Bioprinting the Brain: Advanced 3D Techniques for Neural Tissue Engineering and Regeneration

This article provides a comprehensive overview of current 3D bioprinting techniques for fabricating neural tissue scaffolds, targeted at researchers and drug development professionals.

Bioprinting the Brain: Advanced 3D Techniques for Neural Tissue Engineering and Regeneration

Abstract

This article provides a comprehensive overview of current 3D bioprinting techniques for fabricating neural tissue scaffolds, targeted at researchers and drug development professionals. It explores foundational principles and biomaterial selection, details methodological approaches including extrusion, inkjet, and laser-assisted bioprinting, and discusses critical troubleshooting for cell viability and print fidelity. The content further compares scaffold validation methods and assesses the translational potential of different techniques for modeling neurological diseases, drug screening, and ultimately, clinical neural repair applications.

Building Blocks of the Mind: Fundamentals of Neural Tissue Bioprinting

Within the thesis of 3D bioprinting for neural tissue scaffolds, the development of physiologically relevant 3D neural models is paramount. Traditional 2D cultures fail to replicate the complex cytoarchitecture and cell-cell interactions of the brain, while animal models present significant ethical, translational, and species-specific limitations. This document provides detailed Application Notes and Protocols for establishing advanced 3D neural models, emphasizing bioprinted scaffolds as a foundational technology for neuroscience research and drug discovery.

Application Note 1: Comparative Analysis of Neural Model Systems

Table 1: Quantitative Comparison of Neural Model Platforms

| Parameter | 2D Monolayer Culture | Animal Models (e.g., Mouse) | 3D Bioprinted Neural Construct |

|---|---|---|---|

| Transcriptomic Fidelity to Human Brain | Low (R² ~0.5-0.7) | Moderate (R² ~0.6-0.8, species-specific) | High (R² >0.8, using human iPSCs) |

| Structural Complexity (Layering, Networks) | None | High, but species-specific | Engineered (e.g., grey/white matter mimicry) |

| Microenvironmental Control (ECM, Stiffness) | Low (plastic/glass) | Fixed (in vivo) | High (tunable bioink) |

| Throughput for HTS | High | Very Low | Moderate to High |

| Cost per Experiment (Relative) | 1x | 100-1000x | 10-50x |

| Clinical Translation Predictive Value | Poor (<15%) | Moderate (~50%) | Emerging (Promising for disease phenotype) |

Protocol 1: Bioprinting a Laminar Cortical Model with GelMA-based Bioink

Objective: To fabricate a 3D, layered neural tissue construct mimicking the cortical plate using gelatin methacryloyl (GelMA) bioink laden with human induced pluripotent stem cell-derived neural progenitor cells (hiPSC-NPCs).

Materials & Reagents:

- Bioink: 7% (w/v) GelMA (Type A, ~90% methacrylation), 0.25% (w/v) LAP photoinitiator.

- Cells: hiPSC-NPCs (≥2x10⁶ cells/mL final bioink concentration).

- Bioprinter: Extrusion-based bioprinter with a temperature-controlled stage (4-10°C) and a 405nm UV light source (5-15 mW/cm²).

- Support Bath: 4% (w/v) Carbopol.

Procedure:

- Bioink Preparation: Dissolve GelMA and LAP in warm, sterile PBS. Filter sterilize (0.22 µm). Mix with hiPSC-NPC pellet to achieve final concentration. Keep on ice, protected from light.

- Printing Setup: Load bioink into a sterile, cooled syringe (22G conical nozzle). Fill printing reservoir with Carbopol support bath.

- Printing Parameters: Set stage temperature to 10°C. Print at a pressure of 25-35 kPa and speed of 8 mm/s.

- Layer-by-Layer Fabrication:

- Print first layer (200 µm strand spacing).

- Crosslink immediately with 405nm UV light (10 mW/cm² for 30 seconds).

- Lower stage by 150 µm, print second layer with 90° orientation shift.

- Repeat crosslinking. Repeat for 10 total layers.

- Post-Processing: Gently wash constructs in PBS to remove support bath. Transfer to neural maturation media.

Maturation: Culture in neural basal medium supplemented with B27, BDNF (20 ng/mL), GDNF (10 ng/mL), and cAMP (1 µM) for 4-6 weeks, with media changes every 2-3 days.

Protocol 2: Functional Analysis of 3D Neural Network Activity via MEA

Objective: To record and analyze spontaneous and evoked electrical activity from a matured 3D bioprinted neural construct using a multi-electrode array (MEA) system.

Materials & Reagents:

- MEA Plate: 48- or 96-well MEA plate with TiN electrodes.

- Recording System: MEA amplifier and data acquisition suite.

- Pharmacological Agents: TTX (1 µM), CNQX (10 µM), AP5 (50 µM), Bicuculline (20 µM).

Procedure:

- Transfer: Carefully transfer a 4-week matured construct to a pre-coated (PEI/laminin) MEA well. Allow 1-hour stabilization.

- Baseline Recording: Record spontaneous activity for 10 minutes at 37°C, 5% CO₂. Sample rate: 25 kHz. Bandpass filter: 200-3000 Hz.

- Pharmacological Challenge: Perfuse compounds sequentially with 15-minute intervals and 10-minute recordings post-addition: a. Bicuculline (GABAₐ antagonist) → Assess disinhibition. b. CNQX/AP5 (Glutamate antagonists) → Confirm glutamatergic transmission. c. TTX (Na⁺ channel blocker) → Confirm action potential dependence.

- Data Analysis: Use custom scripts or commercial software to extract:

- Mean firing rate (MFR, in Hz)

- Burst frequency and duration

- Network bursting index

- Synchronization index

Table 2: Expected Functional Readouts from Matured 3D Neural Constructs

| Metric | Week 2 | Week 4 | Week 6 | Response to Bicuculline |

|---|---|---|---|---|

| Mean Firing Rate (Hz) | 0.1 - 0.5 | 1.5 - 5.0 | 3.0 - 10.0 | Increase of 150-300% |

| Bursts / Minute | 0 - 2 | 5 - 15 | 10 - 25 | Significant Increase |

| Synchronization Index | <0.1 | 0.2 - 0.4 | 0.3 - 0.6 | Modulated |

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagent Solutions for 3D Neural Model Development

| Item | Function | Example/Note |

|---|---|---|

| Tunable Hydrogel (Bioink) | Provides biomimetic, printable ECM; dictates mechanical cues. | GelMA, Hyaluronic Acid-MA, PEG-based. RGD motifs critical. |

| hiPSC Lines | Source of patient/disease-specific human neurons & glia. | Use well-characterized, differentiation-competent lines. |

| Neural Induction Cocktail | Efficiently directs hiPSCs to neural lineage. | Dual SMAD inhibition (SB431542, LDN193189). |

| Maturation Factors | Promotes synaptic development, network integration. | BDNF, GDNF, NT-3, cAMP. |

| Live/Dead Viability Assay | Quantifies cell survival post-printing. | Calcein-AM (live)/EthD-1 (dead). |

| Immunostaining Markers | Validates neuronal/glial differentiation & cytoarchitecture. | β-III Tubulin (neurons), GFAP (astrocytes), MAP2 (maturity). |

| MEA System | Functional, non-invasive electrophysiology. | Critical for network phenotyping and compound screening. |

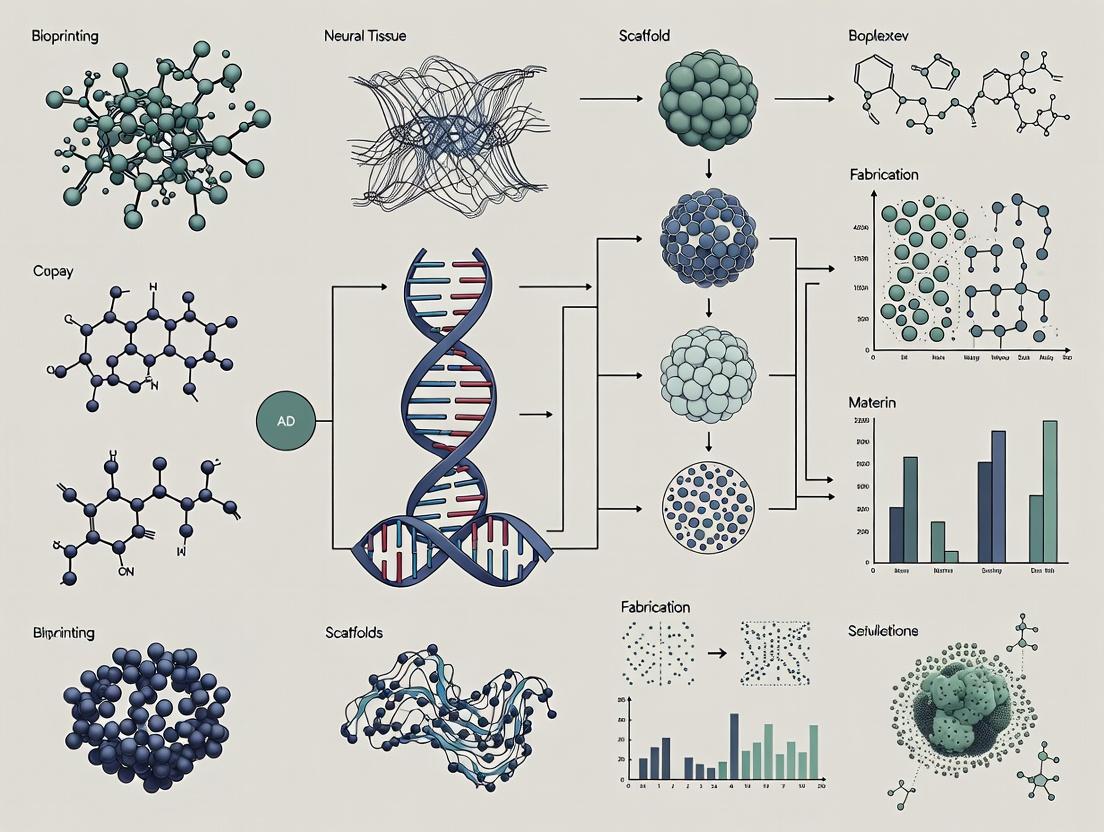

Visualizations

Title: Logic of 3D Neural Model Imperative

Title: 3D Bioprinted Neural Construct Workflow

Title: Key Glutamate Signaling Pathway in 3D Models

Application Notes on Core Components in Neural Tissue Bioprinting

1.1 Bioinks for Neural Applications Bioinks are composite materials designed to encapsulate cells and provide a supportive 3D microenvironment. For neural tissue engineering, they must mimic the delicate, compliant nature of the central nervous system (CNS) and support complex cell-cell interactions. Key bioink categories include:

- Hydrogel-based: Dominant for neural work due to high water content and tunable stiffness. Examples: modified hyaluronic acid (HA), fibrin, gelatin methacryloyl (GelMA), and self-assembling peptides.

- Decellularized extracellular matrix (dECM): Derived from neural or other tissues, providing tissue-specific biochemical cues.

- Composite/Hybrid: Combine polymers (e.g., alginate with GelMA or silk fibroin) to tailor mechanical strength, printability, and bioactivity.

Critical Parameters: Printability (viscosity, shear-thinning), post-printing stability (crosslinking mechanism—UV, ionic, thermal), biocompatibility, and biodegradation rate matching tissue ingrowth.

1.2 Cell Sources for Neural Bioprinting The choice of cell type is pivotal for replicating neural functionality.

- Primary Neural Cells: (e.g., cortical neurons, astrocytes, oligodendrocytes). Offer high fidelity but have limited availability and expansion capability.

- Neural Stem/Progenitor Cells (NSCs/NPCs): Favored for their self-renewal and differentiation potential into major neural lineages. Often derived from induced pluripotent stem cells (iPSCs).

- Induced Pluripotent Stem Cells (iPSCs): Patient-specific, ethically favorable, and capable of indefinite expansion. Require precise differentiation protocols pre- or post-printing.

- Supportive Cells: Co-printing with astrocytes, microglia, or endothelial cells to create more physiologically relevant niches and vascular networks.

1.3 Scaffold Design Principles for Neural Tissues Scaffolds must provide a permissive environment for axonal growth, synaptic connectivity, and electrical activity.

- Topographical Cues: Aligned fibers or microchannels within the bioink guide neurite extension and create anisotropic tissue architecture.

- Mechanical Properties: Stiffness (elastic modulus, E) should approximate brain tissue (0.1-1 kPa). Soft substrates promote neuronal differentiation and network formation.

- Porosity & Permeability: High, interconnected porosity is essential for nutrient diffusion, waste removal, and cell migration. Optimal pore size ranges from 50-200 μm for neural tissues.

- Biochemical Functionalization: Incorporation of adhesion peptides (e.g., RGD, IKVAV) and growth factors (e.g., BDNF, GDNF) via chemical conjugation or affinity-based systems to promote survival and differentiation.

Data Presentation: Quantitative Comparison of Common Neural Bioinks

Table 1: Comparative Analysis of Bioink Formulations for Neural Tissue Bioprinting

| Bioink Material | Typical Conc. | Gelation Method | Elastic Modulus (E) | Key Advantages | Key Limitations for Neural Use |

|---|---|---|---|---|---|

| Hyaluronic Acid (MeHA) | 1-3% (w/v) | UV Crosslinking | 0.5 - 5 kPa | Native CNS component, tunable, supports NPC growth. | Low mechanical strength alone, fast degradation. |

| Gelatin Methacryloyl (GelMA) | 5-15% (w/v) | UV Crosslinking | 1 - 30 kPa | Excellent cell adhesion, tunable RGD density. | Stiffness often >1 kPa at high conc., thermal sensitivity. |

| Fibrin | 5-20 mg/ml | Enzymatic (Thrombin) | 0.1 - 0.5 kPa | Excellent biocompatibility, promotes neurite outgrowth. | Poor mechanical stability, fast degradation. |

| Alginate (with RGD) | 1-4% (w/v) | Ionic (Ca²⁺) | 2 - 100 kPa | Excellent printability, tunable strength. | Non-degradable (standard), inert, requires modification. |

| Self-Assembling Peptides (RADA16-IKVAV) | 0.5-1% (w/v) | Ionic/ pH Shift | 0.1 - 10 kPa | Nanofibrous ECM mimic, precise bioactive epitopes. | Low viscosity, challenging to print standalone. |

| Silk Fibroin | 5-15% (w/v) | Solvent/Shear | 1 - 20 MPa | High strength, controllable degradation. | Requires processing to reduce β-sheet content for soft gels. |

Note: Modulus ranges are highly formulation-dependent. Composite bioinks (e.g., GelMA-Alginate) are commonly used to balance properties.

Experimental Protocols

Protocol 1: Bioprinting a 3D Neural Progenitor Cell (NPC) Niche using Composite GelMA-HA Bioink

Objective: To fabricate a soft, degradable 3D scaffold supporting NPC viability, proliferation, and differentiation.

Materials:

- GelMA (5-10% w/v, low methacrylation degree)

- Hyaluronic Acid Methacrylate (MeHA, 1% w/v)

- Photoinitiator: Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP, 0.1% w/v)

- Human iPSC-derived Neural Progenitor Cells (NPCs)

- Extinction cell culture medium (e.g., DMEM/F12 + B27 + EGF + FGF)

- Sterile PBS

- Extrusion bioprinter with temperature-controlled stage (4-10°C) and 365-405 nm UV curing system

- Printhead with conical nozzle (22-27G)

Method:

- Bioink Preparation: Dissolve GelMA and MeHA in PBS at 37°C. Filter sterilize (0.22 μm). Add LAP and mix thoroughly. Keep solution at 37°C until cell addition.

- Cell Harvesting & Encapsulation: Harvest NPCs as single-cell suspension. Centrifuge and resuspend in a small volume of culture medium. Mix cell suspension with the pre-warmed GelMA-MeHA-LAP solution to achieve a final density of 5-10 x 10⁶ cells/mL. Maintain mixture at 37°C to prevent pre-gelation.

- Printing Parameters: Load bioink into a sterile cartridge. Maintain cartridge temperature at 15-20°C to increase viscosity for printing.

- Nozzle: 25G (≈250 μm inner diameter).

- Pressure: 20-40 kPa (optimize for consistent filament formation).

- Print Speed: 5-10 mm/s.

- Stage Temperature: 4-10°C to aid initial filament stabilization.

- Layer Height: 80% of filament diameter.

- Printing & Crosslinking: Print desired scaffold (e.g., grid structure, 10mm x 10mm, 5 layers). Immediately after deposition of each layer, apply a brief UV light dose (365 nm, 3-5 mW/cm² for 10-30 seconds per layer) to partially crosslink.

- Post-Print Curing: After final layer, apply a final UV dose (10-20 seconds) for complete crosslinking.

- Culture: Transfer constructs to a multi-well plate, wash with PBS, and immerse in NPC proliferation medium. Culture at 37°C, 5% CO₂, with medium changes every other day.

- Differentiation: After 3-5 days of proliferation, switch to differentiation medium (remove EGF/FGF, add BDNF, GDNF).

Protocol 2: Assessing Neurite Outgrowth in 3D Bioprinted Constructs

Objective: To quantify neuronal differentiation and network formation within a bioprinted scaffold.

Materials:

- Bioprinted NPC-laden constructs (from Protocol 1, after 14-21 days differentiation)

- 4% Paraformaldehyde (PFA)

- Permeabilization buffer (0.1-0.5% Triton X-100 in PBS)

- Blocking buffer (5% normal goat serum in PBS)

- Primary antibodies: Anti-βIII-tubulin (neurons), Anti-MAP2 (mature neurites), Anti-GFAP (astrocytes)

- Secondary antibodies (fluorophore-conjugated)

- Nuclear stain (DAPI, 1 μg/mL)

- Confocal microscope

Method:

- Fixation: Wash constructs with PBS and fix in 4% PFA for 45-60 minutes at 4°C.

- Permeabilization & Blocking: Wash 3x with PBS. Permeabilize with 0.3% Triton X-100 for 2 hours. Wash, then block with blocking buffer overnight at 4°C.

- Immunostaining: Incubate with primary antibodies diluted in blocking buffer for 48 hours at 4°C under gentle agitation. Wash extensively (6-8 hours, multiple buffer changes). Incubate with secondary antibodies for 24 hours at 4°C. Wash again thoroughly. Incubate with DAPI for 2 hours.

- Imaging & Analysis: Image using a confocal microscope with Z-stacking capability. For neurite analysis:

- Use maximum intensity projections.

- Employ software (e.g., FIJI/ImageJ with Simple Neurite Tracer or IMARIS) to trace βIII-tubulin⁺/MAP2⁺ processes.

- Quantitative Metrics: Measure Neurite Length, Number of Branches, and Number of Branching Points per neuron. Calculate the percentage of βIII-tubulin⁺ cells with neurites extending >50 μm.

Mandatory Visualizations

Title: Neural Bioprinting Component & Design Workflow

Title: Key Signaling for NPC Differentiation in 3D

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Neural Bioprinting Research

| Item | Function in Neural Bioprinting Context | Example Product/Catalog |

|---|---|---|

| GelMA (High & Low Methacryl.) | Core hydrogel polymer providing cell-adhesive RGD motifs and tunable UV-crosslinkable matrix. | Advanced BioMatrix GelMA Kit, Sigma-Aldrich 900671. |

| Hyaluronic Acid Methacrylate | Provides brain-ECM mimicry, influences stiffness, and supports stem cell niche. | ESI-BIO MeHA, Glycosil. |

| LAP Photoinitiator | Cytocompatible photoinitiator for rapid UV crosslinking of methacrylated polymers. | Sigma-Aldrich 900889. |

| iPSC-Derived Neural Progenitors | Reproducible, scalable, and clinically relevant cell source for neural tissue models. | Axol Bioscience Cortical NPCs, Fujifilm Cellular Dynamics iCell Neurons. |

| BDNF & GDNF Growth Factors | Critical neurotrophins added to differentiation media to promote neuronal survival/maturation. | PeproTech 450-02 & 450-10. |

| IKVAV-Peptide Modified Gel | Laminin-derived peptide that is conjugated to polymers to enhance specific neuronal adhesion. | Nanofiber Solutions PuraMatrix. |

| Calcium Chloride (for Alginate) | Ionic crosslinker for alginate-based bioinks, used in core-shell or composite printing. | Sigma-Aldrich C5670. |

| RGD Peptide (for Alginate) | Must be grafted to inert alginate to enable cell adhesion and spreading. | Sigma-Aldrich A8052. |

Within the broader thesis on 3D bioprinting for neural tissue scaffolds, this document provides application notes and protocols for key biomaterial classes. These materials serve as the foundational bioinks and structural matrices essential for replicating the neural microenvironment, supporting neuronal growth, and facilitating tissue integration.

Application Notes & Quantitative Comparisons

Table 1: Key Properties of Hydrogel Biomaterials for Neural Scaffolds

| Material | Typical Polymer Concentration | Gelation Mechanism | Storage Modulus (G') Range | Key Advantages for Neural Tissue | Primary Limitations |

|---|---|---|---|---|---|

| Hyaluronic Acid (HA) | 0.5 - 2.0% (w/v) | Covalent (e.g., UV, Michael), Ionic | 10 Pa - 2 kPa | Native ECM component, promotes angiogenesis, tunable degradation | Low mechanical strength, potential inflammatory response at low MW |

| Gelatin Methacryloyl (GelMA) | 5 - 15% (w/v) | Photocrosslinking (UV/Vis, 365-405 nm) | 100 Pa - 10 kPa | Excellent cell adhesion (RGD), tunable stiffness, high printability | UV exposure can be cytotoxic, thermal sensitivity pre-crosslinking |

| Fibrin | 5 - 20 mg/mL | Enzymatic (Thrombin + Ca2+) | 50 Pa - 1 kPa | Excellent biocompatibility, inherent bioactivity, promotes neurite extension | Rapid degradation, poor mechanical integrity, batch variability |

| Decellularized ECM (dECM) | 3 - 10 mg/mL | Thermal (e.g., 37°C), pH shift | 50 Pa - 5 kPa | Tissue-specific biochemical cues, complex native composition | High viscosity, difficult printability, undefined composition |

| HA-GelMA Composite | 1% HA / 5% GelMA | Dual: Photocrosslinking + Ionic | 500 Pa - 5 kPa | Combines bioactivity of HA with structural integrity of GelMA | Complex optimization of two crosslinking mechanisms |

Table 2: Performance Metrics in Representative Neural Cell Culture Studies

| Biomaterial System | Cell Type Seeded | Neurite Length (µm) at 7 Days | Cell Viability (%) at Day 7 | Reference (Example) |

|---|---|---|---|---|

| 2% HA (MeHA) | Neural Stem Cells (NSCs) | 120 ± 25 | 92 ± 3 | (Burdick Lab, 2022) |

| 10% GelMA | DRG Neurons | 450 ± 75 | 85 ± 5 | (Heilshorn Lab, 2023) |

| 10 mg/mL Fibrin | PC12 Cells | 300 ± 50 | 95 ± 2 | (Willerth Lab, 2023) |

| 5 mg/mL Brain dECM | iPSC-derived Neurons | 200 ± 40 | 80 ± 7 | (Cho Lab, 2024) |

| 1%HA/7%GelMA Composite | NSC Spheroids | 350 ± 60 | 90 ± 4 | (Zhao et al., 2024) |

Detailed Experimental Protocols

Protocol 1: Synthesis and 3D Bioprinting of GelMA-based Neural Constructs

Objective: To fabricate a 3D neural tissue scaffold using GelMA hydrogel laden with neural progenitor cells (NPCs) via extrusion bioprinting. Materials: See "The Scientist's Toolkit" below. Procedure:

- GelMA Synthesis & Characterization:

- Dissolve type A gelatin (from porcine skin) at 10% (w/v) in Dulbecco's Phosphate Buffered Saline (DPBS) at 50°C.

- Add methacrylic anhydride (MA) dropwise (0.6 mL per gram of gelatin) under vigorous stirring for 3 hours at 50°C.

- Stop reaction with a 5x dilution of warm DPBS. Dialyze against distilled water (12-14 kDa cutoff) for 5-7 days at 40°C. Lyophilize for 48 hours.

- Confirm degree of functionalization (DoF) via 1H NMR (target: ~80%).

- Bioink Preparation:

- Dissense lyophilized GelMA at 7% (w/v) in sterile, warm (37°C) cell culture medium.

- Add 0.25% (w/v) photoinitiator Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP). Protect from light.

- Gently mix with a suspension of human iPSC-derived NPCs at a density of 10 x 10^6 cells/mL.

- 3D Bioprinting Process:

- Load bioink into a sterile, temperature-controlled (20-22°C) syringe fitted to an extrusion bioprinter.

- Use a 22G conical nozzle (410 µm diameter).

- Print a 15mm x 15mm grid structure (2 layers, 0/90° pattern) onto a petri dish.

- Printing Parameters: Pressure: 18-22 kPa, Speed: 8 mm/s, Layer Height: 300 µm.

- Crosslinking & Post-Processing:

- Immediately after printing, expose the construct to 405 nm UV light at an intensity of 5 mW/cm² for 60 seconds.

- Transfer construct to a 24-well plate containing neural maintenance medium.

- Culture at 37°C, 5% CO2, with medium changes every 48 hours. Assessment: Assess cell viability (Live/Dead assay) at 1, 3, and 7 days post-printing. Immunostain for β-III-Tubulin (neurons) and GFAP (astrocytes) at day 14.

Protocol 2: Preparation and Characterization of Decellularized Brain ECM Bioink

Objective: To derive a neural-specific dECM hydrogel from porcine brain tissue and characterize its biochemical and physical properties. Procedure:

- Decellularization:

- Mince 10g of fresh porcine brain cortex (grey matter).

- Wash in deionized (DI) water with agitation (120 rpm) for 24 hours at 4°C.

- Treat with 1% (w/v) sodium dodecyl sulfate (SDS) in DI water for 48 hours at 4°C with agitation.

- Rinse with DI water for 24 hours, then treat with 1% (v/v) Triton X-100 in DI water for 24 hours.

- Perform a final wash in PBS with 1% Antibiotic-Antimycotic for 72 hours, changing solution every 12 hours.

- Lyophilization & Digestion:

- Freeze tissue at -80°C and lyophilize for 72 hours.

- Mill the lyophilized dECM into a fine powder using a cryomill.

- Digest the dECM powder at 10 mg/mL in 0.1M acetic acid containing 1 mg/mL pepsin (w/w relative to dECM) for 48 hours at 4°C under constant stirring.

- Neutralize to pH 7.4 using 0.1M NaOH and dilute to a final concentration of 5 mg/mL with cold PBS. Keep on ice.

- Gelation Kinetics & Characterization:

- Rheology: Transfer 500 µL of dECM pre-gel to a rheometer plate at 4°C. Raise temperature to 37°C at 2°C/min and monitor storage (G') and loss (G'') moduli over 30 minutes. Record gelation time (crossover of G' and G'').

- Biochemical Analysis: Quantify total collagen (Hydroxyproline assay), sulfated glycosaminoglycans (sGAG; DMMB assay), and residual DNA (PicoGreen assay). Target: DNA removal >95% vs native tissue.

- Sterilization: For cell culture, filter sterilize (0.22 µm) the acidic digest pre-neutralization, then neutralize under sterile conditions.

Visualizations

Neural Scaffold Biomaterial Selection Logic

GelMA Neural Construct Bioprinting Workflow

Brain dECM Hydrogel Preparation Protocol

The Scientist's Toolkit: Key Research Reagent Solutions

| Reagent/Material | Vendor Examples (for reference) | Function in Neural Scaffold Research |

|---|---|---|

| Gelatin, Type A | Sigma-Aldrich (G2500), Millipore | Source material for synthesis of GelMA; provides RGD sequences for cell adhesion. |

| Methacrylic Anhydride (MA) | Sigma-Aldrich (276685) | Functionalizing agent for GelMA synthesis; introduces photocrosslinkable methacrylate groups. |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Tokyo Chemical Industry (L0236) | Broad-spectrum, cytocompatible photoinitiator for UV/visible light crosslinking of GelMA and other methacrylated polymers. |

| Hyaluronic Acid, Sodium Salt | Lifecore Biomedical, Bloomage Biotech | High-molecular-weight form used for chemical modification (e.g., methacrylation) to create photopolymerizable hydrogels. |

| Fibrinogen from Human Plasma | Sigma-Aldrich (F3879) | Precursor protein for forming fibrin hydrogels; combined with thrombin for enzymatic gelation in cell encapsulation. |

| Thrombin from Bovine Plasma | Sigma-Aldrich (T7513) | Serine protease that cleaves fibrinogen to initiate fibrin polymerization and hydrogel formation. |

| Pepsin from Porcine Gastric Mucosa | Sigma-Aldrich (P7000) | Proteolytic enzyme used to solubilize decellularized ECM powders into a viscous, gelable pre-polymer solution. |

| DNA Quantitation Kit (PicoGreen) | Invitrogen (P11496) | Ultrasensitive fluorescent assay critical for quantifying residual DNA in dECM to validate decellularization efficiency. |

| Anti-β-III-Tubulin Antibody | Bio-Techne (MMS-435P), Abcam (ab18207) | Primary antibody for immunocytochemical identification of neurons in 3D hydrogel cultures. |

| LIVE/DEAD Viability/Cytotoxicity Kit | Invitrogen (L3224) | Standard assay (Calcein AM/EthD-1) for quantifying cell viability and distribution in 3D bioprinted constructs. |

Application Notes

The pursuit of engineering functional 3D neural tissue via bioprinting necessitates a critical evaluation of cellular building blocks. The choice between NSPCs, iPSCs, and glial support cells profoundly influences the scaffold's fidelity, functionality, and translational applicability. Within bioprinting research, these sources are selected based on their proliferative capacity, differentiation potential, capacity for integration, and ability to recapitulate the native neural microenvironment.

Neural Stem/Progenitor Cells (NSPCs): Sourced from fetal tissue or differentiated from pluripotent stem cells, NSPCs are committed to the neural lineage. They offer a favorable balance between expansion capability and directed differentiation into neurons, astrocytes, and oligodendrocytes. In 3D bioprinting, they are prized for their inherent self-organization tendencies and reduced risk of teratoma formation compared to iPSCs. A key challenge is donor variability and limited long-term expansion without phenotypic drift.

Induced Pluripotent Stem Cells (iPSCs): iPSCs provide a virtually unlimited, patient-specific cell source. They must be pre-differentiated into neural progenitors or specific neural subtypes before printing to ensure construct predictability and safety. The use of iPSC-derived neural cells enables the modeling of neurological diseases in vitro for drug screening and the potential for autologous grafts. However, protocols for large-scale, homogeneous differentiation and the residual risk of undifferentiated cells remain significant hurdles.

Glial Support Cells: Primary or stem cell-derived astrocytes, microglia, and oligodendrocyte precursors are no longer considered mere support actors. Co-printing these cells with neurons is essential for constructing mature, homeostatic, and immunologically competent neural tissues. Astrocytes facilitate synapse formation and nutrient exchange, microglia provide immune surveillance, and oligodendrocytes enable myelination. Their inclusion moves bioprinted scaffolds from simplistic neuronal networks toward authentic neuroglial assemblies.

Experimental Protocols

Protocol 1: Differentiation of iPSCs to Neural Progenitor Cells (NPCs) for Bioprinting

Objective: Generate a scalable, consistent population of NPCs from iPSCs suitable for encapsulation in bioinks.

- Culture iPSCs on Matrigel-coated plates in mTeSR Plus medium until 70-80% confluent.

- Neural Induction: Switch to neural induction medium (e.g., NIM containing DMEM/F12, Neurobasal, N2, B27, 1μM Dorsomorphin, 10μM SB431542). Culture for 10-12 days, changing medium daily.

- NPC Expansion: Manually pick or enzymatically detach emerging neural rosettes. Plate rosettes on Poly-L-ornithine/Laminin-coated dishes in NPC expansion medium (Neurobasal, B27, 20 ng/mL bFGF, 20 ng/mL EGF). Passage every 5-7 days using Accutase.

- Characterization: Validate NPC identity via flow cytometry for Nestin (>90%), PAX6, and SOX1. Confirm multipotency by differentiation into βIII-tubulin+ neurons and GFAP+ astrocytes.

- Bioink Preparation: Harvest NPCs, centrifuge (300 x g, 5 min), and resuspend at 10-20 x 10⁶ cells/mL in chosen bioink (e.g., gelatin methacryloyl (GelMA) blended with hyaluronic acid). Maintain on ice before printing.

Protocol 2: 3D Bioprinting of a Co-culture Neural Scaffold with NSPCs and Astrocytes

Objective: Fabricate a layered construct containing NSPCs and astrocytes in a spatially defined architecture.

- Cell Preparation:

- Differentiate or isolate NSPCs and label with a cytoplasmic dye (e.g., CellTracker Green).

- Culture human induced astrocytes (iAs) and label with a distinct dye (e.g., CellTracker Red).

- Bioink Formulation:

- Bioink A (NSPC-laden): 5% (w/v) GelMA, 0.5% (w/v) LAP photoinitiator, NSPCs at 15 x 10⁶ cells/mL in PBS.

- Bioink B (Astrocyte-laden): 5% (w/v) GelMA, 0.5% LAP, astrocytes at 10 x 10⁶ cells/mL.

- Bioprinting Process:

- Load bioinks into separate cartridges of a stereolithography (SLA) or extrusion bioprinter.

- Print a 10mm x 10mm base layer (100μm thickness) using Bioink B.

- Crosslink with 405nm blue light (5s exposure, 10mW/cm²).

- Print a second lattice layer directly atop using Bioink A.

- Final crosslinking of the full construct (15s exposure).

- Post-Print Culture: Transfer construct to a 6-well plate with co-culture medium (Neurobasal-A, B27, 1% FBS, 10 ng/mL BDNF). Culture for up to 4 weeks, assessing cell viability, neurite outgrowth, and glial integration.

Data Presentation

Table 1: Comparative Metrics of Neural Cell Sources for 3D Bioprinting

| Parameter | Primary NSPCs | iPSC-Derived NPCs | Primary Astrocytes | iPSC-Derived Astrocytes |

|---|---|---|---|---|

| Expansion Potential | Moderate (5-10 passages) | High (>20 passages) | Low (2-4 passages) | High (>15 passages) |

| Typical Yield | 1-5 x 10⁶ per isolation | 1-5 x 10⁹ per differentiation run | 2-5 x 10⁵ per isolation | 1-5 x 10⁸ per differentiation |

| Neuronal Differentiation Efficiency | 60-80% (βIII-tubulin+) | 70-90% (MAP2+) | N/A | N/A |

| Glial Marker Expression | GFAP+ (30-50%), O4+ (10-20%) | GFAP+ (>95% for astro-induction) | GFAP+ (>98%) | GFAP+ (>95%) |

| Printing Viability (Day 1) | 85-90% | 80-88% | 75-85% | 82-90% |

| Cost per 10⁶ Cells | High ($500-$1000) | Medium ($100-$300) | Very High ($1000+) | Medium ($150-$350) |

| Key Advantage | Native commitment, faster maturation | Scalability, genetic engineering | Functional maturity, native phenotype | Scalability, disease modeling |

Table 2: Bioink Formulations and Outcomes for Neural Cell Types

| Bioink Composition | Crosslinking Method | Encapsulated Cell Type | Post-Print Viability (Day 7) | Notable Functional Outcome |

|---|---|---|---|---|

| 5% GelMA, 0.1% HA | Photo (405 nm) | iPSC-NPCs | 78 ± 5% | Extensive neurite extension (>500 μm) by Day 14. |

| 1.5% Alginate, 3% Fibrin | Ionic (Ca²⁺) + Enzymatic | Primary NSPCs | 82 ± 4% | Spontaneous calcium oscillations by Day 21. |

| Hybrid: 3% GelMA, 2% Alginate | Photo + Ionic | Co-culture: NPCs & Astrocytes | 85 ± 3% (NPCs), 80 ± 6% (Astros) | Enhanced neuronal survival (40% increase vs. neurons alone). |

| Peptide Hydrogel (RADA16-I) | pH-triggered self-assembly | Microglia progenitors | 88 ± 2% | Maintained ramified morphology and LPS-responsive activation. |

Diagrams

iPSC to Neural Lineage Differentiation Workflow

Spatially Defined Co-culture Bioprinting Process

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Supplier Examples | Function in Neural Bioprinting Research |

|---|---|---|

| mTeSR Plus Medium | STEMCELL Technologies | Feeder-free, defined medium for maintaining undifferentiated iPSCs prior to neural induction. |

| STEMdiff SMADi Neural Induction Kit | STEMCELL Technologies | A standardized, dual-SMAD inhibition kit for robust, efficient conversion of iPSCs to NPCs. |

| Gelatin Methacryloyl (GelMA) | Advanced BioMatrix, Cellink | A tunable, photocrosslinkable bioink providing cell-adhesive RGD motifs essential for neural cell survival and process outgrowth. |

| LAP Photoinitiator | Sigma-Aldrich, Cellink | (Lithium phenyl-2,4,6-trimethylbenzoylphosphinate) A cytocompatible photoinitiator for visible light crosslinking of bioinks like GelMA. |

| Neurobasal & B-27 Supplements | Thermo Fisher Scientific | Base medium and serum-free supplement critical for long-term survival and differentiation of primary and stem cell-derived neural cells in 3D. |

| Recombinant Human BDNF, GDNF | PeproTech | Trophic factors added to post-print culture media to promote neuronal maturation, synaptic activity, and survival in 3D constructs. |

| CellTracker Dyes | Thermo Fisher Scientific | Fluorescent cytoplasmic dyes for pre-labeling different cell populations (e.g., NSPCs vs. astrocytes) to track their location and interaction post-printing. |

| Poly-L-ornithine & Laminin | Sigma-Aldrich | Standard coating combination for 2D culture of neural cells and often incorporated into bioinks to enhance cell adhesion. |

| Live/Dead Viability/Cytotoxicity Kit | Thermo Fisher Scientific | Standard assay (Calcein AM/EthD-1) for quantifying cell viability within bioprinted constructs at various time points. |

| Matrigel Matrix | Corning | Basement membrane extract used for 2D iPSC culture and sometimes as a bioink component or post-print coating to enhance biocompatibility. |

Application Notes

The regeneration of neural tissue requires scaffolds that recapitulate the complex physical and topological features of the native extracellular matrix (ECM). Within the broader thesis on 3D bioprinting for neural scaffolds, this document outlines the application of engineered porosity, stiffness, and surface topography to direct neural stem/progenitor cell (NSC/NPC) fate, neurite outgrowth, and network formation.

1. Porosity and Permeability: A highly interconnected porous network is critical for nutrient/waste diffusion, cell migration, and vascularization. Optimal pore sizes for neural tissue are typically in the 50-200 µm range, facilitating cell infiltration and spatial organization. Effective porosity (>90%) is often achieved using sacrificial bioinks or cryogelation techniques.

2. Mechanical Cues (Stiffness): The central nervous system (CNS) parenchyma is soft (~0.1-1 kPa), while peripheral nerves are slightly stiffer (~1-10 kPa). Matching scaffold compliance to native tissue modulus is essential to prevent glial scar formation, promote neuronal differentiation, and ensure functional electrophysiology. Stiffness is tuned via polymer concentration, crosslinking density, and composite materials.

3. Topographical Guidance: Aligned fibers, grooves, and patterned surfaces provide contact guidance for axon growth cones, directing neurite extension and enhancing the rate and precision of network assembly. This is crucial for bridging lesion sites in spinal cord injury.

Table 1: Quantitative Parameters for Mimicking the Neural Microenvironment

| Parameter | Target Range (CNS) | Target Range (PNS) | Key Measurement Technique | Influence on Neural Cells |

|---|---|---|---|---|

| Elastic Modulus | 0.1 - 1 kPa | 1 - 10 kPa | Atomic Force Microscopy (AFM) | Soft substrates promote neuronal differentiation; stiff substrates promote glial differentiation. |

| Average Pore Size | 50 - 200 µm | 50 - 150 µm | Micro-CT Scanning, SEM Analysis | Facilitates 3D cell migration, network formation, and diffusion. |

| Porosity | >90% (ideal) | 70-90% | Gravimetric Analysis, Micro-CT | High interconnectivity supports metabolic exchange. |

| Fiber/Groove Alignment | 1 - 5 µm width/height | 1 - 10 µm width/height | Scanning Electron Microscopy (SEM) | Contact guidance for directed neurite outgrowth and Schwann cell alignment. |

| Ligand Density | 1 - 10 µg/cm² (e.g., laminin) | 5 - 20 µg/cm² (e.g., laminin) | Fluorescence Tagging, ELISA | Regulates integrin-mediated adhesion, survival, and differentiation. |

Experimental Protocols

Protocol 1: Fabrication of Anisotropic, Topographically-Patterned Hydrogel Scaffolds via Soft Lithography

Objective: To create 3D hydrogel scaffolds with controlled microgrooves for studying contact guidance of neurites.

- Master Mold Fabrication: Spin-coat SU-8 photoresist on a silicon wafer. Use a photomask with parallel line patterns (width: 2 µm, spacing: 2 µm, height: 5 µm) and UV expose. Develop to create the positive relief master.

- Polydimethylsiloxane (PDMS) Stamp Replication: Mix PDMS base and curing agent (10:1), pour over the master, degas, and cure at 65°C for 2 hours. Peel off the PDMS stamp.

- Hydrogel Patterning: Prepare a 3% (w/v) fibrinogen solution in PBS. Coat the PDMS stamp with the solution. Place a pre-formed, partially crosslinked collagen I hydrogel (1.5 mg/mL, 5 mm thick) on the stage. Gently press the coated stamp onto the hydrogel surface for 5 minutes.

- Scaffold Completion: Carefully remove the stamp, leaving the microgrooved pattern on the hydrogel surface. Immerse the scaffold in a thrombin solution (2 U/mL) for 10 minutes to crosslink the fibrin, creating a stable patterned interface.

- Cell Seeding: Seed primary rat hippocampal neurons (density: 500 cells/mm²) onto the patterned surface in Neurobasal medium. Culture for up to 7 days, fixing at desired time points for immunocytochemistry (β-III-tubulin).

Protocol 2: Tuning Scaffold Stiffness via Crosslinking for NSC Differentiation Studies

Objective: To generate a series of methacrylated gelatin (GelMA) hydrogels with discrete stiffness values to assess NSC fate.

- GelMA Solution Preparation: Prepare 5%, 7%, and 10% (w/v) solutions of GelMA (from porcine skin, ~90% methacrylation) in PBS containing 0.5% (w/v) lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) photoinitiator. Keep solutions at 37°C to prevent gelling.

- Hydrogel Fabrication: Pipette 100 µL of each GelMA solution into a cylindrical mold (8 mm diameter). Expose to 405 nm UV light (6 mW/cm²) for 30 seconds to achieve crosslinking.

- Mechanical Validation: Using a rheometer in oscillatory mode, confirm the storage modulus (G') of each hydrogel batch (n=5). Target moduli: 5% GelMA (~0.5 kPa), 7% GelMA (~2 kPa), 10% GelMA (~8 kPa).

- 3D Cell Encapsulation: Mix human NSCs (ReNcell VM) with the pre-polymer GelMA/LAP solutions at 5 x 10^6 cells/mL. Pipette 50 µL droplets into molds and crosslink as in Step 2.

- Culture and Analysis: Culture scaffolds in NSC maintenance medium for 14 days. Analyze differentiation via qPCR (markers: Tuj1 for neurons, GFAP for astrocytes, O4 for oligodendrocytes) and confocal imaging of immunostained sections.

Protocol 3: Assessing Neurite Outgrowth on Aligned vs. Random Nanofiber Scaffolds

Objective: To quantify the directionality and length of neurite extension on electrospun polycaprolactone (PCL) fibers.

- Scaffold Fabrication:

- Aligned Fibers: Electrospin a 12% (w/v) PCL solution in chloroform/DMF (7:3) onto a high-speed rotating mandrel (2500 rpm). Collect aligned fibers on coverslips.

- Random Fibers: Electrospin the same solution onto a stationary collector.

- Surface Functionalization: Sterilize scaffolds in 70% ethanol for 1 hour. Coat with 10 µg/mL poly-D-lysine for 1 hour, followed by 5 µg/mL laminin in PBS for 2 hours at 37°C.

- Cell Seeding: Seed differentiated PC-12 cells or primary dorsal root ganglion (DRG) neurons onto scaffolds at 100 cells/mm².

- Fixation and Staining: After 48-72 hours, fix cells with 4% PFA for 15 min. Permeabilize, block, and immunostain for β-III-tubulin and the nuclear marker DAPI.

- Image Analysis: Capture confocal microscope images (20x). Use directional orientation plugins (e.g., in ImageJ) to calculate the angle of neurite extension relative to the fiber axis (for aligned scaffolds). Measure total neurite length per cell using skeletonization plugins.

Diagrams

Title: Signaling from Scaffold Cues to Neural Cell Response

Title: Workflow for Neural Scaffold Development & Testing

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Neural Microenvironment Mimicry Experiments

| Item | Function in Research | Example Product/Catalog # (Representative) |

|---|---|---|

| Methacrylated Gelatin (GelMA) | Photocrosslinkable bioink allowing precise stiffness tuning and cell encapsulation. | GelMA, Advanced BioMatrix, #5103 |

| Laminin-1, Mouse Natural | Critical ECM protein coating for promoting neural cell adhesion, neurite outgrowth, and survival. | Laminin I, Invitrogen, #23017015 |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Highly efficient, water-soluble photoinitiator for visible light crosslinking of bioinks. | LAP, Sigma-Aldrich, #900889 |

| Poly-ε-Caprolactone (PCL) | Biodegradable, FDA-approved polymer for electrospinning topographically aligned fiber scaffolds. | PCL, Sigma-Aldrich, #440744 |

| Y-27632 (ROCK Inhibitor) | Small molecule inhibitor of Rho-associated kinase; used to enhance cell viability after seeding and reduce contractility. | Y-27632 dihydrochloride, Tocris, #1254 |

| Anti-β-III-Tubulin Antibody | Primary antibody for specific immunostaining of neurons and their neurites. | Anti-Tuj1, BioLegend, #801201 |

| Neurobasal & B-27 Supplement | Serum-free medium and supplement optimized for long-term survival of primary neurons. | Neurobasal, Gibco, #21103049; B-27, Gibco, #17504044 |

| Recombinant Human BDNF & GDNF | Neurotrophic factors added to culture medium to support neuronal differentiation, maturation, and survival. | BDNF, PeproTech, #450-02; GDNF, PeproTech, #450-10 |

From Blueprint to Biostructure: Key Bioprinting Techniques and Their Neural Applications

Extrusion bioprinting remains the predominant technique for fabricating neural tissue constructs due to its versatility in material handling, cost-effectiveness, and ability to create structurally relevant, cell-laden scaffolds. Within neural tissue engineering research, it addresses three critical fronts: (1) creating complex, 3D architectures that mimic the native extracellular matrix (ECM) to support neuronal growth and network formation; (2) depositing multiple materials to model heterogeneous tissues like gray-white matter interfaces or blood-brain barrier constructs; and (3) employing advanced coaxial printing to generate hollow, vasculature-like channels or core-shell fibers for controlled growth factor delivery, essential for nutrient diffusion in thick neural grafts.

The technique's robustness makes it a "workhorse" for high-throughput screening of drug neurotoxicity, modeling neurodegenerative diseases, and developing implantable scaffolds for spinal cord injury repair. The following protocols and data synthesize current methodologies central to this field.

Key Experimental Protocols

Protocol 2.1: Multi-material Bioprinting of a Gray/White Matter Mimetic Construct Objective: To fabricate a layered neural construct with distinct regions mimicking neuronal cell body-rich gray matter and axonal tract-like white matter. Materials: Bioink A (Gray Matter Mimetic): 3% (w/v) alginate, 1 mg/mL laminin, 1.5 x 10⁶ cells/mL induced neural progenitor cells (iNPCs). Bioink B (White Matter Mimetic): 3% (w/v) alginate, 1 mg/mL hyaluronic acid, 2 mg/mL fibrinogen, 0.5 x 10⁶ cells/mL Schwann cells. Crosslinking solution: 100 mM CaCl₂. Procedure:

- Load Bioinks A and B into separate, temperature-controlled (22°C) printhead cartridges.

- Using a multi-cartridge system, design a CAD model with a central cylinder (Bioink B, diameter 4mm) surrounded by an outer sheath (Bioink A, thickness 2mm).

- Print at a constant pressure of 25 kPa and speed of 8 mm/s using a 25G nozzle (410 μm inner diameter) onto a maintained stage (15°C).

- Immediately post-print, mist the construct with CaCl₂ solution for 60 seconds for ionic crosslinking.

- Transfer to neural maintenance medium. Assess cell viability (Live/Dead assay) at 1, 3, and 7 days and axonal alignment (β-III tubulin staining) at day 7.

Protocol 2.2: Coaxial Bioprinting of Perfusable Neural Microchannels Objective: To create hollow, endothelial-lined channels within a neural hydrogel for perfusion studies. Materials: Shell Bioink: 2% (w/v) gelatin methacryloyl (GelMA), 0.5% (w/v) photoinitiator (LAP). Core Solution: 4% (w/v) Pluronic F127. Human Brain Microvascular Endothelial Cells (HBMECs). Procedure:

- Prepare the shell bioink and keep at 37°C to prevent gelation. Maintain core solution at 4°C.

- Load solutions into a coaxial printhead (22G inner needle, 410 μm; 16G outer needle, 1.19 mm).

- Print linear filaments into a support bath of Carbopol (0.5% w/v) at 20 kPa (shell) and 15 kPa (core) pressure, speed 10 mm/s.

- Post-printing, expose the recovered construct to 405 nm light (15 mW/cm²) for 90 seconds to crosslink GelMA.

- Wash with cold cell medium to liquefy and evacuate the Pluronic core, creating a hollow channel.

- Seed HBMECs (2x10⁶ cells/mL) into the channel via perfusion and culture under flow (0.1 mL/min) after 24 hours. Assess barrier integrity (TEER, ZO-1 immunofluorescence) at day 5.

Data Presentation

Table 1: Comparative Analysis of Bioinks for Extrusion-Based Neural Bioprinting

| Bioink Formulation | Cell Type | Printability (Fidelity Score*) | Post-Print Viability (Day 1) | Neural Marker Expression (Day 14) | Key Application |

|---|---|---|---|---|---|

| 3% Alginate / 1 mg/mL Laminin | Human iPSC-NPCs | 0.85 ± 0.03 | 92% ± 3% | β-III Tubulin: 65% ± 7% | Basic neural networks |

| 2% GelMA / 0.5% HA | Rat Primary Cortical Neurons | 0.78 ± 0.05 | 88% ± 4% | MAP2: 58% ± 6% | Soft parenchymal mimics |

| 1.5% Collagen I / 2% Alginate | SH-SY5Y Neuronal Cells | 0.90 ± 0.02 | 95% ± 2% | Synapsin-1: 40% ± 5% | Mechanically stable scaffolds |

| Coaxial: Alg/GelMA Shell | HBMECs (Core) | 0.82 ± 0.04 (Channel Patency) | 85% ± 5% (Lining Confluence) | CD31: >95% | Perfusable vasculature |

*Fidelity Score (0-1): ratio of printed filament diameter to designed diameter.

Table 2: Effect of Printing Parameters on Neural Cell Viability

| Pressure (kPa) | Speed (mm/s) | Nozzle Gauge (G) | Post-Print Viability (%) | Notes |

|---|---|---|---|---|

| 15 | 5 | 27 | 96 ± 2 | Low shear, but slow, risk of clogging |

| 25 | 8 | 25 | 92 ± 3 | Optimal balance for alginate-based inks |

| 35 | 12 | 22 | 81 ± 4 | High shear stress reduces viability |

| 25 | 8 | Coaxial | 88 ± 3 (Shell) | Viability maintained in core-shell structure |

The Scientist's Toolkit: Research Reagent Solutions

| Reagent/Material | Function in Neural Bioprinting |

|---|---|

| Gelatin Methacryloyl (GelMA) | Photocrosslinkable hydrogel providing cell-adhesive RGD motifs; tunable stiffness crucial for neurite outgrowth. |

| Alginate | Ionic-crosslinkable polysaccharide; provides rapid stabilization and structural integrity to printed scaffolds. |

| Laminin & Fibronectin | ECM protein additives to bioinks to enhance neuronal adhesion, survival, and directed axonal growth. |

| Hyaluronic Acid (HA) | Major CNS ECM component; modulates hydrogel viscosity and mimics the perineuronal net microenvironment. |

| Pluronic F127 | Thermoresponsive sacrificial polymer used in coaxial printing to create temporary, washable cores for hollow channels. |

| Lithium Phenyl-2,4,6-Trimethylbenzoylphosphinate (LAP) | Efficient, cytocompatible photoinitiator for UV (365-405 nm) crosslinking of methacrylated hydrogels like GelMA. |

| Carbopol Microgel | Yield-stress support bath for printing freeform structures and fragile inks, enabling suspended filaments. |

Visualized Pathways and Workflows

Title: Multi-material Neural Construct Bioprinting Workflow

Title: Bioink Growth Factor Signaling in Neural Constructs

The fabrication of complex, perfusable vascular networks is a critical bottleneck in engineering viable neural tissue constructs. Within the thesis framework of 3D bioprinting for neural tissue scaffolds, light-based vat photopolymerization techniques—Stereolithography (SLA) and Digital Light Processing (DLP)—offer unparalleled resolution and precision for creating hierarchical, biomimetic vascular channels. These channels are essential for nutrient diffusion, waste removal, and ultimately, the survival and integration of neuronal and glial cells in thick, clinically relevant tissue models.

Technology Comparison & Quantitative Data

Table 1: Comparative Analysis of SLA and DLP for Vascular Network Fabrication

| Parameter | Stereolithography (SLA) | Digital Light Processing (DLP) | Relevance to Vascular/Neural Scaffolds |

|---|---|---|---|

| Light Source | Single UV/blue laser point | Digital UV/blue light projector (mask) | DLP enables faster layer curing, beneficial for large scaffolds. |

| Resolution (XY-axis) | 25 - 150 µm | 10 - 100 µm | DLP typically offers higher XY resolution for finer capillary features. |

| Resolution (Z-axis) | 10 - 200 µm | 10 - 100 µm | Both can achieve layer heights suitable for capillary (10-20 µm) and larger vessel definition. |

| Build Speed | Medium (serial process) | High (full layer parallel process) | DLP reduces print time for complex, branched vascular trees. |

| Bioink Requirement | Photopolymerizable resin (with photoinitiator) | Photopolymerizable resin (with photoinitiator) | Requires cytocompatible, low-irradiance resins (e.g., GelMA, PEGDA). |

| Key Advantage | Excellent surface finish, depth control | Speed, high resolution at speed | Both enable intricate, interconnected lumens without support material. |

| Vascular Network Fidelity | High for complex 3D paths | Very High for detailed 2.5D layer patterns | Ideal for generating Murray's law-based bifurcating networks. |

| Typical Cell Encapsulation | Post-printing seeding mostly | Yes, in-bath printing possible | DLP's speed better suits direct encapsulation of endothelial/neural progenitor cells. |

Table 2: Recent Benchmark Data for SLA/DLP-Printed Vascular Constructs (2023-2024)

| Ref. | Technique | Material | Minimum Channel Diameter | Printing Time (Construct) | Cell Viability (Post-Print) | Application Focus |

|---|---|---|---|---|---|---|

| Lee et al., 2023 | DLP | GelMA/PEGDA | 18 µm | 120 s (5x5x3 mm) | >92% (HUVECs) | Capillary network formation |

| Schmidt et al., 2024 | SLA | Glycidyl Methacrylate-modified Hyaluronic Acid | 75 µm | 25 min (10x10x2 mm) | >88% (hNSCs) | Neural organoid perfusion |

| Varadarajan et al., 2024 | Multi-material DLP | GelMA/nHA (wall), Pluronic F127 (sacrificial) | 50 µm | 180 s (8x8x4 mm) | >95% (Co-culture: HUVECs & Astrocytes) | Blood-brain barrier model |

Detailed Experimental Protocols

Protocol 3.1: DLP Bioprinting of a Perfusable, Endothelialized Vascular Network for Neural Co-Culture

Objective: To fabricate a dual-layer vascular lumen embedded within a neural progenitor cell-laden hydrogel using a commercially available DLP bioprinter.

Materials: See "The Scientist's Toolkit" below.

Pre-Printing Preparation:

- Bioink 1 (Vascular Lumen Ink): Dissolve 7% (w/v) GelMA and 0.1% (w/v) LAP photoinitiator in PBS at 37°C. Filter sterilize (0.22 µm). Keep at 37°C in dark.

- Bioink 2 (Neural Matrix Ink): Dissolve 3% (w/v) GelMA, 0.5% (w/v) Hyaluronic Acid, and 0.05% (w/v) LAP in neural basal medium. Gently mix with neural progenitor cells (NPCs) at 10x10⁶ cells/mL. Maintain at 22°C.

- Printer Setup: Calibrate the build platform. Load a 405 nm DLP projector mask for the vascular design (single, bifurcating channel, 200 µm diameter). Set layer height to 50 µm.

Printing Procedure:

- Layer 1 (Neural Matrix Base): Dispense 200 µL of Bioink 2 into the build vat. Project first layer pattern (solid rectangle) for 15 seconds. Raise platform.

- Layer 2-10 (Embedded Vascular Channel):

- After Layer 1, aspirate residual Bioink 2 from the vat.

- Add 150 µL of Bioink 1 (acellular) to the vat.

- Project the vascular channel cross-section pattern for 8 seconds per layer.

- After each layer, briefly lower the platform into a PBS bath to rinse uncured Bioink 1 before the next layer.

- Layer 11-20 (Neural Matrix Encapsulation): Aspirate Bioink 1. Return to dispensing Bioink 2 into the vat. Project the neural matrix layer pattern (with a void for the vascular channel) for 12 seconds per layer.

- Post-Printing: Upon completion, submerge the entire construct in PBS. Gently flush the internal vascular channel with PBS using a blunted 27G needle.

- Endothelial Seeding: Perfuse the channel with a suspension of GFP-tagged HUVECs (5x10⁶ cells/mL) using a syringe pump (10 µL/min for 10 min). Rotate construct every 15 min for 1 hour to promote uniform adhesion.

- Culture: Transfer construct to a bioreactor or static culture with endothelial growth medium (EGM-2) for 7 days to form a confluent endothelium before neural differentiation.

Protocol 3.2: SLA-Based Fabrication of a Multi-Scale Vascular Network for Neural Organoid Perfusion

Objective: To create a branching vascular scaffold with discrete inlet/outlet ports for the subsequent integration and perfusion of pre-formed neural organoids.

Materials: See "The Scientist's Toolkit".

Workflow:

- Design: Use CAD software to design a "cage-like" scaffold with primary (1 mm), secondary (500 µm), and tertiary (200 µm) branching channels. Include oversized chambers at branch points to house organoids.

- Resin Preparation: Use a commercial, biocompatible SLA resin (e.g., Biomed Clear). Add 0.5% (w/v) Sudan I dye (optional, for optical contrast) and filter.

- SLA Printing: Load design onto printer. Set laser power to 80 mW, scan speed to 1500 mm/s, and layer thickness to 50 µm. Begin print. Total print time will vary with size (e.g., ~4 hours for a 15 mm cube).

- Post-Processing:

- Washing: Immediately post-print, agitate scaffold in isopropanol for 5 minutes to remove uncured resin.

- Post-Curing: Cure under broad-spectrum UV light for 30 minutes.

- Sterilization: Soak in 70% ethanol for 30 minutes, then rinse extensively with sterile PBS.

- Organoid Integration & Perfusion:

- Manually place individual neural organoids (day 30-40) into the designated chambers using a wide-bore pipette.

- Seal the construct within a custom perfusion chip.

- Connect inlet/outlet to a peristaltic pump and circulate neural culture medium at 100 µL/min.

Diagrams (DOT Scripts)

Title: DLP Bioprinting Workflow for Vascularized Neural Construct

Title: Signaling in Engineered Neurovascular Niche

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for SLA/DLP Bioprinting of Vascular Networks

| Item / Reagent | Function / Role | Example Product / Composition |

|---|---|---|

| Methacrylated Gelatin (GelMA) | Gold-standard photopolymerizable hydrogel; provides cell adhesion motifs (RGD). | Sigma-Aldrich 900637, or synthesized in-lab from type A gelatin. |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Highly efficient, cytocompatible photoinitiator for visible/UV light (405 nm). | Tokyo Chemical Industry L0045. |

| Poly(ethylene glycol) diacrylate (PEGDA) | Synthetic, tunable hydrogel used to enhance mechanical strength of vessel walls. | Sigma-Aldrich 475629 (Mn 700). |

| PoreGEN (Sacrificial Ink) | Photocurable, thermoreversible sacrificial resin for creating hollow, smooth lumens. | Advanced BioMatrix PoreGEN. |

| Hyaluronic Acid (Methacrylated) | Mimics neural ECM, modulates stiffness, often combined with GelMA for neural constructs. | ESI-BIO HYAL-100. |

| Endothelial Growth Medium-2 (EGM-2) | Specialized medium for expansion and maintenance of vascular endothelial cells. | Lonza CC-3162. |

| Human Umbilical Vein Endothelial Cells (HUVECs) | Standard primary cell type for lining engineered vascular channels. | Lonza C2519A. |

| Neural Progenitor Cell (NPC) Kit | Provides expandable, multipotent cells for generating neuronal/glial populations. | STEMCELL Technologies 05835. |

| Biocompatible SLA Resin | Rigid, high-resolution resin for printing perfusion chips and external housings. | Formlabs Biomed Clear (RS-F2-BMCL-04). |

| Perfusion Bioreactor System | Provides controlled, continuous medium flow through printed vascular networks. | Kirkstall Ltd. Quasi Vivo QV500. |

Within the broader thesis on 3D bioprinting for neural tissue scaffolds, the selection of a biofabrication technique is paramount for cell survival and functional outcomes. Laser-Assisted Bioprinting (LAB) and Inkjet Printing are non-contact methods demonstrating exceptional viability for sensitive primary neurons, neural progenitor cells (NPCs), and induced pluripotent stem cell (iPSC)-derived neurons. This document provides application notes and detailed protocols for employing these techniques to construct neural co-cultures and stratified tissue models for neurodegeneration research, drug screening, and axon guidance studies.

Table 1: Performance Metrics of LAB vs. Inkjet for Neural Cell Bioprinting

| Parameter | Laser-Assisted Bioprinting (LAB) | Piezoelectric Inkjet Printing |

|---|---|---|

| Typical Viability (Post-Print) | 90-95% (Primary murine cortical neurons) | 85-92% (iPSC-derived dopaminergic neurons) |

| Cell Density Range | 1x10^6 - 1x10^8 cells/mL | 1x10^5 - 5x10^7 cells/mL |

| Drop Volume / Resolution | 2-150 pL; <10 µm positioning | 1-100 pL; 50-100 µm resolution |

| Key Stressors | Laser pulse energy (fluence), ribbon coating | Shear stress during droplet ejection, nozzle clogging |

| Optimal Bioink Viscosity | 1-300 mPa·s | 3.5-12 mPa·s |

| Advantage for Neural Cells | Gentle, nozzle-free; excellent for high-density, high-viscosity matrices. | High-speed, scalable; good for gradient creation and lower-density networks. |

| Primary Citation | Urbanczyk et al. (2022) Adv. Healthcare Mater. | Giacomoni et al. (2023) Biofabrication |

Detailed Experimental Protocols

Protocol 3.1: Laser-Assisted Bioprinting (LAB) of Cortical Neural Spheroids Objective: To pattern cortical neuron/NPC spheroids into a 3D hydrogel scaffold for layered cortical tissue modeling.

Materials:

- Bioprinter: Commercial or custom LAB system (e.g., equipped with a Nd:YAG laser).

- Ribbon: Gold-coated quartz slide (absorbing layer) coated with Matrigel (50 µm thick).

- Bioink: Spheroids (200 µm diameter) in cold, liquid Matrigel/Collagen I blend (4:1 ratio).

- Receiving Substrate: Fibrin hydrogel (10 mg/mL) in a cell culture insert.

- Cells: Primary rat cortical neurons or human iPSC-derived NPCs.

Method:

- Spheroid & Ribbon Preparation: Generate neural spheroids using AggreWell plates. Coat the ribbon's gold layer with 50 µL of pure Matrigel and let it gel at 37°C for 20 min.

- Loading: Mix spheroids with the liquid Matrigel/Collagen blend. Pipette 40 µL of this suspension onto the gelled Matrigel layer of the ribbon. Place the receiving substrate (fibrin gel) 1-2 mm below the ribbon.

- Printing Parameters: Set laser pulse energy to 30-40 µJ (fluence ~1 J/cm²), spot diameter 60 µm, pulse duration 8 ns. Using CAD pattern, print spheroids at 200 µm intervals.

- Post-Print Culture: Transfer receiving substrate to a 6-well plate. Add neural maintenance medium supplemented with BDNF (20 ng/mL) and NT-3 (10 ng/mL). Change 50% of medium every 2 days.

- Viability Assessment: At 24h post-print, assess viability using Live/Dead assay (Calcein-AM/EthD-1) and confocal imaging.

Protocol 3.2: Piezoelectric Inkjet Printing of a Neuronal-Glial Co-Culture Objective: To precisely deposit a co-culture of sensory neurons and Schwann cells for peripheral nerve model development.

Materials:

- Bioprinter: Precision piezoelectric inkjet system (e.g., MicroFab Jetlab) with a 60 µm nozzle.

- Bioink A: DRG neuron suspension (5x10^6 cells/mL) in PBS with 0.5% (w/v) alginate.

- Bioink B: Schwann cell suspension (1x10^7 cells/mL) in PBS with 0.5% (w/v) alginate.

- Crosslinking Solution: 100 mM CaCl₂.

- Substrate: Poly-L-lysine coated glass coverslip.

Method:

- Printer & Bioink Setup: Sterilize the print head and nozzle with 70% ethanol and UV light. Load Bioinks A and B into separate reservoirs. Maintain bioink temperature at 20°C.

- Waveform Optimization: Set a bipolar waveform: 30V peak, 25 µs rising edge, 15 µs falling edge. This minimizes satellite droplet formation.

- Printing: Print a linear pattern of Bioink A (neurons) onto the substrate. Immediately mist with CaCl₂ solution for 30s for ionic crosslinking.

- Layer 2: Print parallel lines of Bioink B (Schwann cells) adjacent to the neuron lines. Crosslink again.

- Culture: Flood the construct with Schwann cell medium (DMEM/F12 + 10% FBS + NRG1). After 4h, replace with a 1:1 mix of neuron and Schwann cell media.

- Analysis: At 72h, immunostain for β-III-Tubulin (neurons) and S100β (Schwann cells) to assess morphology and interaction.

Diagrams of Experimental Workflows

Title: LAB Process for Neural Spheroids

Title: Inkjet Bioprinting of Neuron-Glial Co-Culture

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for High-Viability Neural Bioprinting

| Item | Function & Relevance | Example/Notes |

|---|---|---|

| Temperature-Sensitive Hydrogel | Provides a printable, cytocompatible matrix that gels gently post-deposition. Critical for reducing shear stress. | Matrigel (for LAB ribbon coating); Alginate (for inkjet, requires crosslinker). |

| Neurotrophic Factor Cocktail | Maintains printed neuron viability, promotes neurite outgrowth, and supports network maturation. | BDNF, GDNF, NT-3. Add to culture medium post-print at 10-50 ng/mL. |

| RGD-Modified Bioink | Enhances cell adhesion and survival by providing integrin-binding sites, crucial for anchorage-dependent neurons. | RGD-Alginate, Peptide-modified Hyaluronic Acid. |

| Shear-Thinning Hydrogel | Reduces mechanical stress during inkjet ejection; protects cell membrane integrity. | Hyaluronic Acid with Nanocellulose, GelMA. |

| Live/Dead Viability Assay | Quantitative, immediate assessment of post-printing cell health. The gold standard for protocol optimization. | Calcein-AM (live) & Ethidium Homodimer-1 (dead). Image 2-24h post-print. |

| Ion Channel Modulators | Can be added to bioink to protect neurons from shear-induced membrane potential disruption. | Gadolinium Chloride (stretch-activated channel blocker), used at low µM. |

| Anti-Apoptotic Supplement | Suppresses early apoptotic pathways triggered by processing stresses. | Y-27632 (ROCK inhibitor), effective for NPCs and some primary neurons. |

Emerging Hybrid and Multi-Modal Bioprinting Strategies

This document provides detailed application notes and protocols for emerging hybrid and multi-modal bioprinting strategies, framed within a thesis on 3D bioprinting techniques for neural tissue scaffolds. The goal is to fabricate complex, biomimetic neural constructs that support cell viability, differentiation, and functional network formation for applications in regenerative medicine, disease modeling, and drug development.

Hybrid strategies combine the strengths of multiple bioprinting techniques to address the competing demands of structural integrity, print fidelity, and cell viability in neural scaffolds.

Table 1: Comparison of Hybrid Bioprinting Modalities

| Modality Combination | Key Advantage | Typical Resolution | Max Cell Viability Reported | Key Neural Cell Type Used | Reference Year |

|---|---|---|---|---|---|

| Extrusion + Inkjet | Structural support + high-res cell patterning | 50-200 µm (Inkjet) | 92% | Neural Progenitor Cells (NPCs) | 2023 |

| Extrusion + Electrospinning | Aligned fibers for neurite guidance | 5-20 µm (Fiber) | 88% | Schwann Cells, DRG neurons | 2024 |

| SLA/DLP + Microfluidics | High-res channels + vascularization | 10-50 µm (SLA) | 85% | iPSC-derived neurons | 2023 |

| Extrusion + Acoustic | Non-contact cell patterning within pre-printed gels | Single Cell | 95% | Primary cortical neurons | 2024 |

Multi-Material/Bioink Formulations for Neural Constructs

The bioink formulation is critical for mimicking the neural extracellular matrix (ECM).

Table 2: Multi-Modal Bioink Components for Neural Scaffolds

| Bioink Component | Concentration Range | Function | Crosslinking Method |

|---|---|---|---|

| Gelatin Methacryloyl (GelMA) | 5-15% w/v | ECM-mimetic, promotes adhesion | UV Light (365-405 nm) |

| Hyaluronic Acid Methacrylate (HAMA) | 1-3% w/v | Mimics brain ECM, supports stemness | UV Light |

| Fibrinogen | 5-20 mg/mL | Promotes neurite extension | Thrombin (10-50 U/mL) |

| Laminin-derived peptides (e.g., IKVAV) | 0.5-2 mg/mL | Enhances neuronal differentiation & adhesion | Covalent (EDC/NHS) or physical |

| Nanocellulose/ Nanofibrillated Cellulose | 0.1-0.5% w/v | Enhances printability & shear-thinning | Ionic (Ca²⁺) or physical |

| PEG-based 4-Arm Acrylate (PEG-4A) | 5-10% w/v | Tuneable mechanical properties | UV Light |

Detailed Protocols

Protocol: Hybrid Extrusion-Inkjet Bioprinting of a Stratified Neural Co-Culture Model

Objective: To fabricate a scaffold with structural glial-rich layers (extrusion) and precisely patterned neuronal aggregates (inkjet).

Materials:

- Bioprinter: Multi-modality system (e.g., BIO X with AFL printhead, or similar custom setup).

- Bioink A (Structural/Glial): 8% GelMA, 1% HAMA, 0.5% photoinitiator LAP, 1x10^6/mL human astrocytes.

- Bioink B (Neuronal): 5% GelMA, 2 mg/mL IKVAV peptide, 5x10^6/mL iPSC-derived neural progenitor cells (NPCs).

- Support Bath: 4% w/v Carbopol.

Method:

- Preparation: Sterilize all components. Maintain bioinks and cells at 4°C until printing.

- Extrusion Printing of Glial Layer:

- Load Bioink A into a sterile 3mL syringe with a 22G conical nozzle.

- Print a 20mm x 20mm grid structure (2 layers) into the Carbopol support bath at 4°C.

- Parameters: Pressure 25-30 kPa, speed 8 mm/s, layer height 150 µm.

- Crosslink the printed structure in-situ with 405 nm UV light (20 mW/cm² for 30 seconds).

- Inkjet Patterning of Neuronal Aggregates:

- Load Bioink B into a sterile inkjet cartridge.

- Using the AFL printhead, deposit 60 pL droplets of Bioink B at predefined nodal points on the first layer.

- Parameters: Voltage 80V, pulse width 25 µs, frequency 200 Hz.

- Print a second extruded glial layer directly over the patterned droplets.

- Perform a final global crosslink with 405 nm UV light (30 mW/cm² for 60 seconds).

- Post-Processing: Carefully remove the printed construct from the support bath using a mesh scoop. Wash 3x in PBS. Transfer to neural culture medium (Neurobasal-A + B27 + GDNF).

- Culture: Maintain at 37°C, 5% CO2. Monitor viability via Live/Dead assay at days 1, 3, and 7.

Protocol: Multi-Modal SLA Printing with Embedded Electrospun Guidance Conduits

Objective: To create a compartmentalized neural scaffold with perfusable channels (SLA) and aligned nanofibers for directed axonal growth (electrospinning).

Materials:

- SLA Printer: High-resolution (e.g., 50 µm XY) desktop SLA printer.

- SLA Resin: 15% PEG-4A, 2% GelMA, 0.5% LAP.

- Electrospinning System: Syringe pump, high-voltage supply, grounded rotating mandrel (2mm diameter).

- Electrospinning Solution: 12% w/v PCL in 70:30 Chloroform:Methanol, with 1% w/w laminin added.

Method:

- SLA Printing of Channeled Scaffold:

- Design a 3D model with two parallel 1mm channels connected by micro-grooves (100µm width).

- Slice the model with 50µm layer thickness.

- Print the structure using the PEG-4A/GelMA resin. Post-print, wash in 70% ethanol to remove uncured resin, then cure under UV for 10 minutes.

- Integration of Aligned Fibers:

- Mount the cured SLA scaffold on the rotating mandrel (500 rpm) of the electrospinning setup.

- Electrospin PCL/Laminin fibers directly across the micro-groove region connecting the two channels.

- Parameters: Flow rate 1.2 mL/h, voltage 18 kV, tip-to-collector distance 15 cm, duration 15 minutes.

- Seeding and Culture:

- Sterilize the hybrid scaffold with 70% ethanol and UV overnight.

- Seed Schwann Cells (2x10^5) suspended in fibrin gel (10 mg/mL fibrinogen, 5 U/mL thrombin) into one channel.

- Seed Dorsal Root Ganglion (DRG) neurons (1x10^5) into the opposite channel.

- Culture in DMEM/F12 + N2 supplement + 50 ng/mL NGF. Assess neurite extension along fibers at day 7 via β-III-tubulin immunostaining.

Visualizations

Diagram: Multi-Modal Bioprinting Workflow for Neural Scaffolds

Title: Workflow for Multi-Modal Neural Bioprinting

Diagram: Key Signaling Pathways in Bioprinted Neural Constructs

Title: ECM-Integrin Signaling in Neural Bioprinting

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Hybrid Neural Bioprinting Experiments

| Item | Function in Neural Bioprinting | Example Product/Catalog |

|---|---|---|

| GelMA (High Degree of Substitution) | Core bioink polymer; provides cell-adhesive RGD motifs and tunable mechanical properties. | "Advanced BioMatrix GelMA Kit, 90% Methacrylation" or "CELLINK GelMA TYPE A" |

| LAP Photoinitiator | Enables rapid, cytocompatible crosslinking of methacrylated bioinks with 405 nm UV/VIS light. | "Sigma-Aldrich Lithium phenyl-2,4,6-trimethylbenzoylphosphinate" |

| IKVAV-Peptide Acrylate | Functionalization agent; confers specific laminin-derived signaling to promote neuronal differentiation. | "Peptides International, IKVAV-S-Acrylate" |

| Carbopol 974P NF Polymer | Creates a yield-stress support bath for extrusion printing of complex, low-viscosity bioinks. | "Lubrizol Carbopol 974P NF" |

| PEG-4-Arm Acrylate (MW 20kDa) | Synthetic, inert polymer for creating stable, high-resolution SLA-printed channel structures. | "JenKem Technology, PEG-4-Acrylate" |

| Laminin from Engelbreth-Holm-Swarm (EHS) tumor | Gold-standard coating for promoting neuronal attachment and neurite extension on printed constructs. | "Corning Matrigel Matrix (Growth Factor Reduced)" or purified "Mouse EHS Laminin" |

| Neurobasal-A Medium + B-27 Supplement | Serum-free culture medium optimized for long-term viability of primary neurons and neural stem cells. | "Gibco Neurobasal-A Medium" & "Gibco B-27 Supplement" |

| Live/Dead Viability/Cytotoxicity Kit | Standard assay for quantifying cell viability and distribution within 3D bioprinted constructs. | "Invitrogen LIVE/DEAD Viability/Cytotoxicity Kit (calcein AM/ethidium homodimer-1)" |

Application Notes

Within the context of advancing 3D bioprinting techniques for neural tissue scaffolds, this spotlight focuses on three critical translational applications. 3D bioprinting enables the fabrication of complex, patient-specific neural tissues that recapitulate key aspects of human pathophysiology and architecture, surpassing the limitations of 2D cultures and animal models.

- Disease Modeling (Alzheimer's, Parkinson's): 3D bioprinted neural scaffolds incorporating patient-derived induced pluripotent stem cells (iPSCs), neurons, glial cells (astrocytes, microglia), and vasculature allow for the spatially controlled study of disease progression. These models facilitate the observation of protein aggregation (e.g., amyloid-β plaques, α-synuclein Lewy bodies), neuroinflammation, and neuronal network dysfunction in a biomimetic microenvironment.

- High-Throughput Drug Screening Platforms: Bioprinted 3D neural tissue arrays in multi-well plate formats provide physiologically relevant platforms for compound testing. They enable parallelized assessment of drug efficacy, toxicity, and blood-brain barrier (BBB) penetration, significantly improving the predictive value of pre-clinical screening and reducing late-stage drug attrition.

- Implantable Grafts for Spinal Cord Injury (SCI): Precisely engineered, biodegradable scaffolds can be bioprinted with aligned topographical cues, neurotrophic factors, and neural progenitor cells. These constructs are designed to bridge lesion sites, providing physical guidance and biochemical signals to promote axonal regeneration, remyelination, and functional recovery post-implantation.

Table 1: Quantitative Data Summary of Recent 3D Bioprinted Neural Tissue Studies

| Application | Cell Types Used | Bioink Formulation | Key Quantitative Outcome | Reference (Example) |

|---|---|---|---|---|

| Alzheimer's Model | iPSC-derived neurons, astrocytes, microglia | GelMA/Hyaluronic acid | 40% increase in amyloid-β42 secretion after 28 days vs. 2D; Microglial phagocytosis reduced by 60% in disease model. | Lee et al., 2023 |

| Parkinson's Model | iPSC-derived dopaminergic neurons | Laminin-enriched fibrin-gelatin | 70% loss of tyrosine hydroxylase+ neurons upon α-synuclein pre-formed fibril exposure; Rescue of 50% viability with candidate drug LRRK2-inh. | Smith et al., 2024 |

| Drug Screening (Neurotoxicity) | Primary cortical neurons, astrocytes | PEG-based bioink with RGD | IC50 for known neurotoxin (MPP+) was 15 μM in 3D vs. 150 μM in 2D, demonstrating 10x greater sensitivity. | Johnson & Park, 2023 |

| Spinal Cord Injury Graft | Neural stem cells (NSCs), endothelial cells | Silk fibroin / Gelatin methacryloyl (Silk/GelMA) | 8-week post-implant in rat SCI: 3x more corticospinal axon regeneration across graft vs. acellular control; 65% improvement in BBB locomotor score. | Chen et al., 2024 |

Detailed Experimental Protocols

Protocol 1: Bioprinting a 3D Alzheimer's Disease Tri-culture Model

Aim: To fabricate a spatially organized neural tissue containing neurons, astrocytes, and microglia to model amyloid-β pathology and neuroinflammation.

Materials:

- Bioink A (Neural Matrix): 5% (w/v) Gelatin Methacryloyl (GelMA), 1% (w/v) Hyaluronic Acid Methacrylate (HAMA), 0.1% (w/v) LAP photoinitiator in PBS.

- Cells: iPSC-derived cortical neurons (Day 15), iPSC-derived astrocytes (Day 30), iPSC-derived microglia (Day 20).

- Bioprinter: Extrusion-based bioprinter with a temperature-controlled stage (4-15°C) and a 365nm UV light source (5-10 mW/cm²).

- Procedure:

- Cell Preparation: Harvest and concentrate each cell type separately. Keep on ice.

- Bioink Preparation: Mix GelMA/HAMA/LAP solution. Divide into three aliquots.

- Cell Loading: Gently resuspend neurons in Bioink A (20x10⁶ cells/mL), astrocytes in Bioink A (10x10⁶ cells/mL), and microglia in Bioink A (5x10⁶ cells/mL). Keep mixtures on ice in syringes.

- Printing: Use a multi-cartridge system. Print a 10x10x1 mm³ construct layer-by-layer:

- Layer 1-2: Print astrocyte-laden bioink in a grid pattern.

- Layer 3-6: Co-print neuron-laden bioink and astrocyte-laden bioink in adjacent nozzles.

- Layer 7-8: Print microglia-laden bioink on top.

- Crosslinking: After each layer, apply a 10-second pulse of 365nm UV light (5 mW/cm²) for partial gelation. After final layer, apply a final 60-second crosslink.

- Culture: Transfer to neural maintenance medium. Treat with γ-secretase inhibitor (e.g., DAPT) for 14 days to induce amyloid-β accumulation. Analyze via immunostaining (Aβ, Iba1, GFAP), ELISA, and calcium imaging.

Protocol 2: High-Throughput Screening of Neuroprotective Compounds in a 3D Parkinson's Model

Aim: To screen a compound library for efficacy in protecting dopaminergic neurons from α-synuclein-induced toxicity in a 96-well bioprinted format.

Materials:

- Bioink: Laminin (1 mg/mL)-doped Fibrinogen (10 mg/mL) / Gelatin (5% w/v).

- Cells: iPSC-derived dopaminergic neurons (Floorplate progenitors, Day 25).

- Inducer: α-synuclein pre-formed fibrils (PFFs).

- Procedure:

- Array Printing: Load cell-laden bioink (15x10⁶ cells/mL) into a pneumatic extrusion printer. Print 40μL micro-tissues (approx. 2mm diameter x 1mm height) into each well of a 96-well plate pre-coated with a thrombin solution (2 U/mL) to initiate fibrin polymerization.

- Maturation: Culture for 7 days in dopaminergic neuron maturation medium.

- Disease Induction: Add PFFs (2 μg/mL) to the medium for 72 hours.

- Compound Screening: Add compounds from the library (e.g., 10μM final concentration in 0.1% DMSO) simultaneously with PFFs. Include controls (vehicle, no PFFs, positive control neurotrophin).

- Endpoint Assay (Day 10):

- Viability: Perform CellTiter-Glo 3D assay. Record luminescence.

- Phenotype: Fix and immunostain for Tyrosine Hydroxylase (TH) and βIII-Tubulin. Perform high-content imaging and automated cell counting.

- Analysis: Normalize TH+ cell count and viability to vehicle-treated (no PFF) controls. Calculate % protection. Z'-factor >0.5 indicates a robust screening assay.

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Neural Tissue Bioprinting |

|---|---|

| Gelatin Methacryloyl (GelMA) | Photocrosslinkable bioink base providing cell-adhesive RGD motifs and tunable mechanical properties. |

| Hyaluronic Acid (Methacrylate) | Key component of the neural extracellular matrix; modulates stiffness and supports hydrogel integrity. |

| LAP Photoinitiator | (Lithium phenyl-2,4,6-trimethylbenzoylphosphinate) A cytocompatible photoinitiator for visible/UV crosslinking. |