Containing VEGF-Loaded Nanoparticles. Objective: To fabricate a cell-laden, prevascularized construct using a bioink containing VEGF-releasing PLGA nanoparticles. Materials:

- Human Umbilical Vein Endothelial Cells (HUVECs)

- Normal Human Dermal Fibroblasts (NHDFs)

- Fibrinogen, Thrombin, Aprotinin

- VEGF-loaded PLGA nanoparticles (VEGF-NPs)

- Multi-material extrusion bioprinter

Methodology:

- Bioink Preparation:

- Bioink A (Vascular Channels): Mix HUVECs (5x10⁶ cells/mL) with fibrinogen (10 mg/mL) and VEGF-NPs (1 mg/mL) in cell culture medium.

- Bioink B (Stromal Matrix): Mix NHDFs (3x10⁶ cells/mL) with fibrinogen (15 mg/mL).

- Prepare a crosslinking solution of thrombin (2 U/mL) and aprotinin (150 KIU/mL).

- Coaxial Bioprinting Setup: Load Bioink A into the core syringe and the thrombin/aprotinin solution into the sheath syringe of a coaxial printhead.

- Printing Process: Co-print a branching vascular tree structure into a pre-printed layer of Bioink B. The simultaneous extrusion crosslinks the fibrinogen in Bioink A upon contact with thrombin.

- Post-Print Culture: Transfer constructs to an incubator (37°C, 5% CO₂) for 15 minutes for complete gelation. Add endothelial growth medium.

- Analysis: At days 3, 7, and 14, fix samples and immunostain for CD31 to visualize endothelial network formation. Quantify total tube length and branch points per field of view.

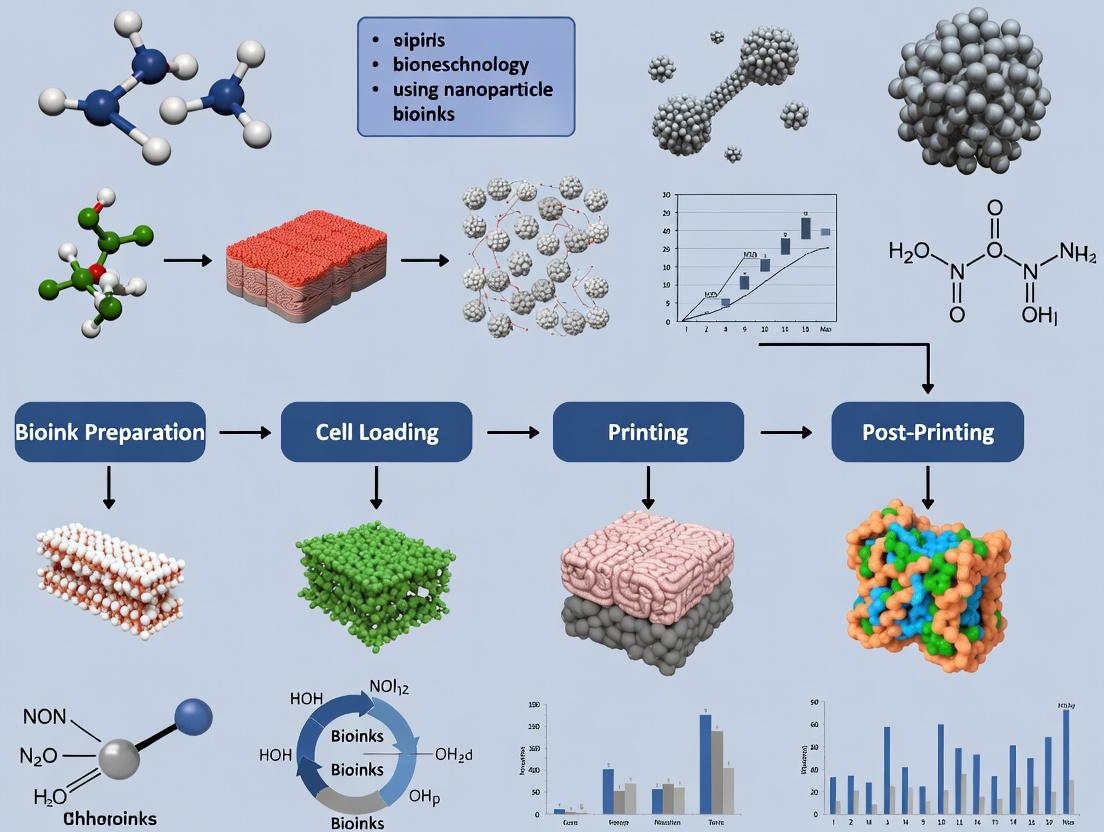

Visualization of Key Concepts

Title: Nanoparticle Bioink Engineering Workflow

Title: Nanoparticle-Induced Angiogenic Signaling Pathway

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Nanoparticle Bioink Research

| Item | Function in Research | Example Vendor/Product Note |

|---|---|---|

| Methacrylated Hydrogels (GelMA, Hyaluronic Acid-MA) | Provides photo-crosslinkable, tunable base matrix with inherent biocompatibility. | Advanced BioMatrix, GelMA Kit; EngiMaTrix, HAMA. |

| Functional Nanoparticles (HAp, GO, PLGA NPs) | Core additive for imparting mechanical, electrical, or drug-delivery properties. | Sigma-Aldrich (nHAp), Graphenea (GO), PolySciTech (PLGA NPs). |

| Photoinitiators (LAP, Irgacure 2959) | Enables rapid UV-mediated crosslinking of bioinks for shape fidelity. | Tokyo Chemical Industry (LAP); CIBA (Irgacure 2959). |

| Rheometer with Temperature Control | Critical for characterizing shear-thinning, recovery, and gelation kinetics of bioinks. | TA Instruments DHR series, Malvern Kinexus. |

| Sterile, Temperature-Controlled Bioprinter | For precise deposition of cell-laden nanocomposite bioinks. | Allevi 3, CELLINK BIO X, Regemat 3D. |

| Cell-Compatible Crosslinkers (CaCl₂, Thrombin) | For ionic (alginate) or enzymatic (fibrin) crosslinking post-printing. | Thermo Fisher Scientific. |

| Live/Dead Viability Assay Kit | Standard for assessing post-printing cell viability in 3D constructs. | Thermo Fisher Scientific (Calcein AM / Ethidium homodimer-1). |

Application Notes

Nanoparticles (NPs) are engineered into bioinks to transcend their traditional role as passive scaffold reinforcements. They impart bioactive, electrical, and diagnostic functionalities, enabling the creation of sophisticated, biomimetic, and intelligent tissue constructs.

1. Mechanical Reinforcement & Printability Nanoparticles like cellulose nanocrystals (CNCs), silica nanoparticles (SiNPs), and graphene oxide (GO) enhance the rheological properties of bioinks. They improve viscosity, yield stress, and shear-thinning behavior, enabling the printing of high-fidelity, self-supporting structures. This is critical for fabricating complex architectures with high shape fidelity.

2. Bioactivation & Signaling Nanoparticles functionalized with growth factors, peptides, or drugs provide sustained, localized biochemical cues. For example, hydroxyapatite nanoparticles (nHA) in bone bioinks adsorb bone morphogenetic protein-2 (BMP-2), promoting osteogenic differentiation. Lipid nanoparticles (LNPs) can deliver mRNA or siRNA to direct stem cell fate within the printed construct.

3. Electrically Conductive Networks NPs such as gold nanorods (AuNRs), graphene, and carbon nanotubes (CNTs) create percolating networks within insulating hydrogels (e.g., GelMA, alginate). This enables the fabrication of cardiac patches or neural tissues that can conduct electrical signals, synchronizing cell contraction and promoting maturation.

4. Real-Time Monitoring & Theranostics Fluorescent, magnetic, or plasmonic nanoparticles (e.g., quantum dots, superparamagnetic iron oxide nanoparticles - SPIONs) can be embedded as biosensors. They allow non-invasive monitoring of tissue maturation, oxygen tension, or specific biomarkers post-printing, merging fabrication with diagnostic capability.

5. Crosslinking & Structural Integrity Photocatalytic nanoparticles like titanium dioxide (TiO₂) or gold nanoparticles (AuNPs) can initiate or enhance crosslinking upon exposure to specific light wavelengths (e.g., visible light vs. UV), leading to deeper, more uniform hydrogel curing and improved cell viability.

Quantitative Data Summary

Table 1: Mechanical Enhancement by Nanoparticles in Alginate/GelMA Bioinks

| Nanoparticle Type | Concentration (w/v %) | Storage Modulus Increase (%) | Compression Modulus (kPa) | Reference Bioink |

|---|---|---|---|---|

| Cellulose Nanocrystals (CNC) | 1.5% | ~220% | 45 ± 3 | 3% Alginate |

| Graphene Oxide (GO) | 0.2% | ~180% | 68 ± 5 | 5% GelMA |

| Silica Nanoparticles (SiNP) | 2.0% | ~150% | 52 ± 4 | 4% Alginate/GelMA Blend |

| n-Hydroxyapatite (nHA) | 2.5% | ~120% | 95 ± 8 | 7% GelMA for Bone |

Table 2: Functional Outcomes in Bioprinted Constructs with NPs

| NP Function | NP Type & Model | Key Outcome Metric | Result vs. Control |

|---|---|---|---|

| Osteogenic Induction | BMP-2 loaded nHA / hMSCs | Alkaline Phosphatase Activity (Day 14) | 3.2-fold increase |

| Cardiac Conduction | AuNRs in GelMA / Cardiomyocytes | Conduction Velocity (cm/s) | 18.5 ± 1.2 vs. 9.8 ± 0.9 |

| Neural Guidance | GO-PEDOT in Hyaluronic Acid / Neural Progenitors | Neurite Length (µm, Day 7) | 350 ± 25 vs. 210 ± 30 |

| Angiogenic Induction | VEGF-loaded PLGA NPs in Bioink / HUVECs | Tubule Formation (Total Length mm/mm²) | 22.5 ± 2.1 vs. 11.3 ± 1.5 |

Experimental Protocols

Protocol 1: Formulation and Characterization of a Mechanically Reinforced CNF/GelMA/GO Bioink for Neural Tissue

Aim: To formulate a bioink with enhanced shear-thinning and electrical conductivity for neural tissue models.

Materials:

- GelMA (Methacryloyl gelatin)

- Photoinitiator (LAP, Lithium phenyl-2,4,6-trimethylbenzoylphosphinate)

- Graphene Oxide (GO) dispersion (2 mg/mL in water)

- Cellulose Nanofibrils (CNF) suspension (1% w/w)

- Phosphate Buffered Saline (PBS)

- Primary Rat Neural Stem Cells (NSCs)

Procedure:

- Bioink Preparation: a. Dissolve GelMA to 7% (w/v) in PBS containing 0.25% (w/v) LAP at 37°C. b. Homogenize CNF suspension (final 0.5% w/v) into the GelMA solution using a dual asymmetric centrifugal mixer at 2000 rpm for 2 minutes. c. Add GO dispersion dropwise under vortex to achieve a final concentration of 0.1% (w/v). Mix for an additional 3 minutes. d. Sterilize the composite bioink by syringe filtration (0.22 µm, if viscosity allows) or UV irradiation on ice for 20 minutes.

Rheological Characterization: a. Load bioink onto a cone-plate rheometer (25°C, gap 0.1 mm). b. Perform a shear rate sweep from 0.1 to 100 s⁻¹ to assess shear-thinning. c. Perform an amplitude sweep at 1 Hz to determine the storage (G') and loss (G'') moduli and yield stress.

3D Bioprinting & Culture: a. Mix NSCs (5 x 10^6 cells/mL) gently into the bioink. b. Print using a pneumatic extrusion bioprinter (22-25°C, 0.41 mm nozzle, 25 kPa). c. Crosslink immediately after printing with visible blue light (405 nm, 10 mW/cm², 60 seconds). d. Culture in neural induction medium. Assess viability (Live/Dead assay) at days 1, 3, and 7. Perform immunocytochemistry for β-III Tubulin and GFAP at day 14.

Protocol 2: Assessment of Osteogenic Differentiation in a BMP-2/nHA Laden Bioink

Aim: To evaluate sustained growth factor delivery from nanoparticles for bone tissue engineering.

Materials:

- Recombinant Human BMP-2

- Hydroxyapatite Nanoparticles (nHA, <200 nm)

- Sodium Alginate (high G-content)

- Calcium Chloride (CaCl₂) crosslinking solution (100 mM)

- Human Mesenchymal Stem Cells (hMSCs)

- Osteogenic medium (base: α-MEM, 10% FBS, 1% P/S)

Procedure:

- BMP-2 Loading onto nHA: a. Incubate nHA (10 mg) with 5 µg of BMP-2 in 1 mL of acetate buffer (pH 5.0) for 24 hours at 4°C under gentle agitation. b. Centrifuge at 12,000 rpm for 10 minutes. Collect supernatant for unbound BMP-2 quantification (ELISA). c. Wash pellet twice with PBS and re-suspend in sterile deionized water.

Bioink Preparation & Printing: a. Prepare 3% (w/v) alginate solution in culture medium. b. Blend BMP-2-loaded nHA into alginate to a final concentration of 2% (w/v) nHA. c. Mix with hMSCs (10 x 10^6 cells/mL) gently. d. Extrude bioink into a 6-well plate containing CaCl₂ solution for instantaneous ionic crosslinking. Print lattice structures (10 x 10 x 2 mm).

In Vitro Culture & Analysis: a. Transfer constructs to osteogenic medium. Change medium twice weekly. b. Quantitative PCR: At days 7, 14, and 21, extract RNA and analyze expression of RUNX2, ALPL, and SPP1 (Osteopontin). Normalize to GAPDH. c. Biochemical Assay: At day 14, measure Alkaline Phosphatase (ALP) activity using a pNPP assay, normalized to total DNA content. d. Histology: At day 28, fix constructs, paraffin-embed, section, and stain with Alizarin Red S for calcium deposition.

Diagrams

Title: Multifunctional Roles of NPs in a Composite Bioink

Title: Workflow for Osteogenic Differentiation Assay

Title: BMP-2/nHA Induced Osteogenic Signaling Pathway

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Nanoparticle-Bioink Research

| Item | Function & Rationale | Example Product/Catalog |

|---|---|---|

| Methacryloyl Gelatin (GelMA) | Photocrosslinkable hydrogel base; provides cell-adhesive RGD motifs. | Sigma-Aldrich, 900637; Advanced BioMatrix, GEL-IPA-1. |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Biocompatible photoinitiator for visible/UV light crosslinking; superior to Irgacure 2959. | Sigma-Aldrich, 900889. |

| Alginate (High G-Content) | Rapid ionic crosslinking with Ca²⁺; allows gentle cell encapsulation. | NovaMatrix, Protanal LF 10/60. |

| Graphene Oxide (GO) Dispersion | Provides electrical conductivity, mechanical reinforcement, and can influence cell signaling. | Graphenea, GO aqueous dispersion (4 mg/mL). |

| Cellulose Nanocrystals (CNCs) | High-aspect-ratio nanoparticles for exceptional rheological modification and shear-thinning. | CelluForce, NCC. |

| Hydroxyapatite Nanoparticles (nHA) | Biomimetic mineral for bone bioinks; high surface area for growth factor adsorption. | Sigma-Aldrich, 677418. |

| Recombinant Human BMP-2 | Potent osteoinductive growth factor for functionalizing nanoparticles. | PeproTech, 120-02. |

| Superparamagnetic Iron Oxide Nanoparticles (SPIONs) | Enable magnetic manipulation of bioinks and serve as MRI contrast agents. | Sigma-Aldrich, 747409 or 725331. |

| Extracellular Matrix (ECM) Nanoparticles | Decellularized, milled ECM from tissues for tissue-specific bioink formulation. | Matricel, ECMatrix products. |

| Dual-Asymmetric Centrifugal Mixer (SpeedMixer) | Essential for homogenous, bubble-free mixing of viscous NP-bioink composites. | FlackTek, DAC 150.1 FVZ-K. |

Within the context of 3D bioprinting, nanoparticle-functionalized bioinks represent a transformative approach for creating advanced tissue constructs. These nanocomposite bioinks enhance printability, mechanical integrity, and biological functionality. This document provides detailed application notes and experimental protocols for utilizing four core nanoparticle classes—Metallic, Polymeric, Ceramic, and 2D—in bioink formulation, emphasizing their native properties and roles in modulating cellular behavior within 3D-bioprinted scaffolds.

Native Properties and Quantitative Comparison

The intrinsic properties of nanoparticles directly influence bioink performance. Key parameters include size, surface charge (Zeta potential), and specific functional characteristics relevant to bioprinting.

Table 1: Native Properties of Key Nanoparticle Classes for Bioink Formulation

| Nanoparticle Class | Typical Examples | Primary Native Properties | Typical Size Range | Key Influence on Bioink |

|---|---|---|---|---|

| Metallic | Gold (Au), Silver (Ag), Iron Oxide (Fe₃O₄) | Plasmonic resonance, Superparamagnetism, High conductivity, Antimicrobial (Ag) | 5-100 nm | Enhance mechanical strength, enable non-invasive imaging (contrast), facilitate magnetic manipulation, provide antimicrobial activity. |

| Polymeric | PLGA, Chitosan, Polycaprolactone (PCL) | Biodegradability, Tunable hydrophobicity/hydrophilicity, High drug loading capacity | 50-500 nm | Control drug release kinetics, improve bioadhesion, modulate degradation rate of the printed construct. |

| Ceramic | Hydroxyapatite (HAp), Silica (SiO₂), Bioactive glass | Osteoconductivity, High compressive strength, Bioactivity, Tunable porosity | 20-300 nm | Promote mineralization and bone regeneration, significantly reinforce mechanical properties (e.g., compressive modulus). |

| 2D | Graphene Oxide (GO), MXenes, Layered Double Hydroxides (LDH) | Ultra-high surface area, Anisotropic mechanical strength, High electrical conductivity, Tunable surface chemistry | Thickness: 1-10 nm Lateral: 100 nm-5 µm | Dramatically improve electrical conductivity for neural/cardiac tissues, provide exceptional mechanical reinforcement at low loadings, enable near-infrared (NIR) light responsiveness. |

Application Notes in 3D Bioprinting

Metallic Nanoparticles (e.g., Gold Nanoparticles - AuNPs)

- Role: Multi-functional crosslinkers and reporters. AuNPs can be surface-functionalized with thiolated polymers (e.g., thiolated hyaluronic acid) to act as photothermal or chemical crosslinking hubs within bioinks, stabilizing the printed structure.

- Key Application: Real-time monitoring of print fidelity via plasmon resonance shifts during extrusion.

Polymeric Nanoparticles (e.g., PLGA)

- Role: Sustained delivery microenvironments. PLGA nanoparticles pre-loaded with growth factors (e.g., BMP-2, VEGF) can be uniformly dispersed in alginate/gelatin bioinks. Post-printing, controlled release directs spatially defined cellular differentiation.

- Key Application: Creating concentration gradients of morphogens within a single printed construct.

Ceramic Nanoparticles (e.g., Nano-Hydroxyapatite - nHAp)

- Role: Biomimetic reinforcement for bone bioinks. nHAp incorporated into gelatin-methacryloyl (GelMA) bioinks mimics the natural bone matrix, enhancing osteogenic differentiation of mesenchymal stem cells (MSCs) and improving resistance to compression.

- Key Application: Fabricating load-bearing osteochondral scaffolds with region-specific mineral content.

2D Nanoparticles (e.g., Graphene Oxide - GO)

- Role: Electroactive and mechanical nanoreinforcement. GO sheets improve the viscosity and shear-thinning behavior of bioinks, enhancing printability. Their conductivity supports synchronous contraction in bioprinted cardiac patches.

- Key Application: Engineering electrically conductive neural guidance conduits or cardiac tissue patches.

Experimental Protocols

Protocol 1: Formulation and Rheological Characterization of nHAp-GelMA Nanocomposite Bioink

Objective: To prepare and characterize a osteogenic bioink with enhanced mechanical properties. Materials: GelMA (5-10% w/v), nHAp suspension (20% w/v in PBS), LAP photoinitiator, PBS. Procedure:

- nHAp Dispersion: Sonicate nHAp suspension for 30 min at 100 W in an ice bath to ensure homogeneity.

- Bioink Preparation: Under sterile conditions, mix GelMA prepolymer solution with LAP (0.25% w/v). Gradually add the sonicated nHAp suspension to achieve a final concentration of 0-5% w/v nHAp under gentle vortexing.

- Homogenization: Pass the mixture through a high-shear mixer (e.g., Thinky mixer) at 2000 rpm for 2 min, followed by degassing.

- Rheology: Load bioink onto a cone-and-plate rheometer. Perform:

- Viscosity vs. Shear Rate: Log-Log plot from 0.1 to 1000 1/s.

- Storage/Loss Modulus (G'/G"): Amplitude sweep (0.1-100% strain) at 1 Hz.

- Printability Assessment: Print a standard lattice structure (e.g., 15x15x2 mm) using a pneumatic extrusion bioprinter. Assess filament uniformity and strand diameter fidelity.

Protocol 2: Assessing Bioactivity via Osteogenic Signaling Pathway Activation

Objective: To evaluate the activation of the BMP-2/Smad signaling pathway in MSCs within a 3D-bioprinted nHAp-GelMA construct. Materials: Human Bone Marrow MSCs, Osteogenic differentiation medium, nHAp-GelMA and pure GelMA bioinks, Anti-phospho-Smad1/5/9 antibody, qPCR reagents for Runx2, Osterix.

Diagram 1: nHAp-Activated BMP-2/Smad Signaling in MSCs (100 chars)

Procedure:

- 3D Cell Culture: Bioprint 5 mm diameter x 2 mm thick discs with MSCs (5x10^6 cells/mL) encapsulated in both nHAp-GelMA and control GelMA bioinks. Crosslink with blue light (405 nm, 5 mW/cm², 60 s).

- Culture: Maintain constructs in osteogenic medium for 7 and 14 days.

- Protein Analysis (Day 3):

- Lyse constructs in RIPA buffer with phosphatase inhibitors.

- Perform Western Blot for phospho-Smad1/5/9 and total Smad.

- Normalize p-Smad intensity to total Smad and then to β-actin.

- Gene Expression (Day 7, 14):

- Extract RNA, synthesize cDNA.

- Perform qPCR for Runx2 and Osterix. Use GAPDH as housekeeper. Calculate fold change via 2^(-ΔΔCt) method.

Protocol 3: Fabrication of an Electrically Conductive Cardiac Patch with GO

Objective: To fabricate and functionally characterize a GO-incorporated GelMA bioink for cardiac tissue engineering. Materials: GO dispersion (2 mg/mL), GelMA, neonatal rat cardiomyocytes (NRCMs), carbon rod electrodes. Procedure:

- Bioink Formulation: Mix GO dispersion with GelMA prepolymer to achieve 0.5 mg/mL GO final concentration. Homogenize and sterilize via UV exposure (30 min).

- Cell Encapsulation: Mix NRCMs (1x10^7 cells/mL) into GO-GelMA and control GelMA bioinks.

- Bioprinting: Print a 15x15x1 mm sheet using a microextrusion printer. Crosslink.

- Functional Assessment (Day 7):

- Place construct in a custom perfusion chamber with parallel carbon electrodes.

- Measure extracellular field potentials using a multi-electrode array (MEA).

- Analyze beating frequency, amplitude, and conduction velocity.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents for Nanoparticle Bioink Research

| Item | Function in Research | Example/Specification |

|---|---|---|

| Methacrylated Biomolecules | Forms photocrosslinkable hydrogel matrix. | GelMA (Dojin, Advanced Biomatrix), degree of substitution >70%. |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Efficient, cytocompatible photoinitiator for visible light crosslinking. | >98% purity, stock solution at 5% w/v in PBS. |

| Functionalized Nanoparticles | Enables covalent integration into hydrogel network. | Thiol- or acrylate-modified AuNPs/GO. |

| Cell-Compatible Dispersant | Prevents NP aggregation in bioink. | Sterile, 1% Pluronic F-68 in PBS. |

| Rheology Modifier | Fine-tunes printability without affecting bioactivity. | Nanocrystalline cellulose (NCC) or gellan gum. |

| Growth Factor Cocktails | Drives specific differentiation in printed constructs. | Recombinant human BMP-2, VEGF, TGF-β3. |

| Live/Dead Viability Assay Kit | Standardized assessment of cell health post-printing. | Calcein AM / Ethidium homodimer-1. |

| Mechanical Tester | Quantifies compressive/tensile modulus of printed constructs. | Instron or Bose ElectroForce with 5N load cell. |

Diagram 2: Workflow for Developing NP-Functionalized Bioinks (99 chars)

Within the advancing field of 3D bioprinting, a central thesis explores the development of next-generation nanoparticle-functionalized bioinks. These materials aim to transcend the limitations of conventional hydrogels by integrating nanoparticles (NPs) that impart mechanical reinforcement, controlled drug release, conductivity, or bioactivity. This document details the application notes and protocols for understanding and achieving synergy between nanoparticles and key hydrogel matrices (Alginate, Gelatin Methacryloyl (GelMA), Collagen). This research is foundational for creating complex, functional tissue constructs and advanced drug screening platforms.

The table below summarizes the primary integration mechanisms and their quantitative effects on composite bioink properties, as cited in recent literature.

Table 1: Mechanisms and Quantitative Effects of Nanoparticle Integration in Hydrogels

| Hydrogel | Nanoparticle (NP) Type | Primary Integration Mechanism | Key Quantitative Effects (Typical Range) | Key References |

|---|---|---|---|---|

| Alginate | Silica NPs (50-100 nm) | Physical encapsulation & ionic crosslink mediation | Compressive Modulus: +40% to +150%Swelling Ratio: Decrease by 20-35%Printability (Fidelity Score): +15% | Gaharwar et al., 2020; Shi et al., 2022 |

| GelMA | Cellulose Nanocrystals (CNCs, 5-20 nm x 100-200nm) | H-bonding, physical entanglement, & photo-crosslinking synergy | Storage Modulus (G'): +80% to +300%Degradation Rate (37°C): Slowed by 25-50%Viability (Day 7): >90% | Li et al., 2021; Li & Kumacheva, 2023 |

| Collagen | Laponite nanoclay (25-50 nm discs) | Electrostatic interactions & nucleation of fibrillogenesis | Storage Modulus (G'): +200% to +500%Gelation Time: Reduced by 30-70%Fibril Diameter: More uniform distribution | Carrow et al., 2021; Patel et al., 2022 |

| Alginate/GelMA Composite | Graphene Oxide (GO, 1-2 nm thick) | Multivalent H-bonding & covalent amidation | Electrical Conductivity: 0.05 - 0.5 S/mYoung's Modulus: +120%Neurite Outgrowth: Increased 2.5-fold | Joshi et al., 2022; Zhang et al., 2023 |

Diagram 1: NP-Hydrogel Integration Pathways

Experimental Protocols

Protocol 3.1: Formulation & Rheological Characterization of CNC-GelMA Nanocomposite Bioink

Objective: To synthesize a GelMA bioink reinforced with cellulose nanocrystals (CNCs) and characterize its printability and mechanical properties.

Materials: See "The Scientist's Toolkit" (Section 5).

Procedure:

- CNC Dispersion: Suspend lyophilized CNCs in PBS at 2% (w/v). Sonicate on ice using a probe sonicator (30% amplitude, 5 min, pulse 2s on/1s off) to obtain a homogeneous suspension.

- GelMA Solution: Dissolve GelMA (Methacrylation degree ~70%) in PBS at 40°C to a final concentration of 7% (w/v). Add 0.25% (w/v) photoinitiator (LAP).

- Bioink Formulation: Gently mix the CNC suspension with the GelMA solution at volume ratios to achieve final CNC concentrations of 0%, 0.5%, 1.0%, and 1.5% (w/v) in the composite. Ensure homogeneous mixing via gentle vortexing and incubation at 37°C for 30 min. Avoid introducing bubbles.

- Rheological Analysis:

- Load bioink onto a 25mm parallel plate rheometer equilibrated at 20°C.

- Flow Sweep: Measure viscosity over a shear rate range of 0.01 to 100 s^-1.

- Amplitude Sweep: At a fixed frequency of 1 Hz, measure storage (G') and loss (G'') moduli as a function of strain (0.1% to 100%).

- Thixotropy Test: Apply a high shear rate (50 s^-1) for 30s, then a low shear rate (0.1 s^-1) for 60s. Monitor recovery of G'.

- Printability Assessment: Load bioink into a sterile cartridge and extrude through a 22G conical nozzle using a pneumatic bioprinter. Print a 20-layer lattice structure (15mm x 15mm). Quantify filament diameter uniformity and pore fidelity using image analysis (ImageJ). Calculate a printability factor (Pf) = (Actual Area / Designed Area) * 100%.

Diagram 2: CNC-GelMA Bioink Workflow

Protocol 3.2: Assessing Sustained Release from Laponite-Alginate Nanocomposite Beads

Objective: To encapsulate a model drug (e.g., Bovine Serum Albumin-FITC, BSA-FITC) in Laponite-reinforced alginate beads and characterize release kinetics.

Procedure:

- Nanocomposite Preparation: Dissolve Laponite RD in deionized water (2% w/v) under vigorous stirring for 1 hour. Mix this suspension with an equal volume of sodium alginate solution (4% w/v in PBS) containing 1 mg/mL BSA-FITC. Stir for 2 hours.

- Ionotropic Gelation: Load the nanocomposite solution into a syringe. Using a syringe pump, extrude droplets into a 100mM CaCl₂ crosslinking bath. Maintain a needle-to-bath distance of 5 cm. Stir the bath gently for 15 min to allow bead curing.

- Release Study: Wash beads (n=50 per group) with PBS and transfer to 5 mL of PBS (pH 7.4) as release medium. Incubate at 37°C with gentle shaking (50 rpm).

- Sampling & Quantification: At predetermined time points (0.5, 1, 2, 4, 8, 24, 48, 72 h), withdraw 500 µL of release medium and replace with fresh PBS. Measure the fluorescence of samples (Ex/Em: 495/519 nm) using a plate reader. Calculate cumulative release percentage against a standard curve.

Table 2: Representative Release Data from Laponite-Alginate Beads

| Time Point (h) | Cumulative Release (%)\n(Alginate Only) | Cumulative Release (%)\n(Alginate + 1% Laponite) | Release Mechanism Shift (Model Fit) |

|---|---|---|---|

| 2 | 45.2 ± 3.5 | 28.7 ± 2.1 | Initial burst reduced |

| 8 | 68.7 ± 4.1 | 45.3 ± 3.8 | Fickian diffusion dominant |

| 24 | 92.5 ± 5.0 | 65.1 ± 4.5 | Sustained release phase |

| 72 | ~100 | 85.4 ± 6.2 | Near-zero-order kinetics |

Signaling Pathway Modulation via NP-Hydrogel Composites

Nanoparticles can locally present bioactive cues (e.g., growth factors, peptides) or modulate mechanical signals that influence encapsulated cell behavior via specific pathways.

Diagram 3: NP-Mediated Cell Signaling

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Nanoparticle-Hydrogel Bioink Research

| Item (Supplier Examples) | Function in Research |

|---|---|

| GelMA (Advanced BioMatrix, Cellink) | Photocrosslinkable hydrogel base providing natural cell adhesion motifs (RGD) and tunable mechanical properties. |

| Sodium Alginate (Sigma-Aldrich, Pronova) | Ionic-crosslinkable polysaccharide for rapid gelation; forms the basis for shear-thinning bioinks. |

| Type I Collagen, Rat Tail (Corning) | Gold-standard natural ECM protein for 3D cell culture; requires pH/thermal gelation. |

| Cellulose Nanocrystals (CNCs) (CelluForce, UMass) | Rod-shaped NPs for mechanical reinforcement, viscosity modulation, and inducing shear-thinning. |

| Laponite RD (BYK) | Synthetic nanoclay discs that act as rheological modifiers and nano-scale crosslinkers, accelerating gelation. |

| Graphene Oxide (GO) Dispersion (Graphenea) | 2D carbon NP for electrical conductivity, mechanical reinforcement, and functionalization with biomolecules. |

| Lithium Phenyl-2,4,6-Trimethylbenzoylphosphinate (LAP) | Efficient, cytocompatible water-soluble photoinitiator for visible/UV crosslinking of GelMA. |

| Calcium Chloride (CaCl₂) Solution | Ionic crosslinker for alginate, forming stable "egg-box" structures. |

| Sulfo-Cyanine5 NHS Ester (Lumiprobe) | Fluorescent dye for covalent labeling of nanoparticles or proteins to track distribution and release. |

Application Notes

Nanoparticle (NP) inclusion in 3D bioprinting bioinks addresses critical limitations in tissue engineering scaffolds. The primary motivations—mechanical reinforcement, electrical conductivity, biological activation, and topographical modification—converge to create biomimetic, functional constructs. Recent research (2023-2024) emphasizes multi-functional NPs that combine these properties to direct cell fate and enhance integration in vivo.

Table 1: Quantitative Performance Metrics of NP-Included Bioinks (2023-2024 Data)

| Motivation | NP Type & Concentration | Base Bioink | Key Quantitative Outcome | Reference/Model Study |

|---|---|---|---|---|

| Mechanical | Silica NPs (2% w/v) | GelMA/HAMA | Young's Modulus ↑ from 15 kPa to 42 kPa; Print fidelity improved by 35% | Adv. Healthcare Mat., 2023 |

| Electrical | Graphene Oxide (GO) (0.5 mg/mL) | Alginate/Collagen | Conductivity: 12 S/m; C2C12 myoblast alignment ↑ 80%; Contraction force ↑ 3.2-fold | Biofabrication, 2024 |

| Biological | Mesoporous Silica NPs loaded with BMP-2 (1% w/v) | GelMA/nanocellulose | Sustained release over 21 days; Osteogenic differentiation (ALP activity) ↑ 4.5x vs. bolus delivery | Small, 2023 |

| Topographical | Laponite nanoclay (3% w/v) | PEGDA | Surface roughness (Ra) ↑ from 5 nm to 120 nm; hMSC spreading area ↑ 150% | Acta Biomater., 2024 |

| Multifunctional | Cellulose Nanocrystals-Au hybrid (1.5% w/v) | Hyaluronic Acid | Compressive strength ↑ to 85 kPa; Electrical impedance ↓ 60%; Neural marker expression (β-III tubulin) ↑ 70% | Nature Comms., 2023 |

Experimental Protocols

Protocol 1: Assessing Mechanical Reinforcement of NP-Bioinks

Objective: To quantify the enhancement in rheological and tensile/compressive properties of a bioink with silica NPs. Materials:

- GelMA (10% w/v) / HAMA (2% w/v) pre-polymer solution.

- Silica nanoparticles (10 nm diameter, functionalized with methacrylate groups).

- Photoinitiator (LAP, 0.25% w/v).

- Rheometer, UV crosslinking system (365 nm, 5 mW/cm²), Universal Testing Machine.

Procedure:

- NP Dispersion: Add silica NPs to deionized water to achieve a 10% w/v stock. Sonicate (30% amplitude, 5 min, pulse 5s on/5s off, on ice).

- Bioink Formulation: Mix GelMA, HAMA, and LAP. Gently blend with the silica NP stock to final concentrations of 2% w/v NPs, 8% w/v GelMA, and 1.5% w/v HAMA. Avoid vortexing; use pipette mixing for 5 min.

- Rheological Testing: Load bioink onto a parallel-plate rheometer (25°C, 1 mm gap). Perform:

- Amplitude sweep (0.1-100% strain, 1 Hz) to determine linear viscoelastic region.

- Frequency sweep (0.1-10 Hz, 1% strain) to record storage (G') and loss (G'') moduli.

- Thixotropy test: Apply high shear (100 s⁻¹ for 30s), then low shear (0.1 s⁻¹ for 60s); monitor viscosity recovery.

- Construct Fabrication & Testing: Print a 15x15x5 mm lattice (22G nozzle, 0.8 mm/s). Crosslink with UV for 60s.

- Condition in PBS at 37°C for 24h.

- Perform unconfined compression test at 1 mm/min until 60% strain. Calculate Young's modulus from the linear slope (10-20% strain).

Protocol 2: Evaluating Bioactive NP Signaling in a Bioprinted Construct

Objective: To assess sustained growth factor release and osteogenic differentiation from MSN-loaded bioinks. Materials:

- Mesoporous Silica NPs (MSNs, pore size 5 nm).

- Recombinant human BMP-2.

- GelMA (7% w/v) / Nanofibrillated Cellulose (1% w/v) bioink.

- hMSCs (passage 4-6), osteogenic assay kit (ALP).

Procedure:

- Growth Factor Loading: Incubate 50 mg of MSNs in 1 mL of BMP-2 solution (10 µg/mL) for 24h at 4°C under gentle agitation. Centrifuge (12,000 rpm, 10 min), wash twice with PBS, and lyophilize.

- Bioink Preparation & Bioprinting: Resuspend BMP-2-loaded MSNs in bioink precursor at 1% w/v. Mix with hMSCs (5x10⁶ cells/mL). Print 8 mm diameter x 3 mm thick discs into a sterile chambered slide. UV crosslink (405 nm, 30s).

- Release Kinetics: Place each printed disc in 1 mL of release medium (PBS + 0.1% BSA) at 37°C. At predetermined time points (1, 3, 7, 14, 21 days), collect entire medium and replenish. Quantify BMP-2 concentration via ELISA.

- Osteogenic Differentiation: Culture constructs in basic medium (no osteogenic inducters) for 21 days. At day 7, 14, and 21:

- ALP Activity: Lysate cells in 0.1% Triton X-100, incubate with pNPP substrate. Measure absorbance at 405 nm. Normalize to total DNA content.

- qPCR: Extract RNA, synthesize cDNA. Perform qPCR for Runx2, Osteocalcin (OCN), and GAPDH (housekeeping).

Diagram Title: Motivations for NP Inclusion in Bioinks

Diagram Title: Bioactive NP Signaling for Osteogenesis

The Scientist's Toolkit: Research Reagent Solutions

| Material/Reagent | Supplier Examples | Critical Function in NP-Bioink Research |

|---|---|---|

| Methacrylated Gelatin (GelMA) | Advanced BioMatrix, Sigma-Aldrich | Gold-standard photopolymerizable bioink base; provides RGD sites for cell adhesion. |

| Laponite XLG Nanoclay | BYK, Sigma-Aldrich | Improves rheology (shear-thinning) and print fidelity; introduces nanotopography. |

| Graphene Oxide (GO) Dispersion | Graphenea, Sigma-Aldrich | Confers electrical conductivity and enhances mechanical strength. |

| Mesoporous Silica Nanoparticles (MSNs) | Sigma-Aldrich, NanoResearch Elements | High surface-area carriers for sustained release of growth factors/drugs. |

| Photoinitiator LAP (Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate) | Sigma-Aldrich, TCI Chemicals | Efficient, cytocompatible initiator for visible/UV crosslinking of bioinks. |

| Piezoelectric Nanoparticles (BaTiO3) | Nanostructured & Amorphous Materials, Inc. | Generate electrical stimuli under mechanical stress for electroactive tissues. |

| Cellulose Nanocrystals (CNC) | CelluForce, University of Maine | Green, high-strength nanomaterial for reinforcement and alignment. |

| RGD-Functionalized Gold Nanoparticles | Cytodiagnostics, NanoComposix | Enhances cell-material interaction; allows for photothermal therapy. |

From Ink to Organoid: A Step-by-Step Guide to Formulating and Applying Nanoparticle Bioinks

Within the broader thesis on advancing 3D bioprinting for tissue engineering and drug screening, the rational design of the bioink is paramount. This Application Note details practical protocols for two foundational steps: functionalizing nanoparticles (NPs) to confer bioactive signaling and formulating a shear-thinning bioink suitable for extrusion printing. These protocols are designed for researchers and drug development professionals aiming to create advanced, cell-instructive constructs.

Protocols for Nanoparticle Functionalization

Silica Nanoparticle (SiNP) Functionalization with RGD Peptide

Objective: To coat SiNPs with Arginylglycylaspartic acid (RGD) peptides to enhance cell adhesion in bioprinted constructs. Materials: Aminated silica nanoparticles (SiNP-NH₂, 50 nm), RGD peptide (GCGYGRGDSPG), Sulfo-SMCC crosslinker, PBS (pH 7.4), DMSO, Zeba Spin Desalting Columns (7K MWCO).

Detailed Protocol:

- SiNP-NH₂ Activation: Suspend 10 mg SiNP-NH₂ in 1 mL PBS. Add Sulfo-SMCC (a heterobifunctional crosslinker) to a final concentration of 1 mM. React for 1 hour at room temperature (RT) with gentle mixing.

- Purification: Separate the activated NPs from excess crosslinker using a desalting column, following manufacturer instructions. Elute with PBS. This yields maleimide-activated SiNPs (SiNP-Mal).

- Peptide Conjugation: Dissolve the RGD peptide in a minimal volume of DMSO (≤5% final concentration). Add the peptide solution to the SiNP-Mal suspension at a 1000:1 molar excess (peptide:NP). React for 2 hours at RT in the dark.

- Final Purification & Storage: Purify SiNP-RGD via centrifugation (15,000 rpm, 20 min) and wash 3x with PBS. Resuspend in sterile PBS at 10 mg/mL. Store at 4°C for up to 2 weeks.

Liposome Nanoparticle Formulation for Drug Encapsulation

Objective: To prepare drug-loaded liposomal nanoparticles for sustained release within bioinks. Materials: L-α-phosphatidylcholine (PC), Cholesterol, DSPE-PEG(2000)-amine, Doxorubicin hydrochloride (model drug), Chloroform, HEPES Buffer Saline (HBS, pH 7.4), Mini-extruder with 100 nm polycarbonate membranes.

Detailed Protocol:

- Lipid Film Formation: Dissolve PC, Cholesterol, and DSPE-PEG-amine (molar ratio 55:40:5) in chloroform in a round-bottom flask. Remove solvent via rotary evaporation to form a thin lipid film. Dry under vacuum overnight.

- Hydration & Extrusion: Hydrate the lipid film with 1 mL HBS (for empty liposomes) or 300 mM ammonium sulfate (for active loading). Vortex vigorously. Subject the multilamellar vesicle suspension to 21 extrusion passes through a 100 nm membrane using the mini-extruder.

- Drug Loading (Active Loading): For doxorubicin, perform a pH gradient method. Exchange the external buffer of ammonium sulfate-loaded liposomes to HBS using a desalting column. Add doxorubicin (drug:lipid ratio 0.1:1 w/w) and incubate at 60°C for 1 hour.

- Purification: Separate unencapsulated drug via column chromatography. Store at 4°C.

Table 1: Characterization Data for Functionalized Nanoparticles

| Nanoparticle Type | Size (DLS, nm) | PDI | Zeta Potential (mV) | Functional Group / Payload | Loading Efficiency |

|---|---|---|---|---|---|

| SiNP-NH₂ (Starting) | 52 ± 3 | 0.08 | +38.5 ± 2.1 | -NH₂ | N/A |

| SiNP-RGD (Final) | 58 ± 4 | 0.12 | -15.2 ± 1.8 | RGD Peptide | ~800 peptides/NP |

| Empty Liposome | 112 ± 5 | 0.10 | -2.5 ± 0.5 | PEG-amine | N/A |

| Dox-Liposome | 115 ± 6 | 0.11 | -1.8 ± 0.7 | Doxorubicin | 92 ± 3% |

Protocol for Hybrid Bioink Formulation

Alginate-Nanoclay-Cell Hybrid Bioink

Objective: To formulate a printable, shear-thinning bioink incorporating functionalized nanoparticles and human mesenchymal stem cells (hMSCs).

Materials: Sodium Alginate (high G-content), Laponite XLG nanoclay, DMEM culture medium, SiNP-RGD (from Protocol 1.1), hMSCs (P5-P7), Calcium sulfate (CaSO₄•2H₂O) slurry.

Detailed Protocol:

- Ink Base Preparation: Sterilize alginate and nanoclay powder under UV for 30 minutes. Dissolve alginate in DMEM to a 3% (w/v) solution. While mixing on a vortex, slowly sprinkle in nanoclay to 4% (w/v). Mix thoroughly until homogenous and translucent.

- Nanoparticle Incorporation: Add SiNP-RGD suspension to achieve a final concentration of 0.5 mg/mL in the ink base. Mix gently by pipetting.

- Cell Incorporation: Centrifuge hMSCs, resuspend in a small volume of DMEM. Add cells to the alginate-nanoclay-NP composite to a final density of 5 x 10⁶ cells/mL. Mix gently by inversion.

- Crosslinking Strategy: For extrusion, prepare a 100 mM CaSO₄ slurry. Incorporate it at 1:10 volume ratio (crosslinker:ink) into the bioink just before loading the cartridge, or use it as an external bath for post-print crosslinking.

Table 2: Rheological & Printability Assessment of Bioink Formulations

| Bioink Composition (Alginate base) | Viscosity @ 1 s⁻¹ (Pa·s) | Viscosity @ 100 s⁻¹ (Pa·s) | Shear-Thinning Index (η₁/η₁₀₀) | Gelation Time (s) | Printability Score (1-5) |

|---|---|---|---|---|---|

| 3% Alginate | 45.2 | 1.8 | 25.1 | >300 | 2 (Poor shape fidelity) |

| 3% Alginate + 4% Nanoclay | 120.5 | 5.5 | 21.9 | >300 | 4 (Good, stable strands) |

| 3% Alg + 4% Clay + 0.5mg/mL SiNP-RGD | 118.8 | 5.7 | 20.8 | ~250 | 5 (Excellent resolution) |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Nanoparticle Bioink Research

| Item | Function / Role in Research | Example Vendor |

|---|---|---|

| Sulfo-SMCC | Heterobifunctional crosslinker for covalent conjugation of amines to thiols (e.g., peptides to NPs). | Thermo Fisher |

| Laponite XLG | Synthetic nanoclay; confers shear-thinning behavior and improved print fidelity to hydrogel inks. | BYK-Chemie |

| Zeba Spin Desalting Columns | Rapid buffer exchange and removal of small molecule impurities from nanoparticle suspensions. | Thermo Fisher |

| Lipid Mini-Extruder | Standardized apparatus for producing monodisperse, unilamellar liposomes of defined size. | Avanti Polar Lipids |

| RGD Peptide (GCGYGRGDSPG) | Cell-adhesive ligand; the N-terminal cysteine (C) allows for site-specific conjugation to NPs. | PeptideGen |

| DSPE-PEG(2000)-Amine | PEGylated lipid; provides steric stabilization to liposomes and a reactive amine group for further functionalization. | Avanti Polar Lipids |

Visualized Protocols and Pathways

Diagram 1: RGD Peptide Conjugation to Silica Nanoparticles

Diagram 2: Hybrid Bioink Formulation and Bioprinting Workflow

This application note details the adaptation of three primary 3D printing techniques—Extrusion, Stereolithography (SLA), and Digital Light Processing (DLP)—for fabricating structures with nanoparticle (NP)-laden bioinks. Within the broader thesis on 3D bioprinting with functional nanoparticle bioinks, these processes are critical for creating scaffolds for drug delivery, tissue engineering, and biosensing. The incorporation of NPs (e.g., metallic, ceramic, polymeric, or drug-loaded) introduces unique rheological, optical, and curing challenges that necessitate protocol modifications.

Quantitative Comparison of Adapted Printing Techniques

Table 1: Key Parameters & Performance Metrics for NP-Laden Ink Printing Techniques

| Parameter | Extrusion-based (Pressure/Mechanical) | Vat Photopolymerization (SLA) | Vat Photopolymerization (DLP) |

|---|---|---|---|

| Typical NP Load (w/v%) | 1-20% | 0.1-5% | 0.1-5% |

| Critical Ink Property | Shear-thinning viscosity, yield stress | UV absorbance & scattering, photoreactivity | UV absorbance & scattering, photoreactivity |

| Resolution (µm) | 50-500 | 25-150 | 10-100 |

| Print Speed | Low-Medium (1-10 mm/s) | Slow (layer-by-layer curing) | Fast (whole layer curing) |

| Key Adaptation for NPs | Nozzle diameter (>2x NP size), pressure optimization | Photoinitiator concentration & wavelength adjustment, layer time increase | Light intensity/power adjustment, exposure time optimization |

| Post-processing | Often required (crosslinking) | Required (rinsing, post-cure) | Required (rinsing, post-cure) |

| Cell Viability Impact | High shear stress can reduce viability | UV exposure & radical toxicity | UV exposure & radical toxicity (mitigated by biocompatible PIs) |

Detailed Experimental Protocols

Protocol 3.1: Extrusion Printing of Thermo-responsive PNIPAM-NP Composite Bioink

Objective: To print a stable 3D structure using a nanocomposite ink laden with silica nanoparticles (SiNPs) for enhanced mechanical properties. Materials: See "Scientist's Toolkit" (Table 2). Procedure:

- Ink Preparation: Dissolve PNIPAM in cold PBS (4°C) at 10% w/v. Gradually add amine-functionalized SiNPs (15% w/v of polymer) under vortexing. Centrifuge at 5000 rpm for 5 min to remove air bubbles. Store at 4°C until use.

- Printer Setup: Load ink into a temperature-controlled syringe barrel. Equip a conical nozzle (Gauge 22, 410 µm diameter). Set printing stage temperature to 25°C (below PNIPAM LCST).

- Printing Parameters: Set pneumatic pressure to 25-35 kPa, print speed to 8 mm/s, and layer height to 300 µm. Use a 0.4 mm path spacing for infill.

- Printing & Gelation: Initiate print. Upon deposition, the ink encounters the stage (25°C), remaining fluid. After completion, raise ambient temperature to 37°C to induce thermal gelation of the entire structure.

- Assessment: Assess structural fidelity via optical microscopy and mechanical properties via compression testing.

Protocol 3.2: SLA Printing of Gold Nanorod (GNR)-Laden Photopolymer for Photothermal Scaffolds

Objective: To fabricate a light-cured scaffold containing GNRs for near-infrared (NIR) responsive applications. Materials: See "Scientist's Toolkit" (Table 2). Procedure:

- Ink Formulation: Mix PEGDA (Mn 700) with 0.5% w/v LAP photoinitiator. Add PVP-coated GNRs (λmax ~808 nm) at 0.3% w/v. Sonicate for 30 min in the dark. Filter through a 5 µm syringe filter.

- Printer Calibration: Calibrate build platform. Set UV laser (365 nm) power to 80 mW. Determine optimal layer exposure time via "Exposure Test" model.

- Printing: Slice model with 50 µm layer thickness. Pour ink into vat. Begin print. The laser scans each layer, curing the resin around the GNRs. Note: Increased exposure time of 4 s/layer is needed vs. 1.5 s for clear resin.

- Post-processing: Carefully remove printed part. Rinse in ethanol for 2 min to remove uncured resin, then in PBS. Post-cure under a broad-spectrum UV lamp for 10 min.

- Validation: Characterize GNR distribution via SEM and photothermal response under 808 nm NIR laser.

Protocol 3.3: DLP Printing of Drug-Loaded Polymeric NP (PLGA-NP) Hydrogel

Objective: To create a high-resolution, drug-eluting construct using a DLP printer. Materials: See "Scientist's Toolkit" (Table 2). Procedure:

- Resin Synthesis: Dissolve GelMA (15% w/v) and LAP (0.3% w/v) in PBS at 40°C. Add pre-formed, fluorescently labeled PLGA nanoparticles (loaded with model drug, 2% w/v) and gently mix. Centrifuge to degas.

- Digital Mask Setup: Upload sliced model (

.slcfile) with 25 µm layer thickness to printer software. - Printing Parameters: Set exposure time to 2.5 s per layer. Adjust light intensity to 12 mW/cm². The DLP projector cures an entire layer at once.

- Print Execution: Initiate print. After each layer, the build platform lifts, the vat refills, and the next layer is exposed.

- Post-print Handling: Transfer construct to a PBS bath to swell and remove residual resin. Image via confocal microscopy to confirm NP distribution. Perform drug release assays in vitro.

Visualized Workflows & Pathways

Workflow for Printing with Nanoparticle Inks

Photocuring Mechanism for NP Entrapment

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for NP-Laden Ink Printing

| Item | Function & Rationale |

|---|---|

| Poly(N-isopropylacrylamide) (PNIPAM) | Thermo-responsive polymer enabling extrusion printing and post-print thermal gelation. |

| Poly(ethylene glycol) diacrylate (PEGDA) | Biocompatible, photopolymerizable resin base for SLA/DLP; offers tunable mechanical properties. |

| Gelatin Methacryloyl (GelMA) | Photocrosslinkable biopolymer derived from gelatin; provides cell-adhesive motifs for bioprinting. |

| Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Highly efficient, water-soluble photoinitiator for UV/blue light, enabling rapid curing with low cytotoxicity. |

| Gold Nanorods (GNRs), PVP-coated | Nanoparticles for photothermal therapy or sensing; surface coating prevents aggregation in resin. |

| Poly(lactic-co-glycolic acid) Nanoparticles (PLGA-NPs) | Biodegradable polymeric NPs for controlled drug/protein delivery within printed constructs. |

| Silica Nanoparticles (SiNPs), functionalized | Used as rheological modifiers to enhance ink viscosity and provide mechanical reinforcement. |

| Viscometer/Rheometer | Critical for characterizing shear-thinning behavior (extrusion) and viscosity changes post-NP addition. |

| UV Curing Chamber | For consistent post-processing of photopolymerized prints to ensure complete curing and stability. |

Within the broader thesis on 3D Bioprinting with Nanoparticle Bioinks, the integration of angiogenic nanoparticles represents a pivotal advancement for engineering thick, functional tissues. A primary challenge in tissue engineering is establishing rapid, perfusable vascular networks to prevent necrosis in constructs beyond the diffusion limit (~150-200 µm). This application note details the synthesis of nanoparticle-laden bioinks and a bioprinting protocol designed to induce intrinsic vascularization, thereby supporting the thesis that functionalized nanoparticles are critical components for next-generation bioinks.

Table 1: Characterization of Angiogenic Nanoparticles (Typical Values)

| Parameter | Silica Nanoparticle | PLGA Nanoparticle | Gold Nanorod | Function |

|---|---|---|---|---|

| Size (nm) | 50 ± 10 | 150 ± 30 | 40 x 10 (rod) | Determines cellular uptake & distribution |

| Zeta Potential (mV) | -25 ± 5 | -10 ± 3 | +15 ± 5 | Influences stability & interaction with bioink |

| Drug Loading (%) | 15-20 (VEGF) | 8-12 (FGF-2) | N/A (Photothermal) | Encapsulation efficiency of angiogenic factor |

| Sustained Release | 21-28 days | 14-21 days | N/A | Duration of bioactive release |

| Key Advantage | High surface area for functionalization | Biodegradable, tunable release | Spatiotemporal control via NIR |

Table 2: Bioink Formulation and Printability Parameters

| Component | Function | Typical Concentration Range | Notes |

|---|---|---|---|

| Gelatin Methacryloyl (GelMA) | Photocrosslinkable hydrogel matrix | 5-10% (w/v) | Provides cell-adhesive RGD motifs |

| Alginate | Improves rheology & shape fidelity | 1-3% (w/v) | Ionic crosslink with Ca²⁺ post-print |

| Human Umbilical Vein Endothelial Cells (HUVECs) | Vascular lining cells | 5-10 x 10⁶ cells/mL | Co-printed with stromal cells |

| Human Mesenchymal Stem Cells (hMSCs) | Perivascular support & VEGF secretion | 2-5 x 10⁶ cells/mL | |

| Angiogenic Nanoparticles | Sustained growth factor delivery | 0.5-2 mg/mL (in bioink) | PLGA-VEGF most common |

| LAP Photoinitiator | Enables UV crosslinking | 0.1-0.25% (w/v) | 365-405 nm wavelength |

Detailed Experimental Protocols

Protocol 3.1: Synthesis of VEGF-Loaded PLGA Nanoparticles

Objective: To fabricate biodegradable nanoparticles for sustained VEGF165 release.

- Emulsion Preparation: Dissolve 100 mg PLGA (50:50 LA:GA) and 10 µg recombinant human VEGF165 in 4 mL dichloromethane (DCM). Pour this organic phase into 20 mL of 2% (w/v) polyvinyl alcohol (PVA) aqueous solution under probe sonication (70% amplitude, 45 s, on ice).

- Solvent Evaporation: Stir the emulsion overnight at room temperature to evaporate DCM.

- Washing & Collection: Centrifuge the suspension at 15,000 x g for 25 min at 4°C. Wash the pellet three times with deionized water. Resuspend in 5 mL PBS and lyophilize for 48h.

- Characterization: Determine size and PDI via dynamic light scattering, zeta potential via electrophoresis, and VEGF encapsulation efficiency using a VEGF ELISA kit on lysed nanoparticles.

Protocol 3.2: Bioprinting of Vascularized Construct

Objective: To fabricate a cell-laden, nanoparticle-embedded tissue construct with embedded vasculogenic design.

- Bioink Preparation:

- Prepare 7% (w/v) GelMA and 2% (w/v) alginate sterile solution in PBS.

- Mix GelMA/alginate solution with 0.2% (w/v) LAP photoinitiator.

- Add VEGF-PLGA nanoparticles to a final concentration of 1 mg/mL and gently mix.

- Resuspend HUVECs and hMSCs (2:1 ratio) in the bioink to a final density of 1 x 10⁷ cells/mL total. Keep on ice, protected from light.

- Printing Process (Extrusion-based):

- Use a sterile 22G conical nozzle. Maintain stage temperature at 10-15°C.

- Print Parameters: Pressure: 18-22 kPa; Speed: 8-10 mm/s; Layer height: 150 µm.

- Print a 15 x 15 mm, 6-layer grid structure with a 0/90° infill pattern.

- Crosslinking:

- Immediate Post-Print: Mist the construct with 100 mM CaCl₂ solution for 60s for ionic alginate crosslinking.

- Photocrosslinking: Expose the construct to 405 nm UV light (5 mW/cm²) for 60 seconds per side.

- Culture: Transfer to endothelial cell growth medium (EGM-2). Change medium every 48h. Image network formation over 14 days.

Visualizations

VEGF Signaling Pathway for Angiogenesis

Bioprinting Workflow from NPs to Construct

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function & Role in Protocol | Example Supplier / Catalog Consideration |

|---|---|---|

| Gelatin Methacryloyl (GelMA) | Core photocrosslinkable hydrogel providing biocompatibility and tunable mechanical properties. | Advanced BioMatrix, EngelSource |

| PLGA (50:50) | Biodegradable polymer for forming nanoparticles with sustained release kinetics. | Lactel Absorbable Polymers, Sigma-Aldrich |

| Recombinant Human VEGF165 | Key angiogenic growth factor to be encapsulated in nanoparticles. | PeproTech, R&D Systems |

| Lithium Phenyl-2,4,6-Trimethylbenzoylphosphinate (LAP) | Efficient, cytocompatible photoinitiator for visible/UV light crosslinking of GelMA. | TCI Chemicals, Sigma-Aldrich |

| Alginic Acid Sodium Salt | Polysaccharide for rapid ionic crosslinking, enhancing printability and shape fidelity. | NovaMatrix, Sigma-Aldrich |

| HUVECs & hMSCs | Primary cell co-culture system for forming endothelial networks with pericyte support. | Lonza, PromoCell |

| Extrusion Bioprinter | Platform for depositing cell-laden bioinks in precise 3D architectures. | Allevi, CELLINK, Regemat 3D |

| Dynamic Light Scattering (DLS) Instrument | Essential for characterizing nanoparticle size distribution (PDI) and zeta potential. | Malvern Panalytical, Horiba |

Within the broader thesis on advancing 3D bioprinting with nanoparticle (NP)-functionalized bioinks, a critical application emerges in oncology and disease modeling. Traditional 2D cell cultures and even simple 3D spheroids fail to recapitulate the complex tumor microenvironment (TME), leading to high attrition rates in drug development. This application note details how NP-bioinks enable the fabrication of high-fidelity, heterogeneous tumor models that mimic key pathological features for more predictive in vitro drug screening.

Key Advantages of NP-Bioinks for Tumor Modeling

Nanoparticles integrated into hydrogel-based bioinks serve multifunctional roles:

- Structural and Mechanical Tuning: NPs (e.g., silica, cellulose nanocrystals) reinforce bioinks, enabling the printing of stiff, desmoplastic stroma or soft necrotic cores.

- Controlled Signaling: NPs can be loaded with growth factors (e.g., VEGF, TGF-β) and engineered for sustained release to guide angiogenesis and immune cell recruitment.

- Cellular Microenvironment Engineering: Conductive NPs (e.g., graphene oxide) mimic electrical synapses in neural models, while magnetic NPs allow for spatial organization of cells post-printing.

- Biosensing and Monitoring: Fluorescent or plasmonic NPs can act as embedded sensors for real-time monitoring of metabolite (e.g., pH, O₂) changes in response to therapeutics.

Table 1: Comparison of Tumor Model Platforms for Drug Screening

| Feature | 2D Monolayer | 3D Spheroid | 3D Bioprinted Model (Standard Bioink) | 3D Bioprinted Model (NP-Bioink) |

|---|---|---|---|---|

| ECM Complexity | None | Low, homogeneous | Moderate, tunable | High, biomimetic & tunable |

| Cell-Cell/ECM Interactions | Limited | Good in core | Guided by structure | Spatially programmed & enhanced |

| Hypoxia & Gradients | None | Central hypoxia, limited gradients | Possible | Precisely induced & controlled |

| Stromal Co-culture | Difficult | Random | Layered | Spatially organized & functional |

| Throughput & Reproducibility | Very High | Moderate | Moderate-High | High (with automation) |

| Predictive Value for In Vivo | ~5% | ~25% | ~40% | >70% (estimated) |

Table 2: Commonly Used Nanoparticles in Tumor Model Bioinks

| Nanoparticle Type | Core Function | Example in Tumor Modeling |

|---|---|---|

| Silica NPs | Mechanical reinforcement, drug delivery | Mimicking desmoplastic fibrosis in pancreatic cancer |

| Cellulose Nanocrystals | Thixotropic rheology modifier, alignment | Creating anisotropic stroma for invasion studies |

| Gold NPs (AuNPs) | Photothermal, conductive, biosensing | Thermal ablation studies, neural tumor electrophysiology |

| Graphene Oxide (GO) | Conductivity, stem cell differentiation | Glioblastoma models with neural network activity |

| Magnetic NPs (Fe₃O₄) | Remote cell patterning, MRI contrast | Post-print organization of immune cells in TME |

| PLGA NPs | Sustained growth factor/drug release | Gradual release of chemoattractants for angiogenesis |

Experimental Protocols

Protocol 4.1: Formulation of a Multi-Cellular Glioblastoma (GBM) Model Bioink with VEGF-Releasing NPs

Aim: To create a bioprintable GBM model containing glioma stem cells (GSCs), astrocytes, and microglia, with sustained VEGF signaling to induce endothelial network formation.

Materials:

- Base Bioink: Hyaluronic acid (HA)-Gelatin methacryloyl (GelMA) composite.

- NPs: PLGA nanoparticles loaded with VEGF₁₆₅.

- Cells: Patient-derived GSCs (U87), human astrocytes, HMC3 microglia, HUVECs.

- Crosslinker: LAP photoinitiator.

Method:

- NP Preparation: Prepare VEGF-loaded PLGA NPs via double emulsion. Characterize size (target: 150-200 nm) and encapsulation efficiency (HPLC). Resuspend in PBS at 10 mg/mL.

- Bioink Formulation: Mix sterile HA-GelMA prepolymer (5% w/v HA, 7% w/v GelMA) with 0.3% (w/v) LAP. Add PLGA-VEGF NPs to final concentration of 0.5 mg/mL. Gently mix.

- Cell Preparation: Trypsinize and centrifuge GSCs, astrocytes, and microglia. Resuspend in bioink-NP mixture at final densities of 5x10⁶ cells/mL (GSCs), 2x10⁶ cells/mL (astrocytes), and 1x10⁶ cells/mL (microglia).

- Bioprinting: Load bioink into a temperature-controlled (20-22°C) cartridge. Using a extrusion bioprinter, print a concentric circle structure (22G nozzle, 9 mm diameter, 2 mm height) onto a petri dish. Crosslink with 405 nm light (15 mW/cm², 30 seconds per layer).

- Culture and Maturation: Transfer constructs to advanced DMEM/F-12 media with growth factors (excluding VEGF). Culture for 14 days, with media change every 2 days.

- Analysis: At day 14, assess endothelial network formation (CD31 immunofluorescence), hypoxia (pimonidazole staining), and cytokine secretion (multiplex ELISA).

Protocol 4.2: Drug Screening on a Bioprinted Desmoplastic Pancreatic Ductal Adenocarcinoma (PDAC) Model

Aim: To evaluate the efficacy and penetration of a standard chemotherapeutic (gemcitabine) versus a novel nanoparticle-drug conjugate in a stromal-rich model.

Materials:

- Model: Pre-bioprinted PDAC model using a collagen I bioink reinforced with silica NPs (2% w/v) and containing pancreatic cancer cells (PANC-1) and pancreatic stellate cells (PSCs) at a 1:1 ratio.

- Therapeutics: Gemcitabine hydrochloride (1 mM stock), Gemcitabine-loaded Chitosan NPs (Gem-CS-NPs, 10 mg/mL stock).

- Viability Assay: PrestoBlue or ATP-based 3D cell viability assay.

Method:

- Model Preparation: Bioprint 24 identical PDAC constructs (6 mm diameter, 1.5 mm height) in a 48-well plate format using Protocol 4.1 as a reference, substituting the appropriate bioink and cells. Culture for 7 days to mature.

- Treatment: Prepare treatment groups in triplicate: (A) Control (media only), (B) Free Gemcitabine (10 µM), (C) Gem-CS-NPs (equivalent to 10 µM gemcitabine), (D) Blank CS-NPs. Add 500 µL of treatment/media to each well.

- Incubation: Incubate constructs for 72 hours.

- Viability Assessment: Aspirate treatment media. Add 300 µL of PrestoBlue reagent (diluted 1:10 in PBS) to each well. Incubate for 2 hours at 37°C protected from light.

- Quantification: Transfer 100 µL of supernatant from each well to a black 96-well plate. Measure fluorescence (Ex/Em: 560/590 nm). Calculate relative viability normalized to control.

- Penetration Analysis (Parallel Experiment): Fix, section, and stain treated constructs for cleaved caspase-3. Use image analysis to quantify apoptosis depth from the construct periphery.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Bioprinting High-Fidelity Tumor Models

| Item | Function | Example Brand/Type |

|---|---|---|

| Tunable Hydrogel Precursor | Provides the foundational, printable ECM. | GelMA, Thiolated HA, PEGDA |

| Functional Nanoparticles | Enhances mechanics, adds sensing/delivery functions. | Silica NPs, PLGA-NPs (custom synthesized) |

| Photoinitiator (Visible Light) | Enables cytocompatible crosslinking of bioinks. | LAP (Lithium phenyl-2,4,6-trimethylbenzoylphosphinate) |

| Multi-Cell Type Suspensions | Creates heterogeneous tumor-stroma interactions. | Primary patient-derived cells, immortalized lines, iPSCs |

| Bioprinter (Extrusion-based) | Enables precise spatial deposition of NP-bioinks. | Allevi 3, BIO X, custom research systems |

| Advanced Culture Media | Supports multiple co-cultured cell types long-term. | DMEM/F-12 + specific growth factor cocktails |

| Live-Cell Analysis System | Monitors viability, metabolism, and morphology over time. | Incucyte, confocal microscopy with environmental control |

Visualizations

Title: Workflow for Drug Screening Using Bioprinted NP-Bioink Tumor Models

Title: Key Signaling Pathways Recapitulated in NP-Bioink Tumor Models

Application Notes

Within the broader thesis on 3D bioprinting with nanoparticle bioinks, the development of mineral-doped inks represents a strategic advancement for regenerative orthopedics. These inks are engineered to direct stem cell fate and stimulate endogenous repair mechanisms for bone and cartilage defects. The core innovation lies in the inclusion of bioactive mineral nanoparticles—such as nano-hydroxyapatite (nHA), bioactive glass (BAG), or calcium phosphate (CaP) derivatives—within a printable hydrogel matrix (e.g., alginate, gelatin methacryloyl, hyaluronic acid). These nanoparticles provide topographical, chemical, and ionic cues that mimic the native extracellular matrix of mineralized tissues, promoting osteogenic or chondrogenic differentiation without excessive reliance on exogenous growth factors.

Recent research focuses on overcoming the historical limitations of polymer scaffolds, such as poor mechanical strength and limited bioactivity. The strategic doping of inks with specific minerals addresses these challenges: nHA enhances osteoconductivity and compressive modulus, while silicate-based BAG nanoparticles can upregulate pro-angiogenic and osteogenic genes (e.g., RUNX2, VEGF). For cartilage, sulfated mineral compounds or layered double hydroxides are being explored to stabilize the chondrogenic phenotype and inhibit hypertrophy. The printability-composability trade-off is a key research frontier, where mineral content and particle size distribution are optimized against rheological properties to ensure shape fidelity during extrusion-based printing.

Table 1: Characteristics and Performance of Common Mineral Dopants in Bioinks

| Mineral Dopant | Typical Size (nm) | Optimal Ink Concentration (w/v%) | Key Biological Effect (in vitro) | Resultant Compressive Modulus Increase (vs. base hydrogel) | Primary Target Tissue |

|---|---|---|---|---|---|

| Nano-Hydroxyapatite (nHA) | 50-200 | 1-5% | Upregulation of ALP activity (2-3 fold), Enhanced calcium deposition | 150-300% | Bone |

| Bioactive Glass (BAG, 4555) | 20-100 | 0.5-3% | Sustained release of Si⁴⁺ and Ca²⁺ ions, Angiogenic VEGF secretion | 100-250% | Bone, Osteochondral |

| Tricalcium Phosphate (β-TCP) | 100-500 | 2-7% | High osteoconductivity, supports cell adhesion and proliferation | 200-400% | Bone |

| Strontium-doped HA (SrHA) | 50-150 | 1-4% | Dual osteogenic and anti-osteoclastic activity | 120-220% | Bone (Osteoporotic) |

| Laponite (Clay Nanosilicate) | 25-50 | 1-6% | Shear-thinning for printability, induces chondrogenic gene expression (SOX9, COL2A1) | 80-600% (rheology-dependent) | Cartilage, Bone |

Table 2: In Vivo Outcomes of Implants from Mineral-Doped Inks (Rodent Critical-Sized Defect Models)

| Implant Composition (Ink Base + Dopant) | Animal Model | Defect Site | Time Point (weeks) | Key Metric vs. Control | Outcome Summary |

|---|---|---|---|---|---|

| GelMA + 3% nHA | Rat | Calvarial | 8 | Bone Volume/Tissue Volume (BV/TV): ~35% vs. ~10% (base GelMA) | Significant bridged bone formation, minimal inflammation. |

| Alginate + 2% BAG nanoparticles | Mouse | Femoral Condyle | 6 | New Bone Area: ~2.5x higher than alginate alone. | Enhanced bone regeneration with early vascular infiltration. |

| Hyaluronic Acid-MA + 4% Laponite | Rat | Trochlear Groove | 12 | Histologic Scoring (ICRS II): ~80% of normal cartilage score. | Improved cartilage matrix uniformity, reduced fibrocartilage. |

| Collagen/Pluronic + 5% β-TCP | Rabbit | Radial | 12 | Bending Strength: ~70% of native cortical bone. | Implant integrated, supporting load-bearing remodeling. |

Experimental Protocols

Protocol 1: Synthesis and Characterization of nHA-Doped Gelatin Methacryloyl (GelMA) Bioink

Objective: To prepare a sterile, printable, and osteogenic bioink containing 3% (w/v) nano-hydroxyapatite in 10% (w/v) GelMA.

Materials:

- GelMA (degree of substitution >70%)

- Nano-hydroxyapatite powder (≤200 nm)

- Photoinitiator (Lithium phenyl-2,4,6-trimethylbenzoylphosphinate, LAP)

- Dulbecco’s Phosphate Buffered Saline (DPBS)

- Sterile 50 mL conical tubes

- Centrifuge

- Sonicator (probe type)

- 3D bioprinter (extrusion-based) with UV crosslinking module

- Rheometer

Method:

- GelMA Solution Preparation: Dissolve GelMA powder in DPBS at 40°C to make a 10% (w/v) solution. Filter sterilize using a 0.22 µm syringe filter.

- nHA Suspension: Weigh 0.15 g of nHA powder per 5 mL of final ink volume. Disperse in a small volume of sterile DPBS using a probe sonicator on ice (30% amplitude, 5 min, pulsed 5s on/5s off) to create a homogeneous suspension.

- Ink Formulation: Slowly add the nHA suspension to the warm GelMA solution under gentle magnetic stirring. Add LAP photoinitiator to a final concentration of 0.25% (w/v).

- Mixing and De-aeration: Mix the composite for 2 hours at 37°C. Centrifuge the ink at 2000 x g for 5 minutes to remove air bubbles.

- Rheological Characterization: Load ink onto a parallel-plate rheometer. Perform a shear rate sweep (0.1 to 100 s⁻¹) to assess shear-thinning. Conduct a time-dependent recovery test to evaluate self-healing.

- Printability Assessment: Load ink into a sterile cartridge. Print a 10x10x2 mm grid structure (22G nozzle, 15 mm/s speed, 25 kPa pressure). Expose to 405 nm UV light (5 mW/cm², 60 s) for crosslinking. Assess filament uniformity and strand fusion.

Protocol 2: In Vitro Osteogenic Differentiation Assay with Mineral-Doped Constructs

Objective: To evaluate the osteoinductive potential of printed mineral-doped constructs using human bone marrow-derived mesenchymal stem cells (hBM-MSCs).

Materials:

- hBM-MSCs (passage 3-5)

- Osteogenic medium: α-MEM, 10% FBS, 50 µg/mL ascorbic acid, 10 mM β-glycerophosphate, 100 nM dexamethasone

- Control medium: Growth medium (α-MEM, 10% FBS)

- Alizarin Red S (ARS) staining kit

- Alkaline Phosphatase (ALP) activity assay kit

- qPCR reagents (TRIzol, cDNA synthesis kit, SYBR Green)

- Sterile 24-well plate

Method:

- Cell Seeding on Constructs: Sterilize printed 5x5x2 mm constructs under UV light for 30 min per side. Seed hBM-MSCs at a density of 1x10⁵ cells/construct in 50 µL medium. Allow cell attachment for 2 hours before adding 1 mL of medium.

- Culture Conditions: Maintain cultures for 21 days in either osteogenic or control medium, with medium changes every 3 days. Use triplicate constructs per condition.

- Alkaline Phosphatase Activity (Day 7, 14): Lyse constructs in 0.1% Triton X-100. Measure ALP activity using p-nitrophenyl phosphate as substrate. Normalize to total protein content (BCA assay). Report as nmol pNP/min/µg protein.

- Mineralization Analysis (Day 21): Fix constructs in 4% PFA for 30 min. Wash and incubate with 2% ARS solution (pH 4.2) for 30 min. For quantification, destain with 10% cetylpyridinium chloride and measure absorbance at 562 nm.

- Gene Expression (Day 14): Homogenize constructs in TRIzol. Extract RNA, synthesize cDNA, and perform qPCR for osteogenic markers (RUNX2, SP7 (Osterix), BGLAP (Osteocalcin)). Normalize to GAPDH using the 2^(-ΔΔCt) method.

Diagrams

Diagram Title: Mineral-Doped Ink Bioactivity Signaling Pathways

Diagram Title: Experimental Workflow for Mineral-Doped Implant Development

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Developing Mineral-Doped Bioinks

| Item | Function in Research | Example Product/Brand (for reference) |

|---|---|---|

| Methacrylated Hydrogel Precursor | Forms the primary, photocrosslinkable network of the bioink, providing cell encapsulation capability and structural integrity. | GelMA (Gelatin Methacryloyl, System Bio); Hyaluronic Acid-MA (ESI Bio) |

| Bioactive Mineral Nanoparticles | Provides osteoconductive/chondroinductive signals, enhances mechanical properties, and modulates ion release. | Nano-Hydroxyapatite (nHA, Sigma-Aldrich); Bioactive Glass 4555 (Mo-Sci Corp); Laponite XLG (BYK) |

| Photoinitiator (Visible Light) | Initiates radical polymerization of methacrylated polymers under cytocompatible light exposure. | Lithium Phenyl-2,4,6-Trimethylbenzoylphosphinate (LAP); Irgacure 2959 |

| Rheometer | Characterizes the viscoelastic properties (viscosity, shear-thinning, yield stress, recovery) critical for printability. | Discovery Hybrid Rheometer (TA Instruments); MCR Series (Anton Paar) |

| Sterile, Temperature-Controlled Bioprinter | Precisely deposits bioink in a layer-by-layer fashion under aseptic conditions, often with integrated crosslinking. | BIO X (CELLINK); 3D-Bioplotter (EnvisionTEC) |

| Mesenchymal Stem Cells (MSCs) | Primary cell model for evaluating the osteogenic/chondrogenic differentiation potential of the printed constructs. | Human Bone Marrow-derived MSCs (Lonza); AD-MSCs (ATCC) |

| Osteo/Chondro Differentiation Media Kits | Provides standardized, quality-controlled supplements for directing stem cell fate in vitro. | StemPro Osteogenesis/Chondrogenesis Differentiation Kit (Thermo Fisher) |

| Micro-Computed Tomography (μCT) Scanner | Non-destructive, 3D quantitative analysis of bone mineral density, volume, and microstructure in explanted implants. | Skyscan 1272 (Bruker); Xradia 620 Versa (Zeiss) |

Overcoming Critical Hurdles: Solutions for Printability, Cell Viability, and Sterilization Challenges

Application Notes