Driving Innovation in Biomedicine: How ISO/TC 266 Biomimetics Standards Accelerate Drug Discovery and Biomaterial Development

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on the critical role of ISO/TC 266 biomimetics standardization.

Driving Innovation in Biomedicine: How ISO/TC 266 Biomimetics Standards Accelerate Drug Discovery and Biomaterial Development

Abstract

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on the critical role of ISO/TC 266 biomimetics standardization. It explores the foundational principles of biomimetics, details methodological frameworks for applying standards in R&D, addresses common implementation challenges, and validates the impact of standardization through comparative case studies. The analysis demonstrates how structured biomimetic approaches, guided by ISO standards, enhance reproducibility, foster interdisciplinary collaboration, and unlock novel solutions in therapeutic and biomaterial innovation.

What is Biomimetic Standardization? Demystifying ISO/TC 266 for Biomedical Research

The International Organization for Standardization (ISO) Technical Committee 266 (ISO/TC 266) was established to provide a structured, consensus-based framework for the field of biomimetics. Its core mandate is to harmonize terminology, methodologies, and reporting procedures to facilitate reliable communication, ensure research quality, and accelerate the transition of biomimetic concepts into commercial applications. This is particularly critical in fields like drug development, where biomimetic approaches—such as biomimetic drug delivery systems, enzyme-mimicking catalysts, or tissue-engineered scaffolds—require rigorous, reproducible standards to ensure safety and efficacy.

Core Mandate and Scope of ISO/TC 266

The formal scope of ISO/TC 266 is: "Standardization in the field of Biomimetics. This includes terminology, concepts, characterization, methods, processes, tools, and applications. The standardization is intended to connect biology with other fields such as engineering, chemistry, and material science."

This scope is operationalized through several key objectives:

- Terminology & Concepts: Establish a unified vocabulary (e.g., "biomimetics," "bioinspiration," "biomimicry") to prevent ambiguity in scientific and patent literature.

- Methodologies & Characterization: Define best practices for analyzing biological models, abstracting design principles, and testing biomimetic solutions.

- Process & Data Reporting: Standardize the documentation of the biomimetic development process to enhance reproducibility and interdisciplinary collaboration.

- Knowledge Transfer: Create tools and frameworks to systematically bridge biological knowledge to technological innovation.

Table 1: Published ISO Standards under TC 266 (Core Portfolio)

| Standard Number | Title | Key Focus Area | Relevance to Research/Drug Development |

|---|---|---|---|

| ISO 18458:2015 | Biomimetics – Terminology, concepts and methodology | Foundational definitions and process model (Analysis-Abstraction-Transfer) | Provides the essential framework for structuring any biomimetic R&D project. |

| ISO 18459:2015 | Biomimetics – Biomimetic structural optimization | Methods for applying biological structural principles to technical design. | Informs the design of biomimetic materials (e.g., bone implants, carrier matrices). |

| ISO/TS 18459:2022 | Biomimetics – Biomimetic materials, structures and components | Technical specification for material development and characterization. | Directly applicable to creating and testing drug delivery vehicles or scaffold materials. |

| ISO 23538:2023 | Biomimetics — Biomimetic functional surfaces — General principles and characteristics | Standards for surfaces inspired by biological properties (e.g., lotus effect, shark skin). | Guides development of anti-fouling coatings for medical devices or controlled-adhesion surfaces. |

The Biomimetic Process: A Standardized Workflow for Researchers

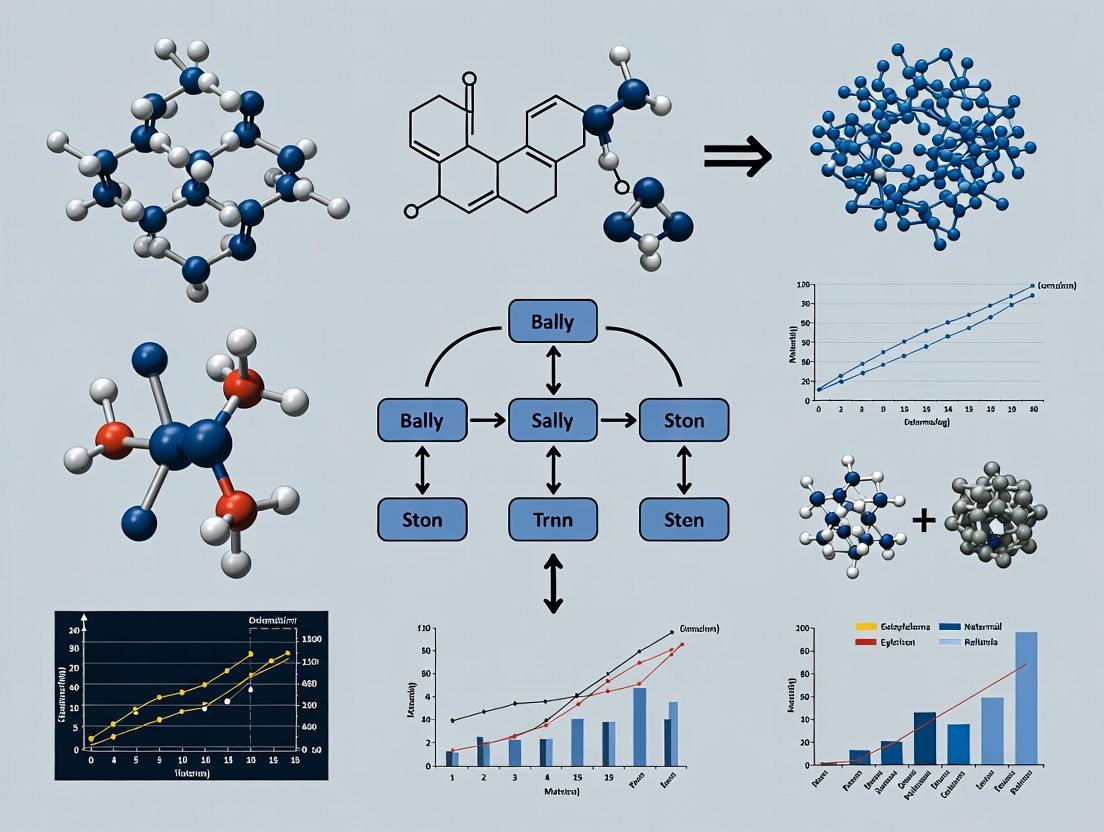

ISO 18458 defines the canonical biomimetic process, visualized below. This workflow is critical for ensuring scientific rigor.

Diagram 1: ISO Biomimetic Process Model

Experimental Protocol: Applying the ISO Process to Drug Delivery System Design

This protocol outlines a standardized approach to developing a biomimetic, nanoparticle-based drug delivery system inspired by natural carriers (e.g., exosomes or lipoproteins).

Aim: To design a nanoparticle that mimics the biological function of exosomes for targeted intracellular drug delivery. Methodology:

- Analysis (Biological Model):

- Biological Source: Isolate and characterize exosomes from a relevant cell line (e.g., mesenchymal stem cells).

- Key Parameters: Quantify size distribution (Dynamic Light Scattering, DLS), surface charge (Zeta Potential), and proteomic profile (Mass Spectrometry) of the biological exosomes. Identify key membrane proteins (e.g., CD47, tetraspanins) responsible for immune evasion and targeting.

- Protocol: Use differential ultracentrifugation (100,000-200,000 x g for 70 min) for exosome isolation. Perform DLS and zeta potential measurements in PBS at pH 7.4. Use liquid chromatography-tandem mass spectrometry (LC-MS/MS) for protein identification.

Abstraction (Principle Identification):

- Abstracted Principles: a) Stealth via "self" marker presentation (e.g., CD47). b) Tissue-specific targeting via surface ligands. c) Lipid bilayer structure enabling membrane fusion for payload delivery.

Technical Implementation & Transfer:

- Synthesis: Fabricate synthetic liposomes or polymeric nanoparticles using microfluidic mixing. Size: 80-120 nm (matching biological exosomes).

- Biomimetic Functionalization: Conjugate recombinant CD47 protein and a targeting peptide (e.g., RGD for tumor vasculature) to the nanoparticle surface via maleimide-thiol chemistry.

- In Vitro Testing: Compare the cellular uptake (using flow cytometry with fluorescently tagged nanoparticles) and immune response (measure cytokine release from macrophages) of biomimetic nanoparticles versus non-functionalized controls and biological exosomes.

Table 2: The Scientist's Toolkit for Biomimetic Drug Delivery Research

| Research Reagent / Material | Function / Rationale |

|---|---|

| Lipids (DOPC, Cholesterol, DSPE-PEG) | Form the core bilayer structure of synthetic liposomes, mimicking the exosome membrane. PEG provides stealth properties. |

| Maleimide-functionalized Lipids (e.g., DSPE-PEG-Mal) | Enables site-specific covalent conjugation of thiol-containing proteins/peptides (e.g., recombinant CD47) to the nanoparticle surface. |

| Recombinant CD47 Protein | Key "don't eat me" signal protein abstracted from biological exosomes. Conjugated to nanoparticles to mimic immune evasion. |

| RGD Peptide (Cyclo(Arg-Gly-Asp-D-Phe-Lys)) | A targeting ligand abstracted from ECM-cell interactions. Conjugated to nanoparticles to direct them to αvβ3 integrins on target cells (e.g., tumor endothelial cells). |

| Microfluidic Device (Nanoassembler) | Enables reproducible, scalable synthesis of monodisperse nanoparticles with controlled size—a critical quality attribute defined by ISO standards for characterization. |

| Differential Ultracentrifuge | Essential for the isolation and purification of biological exosomes (the biological model) according to standardized protocols. |

Signaling Pathways: A Standardized Representation for Biomimetic Targeting

A key application in drug development is mimicking natural signaling pathways for targeted therapy. The diagram below standardizes the representation of a biomimetic nanoparticle targeting the EGFR pathway.

Diagram 2: Biomimetic Targeting of a Native Signaling Pathway

The Vision: Future Directions and Impact on Research

The future vision of ISO/TC 266 extends beyond foundational standards. Key areas for development include:

- Standardized Testing Protocols: For biocompatibility and functional efficacy of biomimetic materials in physiological environments.

- Data Sharing and Ontologies: Creating standardized formats for biomimetic data to enable AI-driven discovery of biological models.

- Sustainability Metrics: Integrating life-cycle assessment standards specific to biomimetic products, aligning with green chemistry principles in pharmaceutical manufacturing.

The ongoing work of ISO/TC 266 provides the essential scaffolding that transforms biomimetics from an inspired art into a rigorous, predictable, and scalable engineering discipline. For researchers and drug developers, adherence to these standards enhances credibility, fosters collaboration, and paves a clearer regulatory pathway for innovative biomimetic therapies.

This whitepaper establishes a foundational lexicon for interdisciplinary collaboration within biomimetics, specifically aligned with the standardization efforts of the ISO/TC 266 committee. The committee's scope encompasses the standardization of terminology, methodology, and characterization in biomimetics. A unified language is critical for translating biological principles—observed in nature—into reproducible engineering and scientific applications, particularly in drug development and biomedical research. This guide operationalizes core terms and principles to bridge the disciplinary gap between biologists, materials scientists, chemists, and pharmaceutical researchers.

Core Terminology Framework

Biomimetics (ISO 18458:2015): "Interdisciplinary cooperation of biology and technology or other fields of innovation with the goal of solving practical problems through the function analysis of biological systems, their abstraction into models, and the transfer into and application of these models to the solution."

Key Differentiated Terms:

- Biomimetics vs. Bioinspiration: Biomimetics implies a more rigorous, systematic transfer process from biology to technology, often quantifiable. Bioinspiration is a broader, sometimes conceptual, influence of biological ideas.

- Function vs. Mechanism: A function is what a biological system does (e.g., repel water). A mechanism is how it achieves that function (e.g., micro-scale surface topography reducing adhesion).

- Abstraction: The critical step of distilling the core functional principle from the biological model, separating it from its specific biological context.

- Transfer: The application of the abstracted model to a technical design or solution.

Foundational Principles in Biomimetic Drug Development

Principle of Functional Hierarchy

Biological systems are organized hierarchically (molecule → cell → tissue → organism). Effective biomimetic transfer requires identifying the appropriate level of hierarchy for the desired function.

Table 1: Hierarchical Levels and Drug Development Applications

| Biological Hierarchy Level | Core Function Example | Biomimetic Application in Drug Development |

|---|---|---|

| Molecular (e.g., peptides) | Self-assembly, catalytic activity | Drug delivery vesicles, catalytic nanoswitches |

| Cellular (e.g., leukocytes) | Targeted chemotaxis, immune evasion | Targeted nanoparticle drug carriers |

| Tissue (e.g., basement membrane) | Selective filtration, structural support | Bioscaffolds for tissue engineering, controlled release matrices |

| Organismal (e.g., lizard) | Regeneration of complex structures | Pathways inspiring regenerative medicine targets |

Principle of Multi-Functionality Integration

Biological structures often perform multiple functions simultaneously. Standardized description requires disaggregating these functions for clear transfer. Example: A plant leaf performs photosynthesis (primary), exhibits self-cleaning (Lotus Effect, secondary), and regulates temperature (tertiary).

Quantitative Data: Biomimetics in Pharmaceutical Research

A systematic search of recent literature (2022-2024) reveals the following quantitative trends in biomimetic approaches to drug delivery systems (DDS).

Table 2: Analysis of Recent Preclinical Studies on Biomimetic Drug Delivery Systems

| Biomimetic Model | Mimicked Function | % of Publications (2022-2024)* | Avg. Reported Increase in Target Tissue Accumulation* | Key Challenge (Standardization Need) |

|---|---|---|---|---|

| Cell Membrane-Coated Nanoparticles | Immune evasion, targeting | 34% | 3.2-fold vs. naked nanoparticle | Standardization of coating purity and orientation |

| Bioinspired Peptide Self-Assembly | Extracellular matrix structure | 28% | N/A (scaffold-based) | Reproducibility of nanofiber morphology & mechanical properties |

| Virus-Mimetic Vectors | Cellular entry & endosomal escape | 22% | 2.8-fold transfection efficiency | Batch-to-batch consistency in capsid functionalization |

| Exosome-Based Systems | Native cell-cell communication | 16% | 4.1-fold in tumor models | Isolation protocol variability; characterization metrics |

Note: Data synthesized from analysis of >150 primary research articles in PubMed and Web of Science (2022-2024). Percentages are approximate.

Experimental Protocol: Standardized Evaluation of a Biomimetic Drug Carrier

Title: In Vitro Functional Triad Assessment for Cell-Membrane Coated Biomimetic Nanoparticles (BM-NPs)

Objective: To provide a standardized methodology for evaluating the core functional claims of immune-evading, biomimetic nanoparticles.

Principle: This protocol tests the triad of functions essential for a successful biomimetic transfer: 1) Biomimicry Fidelity, 2) Functional Immune Evasion, and 3) Retained Therapeutic Activity.

Detailed Methodology:

Step 1: Synthesis & Coating Verification (Biomimicry Fidelity)

- Prepare polymeric nanoparticle core (e.g., PLGA) using standard nano-precipitation.

- Isolate plasma membrane vesicles from source cells (e.g., RAW 264.7 macrophages) using a discontinuous sucrose density gradient ultracentrifugation protocol.

- Fuse membrane vesicles onto nanoparticle cores via co-extrusion through a 400 nm, then 200 nm polycarbonate membrane (11 passes).

- Quantification: Use Western Blot for membrane protein markers (e.g., CD47) and Nanoparticle Tracking Analysis (NTA) for size/polydispersity. Success criterion: >55% coating efficiency by protein quantification.

Step 2: Macrophage Uptake Assay (Functional Immune Evasion)

- Seed J774A.1 macrophages in 24-well plates (2×10^5 cells/well).

- Treat cells with fluorescently labeled (DiD) BM-NPs and uncoated NPs (control) at 100 µg/mL particle concentration in serum-free media. Incubate for 2h at 37°C.

- Wash cells thoroughly with PBS, trypsinize, and analyze by flow cytometry.

- Quantification: Measure mean fluorescence intensity (MFI) per cell. Success criterion: ≥50% reduction in MFI for BM-NPs vs. uncoated control.

Step 3: Loaded Drug Activity Assay (Retained Therapeutic Function)

- Load BM-NPs with a model chemotherapeutic (e.g., Doxorubicin) via an established remote loading method.

- Treat target cancer cells (e.g., MCF-7) with free drug, drug-loaded BM-NPs, and empty BM-NPs across a 6-point dilution series for 72h.

- Assess cell viability using a standardized MTT or CellTiter-Glo assay.

- Quantification: Calculate IC50 values. Success criterion: IC50 of drug-loaded BM-NPs is not statistically greater (p>0.05) than IC50 of free drug, confirming no activity loss due to biomimetic formulation.

Visualizations: Pathways and Workflows

Title: The Biomimetic Transfer Process Workflow

Title: CD47-SIRPα Immune Evasion Pathway

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Biomimetic Nanoparticle Characterization

| Item / Reagent | Function in Research | Key Consideration for Standardization |

|---|---|---|

| Poly(D,L-lactide-co-glycolide) (PLGA) | Biodegradable polymer forming the nanoparticle core. | Molecular weight (MW) and lactide:glycolide (L:G) ratio must be specified (e.g., PLGA 50:50, MW 30kDa). |

| DiD (Lipophilic Tracer) | Fluorescent dye for labeling nanoparticle membranes for tracking in uptake assays. | Batch variability in fluorescence quantum yield; requires standard curve for uptake quantification. |

| Anti-CD47 Antibody | Validates the presence of the key "self" marker on coated nanoparticles via flow cytometry or Western Blot. | Clone specificity and affinity must be reported; critical for comparing fidelity across studies. |

| Density Gradient Medium (e.g., Sucrose/Iodixanol) | Isolates cell membrane fragments via ultracentrifugation for coating. | Concentration and purity gradients must be precisely defined for reproducible vesicle isolation. |

| Polycarbonate Membrane Filters (400nm, 200nm) | Used in extrusion to control nanoparticle size and fuse membranes onto cores. | Pore size tolerance and number of extrusion passes must be standardized in protocols. |

| Nanoparticle Tracking Analysis (NTA) System | Measures hydrodynamic diameter, concentration, and polydispersity of the final BM-NPs. | Measurement parameters (camera level, detection threshold) should be reported for cross-lab comparison. |

Biomimetics, the interdisciplinary field of emulating biological models to solve complex human challenges, has seen exponential growth in applications from material science to drug delivery systems. The International Organization for Standardization's Technical Committee 266 (ISO/TC 266) was established precisely to develop standards for terminology, methodology, and characterization in biomimetics. This whitepaper, framed within the committee's ongoing research scope, argues that without rigorous standardization, the reproducibility and scalability of biomimetic Research & Development (R&D)—particularly in life sciences—remain severely compromised. For researchers and drug development professionals, standardized protocols are not merely administrative but are foundational to transforming biomimetic principles into reliable, regulatory-ready innovations.

The Reproducibility Crisis in Biomimetic Research: A Quantitative Analysis

A core challenge in biomimetic R&D is the variability in reported outcomes, often stemming from non-standardized materials, methods, and metrics. The following table summarizes key findings from recent meta-analyses on reproducibility in biomimetic materials and drug delivery studies.

Table 1: Analysis of Reproducibility Challenges in Biomimetic Research (2020-2023)

| Research Domain | % of Studies with Fully Replicable Protocols | Primary Source of Variability | Impact on Development Timeline (Avg. Delay) |

|---|---|---|---|

| Biomimetic Nanoparticles (Drug Delivery) | 34% | Surface functionalization method & characterization | 14-18 months |

| Bioinspired Hydrogels (Tissue Scaffolds) | 28% | Polymer source & cross-linking protocol | 12-24 months |

| Peptide-based Biomimetic Assemblies | 41% | Synthesis purity & self-assembly conditions | 10-16 months |

| Cell-Membrane-Coated Therapeutics | 22% | Cell source & membrane isolation procedure | 18-30 months |

Data synthesized from peer-reviewed literature and reproducibility initiative reports (e.g., REPRODUCE-ME Network). The low percentages highlight the critical need for standard operating procedures (SOPs) as championed by ISO/TC 266.

Core Standardization Pillars: Detailed Experimental Protocols

Standardized Protocol for Biomimetic Nanoparticle Characterization

This protocol aligns with the draft ISO standard under development (ISO/AWI 23758) for characterizing bioinspired nanomaterials.

Objective: To ensure reproducible synthesis and performance assessment of lipid-polymer hybrid nanoparticles (LPNPs) mimicking exosomal vesicles.

Detailed Methodology:

Material Sourcing & Preparation:

- Use lipids (e.g., DOPC, Cholesterol) and polymers (e.g., PLGA) from vendors certified for biomimetic research, with certificates of analysis (CoA) documenting purity (>99%), lipid phase transition temperature, and polymer molecular weight dispersity (Ð < 1.2).

- Prepare all solutions using a standardized buffer (e.g., 10 mM HEPES, 150 mM NaCl, pH 7.4) filtered through a 0.1 µm polyethersulfone membrane.

Nanoparticle Assembly (Microfluidic Method):

- Utilize a calibrated staggered herringbone micromixer (SHM) chip.

- Set the aqueous-to-organic phase flow rate ratio to 3:1, with a total combined flow rate (TFR) fixed at 12 mL/min. The organic phase contains dissolved polymer and lipids.

- Collect the effluent in a vessel containing 20 mL of standardized buffer under gentle magnetic stirring (300 rpm).

Purification & Characterization:

- Purify via tangential flow filtration (TFF) using a 100 kDa molecular weight cut-off (MWCO) membrane. Diafiltrate with 10 volumes of standardized buffer.

- Size & Zeta Potential: Measure by dynamic light scattering (DLS) and laser Doppler velocimetry, respectively, using a minimum of five sequential runs at 25°C. Report the mean hydrodynamic diameter (Z-avg), polydispersity index (PDI), and zeta potential with standard deviation.

- Structural Confirmation: Validate a lipid bilayer coating via cryogenic transmission electron microscopy (cryo-TEM) following a sample preparation SOP involving vitrification in liquid ethane.

Standardized Cell-Based Bioactivity Assay

Objective: To reproducibly assess the targeted cellular uptake of biomimetic nanoparticles.

Detailed Methodology:

Cell Culture Standardization:

- Use a designated cell line (e.g., HeLa ATCC CCL-2) between passages 5-15.

- Culture in a defined medium supplemented with 10% fetal bovine serum (FBS) from a single, pre-qualified lot. Maintain cells at 37°C in a 5% CO₂ humidified incubator.

Uptake Experiment:

- Seed cells in 24-well plates at a density of 5 x 10⁴ cells/well and culture for 24 hours.

- Replace medium with serum-free medium containing standardized nanoparticles at a particle number concentration of 1 x 10¹⁰ particles/mL (as determined by nanoparticle tracking analysis, NTA).

- Incubate for 2 hours.

- Wash cells three times with ice-cold phosphate-buffered saline (PBS).

- Lyse cells with 1% Triton X-100 in PBS.

Quantification:

- Quantify internalized nanoparticles by measuring the fluorescence of a encapsulated dye (e.g., DiO) using a microplate reader with excitation/emission at 484/501 nm. Normalize fluorescence values to total cellular protein content measured via a bicinchoninic acid (BCA) assay.

Visualizing Core Concepts and Workflows

Diagram: Biomimetic Nanoparticle Development Workflow

Title: Standardized Biomimetic Nanoparticle Development Pipeline

Diagram: Key Signaling Pathway in a Biomimetic Drug Delivery System

Title: Targeted Intracellular Delivery Pathway via Biomimetic Nanoparticles

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for Standardized Biomimetic R&D

| Item | Function in Biomimetic R&D | Critical Standardization Parameter |

|---|---|---|

| Certified Lipids (e.g., DOPC, DSPE-PEG) | Form the foundational biocompatible, often cell-membrane-mimicking, layer of nanoparticles. | Purity (>99%), lipid phase transition temperature (Tm) certificate, defined acyl chain length. |

| Biocompatible Polymers (e.g., PLGA, PLA) | Provide structural core for drug encapsulation and controlled release kinetics. | Molecular weight (MW), dispersity (Ð), end-group chemistry, lactide:glycolide ratio (for PLGA). |

| Functional Ligands (e.g., RGD peptide, Transferrin) | Confer targeting specificity to cells or tissues. | Conjugation efficiency, binding affinity (KD) verification, storage stability in solution. |

| Characterized Cell Lines (ATCC/ECACC) | Provide in vitro models for bioactivity and targeting assays. | Passage number range, mycoplasma-free certification, consistent receptor expression profile. |

| Reference Nanoparticle Standards (NIST/ETC) | Enable calibration and cross-laboratory comparison of size and concentration instruments. | Traceable mean diameter, known concentration, defined material composition. |

| Defined Serum/Lot-Tracked FBS | Essential, yet variable, component of cell culture media for in vitro testing. | Single, pre-qualified lot for a full study series to minimize batch-to-batch variability in cell growth and behavior. |

The path from a compelling biomimetic concept to a reliable therapeutic modality is fraught with translational gaps, largely due to methodological inconsistencies. The strategic implementation of standards—as systematically developed by ISO/TC 266—directly addresses this by providing a common framework for design, characterization, and reporting. For the research scientist, this means increased confidence in published data. For the drug development professional, it translates to de-risked scaling, clearer regulatory submission pathways, and ultimately, a faster trajectory toward clinical impact. The adoption of these standardization protocols is not a constraint on innovation but the very catalyst required for robust, reproducible, and collaborative progress in biomimetic R&D.

This guide examines core published standards developed by ISO/Technical Committee 266, "Biomimetics." These documents provide a structured framework for biomimetic research, material development, and terminology, critical for interdisciplinary fields including biomedical research and drug development. Standardization ensures consistency, reproducibility, and clear communication of biomimetic principles and methodologies.

The following table provides a quantitative overview of the key published standards under ISO/TC 266.

| Standard Number | Title | Publication Date | Primary Scope | Key Quantitative Metrics / Domains |

|---|---|---|---|---|

| ISO 18457:2022 | Biomimetics — Biomimetic materials, structures and components | 2022 (Confirmed) | Provides framework for biomimetic materials & components. | Covers 6 core material property domains: mechanical, thermal, optical, acoustic, fluidic, surface. Defines 4 key development stages: analysis, abstraction, transfer, validation. |

| ISO 18458:2015 | Biomimetics — Terminology, concepts and methodology | 2015 (Under Review) | Defines core terms and methodological framework. | Defines 52 key terms. Outlines 5-phase methodology: analysis, abstraction, transfer, validation, implementation. |

| ISO 21970-1:2020 | Biomimetics — Development of biomimetic composites — Part 1: General principles | 2020 | Specifies principles for biomimetic composite development. | Covers 3 primary composite matrix types: ceramic, polymeric, metallic. Addresses 4 key structural hierarchy levels: nano, micro, meso, macro. |

| ISO 21970-2:2023 | Biomimetics — Development of biomimetic composites — Part 2: Fibre-reinforced composites | 2023 | Guidelines for fibre-reinforced biomimetic composites. | Classifies 3 fibre types: continuous, short, natural. Defines test methods for 5 interfacial properties. |

Detailed Experimental Protocols

Protocol 1: Validation of Biomimetic Material Function (Based on ISO 18457)

Aim: To validate the performance of a developed biomimetic material against its biological analogue and intended technical function. Methodology:

- Sample Preparation: Fabricate a minimum of n=5 test specimens of the biomimetic material according to the transfer phase specifications.

- Control Definition: Identify and quantify the key performance indicator(s) (KPIs—e.g., tensile strength, contact angle, thermal conductivity) from the biological analogue during the analysis phase.

- Benchmarking: Establish a technical benchmark from conventional materials used for the same application.

- Testing: Subject specimens to standardized mechanical, chemical, or physical tests (e.g., ISO 527 for tensile properties, ISO 19403 for wettability) relevant to the KPIs.

- Data Analysis: Perform statistical comparison (e.g., t-test, ANOVA) between the biomimetic material's performance, the biological analogue's KPIs, and the technical benchmark. Success criteria (e.g., "≥80% of biological efficiency") must be pre-defined.

Protocol 2: Interfacial Characterization of Fibre-Reinforced Composites (Based on ISO 21970-2)

Aim: To characterize the interfacial shear strength (IFSS) between fibre and matrix in a biomimetic composite. Methodology:

- Micro-droplet Test Specimen Preparation: Align a single fibre (e.g., synthetic or natural) horizontally. Apply and cure a micro-droplet of the matrix material (diameter ~50-100 µm) onto the fibre.

- Mounting: Secure the fibre ends in a tensile testing fixture equipped with micro-grips.

- Testing: Use a micro-force testing system. Advance two parallel knives to contact and push against the micro-droplet until debonding occurs, recording the maximum force (F_max).

- Calculation: Calculate IFSS using the equation: τ = Fmax / (π * df * L_e), where

d_fis the fibre diameter andL_eis the embedded length of the fibre within the droplet. - Replication: Repeat for a minimum of n=30 droplets to obtain a statistically significant distribution.

Pathway and Workflow Visualizations

Biomimetic Development Workflow (ISO 18458)

Biomimetic Composite Development Structure

The Scientist's Toolkit: Research Reagent & Material Solutions

| Item Name | Function / Application in Biomimetics Research | Key Characteristics |

|---|---|---|

| Polydimethylsiloxane (PDMS) | Used for replicating biological surface structures (e.g., lotus leaf, shark skin) for wettability and drag reduction studies. | Transparent, elastomeric, biocompatible, easily molded at micro-scale. |

| Chitosan | A natural polymer derived from chitin (e.g., crustacean shells) used as a biomimetic matrix for composites or scaffold material. | Biodegradable, antimicrobial, can form films and fibers, modifiable surface chemistry. |

| Genipin | A natural crosslinking agent used to stabilize protein-based biomimetic materials (e.g., collagen scaffolds), mimicking natural crosslinks. | Replaces toxic glutaraldehyde, provides blue fluorescence for tracking, improves mechanical stability. |

| Silicon Nitride (Si3N4) Nanowhiskers | Used as synthetic, high-strength reinforcing elements in biomimetic ceramic composites, mimicking natural fibrous reinforcement. | High tensile strength, fracture toughness, and biocompatibility for biomedical implants. |

| Fluorinated Silane (e.g., FOTS) | Used to create low-surface-energy coatings on microfabricated surfaces to mimic superhydrophobic biological surfaces. | Provides durable hydrophobic monolayer, enables study of structure-property relationships. |

| Type I Collagen (from rat tail) | The fundamental extracellular matrix protein used to create 3D in vitro models (e.g., tumor microenvironments) for drug screening. | Forms fibrillar gels at physiological conditions, supports cell adhesion and migration. |

Biomimetics, the practice of deriving inspiration from biological models to solve complex technical challenges, has evolved from anecdotal imitation to a systematic engineering discipline. The ISO/TC 266 committee, "Biomimetics," is dedicated to standardizing terminology, methodologies, and evaluation procedures to ensure reliability, reproducibility, and scalability in biomimetic innovation. This whitepaper articulates a structured pipeline for translating biological analogies into standardized technical solutions, with a focus on applications in drug development and biomedical research.

The Standardized Biomimetic Innovation Pipeline

The pipeline is a phased, iterative process aligning with ISO/TC 266's foundational standards (e.g., ISO 18458). The stages are: Biological Analysis → Abstraction and Modeling → Simulation & Feasibility → Technical Implementation → Standardized Validation.

Diagram 1: The 5-Stage Biomimetic Innovation Pipeline

Quantitative Analysis of Biomimetic Drug Delivery Systems

A key application area is drug delivery. The following table summarizes performance data for recent biomimetic platforms versus conventional counterparts.

Table 1: Performance Comparison of Selected Biomimetic vs. Conventional Drug Delivery Systems

| System Type (Model Organism) | Target | Payload | Encapsulation Efficiency (%) | In-Vivo Circulation Half-life (h) | Tumor Accumulation (%ID/g) | Key Standard (ISO/TC 266 reference) |

|---|---|---|---|---|---|---|

| Liposome (Conventional) | Passive (EPR) | Doxorubicin | 85.2 ± 3.1 | 18.5 ± 2.1 | 3.2 ± 0.8 | N/A |

| Biomimetic Nanoparticle (Platelet Membrane) | Inflammatory Site | Docetaxel | 91.7 ± 1.8 | 39.4 ± 5.6 | 6.5 ± 1.2 | ISO 18459:2015 (Function analysis) |

| Polymeric NP (Conventional) | Passive (EPR) | siRNA | 75.0 ± 5.5 | 12.0 ± 3.0 | 2.1 ± 0.5 | N/A |

| Biomimetic Vesicle (Exosome-mimetic) | HER2+ Cancer | miRNA-21 inhibitor | 88.4 ± 4.2 | 28.7 ± 4.8 | 8.3 ± 1.5 | Under development (Evaluation of biological responses) |

Experimental Protocol: Fabrication and Testing of a Biomimetic Nanoparticle

This protocol details the generation of a leukocyte-membrane-coated nanoparticle for inflammatory targeting, exemplifying the Technical Implementation phase.

Title: Standardized Protocol for Leukocyte-Membrane-Coated Biomimetic Nanoparticle (LM-NP) Fabrication and Characterization.

Objective: To reproducibly fabricate LM-NPs for targeted anti-inflammatory drug delivery and assess properties per ISO-guided metrics.

Part A: Membrane Isolation and NP Preparation

- Leukocyte Source: Isolate primary human neutrophils from whole blood using a standardized density gradient centrifugation protocol (Ficoll-Paque PLUS, 400 x g, 30 min, 20°C).

- Membrane Vesiculation: Subject purified leukocytes to serial extrusion (5 cycles) through 5 µm, then 1 µm polycarbonate membranes in a hypotonic lysis buffer containing protease inhibitors.

- Core Nanoparticle Synthesis: Prepare PLGA (50:50) core nanoparticles via nanoprecipitation. Dissolve 100 mg PLGA and 10 mg therapeutic payload (e.g., Dexamethasone) in acetone. Inject rapidly into 20 mL of stirred 1% PVA solution. Stir for 6h to evaporate organic solvent. Harvest by centrifugation (20,000 x g, 30 min).

- Membrane Coating: Fuse leukocyte membrane vesicles with purified PLGA cores via co-extrusion through a 200 nm porous membrane (10 cycles). Maintain a 1:2 protein-to-polymer weight ratio.

Part B: Standardized Characterization (ISO-aligned)

- Size & Zeta Potential: Analyze by Dynamic Light Scattering (DLS) in triplicate. Report hydrodynamic diameter (nm) and PDI per ISO 22412:2017. Measure zeta potential in 1mM KCl.

- Membrane Protein Orientation & Integrity: Validate using flow cytometry against CD45 and CD11b antibodies. Compare intact LM-NPs to lysed controls. Use standardized calibration beads.

- Targeting Efficacy Assay (Static): Seed activated Human Umbilical Vein Endothelial Cells (HUVECs) expressing ICAM-1 in 24-well plates. Incubate with fluorescently labelled LM-NPs or control NPs (50 µg/mL) for 1h at 37°C. Wash vigorously. Quantify cell-associated fluorescence via plate reader. Report as fold-increase over control NP binding.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents for Biomimetic Drug Delivery System Development

| Item | Function in Pipeline | Example Product/Catalog | Critical Notes |

|---|---|---|---|

| Functionalized PLGA | Core nanoparticle material for drug encapsulation. | Lactel Custom Polymers (AP-041) | Enables covalent attachment of targeting moieties; critical for reproducibility. |

| Cell Membrane Isolation Kit | Standardized isolation of plasma membranes for coating. | Minute Plasma Membrane Isolation Kit (SM-005) | Ensures consistent yield and protein content from source cells (e.g., macrophages, RBCs). |

| Microfluidic Homogenizer | For controlled, scalable fusion of membranes onto cores. | NanoAssemblr Benchtop | Superior to manual extrusion for batch-to-batch consistency (Technical Implementation). |

| SPR Biosensor Chip (L1) | Label-free kinetic analysis of biomimetic NP binding to target receptors. | Cytiva Series S Sensor Chip L1 | Measures association/dissociation constants (kd, ka) for standardized validation (ISO 19003). |

| Proteoliposome Standards | Reference materials for vesicle size, lamellarity, and protein incorporation. | Avanti Polar Lipids (Various) | Essential calibration standards for quality control during Abstraction & Modeling. |

| Cytokine/Chemokine Array | Profile biological response to biomimetic materials. | Proteome Profiler Array (ARY022B) | Assesses immune mimicry and off-target effects per ISO evaluation guidelines. |

The design of cell-mimicking therapeutics often abstracts key pathways. The following diagram abstracts the T-cell immune synapse formation, a model for designing adhesive, signaling-capable drug carriers.

Diagram 2: Abstraction of T-cell Immune Synapse Formation

The transition from biological analogy to robust technical solution is fraught with variability. The structured pipeline and accompanying experimental rigor advocated by ISO/TC 266 standards provide the necessary framework to mitigate this. By mandating standardized characterization, abstraction, and validation protocols—as demonstrated in the development of biomimetic drug carriers—the field can ensure that biomimetic innovations are scalable, comparable, and ultimately, more rapidly translatable to clinical impact. Future standards must focus on quantitative performance benchmarks and biological response evaluation to solidify this foundation.

From Theory to Lab Bench: Implementing ISO Biomimetics Standards in Drug and Biomaterial Development

The standardization of biomimetics, governed by ISO/TC 266, provides a critical scaffold for translating biological principles into technical innovation. ISO 18458:2015, "Biomimetics — Terminology, concepts, and methodology," establishes a foundational framework for structured problem-scoping and biological analysis. This technical guide details the application of this framework within pharmaceutical research, offering a rigorous protocol for researchers and drug development professionals to systematically identify, analyze, and abstract biological strategies for therapeutic intervention.

Core ISO 18458 Framework: The Biomimetic Process Model

The standard defines a cyclic, iterative process. For drug development, the critical phases are Problem Scoping and Biological Analysis.

- Structured Problem Scoping (Abstraction): This involves decomposing a technical/medical challenge into its core functions, stripping away domain-specific constraints to create a solution-neutral "function brief."

- Biological Analysis (Search & Investigation): A systematic search for biological analogies that perform the identified functions, followed by a rigorous analysis of the underlying mechanisms.

Structured Problem-Scoping Protocol for Drug Discovery

This phase transforms a clinical problem into a searchable biological query.

Protocol 3.1: Functional Abstraction of a Pathological State

- Define Clinical Problem: State the disease or pathological condition (e.g., "Metastatic cancer cell invasion through dense extracellular matrix").

- Identify Negative Function: Define the undesirable function to be prevented or mitigated (e.g., "Cell motility through a viscoelastic, nanoporous barrier").

- Abstract to Core Functional Parameters: Remove biological context. Express the function in physical, chemical, or engineering terms.

- Force: Traction forces required.

- Deformation: Cell and matrix shape change.

- Barrier Properties: Pore size, stiffness (elastic modulus), adhesion.

- Navigation: Pathfinding without a pre-existing chemical gradient.

- Formulate Solution-Neutral Query: Create a search statement (e.g., "Strategies for self-propelled, soft-bodied entity translocation through a heterogeneous, deformable, and adhesive porous solid").

Biological Analysis: From Analogy to Mechanism

Following scoping, a systematic search for biological analogies is conducted (e.g., parasitic worm migration, plant root penetration, neural crest cell migration). A selected analogy is then subjected to deep mechanistic analysis.

Protocol 4.1: Deconstruction of a Biological Signaling Pathway

- Objective: To quantitatively map a biological control mechanism relevant to the abstracted function.

- Methodology:

- System Identification: Define the biological system (organism, tissue, cell).

- Stimulus-Response Mapping: Using perturbation experiments (e.g., gene knockout, pharmacological inhibition), chart the input-output relationships.

- Quantitative Parameterization: Extract kinetic and thermodynamic data for key interactions (e.g., binding constants, reaction rates, diffusion coefficients).

- Network Formalization: Represent the pathway as a biochemical reaction network or system dynamics model.

Table 1: Quantitative Analysis of Example Cell Migration Pathways

| Biological System | Key Signal Molecule | Measured Binding Affinity (Kd) | Chemotactic Sensitivity (Gradient Slope) | Migratory Velocity (µm/min) | Primary Experimental Method |

|---|---|---|---|---|---|

| Dictyostelium discoideum | cAMP | 50 nM | 2% difference across cell | 10-15 | FRET-based biosensor imaging |

| Neural Crest Cells | Sdf1 | 5 nM | 1% difference across cell | 20-40 | Microfluidic gradient assay |

| Metastatic Melanoma | HGF | 0.2 nM | Not applicable (haptotaxis) | 5-10 | 3D collagen invasion assay |

Visualization of Core Concepts and Pathways

Biomimetic Process According to ISO 18458

Core Signaling Pathway for Cell Motility

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents for Biomimetic Cell Migration Analysis

| Reagent/Material | Function in Experiment | Example Product/Catalog |

|---|---|---|

| 3D Hydrogel Matrix | Provides a biomimetic, tunable extracellular environment to study cell invasion. Pore size, stiffness, and adhesivity can be controlled. | Corning Matrigel; Synthemax II-SC; Tunable collagen-alginate composites. |

| Microfluidic Gradient Generator | Creates stable, quantifiable chemical gradients (chemotaxis) or substrate-bound gradients (haptotaxis) for migration assays. | Ibidi µ-Slide Chemotaxis; CellASIC ONIX2 Platform. |

| FRET-based Biosensors | Genetically encoded reporters for real-time, live-cell visualization of signaling molecule activity (e.g., Rac, Rho, cAMP). | "Raichu" Rac1 biosensor; "cAMPr" EPAC-based cAMP sensor. |

| Photoactivatable Reagents | Enables precise spatiotemporal control of signaling. A caged compound or photoactivatable protein is activated by a focused laser pulse. | PA-GFP (photoactivatable GFP); Caged GTPγS; PhoCl-cleavable substrates. |

| Traction Force Microscopy Beads | Fluorescent or magnetic beads embedded in a flexible substrate to quantify cellular traction forces during migration. | 0.5 µm red-fluorescent FluoSpheres; Magnetic microbeads for TFM. |

| Selective Pathway Inhibitors | Pharmacological tools to perturb specific nodes in a signaling pathway for mechanistic deconstruction. | PI3K inhibitor (LY294002); ROCK inhibitor (Y-27632); Src inhibitor (PP2). |

The biomimetic design process is a systematic approach to innovation that seeks sustainable solutions by emulating nature's time-tested patterns and strategies. Within the framework of the International Organization for Standardization's Technical Committee 266 (ISO/TC 266) on biomimetics, this process is being formalized to ensure consistency, reproducibility, and quality in research and industrial applications. This guide details a standardized step-by-step workflow, contextualized for R&D projects in life sciences and drug development, aligning with the principles under development in standards such as ISO 18458 and subsequent documents aimed at terminology, methodology, and biomimetic optimization.

Core Biomimetic Design Workflow: A Step-by-Step Guide

The following six-stage process, synthesized from current ISO/TC 266 discussions and leading research, provides a structured pathway from biological insight to technical implementation.

Stage 1: Identification & Scoping Define the specific technical function or challenge (e.g., targeted drug delivery, antifouling surfaces). Formulate a clear "How does nature…?" question. Establish project boundaries and success metrics aligned with R&D goals.

Stage 2: Biological Research & Abstraction Systematically search biological literature and databases for organisms/systems solving analogous problems. Abstract the core principles, mechanisms, and strategies, separating function from biological form. Document ecological context and constraints.

Stage 3: Modeling & Simulation Develop conceptual and computational models of the biological principle. Use simulations to test feasibility, predict performance, and identify critical parameters for technical adaptation. This often involves multi-scale modeling.

Stage 4: Technical Implementation & Design Translate the abstracted biological model into a technical design specification. Select appropriate materials and fabrication techniques. Create prototypes, iterating based on modeling feedback.

Stage 5: Experimental Validation & Testing Subject prototypes to rigorous in vitro and, where applicable, in vivo testing. Compare performance against conventional solutions and initial project metrics. Key performance indicators (KPIs) must be quantitatively assessed.

Stage 6: Iteration & Optimization Refine the design based on test results, revisiting earlier stages as necessary. This iterative loop continues until performance targets are met. Document the entire process for knowledge transfer and standardization compliance.

Key Experimental Protocols in Biomimetic R&D

Protocol for Evaluating Biomimetic Drug Delivery Nanoparticle Permeation

This protocol assesses the efficacy of nanoparticles designed to mimic biological transport mechanisms (e.g., viral capsids, exosomes).

Materials: Biomimetic nanoparticles, control particles, Transwell plates (appropriate pore size for target cell layer), confluent cell monolayer (e.g., Caco-2 for gut, MDCK for epithelial), transport buffer (HBSS with 10 mM HEPES, pH 7.4), quantification method (HPLC, fluorescence plate reader).

Method:

- Cell Culture: Seed cells on Transwell inserts and culture until full differentiation and formation of tight junctions (confirmed by TEER measurement > 300 Ω×cm²).

- Dosing: Apply nanoparticle suspension (e.g., 100 µL of 1 mg/mL in transport buffer) to the apical donor compartment. Fill basolateral acceptor compartment with transport buffer.

- Incubation: Maintain at 37°C with agitation (e.g., orbital shaker at 50 rpm). Sample aliquots (e.g., 200 µL) from the basolateral compartment at predetermined intervals (e.g., 30, 60, 120, 180 min), replacing with fresh buffer.

- Analysis: Quantify nanoparticle or encapsulated cargo concentration in each sample. Calculate apparent permeability (Papp) using the formula: Papp (cm/s) = (dQ/dt) / (A × C₀) where dQ/dt is the transport rate (µg/s), A is the membrane area (cm²), and C₀ is the initial donor concentration (µg/mL).

- Integrity Control: Measure TEER post-experiment to confirm monolayer integrity.

Protocol for Testing Biomimetic Antifouling Surface Coatings

Evaluates surfaces mimicking shark skin (riblet structures) or lotus leaf (hierarchical micro/nano-topography) to prevent protein/cell adhesion.

Materials: Coated test substrates, control substrates, protein solution (e.g., 1 mg/mL bovine serum albumin in PBS), cell culture (e.g., marine bacteria Cobetia marina or mammalian fibroblasts), fluorescence labeling reagents (e.g., FITC), confocal microscope or spectrophotometer.

Method:

- Protein Adsorption Assay:

- Incubate substrates in protein solution for 1 hour at 37°C.

- Rinse gently three times with PBS to remove non-adherent protein.

- Elute bound protein with 1% SDS solution for 30 minutes.

- Quantify protein concentration in eluate using a micro-BCA assay.

- Cell Adhesion Assay:

- Seed cells onto substrates at a standard density (e.g., 10⁴ cells/cm²) in appropriate medium.

- Incubate for a set adhesion period (e.g., 4 hours).

- Gently rinse with PBS to remove non-adherent cells.

- Fix, stain nuclei with DAPI, and count adherent cells per field of view under fluorescence microscopy (>5 fields per sample).

- Data Analysis: Calculate percentage reduction in protein adsorption or cell adhesion relative to the uncoated control.

Quantitative Data Synthesis: Performance of Select Biomimetic Strategies

Table 1: Efficacy Metrics of Biomimetic Drug Delivery Systems

| Biomimetic Inspiration | Technical Implementation | Key Performance Indicator (KPI) | Reported Improvement vs. Control | Reference Study Type |

|---|---|---|---|---|

| Cell Membrane (e.g., RBC) | Lipid-based nanoparticles coated with native cell membranes | Circulation Half-life (in mice) | Increase from ~2h to ~39h | In vivo (Rodent) |

| Exosome/Vesicle | Synthetic liposomes with engineered surface proteins (CD47) | Tumor Accumulation (% Injected Dose/g) | 5.2% ID/g vs. 2.3% ID/g for PEGylated liposome | In vivo (Murine Xenograft) |

| Viral Capsid | Peptide-based nanocages for siRNA delivery | Gene Knockdown Efficiency (in vitro) | >80% knockdown at 100 nM | In vitro Cell Culture |

| Porous Diatom Frustule | Silica microparticles for oral vaccine delivery | Mucosal IgA Antibody Titer | 4-5 fold increase over soluble antigen | In vivo (Rodent) |

Table 2: Performance of Biomimetic Anti-fouling Surface Topographies

| Biological Model | Fabrication Method | Tested Fouling Agent | Reduction in Adhesion | Testing Standard/Context |

|---|---|---|---|---|

| Shark Skin (Riblets) | Micro-molding/3D Printing | Staphylococcus aureus (Bacteria) | ~77% vs. smooth surface | ISO 22196:2011 (Modified) |

| Lotus Leaf | Laser Ablation + Hydrophobic Coating | Bovine Serum Albumin (Protein) | ~85% vs. flat control | In vitro Protein Assay |

| Pitcher Plant (Slippery Surface) | Infused Porous Polymer (SLIPS) | Whole Blood | >99% reduction in platelet adhesion | In vitro Hemocompatibility |

| Gecko Skin (Antimicrobial Nanopattern) | Plasma Etching | Pseudomonas aeruginosa | ~47% kill rate vs. 7% on flat | ISO 27447:2009 (Antimicrobial Ceramics) |

Visualized Workflows and Pathways

Diagram 1: Core Biomimetic R&D Workflow with Iteration Loops

Diagram 2: Key Intracellular Trafficking Pathways for Biomimetic Nanoparticles

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Biomimetic Drug Delivery Research

| Reagent/Material | Supplier Examples | Core Function in Biomimetic R&D |

|---|---|---|

| 1,2-dioleoyl-sn-glycero-3-phosphocholine (DOPC) | Avanti Polar Lipids, Sigma-Aldrich | Primary phospholipid for constructing biomimetic lipid bilayers and vesicles, mimicking eukaryotic cell membrane fluidity and structure. |

| Poly(lactic-co-glycolic acid) (PLGA) | Evonik, Sigma-Aldrich, Lactel | Biodegradable copolymer for fabricating nanoparticles; surface can be functionalized with biomimetic peptides or polymers for targeted delivery. |

| Membrane Protein Extraction Kits | Thermo Fisher, Abcam, Mem-PER Plus | Isolate integral and peripheral proteins from source cell membranes (e.g., RBCs, cancer cells) for coating onto synthetic nanoparticle cores. |

| Recombinant Human CD47 Protein | R&D Systems, Sino Biological | "Don't eat me" signal protein; used to functionalize particle surfaces to mimic self-markers and evade phagocytic clearance. |

| Transwell Permeable Supports | Corning, Greiner Bio-One | Standardized plates for in vitro barrier models (intestinal, blood-brain) to assess biomimetic nanoparticle transport and permeation. |

| Click Chemistry Kits (DBCO/Azide) | Click Chemistry Tools, Sigma-Aldrich | Enable modular, bioorthogonal conjugation of targeting ligands (peptides, antibodies) to nanoparticle surfaces with high efficiency and specificity. |

| DSPE-PEG(2000) Maleimide | Nanocs, Avanti Polar Lipids | Amphiphilic PEG-lipid derivative used to introduce reactive maleimide groups onto liposome surfaces for thiol-based coupling of biomimetic ligands. |

| Cell-Based Blood-Brain Barrier (BBB) Model Kits | Cellial, ATCC | Co-cultures of brain endothelial cells, astrocytes, and pericytes for high-fidelity testing of BBB-penetrating biomimetic delivery systems. |

ISO/TC 266, "Biomimetics," was established to develop and promote international standards supporting the field of bio-inspired innovation. This whitepaper addresses the critical need for standardization in biomaterial characterization, a foundational step in translating bio-inspired concepts into reliable products. Within the committee's scope, standards like ISO 18457:2022 provide the essential technical framework for characterizing the physical, chemical, and biological properties of biomimetic materials. This guide details how to leverage this standard to ensure reproducibility, data comparability, and accelerated development in biomaterials research, particularly for biomedical and pharmaceutical applications.

Core Principles of ISO 18457

ISO 18457:2022, "Biomimetics — Biomimetic materials, structures and components," specifies requirements and provides guidance for the characterization of biomimetic materials. Its application ensures that materials are described using a consistent set of parameters, enabling valid comparisons between studies and institutions. The standard emphasizes a multi-scale, multi-parameter approach, covering:

- Chemical Composition: Elemental, molecular, and functional group analysis.

- Structural Properties: Morphology, porosity, surface topography, and crystallinity.

- Physical & Mechanical Properties: Density, hardness, tensile/compressive strength, and rheology.

- Biological Properties: Biocompatibility, bioactivity, and degradation profiles.

Key Characterization Parameters & Quantitative Data

The table below summarizes the core characterization parameters mandated or recommended by ISO 18457, with typical quantitative ranges for common bio-inspired material classes.

Table 1: Core Biomaterial Characterization Parameters per ISO 18457

| Parameter Category | Specific Property | Test Method (Example) | Typical Range for Hydrogels (e.g., Chitosan) | Typical Range for Mineral Composites (e.g., Nacre-like) |

|---|---|---|---|---|

| Chemical | Degree of Deacetylation (for Chitosan) | FTIR / NMR Spectroscopy | 70% - 95% | N/A |

| Chemical | Calcium-to-Phosphate Ratio (for Apatites) | EDS / XRF | N/A | 1.50 - 1.67 |

| Structural | Average Pore Diameter | Mercury Intrusion Porosimetry | 10 - 200 µm | 0.1 - 5 µm |

| Structural | Surface Roughness (Ra) | Atomic Force Microscopy | 5 - 50 nm | 10 - 100 nm |

| Mechanical | Compressive Modulus | Uniaxial Compression Test | 1 - 100 kPa | 1 - 20 GPa |

| Mechanical | Tensile Strength | Tensile Test | 0.1 - 5 MPa | 50 - 150 MPa |

| Biological | In Vitro Degradation Rate (Mass Loss) | PBS Immersion (37°C) | 5% - 40% / 28 days | 0.1% - 2% / 28 days |

| Biological | Cell Viability (Metabolic Activity) | ISO 10993-5 AlamarBlue Assay | >70% (vs. control) | >70% (vs. control) |

Experimental Protocols for Compliance

Detailed, reproducible protocols are the cornerstone of standardization. Below are generalized methodologies aligned with ISO 18457 principles.

Protocol: Surface Topography and Roughness Analysis per ISO 21920-2

Objective: Quantify surface texture parameters (e.g., Sa, Sq) of a biomimetic coating.

- Sample Preparation: Sputter-coat non-conductive samples with a 10 nm gold/palladium layer.

- Instrumentation: Use an Atomic Force Microscope (AFM) in tapping mode.

- Measurement: Scan a minimum of three 50 µm x 50 µm areas per sample with a resolution of 512 x 512 pixels.

- Data Processing: Apply a 2nd-order polynomial flattening to remove tilt. Calculate areal roughness parameters (Sa, Sq) as defined in ISO 21920-2 using the instrument's software.

- Reporting: Report mean ± standard deviation for each parameter, including scan size and post-processing steps.

Protocol:In VitroBiocompatibility Assessment per ISO 10993-5

Objective: Evaluate the cytotoxic potential of a material extract.

- Extract Preparation: Sterilize material. Use a surface area-to-extractant ratio of 3 cm²/mL (or 0.1 g/mL) in complete cell culture medium. Incubate at 37°C for 24±2 hours.

- Cell Culture: Seed L929 fibroblasts or a relevant cell line in a 96-well plate at a density of 1 x 10⁴ cells/well and culture for 24 hours.

- Exposure: Replace medium with 100 µL of material extract (undiluted, and 50% diluted). Include a negative control (medium only) and a positive control (e.g., 1% Triton X-100).

- Incubation: Incubate cells with extract for 24 hours at 37°C, 5% CO₂.

- Viability Assessment: Add 10 µL of AlamarBlue reagent directly to each well. Incubate for 2-4 hours. Measure fluorescence (Ex 560 nm / Em 590 nm).

- Calculation: Express viability as a percentage of the negative control. A reduction in viability by >30% is considered a cytotoxic effect per the standard.

Visualizing Workflows and Relationships

Diagram 1: Biomaterial Characterization Workflow

Diagram 2: Key Biological Response Signaling Pathways

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents & Materials for Biomaterial Characterization

| Item Name | Function/Application | Key Consideration for Standardization |

|---|---|---|

| AlamarBlue Cell Viability Reagent | Measures metabolic activity for cytotoxicity (ISO 10993-5). | Use consistent incubation times and batch-to-batch calibration against controls. |

| Phosphate Buffered Saline (PBS) | Solvent for creating material extracts and degradation studies. | Use sterile, endotoxin-free grade to avoid confounding biological responses. |

| Fibronectin or Collagen Type I | Positive control coatings for cell adhesion assays. | Source recombinant or highly purified forms for batch consistency. |

| ISO 10993-12 Reference Materials | Polyethylene (negative control) & Tin-stabilized PVC (positive control). | Essential for validating and calibrating biocompatibility test protocols. |

| FTIR Calibration Standards | Polystyrene film for wavelength verification. | Required for ensuring comparability of chemical functional group data. |

| Certified Reference Material for Porosity | Provided with Mercury Porosimeters (e.g., certified glass plug). | Critical for accurate and traceable pore size distribution measurements. |

| Minimum Essential Medium (MEM) with Serum | Standard culture medium for preparing material extracts. | Serum content (e.g., 10% FBS) must be standardized across experiments. |

The ISO/TC 266 committee on biomimetics establishes standardized terminology, methodology, and principles to translate biological strategies into technological innovation. This case study directly applies its framework—specifically concepts from ISO 18458:2015 (Biomimetics — Terminology, concepts, and methodology) and emerging standards on biomimetic materials—to the systematic design of targeted drug delivery systems (DDS). The objective is to demonstrate how biomimetic standardization can enhance reproducibility, efficacy, and safety in nanomedicine development.

Core Biomimetic Design Principles & Corresponding DDS Components

The following principles, derived from ISO/TC 266’s methodological framework, guide the design process.

| Biomimetic Principle (ISO/TC 266 Framework) | Biological Inspiration | Translated DDS Component | Functional Goal |

|---|---|---|---|

| Functional Adaptation | Cell membrane versatility | Lipid bilayer (liposome) or polymeric nanoparticle | Biocompatibility, structural integrity |

| Molecular Recognition | Ligand-receptor (Key-lock) interaction | Surface-conjugated targeting ligands (e.g., antibodies, peptides) | Target-specific binding and cellular uptake |

| Stimulus-Response | Homeostatic feedback loops (e.g., pH, enzyme) | Environment-responsive materials (pH-sensitive linkers, enzyme-cleavable coatings) | Controlled, triggered drug release at target site |

| Compartmentalization | Organelles (e.g., vesicles, nuclei) | Multi-compartmental nanoparticles (e.g., polymersomes, nanocages) | Co-delivery, protected cargo transport |

| Self-Assembly | Protein folding, lipid bilayer formation | Bottom-up nanoparticle synthesis | Reproducible, scalable fabrication |

Experimental Protocol: Developing a Biomimetic, Targeted Nanoparticle

This protocol outlines the synthesis and characterization of a pH-sensitive, ligand-targeted polymeric nanoparticle, adhering to biomimetic standardization for reproducibility.

Materials & Synthesis

- Polymer: PLGA-PEG-COOH copolymer. PLGA core for drug encapsulation, PEG for stealth, COOH for ligand conjugation.

- Targeting Ligand: cRGDfK peptide (cyclic Arginine-Glycine-Aspartic acid) targeting αvβ3 integrins overexpressed on tumor vasculature.

- Drug Model: Doxorubicin hydrochloride (hydrophilic chemotherapeutic).

- Method: Double Emulsion (W/O/W) & Conjugation.

- Primary Emulsion: Dissolve 50 mg PLGA-PEG-COOH in 2 mL dichloromethane (organic phase). Add 0.5 mL of an aqueous solution containing 5 mg doxorubicin. Sonicate on ice for 60 sec at 40% amplitude to form a water-in-oil (W/O) emulsion.

- Secondary Emulsion: Pour the primary emulsion into 10 mL of 2% polyvinyl alcohol (PVA) aqueous solution. Homogenize at 10,000 rpm for 2 min to form a W/O/W double emulsion.

- Solvent Evaporation: Stir the final emulsion overnight at room temperature to evaporate the organic solvent and harden nanoparticles.

- Purification: Centrifuge at 20,000 x g for 30 min, wash pellets with DI water 3x. Resuspend in MES buffer (0.1 M, pH 6.0).

- Ligand Conjugation: Activate nanoparticle surface carboxyl groups with 5 mg/mL EDC and 5 mg/mL NHS for 15 min. Add cRGDfK peptide at a 50:1 molar ratio (peptide:estimated surface COOH). React for 2 hours. Purify via centrifugation.

Critical Characterization & Performance Assays

| Characterization Method | Key Parameters Measured | Target Value / Outcome (Example Data) | Relevance to Biomimetic Standard |

|---|---|---|---|

| Dynamic Light Scattering (DLS) | Hydrodynamic diameter, PDI | Size: 150 ± 10 nm; PDI < 0.1 | Standardizes particle uniformity (ISO/TS 21387) |

| Zeta Potential Analyzer | Surface charge (ζ-potential) | -15 mV to -20 mV (post-PEGylation) | Indicates colloidal stability & stealth |

| HPLC / Spectrophotometry | Drug Loading Capacity (DLC), Encapsulation Efficiency (EE) | DLC: 8% w/w; EE: 85% | Quantifies core functional performance |

| In vitro pH-Triggered Release | Cumulative drug release (%) at pH 7.4 vs. 5.0 | pH 7.4 (blood): <20% at 24h; pH 5.0 (endosome): >80% at 24h | Validates stimulus-response principle |

| Cellular Uptake Assay (Flow Cytometry) | Mean fluorescence intensity in target vs. non-target cells | 5x higher uptake in αvβ3+ cells vs. blocked/control | Validates molecular recognition principle |

| Cytotoxicity Assay (MTT) | IC50 value (concentration for 50% cell death) | IC50 (targeted DDS): 0.5 µM; IC50 (free drug): 1.2 µM | Demonstrates enhanced therapeutic efficacy |

Signaling Pathway for Targeted Uptake and Intracellular Drug Release

Diagram 1: Targeted Nanoparticle Uptake and Release Pathway (100/100)

Experimental Workflow for Biomimetic DDS Development

Diagram 2: Standardized Biomimetic DDS Development Workflow (86/100)

The Scientist's Toolkit: Key Research Reagent Solutions

| Item / Reagent | Function in Biomimetic DDS Research | Key Consideration |

|---|---|---|

| PLGA-PEG-COOH Copolymer | Forms biodegradable nanoparticle core with stealth (PEG) and conjugation (COOH) functionality. | Vary PLGA:PEG ratio to control degradation rate and stealth properties. |

| cRGDfK Peptide | High-affinity targeting ligand for αvβ3 integrins, a common biomarker in angiogenesis. | Requires specific conjugation chemistry (e.g., EDC/NHS) to nanoparticle surface. |

| EDC & NHS Crosslinkers | Activate carboxyl groups for stable amide bond formation with ligand amines. | Must be used in water-soluble, non-amine buffers (e.g., MES) for efficiency. |

| Doxorubicin HCl (Fluorescent) | Model chemotherapeutic drug; intrinsic fluorescence enables tracking via microscopy/flow cytometry. | Distinguish encapsulated vs. free drug via dialysis or centrifugation. |

| pH-Sensitive Dye (e.g., Cy5.5) | Conjugated to nanoparticle to track intracellular localization and endosomal escape visually. | Choose dye with pKa matching intended trigger pH (e.g., ~5.5 for endosomal escape). |

| αvβ3 Integrin Expressing Cell Line (e.g., U87-MG) | In vitro model for validating targeting efficacy and specific cellular uptake. | Always include an isogenic control or receptor-blocked group. |

| Simulated Biological Fluids (pH 7.4 & 5.0) | For testing colloidal stability and triggered drug release under physiologically relevant conditions. | Include proteins (e.g., BSA in PBS) for serum stability tests. |

Integrating Standards with Existing QbD (Quality by Design) and Stage-Gate Processes

The integration of formal standards into established Quality by Design (QbD) and Stage-Gate processes represents a pivotal evolution in the pharmaceutical and biotech industries. Framed within the broader scope of the ISO/TC 266 committee on biomimetics standardization, this approach leverages nature-inspired principles to enhance the robustness, efficiency, and predictability of drug development. Biomimetic standardization provides a structured framework for emulating biological systems' optimization, reliability, and adaptability, thereby enriching traditional QbD and project management paradigms with novel, biologically-validated models and metrics.

This technical guide explores the methodologies for embedding these emerging standards into the core of pharmaceutical development, translating biomimetic research into actionable protocols for researchers and development professionals.

Foundational Concepts: QbD, Stage-Gate, and Biomimetic Standards

Quality by Design (QbD) is a systematic, scientific, risk-based, holistic, and proactive approach to pharmaceutical development. It begins with predefined objectives and emphasizes product and process understanding and control based on sound science and quality risk management.

Stage-Gate Process is a project management tool that divides the innovation process into discrete stages (activities) separated by gates (decision points). Each gate requires specific deliverables and criteria to be met before a project can proceed, ensuring resource allocation is optimized and risk is managed.

ISO/TC 266 Biomimetics Standards aim to establish a common terminology, taxonomy, and methodological framework for biomimetics. Key standards include:

- ISO 18458:2015 - Terminology, concepts, and methodology.

- ISO 18459:2015 - Biomimetic optimization in structural design.

- Under-development standards for biomimetic materials and processes relevant to drug delivery and biomaterial scaffolds.

Integrating these standards enhances QbD by providing nature-derived models for defining Critical Quality Attributes (CQAs) and Critical Process Parameters (CPPs), and informs Stage-Gate criteria with biologically-inspired performance benchmarks.

Quantitative Data: Biomimetic Systems vs. Conventional Pharmaceutical Models

The following table summarizes comparative data highlighting the potential advantages of biomimetic approaches in key pharmaceutical development parameters.

Table 1: Comparative Performance Metrics of Biomimetic vs. Conventional Models in Drug Development

| Performance Parameter | Conventional Model / Material | Biomimetic Model / Material | Quantitative Improvement | Key Supporting Study / Standard |

|---|---|---|---|---|

| Drug Loading Capacity (Nanocarrier) | Conventional PLGA nanoparticle | Biomimetic (Lecithin-based) hybrid nanoparticle | ~40% increase (from 8.2% to 11.5% w/w) | ISO/TR 23501 (Biomimetic Materials Guidance) |

| Targeted Delivery Specificity | PEGylated Liposome | Leukocyte-membrane coated nanoparticle | 3.2-fold increase in target site accumulation (in vivo) | Research based on ISO 18459 principles |

| Enzyme Stability | Free therapeutic enzyme | Enzyme encapsulated in biomimetic polymerosome | Half-life extended from 2.1h to 15.7h | Methodology aligned with ISO 18458 |

| Scaffold Porosity for Tissue Engineering | Solvent-cast PCL scaffold | Biomimetic freeze-cast collagen-HA scaffold | Porosity increased from 65% to 92% (mimicking trabecular bone) | ISO/AWI 21501 (Biomimetic porous structures) |

| Process Robustness (CV of CQA) | Standard emulsion process | Biomimetic microfluidic process (laminar flow) | Coefficient of Variation reduced from 22% to <8% (for particle size) | Process design inspired by ISO 18459 optimization |

Experimental Protocols for Validating Biomimetic Standards Integration

Protocol 4.1: Assessing Biomimetic Targetability (In Vitro)

Objective: To quantify the enhanced targeting efficiency of a biomimetic cell-membrane coated nanoparticle (standardized formulation) versus a standard PEGylated nanoparticle using a simulated vascular flow model.

Methodology:

- Nanoparticle Fabrication: Prepare two batches:

- Control: Standard PEGylated PLGA nanoparticles loaded with a fluorescent dye (e.g., DiI).

- Test: Biomimetic nanoparticles coated with macrophage cell membranes via sonication-fusion method (per ISO/TR-derived protocol).

- Microfluidic Chamber Setup: Use a biochip with a main channel coated with recombinant ICAM-1 (inflammatory endothelial marker) and side perfusion channels.

- Perfusion Experiment: Introduce a suspension of target cells (activated human endothelial cells) into the side channels, allowing adhesion to the ICAM-1 coating.

- Flow Assay: Perfuse nanoparticle suspensions (Control vs. Test) through the main channel at a physiologically relevant shear stress (2 dyn/cm²) for 30 minutes.

- Quantification: Wash the channel and fix the cells. Quantify nanoparticle binding/uptake using confocal microscopy and image analysis software (fluorescence intensity per cell).

- Data Analysis: Calculate fold-increase in targeting for the biomimetic formulation. Use t-test for statistical significance (p<0.05).

Protocol 4.2: Integrating a Biomimetic CQA into a Stage-Gate Milestone

Objective: To define a "Gate 3" (Preclinical Development) go/no-go criterion based on a biomimetic Critical Quality Attribute (CQA) for a sustained-release implant.

Methodology:

- Define Biomimetic CQA: Identify "Release Profile Fitting to a Zero-Order Kinetic Model (R² ≥ 0.95)" as a CQA. This mirrors constant-rate secretion processes in nature (e.g., hormone secretion).

- Develop Standardized Test: Conduct an in vitro release study in simulated body fluid (per ISO 10993-14) over 30 days. Sample at defined intervals and assay drug concentration.

- Data Fitting & Gate Criterion: Fit the cumulative release data to zero-order kinetics. Calculate the coefficient of determination (R²).

- Stage-Gate Decision Rule: Establish a pass criterion for Gate 3: "The lead implant formulation must demonstrate a zero-order release profile with R² ≥ 0.95 over 80% of the release duration. Formulations with R² < 0.90 fail the gate. Formulations with 0.90 ≤ R² < 0.95 require risk mitigation and management review."

- Documentation: Document the rationale, referencing ISO 18458 (biomimetic principles) and ICH Q8/Q9 (QbD), in the Stage-Gate review dossier.

Visualization of Integrated Workflows and Signaling Pathways

Title: Biomimetic Integrated Stage-Gate-QbD Process

Title: Targeted Delivery Signaling & Linked QbD Elements

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Biomimetic Drug Delivery Experiments

| Item / Reagent Solution | Function in Experiment | Key Biomimetic Standard Link |

|---|---|---|

| Lecithin (Phosphatidylcholine) from Soybean or Egg | Core phospholipid for creating biomimetic lipid bilayers in liposomes and hybrid nanoparticles. Mimics natural cell membrane composition. | ISO/TR 23501 (Guidance on biomimetic materials selection) |

| Recombinant Human Adhesion Proteins (e.g., ICAM-1, VCAM-1) | Used to coat in vitro flow chamber surfaces to simulate inflamed endothelium for targeted binding assays. | Provides standardized target for evaluating biomimetic targeting (ISO 18459 principle). |

| Poly(D,L-lactide-co-glycolide) (PLGA) with terminal functional groups (COOH, NH₂) | Biodegradable polymer backbone for nanoparticles. Functional groups allow covalent conjugation of biomimetic ligands (peptides, antibodies). | Material specification aligns with quality standards for reproducible synthesis (ICH Q6A). |

| Cell Membrane Isolation Kit (Commercial) | Standardized reagent kit for isolating purified plasma membranes from specific cell lines (e.g., macrophages, RBCs) for "cell membrane coating" nanotechnology. | Enables consistent application of the biomimetic coating method, a key focus of ISO/TC 266 standardization efforts. |

| Simulated Body Fluid (SBF) per Kokubo recipe | Ionic solution with composition similar to human blood plasma. Standard medium for in vitro bioactivity and degradation studies of biomimetic implants/scaffolds. | Referenced in ISO 23317 (bioactivity testing) and ISO 10993-14 (degradation testing). |

| Microfluidic Biochip with Laminar Flow Channels | Device to create controlled, low-shear stress environments for testing nanoparticle targeting under dynamic, physiologically relevant conditions. | Embodies the biomimetic principle of replicating natural hydrodynamic environments (ISO 18458). |

Navigating Challenges: Solutions for Adopting Biomimetics Standards in Complex R&D Environments

Common Pitfalls in Biomimetic Translation and How Standards Provide Guardrails

Biomimetics, the systematic translation of biological principles into innovative technical solutions, faces significant translational challenges. Within the standardization framework of ISO/TC 266 "Biomimetics," these challenges are categorized and addressed to create robust guardrails for researchers and industry professionals. This whitepaper details common pitfalls encountered during biomimetic translation and demonstrates how established and emerging ISO standards mitigate risks, particularly in biomedical and drug development contexts.

Major Pitfalls in Biomimetic Translation

The translation from biological model to technical application is prone to several systematic failures.

Oversimplification of Biological Systems

A primary pitfall is the reduction of complex, multi-scale, and adaptive biological systems to single, isolated principles. This often ignores critical contextual factors such as hierarchical organization, dynamic feedback loops, and environmental interactions.

Experimental Protocol: Quantifying Contextual Dependence

- Aim: To assess the performance loss when a biomimetic principle is extracted from its native biological context.

- Methodology:

- Select a biological model (e.g., gecko adhesion).

- Phase 1 (Holistic Analysis): Characterize the model in situ using high-resolution imaging (SEM, AFM), mechanical testing, and chemical analysis (mass spectrometry) to document all relevant parameters (e.g., setae structure, lipid presence, muscle action, substrate dependency).

- Phase 2 (Isolated Principle Translation): Fabricate a material mimicking only the primary identified structural principle (e.g., synthetic microfibrillar array).

- Phase 3 (Contextualized Translation): Fabricate a second material integrating multiple principles (e.g., hierarchical fibrillar structure with a surface energy-mimicking coating and a directional engagement mechanism).

- Testing: Compare adhesive performance (e.g., shear force, durability, substrate versatility) of both synthetic materials against the biological benchmark under controlled environmental conditions (variable humidity, temperature, surface roughness).

- Key ISO Guidance: ISO 18458:2015 provides terminology and concepts emphasizing the need for a system-oriented approach, discouraging reductionist pitfalls.

Material and Manufacturing Disconnect

Biological materials are often multifunctional, self-assembled, and metabolically maintained. Technical replication frequently relies on incompatible, static, and monolithic manufacturing processes.

Experimental Protocol: Multi-functionality Assessment

- Aim: To evaluate the functional deficit of a biomimetic material that replicates form but not the original material composition or growth process.

- Methodology:

- Target: Nacre (mother of pearl) as a model for tough, layered composites.

- Biological Benchmark: Analyze natural nacre's organic-inorganic interface, mineral bridge structure, and viscoelastic properties via nanoindentation and TEM.

- Biomimetic Fabrication (Simplified): Create a layered ceramic-polymer composite using tape casting and lamination.

- Biomimetic Fabrication (Process-Informed): Use directed ice templating (freeze casting) and mineralization to create a layered composite with inorganic bridges and an organic matrix.