GelMA Hydrogel Fabrication for Advanced Neural Constructs: A Comprehensive Guide for Researchers

This article provides a thorough, research-oriented guide to Gelatin Methacryloyl (GelMA) hydrogel fabrication for neural tissue engineering.

GelMA Hydrogel Fabrication for Advanced Neural Constructs: A Comprehensive Guide for Researchers

Abstract

This article provides a thorough, research-oriented guide to Gelatin Methacryloyl (GelMA) hydrogel fabrication for neural tissue engineering. Covering foundational principles, detailed synthesis protocols, and advanced application methodologies for 3D neural constructs, it addresses common troubleshooting issues and optimization strategies for mechanical and biological properties. Furthermore, it outlines critical validation techniques, including rheological assessment, biocompatibility testing, and comparative analysis with other biomaterials, offering scientists and drug development professionals a complete framework for implementing GelMA in neural disease modeling, drug screening, and regenerative medicine applications.

GelMA 101: Unpacking the Core Chemistry and Neural Tissue Engineering Potential

Chemical Structure

GelMA is a photocrosslinkable hydrogel synthesized by the reaction of gelatin with methacrylic anhydride (MA). This modification introduces methacryloyl groups onto the amine-containing side chains (primarily lysine and hydroxylysine) and hydroxyl-containing residues (e.g., serine, threonine) of gelatin. The degree of functionalization (DoF), or methacrylation, is a tunable parameter that dictates key physicochemical properties. The resultant structure retains integrin-binding motifs (e.g., RGD) and matrix metalloproteinase (MMP)-sensitive degradation sites native to gelatin, while the appended methacrylate groups enable rapid, radical-initiated photopolymerization.

Synthesis Protocol

Materials:

- Type A or B gelatin (typically from porcine skin)

- Methacrylic anhydride (MA)

- Phosphate-Buffered Saline (PBS, 0.1 M, pH 7.4)

- Dialysis tubing (MWCO 12-14 kDa)

- Lyophilizer

Detailed Methodology:

- Dissolution: Dissolve gelatin at a concentration of 5-10% (w/v) in PBS at 50-60°C with continuous stirring until fully dissolved.

- Methacrylation: Slowly add methacrylic anhydride (MA) dropwise to the gelatin solution. The MA volume is calculated as a function of the gelatin mass to achieve the target DoF (e.g., 0.6 mL MA per gram of gelatin for a DoF of ~60%). Maintain vigorous stirring and reaction temperature at 50-60°C for 1-3 hours. The pH may drift acidic; it can be maintained at ~7.4 using additional PBS or a basic solution.

- Termination & Dilution: Stop the reaction by diluting the mixture with 2-5 volumes of warm PBS (40-50°C).

- Purification: Transfer the solution to pre-treated dialysis tubing. Dialyze against distilled water for 5-7 days at 40°C to remove unreacted MA, methacrylic acid, and salts. Change the water at least twice daily.

- Lyophilization: After dialysis, freeze the solution at -80°C and lyophilize for 5-7 days to obtain a dry, porous foam of GelMA. Store at -20°C, protected from light and moisture.

Key Properties

The properties of GelMA hydrogels are tunable by modifying the DoF, polymer concentration, and photocrosslinking parameters (photoinitiator type, concentration, UV light intensity, time).

Table 1: Key Tunable Properties of GelMA Hydrogels

| Property | Typical Range | Influencing Factors | Relevance to Neural Constructs |

|---|---|---|---|

| Mechanical Modulus | 1 - 100 kPa | GelMA concentration, DoF, crosslinking density | Mimics soft neural tissue; directs stem cell differentiation. |

| Swelling Ratio | 300 - 1000% | Crosslinking density, DoF | Affects nutrient diffusion & cell migration. |

| Degradation Time | 3 days - 4 weeks | DoF, GelMA concentration, MMP activity | Should match neurite outgrowth & tissue remodeling pace. |

| Pore Size | 50 - 500 μm | GelMA concentration, crosslinking method | Critical for 3D cell infiltration and network formation. |

| Gelation Time | Seconds - Minutes | Photoinitiator conc., UV intensity (365-405 nm), temperature | Enables injectable delivery & in situ encapsulation. |

Application Notes for Neural Constructs

Within a thesis on hydrogel fabrication for neural research, GelMA serves as a foundational bioink or scaffold. Its key advantages include:

- Bioactivity: Presents native cell-adhesive ligands to support neuronal attachment and neurite extension.

- Tunability: Stiffness and degradability can be matched to specific neural tissues (e.g., brain ~0.1-1 kPa, spinal cord).

- Fabrication Flexibility: Amenable to 3D bioprinting, soft lithography, and microfluidics for creating structured constructs.

- Drug/Cell Delivery: Enables encapsulation of neural progenitor cells (NPCs), glial cells, and neurotrophic factors (e.g., BDNF, NGF).

Experimental Protocol: Fabricating a 3D Neural Culture in GelMA

Aim: To create a 3D hydrogel encapsulating primary neural stem cells (NSCs) for neuronal differentiation studies.

Materials & Reagent Solutions: Table 2: Research Reagent Solutions Toolkit

| Item | Function | Example/Concentration |

|---|---|---|

| GelMA (DoF ~70%) | Hydrogel backbone providing structural and bioactive support. | 5-7% (w/v) in PBS. |

| Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Cytocompatible photoinitiator for visible light crosslinking (405 nm). | 0.25% (w/v) in PBS. |

| Neural Stem Cell Suspension | Primary cells for 3D culture and differentiation. | 5-10 x 10^6 cells/mL. |

| Neural Differentiation Media | Promotes differentiation of NSCs to neurons/glia. | DMEM/F-12, B-27 supplement, BDNF, NT-3. |

| Sterile PBS | Diluent and washing agent. | 1x, pH 7.4. |

| 405 nm Blue Light Source | Light source for initiating photopolymerization. | 5-10 mW/cm² intensity. |

Detailed Methodology:

- Solution Preparation: Dissolve lyophilized GelMA and LAP photoinitiator in warm PBS (37°C) to create a 7% (w/v) GelMA / 0.25% LAP stock solution. Sterilize by syringe filtration (0.22 μm).

- Cell Encapsulation: Gently mix the NSC suspension with the GelMA/LAP solution on ice to achieve a final density of 1-5 x 10^6 cells/mL in 5% GelMA. Keep the solution on ice to prevent premature gelation.

- Hydrogel Molding: Pipet the cell-laden GelMA solution into a polydimethylsiloxane (PDMS) mold or a multi-well plate. Carefully avoid bubbles.

- Photocrosslinking: Expose the solution to 405 nm light at 5 mW/cm² for 30-60 seconds to form a stable hydrogel.

- Culture: After gelation, add pre-warmed neural differentiation media to the well. Culture at 37°C, 5% CO2.

- Analysis: Monitor cell viability (Live/Dead assay), neurite outgrowth (β-III-tubulin immunostaining), and network activity (calcium imaging) over 7-28 days.

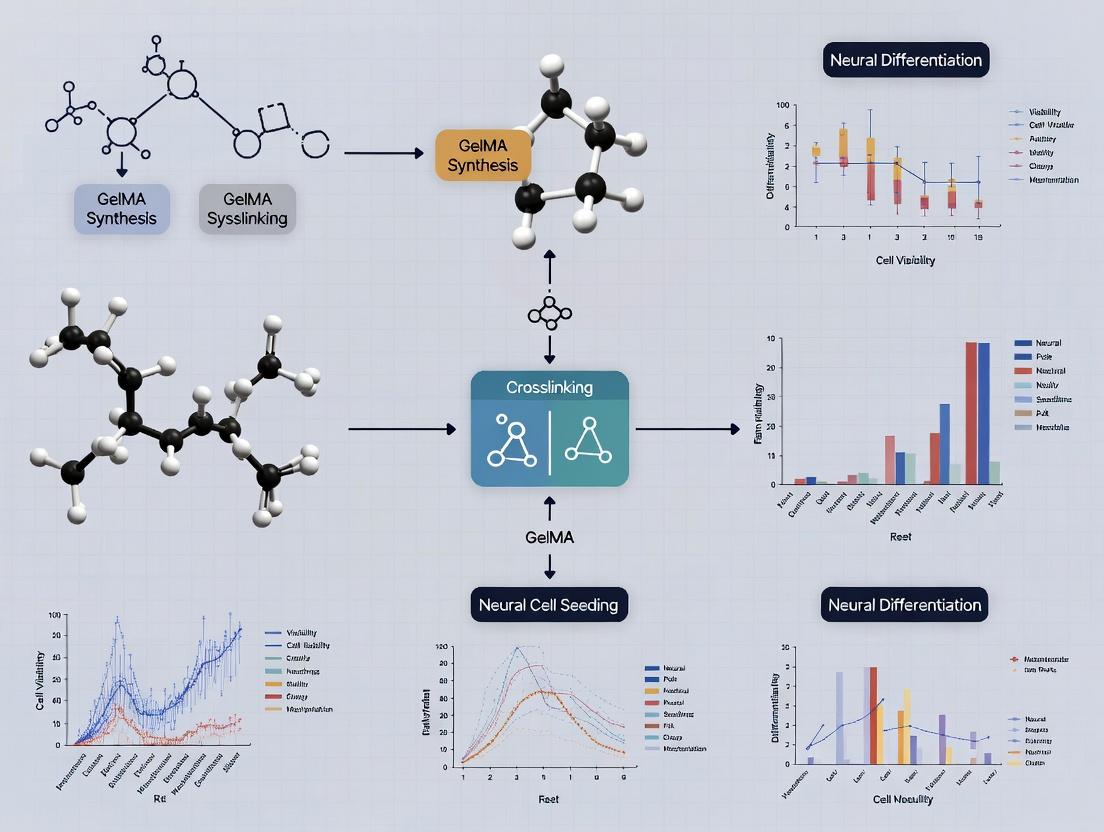

Visualizations

Diagram 1: GelMA Synthesis Workflow

Diagram 2: 3D Neural Construct Fabrication

Why GelMA for Neural Constructs? Mimicking the Neural Extracellular Matrix.

This application note, situated within a broader thesis on GelMA hydrogel fabrication for neural constructs, details the rationale and methodologies for utilizing Gelatin Methacryloyl (GelMA) in neural tissue engineering. GelMA's unique properties enable the recapitulation of critical aspects of the neural extracellular matrix (ECM), providing a permissive and instructive microenvironment for neural cell culture, tissue regeneration, and drug screening.

Key Properties of GelMA Mimicking the Neural ECM

The native neural ECM is a soft, hydrated, bioactive network. GelMA closely mimics its biochemical and biophysical properties, as summarized below.

Table 1: Comparison of Neural ECM and Key GelMA Hydrogel Properties

| Property | Native Neural ECM | Tunable GelMA Hydrogel Characteristics | Biological Impact |

|---|---|---|---|

| Stiffness (Elastic Modulus) | 0.1 - 1 kPa (Brain) | 0.1 - 30 kPa via concentration & crosslinking | Directs neural stem cell differentiation, promotes neurite outgrowth. |

| Ligand Density | RGD, GFOGER from collagen/laminin | Inherent RGD motifs from gelatin backbone (~40 μg/mg) | Supports integrin-mediated cell adhesion, spreading, and survival. |

| Hydration & Porosity | Highly hydrated, porous for diffusion | >90% water content, tunable pore size via crosslink density | Facilitates nutrient/waste diffusion and 3D cell infiltration. |

| Degradation | MMP-sensitive, dynamic remodeling | MMP-degradable peptides within crosslinked network | Enables cell-mediated remodeling and matrix invasion. |

| Biofunctionalization | Binds growth factors (BDNF, NGF) | Easy conjugation of peptides (IKVAV, YIGSR) & proteins | Enhances specific bioactivity and signaling. |

Core Protocols

Protocol 2.1: Fabrication of Soft GelMA Hydrogels for Neural Cultures

Objective: To synthesize a ~1 kPa GelMA hydrogel, mimicking brain tissue stiffness, for 3D neural stem cell encapsulation.

Materials (Research Reagent Solutions):

- GelMA Precursor: Lyophilized GelMA (Methacrylation degree ~70%). Function: Primary hydrogel polymer providing structure and bioactivity.

- Photoinitiator: Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP). Function: UV-activated catalyst for rapid, cytocompatible crosslinking.

- Dulbecco's Phosphate-Buffered Saline (DPBS): Function: Solvent for preparing sterile hydrogel precursor solutions.

- UV Light Source (λ=365 nm): Function: Provides energy for photo-crosslinking at low intensity (e.g., 5-10 mW/cm²).

Method:

- Dissolve lyophilized GelMA in DPBS at 37°C to a final concentration of 5% (w/v). Sterilize via 0.22 μm syringe filter.

- Add LAP photoinitiator to the GelMA solution to a final concentration of 0.25% (w/v). Protect from light.

- Resuspend neural stem/progenitor cells (NSPCs) in the GelMA-LAP solution at a density of 5-10 x 10⁶ cells/mL.

- Pipette 50-100 μL of cell-laden solution into a mold (e.g., silicone gasket on glass).

- Crosslink under UV light (λ=365 nm, 5 mW/cm²) for 30-60 seconds.

- Culture the resulting hydrogel in neural basal medium supplemented with growth factors (EGF/bFGF).

Protocol 2.2: Functionalization of GelMA with Laminin-Derived Peptides

Objective: To enhance the neuro-instructive capability of GelMA by conjugating the IKVAV peptide.

Materials (Research Reagent Solutions):

- Acrylate-PEG-IKVAV: Acrylate-functionalized peptide. Function: Conjugates covalently into hydrogel network via co-polymerization.

- Methacrylic Anhydride (MA): Function: Used in the synthesis of GelMA to provide methacrylate groups for crosslinking.

- Triethanolamine (TEA): Function: Buffer agent for maintaining pH during functionalization reactions.

Method:

- Synthesize GelMA following standard protocols using MA and type A gelatin.

- Prepare a pre-gel solution of 7% (w/v) GelMA and 1 mM Acrylate-PEG-IKVAV in DPBS with 0.25% LAP.

- Allow the solution to react for 15 minutes at room temperature, protected from light, to enable Michael-type addition between acrylate and thiols (if present) or for pre-mixing.

- Crosslink the functionalized pre-gel solution with UV light as in Protocol 2.1. The acrylate group on the peptide will co-polymerize with the methacrylate groups on GelMA.

Signaling Pathways in GelMA-Based Neural Constructs

Title: GelMA Mechanochemical Signaling in Neural Cells

Experimental Workflow for Neural Construct Evaluation

Title: GelMA Neural Construct Workflow from Fabrication to Analysis

The Scientist's Toolkit: Essential Reagents for GelMA Neural Research

Table 2: Key Research Reagent Solutions for GelMA Neural Constructs

| Reagent / Material | Function / Role | Example Use Case |

|---|---|---|

| High Methacrylation GelMA (≥70%) | Provides rapid crosslinking, higher stability for structural support. | Printing complex 3D neural scaffolds. |

| Lithium Phenyl-2,4,6-Trimethylbenzoylphosphinate (LAP) | Cytocompatible photoinitiator for visible/UV light crosslinking. | Encapsulating sensitive primary neurons. |

| Laminin-Derived Peptides (IKVAV, YIGSR) | Imparts specific neuro-adhesive and instructive signals. | Directing neural stem cell differentiation towards neurons. |

| Matrix Metalloproteinase (MMP) Sensitive Crosslinker | Creates cell-degradable crosslinks for invasive growth. | Modeling axon infiltration in 3D injury models. |

| Neurotrophic Factors (BDNF, GDNF, NGF) | Soluble signals for survival, differentiation, and maturation. | Matureing and maintaining 3D neuronal networks. |

| Soft Hydrogel-Calibrated Stiffness Kit | Pre-characterized GelMA formulations for specific elastic moduli. | Studying the precise impact of stiffness on glioblastoma invasion. |

Application Notes

This document details the critical parameters influencing the physicochemical and biological properties of Gelatin Methacryloyl (GelMA) hydrogels, specifically for neural construct research. Precise control over these parameters is essential to replicate the neural extracellular matrix and direct desired cellular responses.

1. Degree of Functionalization (DoF) The DoF, defined as the percentage of lysine and hydroxylysine groups modified with methacryloyl groups, directly governs hydrogel crosslinking density, mechanical stiffness, and degradation kinetics. For neural applications, a lower DoF (~30-60%) is often preferable to create softer matrices (0.5-2 kPa) that promote neural stem/progenitor cell (NSC/NPC) viability, neurite extension, and 3D network formation. Higher DoF (>70%) yields stiffer, more stable hydrogels but can limit cell spreading and differentiation.

2. Molecular Weight (MW) The MW of the parent gelatin (typically Type A or B from porcine or bovine skin) influences pre-crosslinking viscosity, gelation temperature, and post-crosslinking mesh size. Lower MW GelMA (<50 kDa) forms hydrogels with smaller pores, potentially restricting 3D cell infiltration but providing higher resolution for bioprinting. Higher MW GelMA (>100 kDa) better preserves natural RGD motifs, enhancing cell adhesion and forming larger pore networks conducive to neural network ingrowth and nutrient diffusion.

3. Source Material The gelatin source (porcine skin Type A, bovine skin Type B) and bloom strength affect the isoelectric point (pI) and residual cytokine content. Type A (pI ~7-9) is superior for neurite outgrowth compared to Type B (pI ~4-5) under physiological pH. Sourcing must be consistent and documented to ensure batch-to-batch reproducibility, critical for in vitro disease modeling and drug screening.

Table 1: Impact of Critical Parameters on GelMA Hydrogel Properties for Neural Applications

| Parameter | Typical Range | Key Influence on Neural Constructs | Optimal Range for Neural Constructs |

|---|---|---|---|

| DoF | 20% - 95% | Crosslinking density, Stiffness (G'), Degradation rate, Swelling ratio | 30% - 60% |

| MW (kDa) | 20 - 200 kDa | Pre-gel viscosity, Pore size, Cell adhesion site density, Printability | 50 - 100 kDa |

| Gelatin Source | Porcine Skin (Type A), Bovine Skin (Type B) | Isoelectric point (pI), Bioactive motif density, Immunogenicity risk, Batch variability | Porcine Skin, Type A |

| Resulting Stiffness | 0.5 - 20 kPa | NSC differentiation fate: Soft (<1 kPa) favors neurons, stiffer (>5 kPa) promotes glial lineages. | 0.5 - 2 kPa |

| Degradation Time | 3 days - 4 weeks | Should match rate of neural tissue ingrowth and ECM deposition. | 1 - 3 weeks |

Table 2: Example Characterization Data for GelMA Variants

| GelMA ID | Source | MW (kDa) | DoF (%) | Stiffness (kPa) | NSC Viability (Day 7) | Avg. Neurite Length (µm, Day 5) |

|---|---|---|---|---|---|---|

| GelMA-L | Porcine Skin, A | 100 | 40 | 1.2 ± 0.3 | 95 ± 3% | 245 ± 45 |

| GelMA-H | Bovine Skin, B | 50 | 80 | 8.5 ± 1.2 | 78 ± 5% | 110 ± 30 |

Experimental Protocols

Protocol 1: Determining Degree of Functionalization (DoF) via ¹H NMR

Objective: To quantitatively measure the substitution of methacryloyl groups on gelatin.

Materials:

- Lyophilized GelMA sample (20 mg)

- Deuterium oxide (D₂O)

- Nuclear Magnetic Resonance spectrometer (400 MHz or higher)

Procedure:

- Sample Preparation: Dissolve 20 mg of thoroughly dried GelMA in 1 mL of D₂O at 60°C for 1 hour. Transfer 600 µL to a 5 mm NMR tube.

- ¹H NMR Acquisition: Run a standard proton NMR spectrum at 60°C. Key spectral regions:

- δ = 5.3 and 5.6 ppm (vinyl protons of methacrylate, doublet peaks).

- δ = 2.9 ppm (lysine ε-CH₂ protons).

- Calculation:

- Let Avinyl be the average integrated area of the two methacrylate vinyl peaks.

- Let Alys be the integrated area of the lysine ε-CH₂ peak.

- DoF (%) = [Avinyl / (Avinyl + A_lys)] × 100.

Protocol 2: Fabricating Neural Constructs with Tunable Stiffness

Objective: To prepare 3D GelMA hydrogels encapsulating neural stem cells (NSCs) with controlled mechanical properties.

Materials:

- GelMA stock solution (DoF: 40%, 70%, MW: 100 kDa, porcine Type A)

- Photoinitiator: Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP)

- NSC culture medium (Neural Basal, B-27, bFGF, EGF)

- UV light source (365 nm, 5-10 mW/cm²)

Procedure:

- GelMA Precursor Solution: Dissolve GelMA in PBS at 60°C to make a 7% (w/v) solution. Add LAP to a final concentration of 0.1% (w/v). Sterilize by syringe filtration (0.22 µm).

- Cell Encapsulation: Harvest NSCs, centrifuge, and resuspend in GelMA/LAP solution at 5 × 10⁶ cells/mL. Maintain temperature at 37°C to prevent gelation.

- Hydrogel Crosslinking: Pipette 50 µL of cell-laden solution into a cylindrical mold. Expose to UV light (365 nm, 5 mW/cm²) for 30 seconds. For softer gels, use lower DoF GelMA or reduce UV exposure; for stiffer gels, use higher DoF GelMA or increase crosslinking time.

- Culture: Transfer crosslinked hydrogels to NSC medium. Change medium every other day.

- Analysis: Assess viability (Live/Dead assay), stiffness (rheometry), and neurite outgrowth (β-III-tubulin immunostaining) at days 1, 3, and 7.

Visualizations

Parameter Influence on Neural Constructs

GelMA Neural Construct Workflow

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for GelMA Neural Constructs

| Reagent/Material | Function & Importance | Example Product/Catalog |

|---|---|---|

| Gelatin, Type A (Porcine Skin) | Source material. Provides optimal pI and RGD density for neural cell adhesion and neurite outgrowth. | Sigma-Aldrich, G2500 |

| Methacrylic Anhydride (MA) | Methacryloylating agent. Purity and reaction time directly control the final DoF. | Sigma-Aldrich, 276685 |

| Photoinitiator (LAP) | UV-activated initiator. Enables rapid, cytocompatible crosslinking of GelMA with minimal radical cytotoxicity. | Sigma-Aldrich, 900889 |

| Neural Basal Medium + B-27 Supplement | Culture medium for NSCs/NPCs. Provides essential hormones and proteins for maintaining neural phenotype. | Thermo Fisher, 21103049 & 17504044 |

| β-III-Tubulin Antibody | Immunostaining marker for immature and mature neurons. Key for quantifying neural differentiation. | Abcam, ab18207 |

| Live/Dead Viability/Cytotoxicity Kit | Dual-fluorescence assay to quantify cell viability and distribution within 3D hydrogel constructs. | Thermo Fisher, L3224 |

| Rheometer (with Peltier plate) | Essential for measuring storage modulus (G') and gelation kinetics of GelMA hydrogels to confirm mechanical properties. | TA Instruments, DHR series |

This document serves as a detailed application note and protocol compendium for a broader thesis investigating the fabrication and optimization of Gelatin Methacryloyl (GelMA) hydrogels for advanced in vitro neural constructs. The thesis posits that the precise tuning of GelMA's physico-chemical properties—including stiffness, degradation rate, and biofunctionalization—is paramount for creating biomimetic microenvironments that direct neural cell fate and function. The applications detailed herein—regeneration, disease modeling, and drug screening—represent the primary translational axes validating the engineered hydrogel platforms.

Table 1: Correlating GelMA Properties with Neural Cell Behavior

| GelMA Property | Typical Range for Neural Applications | Primary Neural Cell Type Studied | Key Functional Outcome | Citation Trend (2023-2024) |

|---|---|---|---|---|

| Stiffness (Elastic Modulus) | 0.5 - 5 kPa | Neural Stem/Progenitor Cells (NSCs/NPCs) | Optimal neuronal differentiation at ~1 kPa; Gliogenesis favored at >3 kPa | High focus on mimicking brain tissue softness |

| Polymer Concentration | 5% - 10% (w/v) | Primary Neurons, NPCs | 7-8% often balances porosity for 3D network formation & mechanical integrity | Standard range, with interest in composite blends |

| Methacrylation Degree | 60% - 80% | iPSC-derived Neurons, Neuroblastoma lines | Higher crosslinking density (high DoM) enhances stability for long-term culture (>28 days) | Optimization for specific crosslinking mechanisms (e.g., visible light) |

| Degradation Rate | 7 - 21 days (full hydrogel) | Cortical & Motor Neurons | Tunable degradation supports axon elongation and host integration in regeneration models | Key parameter for in vivo translation |

| RGD Density (via modification) | 0.5 - 2.0 mM | Dorsal Root Ganglion (DRG) neurons, Schwann Cells | Increased density promotes neurite outgrowth and cell migration in 3D | Growing focus on spatial patterning |

Table 2: Applications Benchmark: GelMA vs. Other Hydrogels in Neural Research

| Application | Preferred GelMA Formulation | Key Advantage over Matrigel | Key Advantage over Agarose/Collagen | Typical Readout |

|---|---|---|---|---|

| Axon Regeneration | 5% GelMA, Low DoM (~60%), RGD-functionalized | Defined composition; tunable mechanical cues | Superior cell-adhesion ligand density | Neurite length (μm), fasciculation |

| Organoid/Spheroid Culture | 7% GelMA, Medium DoM (~70%) | Reduced batch variability; structural support for polarity | Prevents uncontrolled fusion; better diffusion control | Organoid size uniformity, layered cytoarchitecture |

| Neurovascular Unit Modeling | 5-7% GelMA, composite with Fibrin | Independent tuning of neural and vascular compartment properties | Enables precise co-culture spatial patterning | Barrier integrity (TEER), angiogenesis assay |

| High-Throughput Toxicity Screening | 8% GelMA, High DoM (~80%) in 96-well plates | Reproducible 3D microenvironment for phenotypic screening | Faster gelation for automation compatibility | Cell viability (ATP assay), neurite integrity (high-content imaging) |

| Glioblastoma Invasion | 3-5% GelMA, Very Low Stiffness (0.5-1 kPa) | Mimics soft brain tumor niche; quantifiable invasion metrics | Controllable porosity for migration studies | Invasion distance from spheroid core (μm) |

Detailed Experimental Protocols

Protocol 1: Fabrication of 3D GelMA Hydrogel for Neuronal Differentiation from iPSCs

Title: 3D Encapsulation of iPSC-Derived Neural Progenitors in GelMA for Cortical Differentiation.

Objective: To generate human cortical neuron networks within a tunable 3D GelMA matrix for disease modeling or regeneration studies.

Materials (Research Reagent Solutions):

- GelMA Precursor: Lyophilized GelMA (DoM ~70%), sterile.

- Photoinitiator: Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP), 0.25% (w/v) in PBS.

- Cell Source: iPSC-derived neural progenitor cells (NPCs), >90% PAX6+/SOX2+.

- Culture Medium: Neural basal medium supplemented with B27, BDNF, GDNF, and cAMP.

- Crosslinking Device: LED blue light source (405 nm, 5-10 mW/cm²).

Procedure:

- Hydrogel Precursor Preparation: Dissolve GelMA powder in the LAP solution at 37°C to achieve a final concentration of 7% (w/v). Sterilize via 0.22 μm syringe filter.

- Cell Encapsulation: Pellet 2 x 10⁶ NPCs. Resuspend the pellet thoroughly in 100 μL of the warm GelMA-LAP solution to achieve a final density of 20 x 10⁶ cells/mL. Avoid bubbles.

- Molding & Crosslinking: Pipette 40 μL of cell-laden solution into a sterile silicone mold (or a well of a 48-well plate). Irradiate with 405 nm light for 30 seconds at 5 mW/cm².

- Culture Initiation: Gently transfer the polymerized hydrogel to a well containing pre-warmed neural medium. Culture at 37°C, 5% CO₂.

- Medium Change: Perform 50% medium changes every other day. Monitor neurite extension via phase-contrast microscopy.

- Analysis (Day 28): Fix constructs in 4% PFA for immunostaining (β-III Tubulin, MAP2, Synapsin). Extract RNA for qPCR analysis of cortical markers (TBR1, CTIP2).

Protocol 2: Establishing a GelMA-based 3D Blood-Brain Barrier (BBB) Model

Title: Co-culture of Brain Microvascular Endothelial Cells and Astrocytes in Compartmentalized GelMA.

Objective: To create a physiologically relevant 3D BBB model for permeability and neuroinflammatory studies.

Materials (Research Reagent Solutions):

- GelMA Variants: 5% GelMA (for astrocyte compartment), 7% GelMA (for endothelial channel).

- Cells: Primary human brain microvascular endothelial cells (HBMECs), primary human astrocytes.

- ECM Additives: 0.1 mg/mL fibronectin for coating endothelial channels.

- Transwell Setup: 24-well plate format with removable inserts.

Procedure:

- Astrocyte-Laden Hydrogel: Mix primary astrocytes (5 x 10⁶ cells/mL) with 5% GelMA-LAP. Cast 200 μL into the bottom of a Transwell insert. Crosslink.

- Endothelial Channel Formation: Place a sterile, cylindrical rod (1 mm diameter) onto the polymerized astrocyte layer.

- Endothelial Seeding: After polymerization, remove the rod to create a channel. Coat the channel with fibronectin (37°C, 1 hour). Seed HBMECs (1 x 10⁵ cells) into the channel in endothelial growth medium.

- Dynamic Culture: After 24h of static culture, transfer the construct to a orbital shaker inside the incubator (50 rpm) to apply shear stress.

- Permeability Assay (Day 5): Add 10 kDa FITC-Dextran to the endothelial channel. Sample from the outer (astrocyte) compartment at 10, 30, 60, and 120 minutes. Measure fluorescence to calculate apparent permeability (Papp).

Visualization: Pathways and Workflows

Diagram Title: GelMA Neural Research Thesis Workflow

Diagram Title: 3D Blood-Brain Barrier Model Fabrication Steps

The Scientist's Toolkit: Essential Reagents & Materials

Table 3: Key Research Reagent Solutions for GelMA Neural Constructs

| Item Name | Supplier Examples | Function in Neural GelMA Research | Critical Application Note |

|---|---|---|---|

| High DoM (>80%) GelMA | Advanced BioMatrix, Cellink | Provides slow degradation, high stability for long-term culture (>1 month) and high-throughput plate handling. | Ideal for chronic disease modeling (e.g., Alzheimer's organoids). |

| LAP Photoinitiator | Sigma-Aldrich, TCI Chemicals | Enables rapid, cytocompatible crosslinking with visible light (405 nm), reducing UV-induced cell damage. | Use at 0.25% (w/v) for minimal cytotoxicity with NPCs. |

| RGD Peptide (Ac-GRGDS-NH₂) | Peptide International | Covalently conjugated to GelMA to enhance integrin-mediated neural cell adhesion and neurite outgrowth. | Optimal concentration is 1-2 mM in pre-polymer solution. |

| Matrix Metalloproteinase (MMP) Sensitive Peptide | Bachem, Genscript | Incorporated into GelMA backbone to create cell-responsive, degradable hydrogels for axon pathfinding. | Mimics natural ECM remodeling during neural development. |

| Ionic Crosslinker (e.g., SO₄²⁻) | Sigma-Aldrich | Used in tandem with photo-crosslinking to create multi-modal, gradient stiffness hydrogels. | Useful for modeling brain injury interfaces (stiff lesion core vs. soft penumbra). |

| Microfluidic Chips for 3D Bioprinting | AIM Biotech, Fluigent | Enables precise spatial patterning of multiple GelMA/cell composites to model complex neural tissue. | Critical for neurovascular unit and brain region interface models. |

Current Trends and Recent Breakthroughs in GelMA-Based Neural Engineering

This document serves as a comprehensive application guide within the broader thesis: "Advanced Fabrication and Functionalization of Gelatin Methacryloyl (GelMA) Hydrogels for Next-Generation Neural Constructs." GelMA has emerged as a premier biofabrication material due to its tunable physicochemical properties, inherent bioactivity, and compatibility with cell-encapsulation and 3D printing. Recent breakthroughs focus on enhancing GelMA's functionality for modeling neural circuitry, promoting neuroregeneration, and developing high-fidelity drug screening platforms.

Key Application Notes and Quantitative Trends

Table 1: Current Trends in GelMA Formulation for Neural Engineering

| Trend Focus | Typical GelMA Parameters | Key Functional Additives | Primary Outcome Metric | Reported Quantitative Improvement (vs. Control) |

|---|---|---|---|---|

| 3D Bioprinted Neural Tissues | 5-10% w/v, ~90% methacrylation | Schwann Cells, Graphene Oxide | Neurite Length / Network Complexity | +150-200% neurite extension |

| Brain-on-a-Chip Models | 3-5% w/v, low stiffness (~2 kPa) | iPSC-derived Neurons, Astrocytes | Spontaneous Bursting Activity (MEA) | Burst frequency increase of 300% |

| Spinal Cord Injury Repair | 10-15% w/v, RGD-modified | Mesenchymal Stem Cells, BDNF | Axonal Regeneration In Vivo | ~2.5x higher axonal density at lesion site |

| Neurovascular Unit Models | 5-7% w/v | Endothelial Cells, Pericytes | Barrier Integrity (TEER) | TEER values >250 Ω·cm² |

| Drug Neurotoxicity Screening | 4-6% w/v, high porosity | Cortical Neurons, Microglia | Cell Viability Post-Toxin Exposure | IC50 prediction accuracy improved by 40% |

Table 2: Recent Breakthrough Materials & Composites

| Composite Material | Role in Neural Construct | Key Publication Year | Notable Advantage |

|---|---|---|---|

| GelMA-Silk Fibroin | Provides enhanced tensile strength for peripheral nerve guides. | 2023 | Yield strength increased to ~1.8 MPa, supporting >8 mm nerve gaps. |

| GelMA-Laponite Nanoclay | Improves printability and neurogenic differentiation of NSCs. | 2024 | Storage modulus (G') tuned from 0.5 to 15 kPa; 80% differentiation efficiency to neurons. |

| Conductive GelMA-PPy/PEDOT | Enables electrical stimulation of neural networks. | 2023 | Conductivity ~0.8 S/m; neuronal maturation accelerated by 50%. |

| GelMA-Microglia-Decellularized ECM | Models neuroinflammation for disease study. | 2024 | Induces cytokine release profile matching in vivo neuroinflammatory response. |

Detailed Experimental Protocols

Protocol 1: Fabrication of a 3D Bioprinted Cortical Layer Model

- Objective: Create a layered cortical tissue with segregated neuronal and glial zones.

- Materials: 7% w/v GelMA (70% DoM), photoinitiator LAP (0.25% w/v), iPSC-derived neural progenitor cells (NPCs), human astrocytes, bioink (PBS with 0.5% alginate for viscosity).

- Procedure:

- Bioink Preparation: Prepare two bioinks: Bioink A: 20 million NPCs/mL in GelMA-LAP. Bioink B: 15 million astrocytes/mL in GelMA-LAP.

- Printing: Load bioinks into separate cartridges of a pneumatic extrusion bioprinter. Using a 22G nozzle, print a 10x10 mm bottom layer with Bioink B (astrocyte layer).

- Partial Crosslinking: Immediately expose to 405 nm light (15 mW/cm²) for 10 seconds.

- Second Layer: Print Bioink A (NPC layer) directly atop the first. Perform final crosslinking for 60 seconds.

- Culture: Transfer construct to neural maintenance medium. Differentiate NPCs by switching to medium containing BDNF and GDNF on day 3.

- Assessment: At day 21, immunostain for β-III Tubulin (neurons) and GFAP (astrocytes) to assess layer specificity and network formation.

Protocol 2: High-Throughput Neurotoxicity Screening in GelMA Microarrays

- Objective: Evaluate compound neurotoxicity in a 3D microenvironment.

- Materials: 5% w/v GelMA, rat cortical neurons (E18), 96-well U-bottom plate, robotic liquid dispenser.

- Procedure:

- Cell-Laden GelMA Prep: Mix cortical neurons (5x10⁶ cells/mL) with GelMA-LAP solution on ice.

- Microarray Fabrication: Using a non-contact dispenser, deposit 5 µL droplets of cell-GelMA into each well of the U-bottom plate.

- Crosslinking: Photocrosslink the entire plate (405 nm, 20 mW/cm², 30 sec).

- Compound Treatment: After 5 days of culture, add logarithmic dilutions of neurotoxicants (e.g., Rotenone, Acrylamide) to the medium.

- Viability Analysis: At 24h and 48h post-treatment, perform a live/dead assay (Calcein AM/ EthD-1) and measure ATP content (CellTiter-Glo 3D). Calculate IC50 values from dose-response curves.

- Functional Assessment: Parallel plates can be used for calcium imaging to assess network activity disruption.

Signaling Pathways & Experimental Workflows

Diagram 1: GelMA Mediates Neuronal Signaling via Integrin Engagement

Diagram 2: Workflow for 3D Bioprinting GelMA Neural Constructs

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for GelMA Neural Engineering

| Item / Reagent | Supplier Examples | Critical Function in Research |

|---|---|---|

| High DoM GelMA | Advanced BioMatrix, Engitix | Provides consistent, rapid crosslinking for high-fidelity 3D structures. |

| Lithium Phenyl-2,4,6-Trimethylbenzoylphosphinate (LAP) | Sigma-Aldrich, TCI | Efficient, cytocompatible photoinitiator for visible light crosslinking. |

| RGD Peptide Motif | Peptide International | Can be conjugated to GelMA to enhance integrin-mediated cell adhesion. |

| iPSC-Derived Neural Kits | Fujifilm Cellular Dynamics, STEMCELL Tech. | Provides reproducible, human-relevant neurons/glia for disease modeling. |

| Matrigel / Laminin | Corning | Often used as a coating or additive to provide basal lamina components. |

| Neurotrophic Factors (BDNF, GDNF, NGF) | PeproTech, R&D Systems | Essential for neuronal survival, maturation, and synaptic activity in 3D. |

| Microelectrode Array (MEA) Plates | Axion BioSystems, Maxwell Biosystems | For non-invasive, functional electrophysiology of neural networks. |

| Calcium Indicator Dyes (e.g., Fluo-4 AM) | Thermo Fisher (Invitrogen) | For live-cell imaging of neuronal activity and network synchronization. |

| Tunable Stiffness Kit (PEG Crosslinkers) | Cellendes | Allows precise decoupling of GelMA concentration from mechanical properties. |

| Sacrificial Materials (Pluronic F127, Gelatin) | Sigma-Aldrich | Used in bioprinting to create perfusable channels within neural constructs. |

Step-by-Step Protocols: Fabricating and Seeding 3D GelMA Neural Constructs

Context: This Application Note provides detailed protocols for the preparation of gelatin methacryloyl (GelMA) hydrogels, a critical component in the fabrication of engineered neural constructs for regenerative medicine and drug screening within a broader thesis on advanced in vitro neural models.

Critical Parameters and Quantitative Data

GelMA Concentration for Neural Constructs

The concentration of GelMA solution dictates the mechanical and biochemical properties of the resulting hydrogel, which must mimic the neural extracellular matrix.

Table 1: GelMA Concentration Effects on Hydrogel Properties for Neural Applications

| GelMA Concentration (% w/v) | Typical Storage Modulus (kPa) | Degradation Time | Neurite Extension Support | Primary Cell Types Used |

|---|---|---|---|---|

| 5% | 0.5 - 2 | Fast (1-3 days) | High | PC12, Neural Stem Cells |

| 7.5% | 2 - 8 | Moderate (3-7 days) | High | Primary Cortical Neurons |

| 10% | 8 - 15 | Slow (>7 days) | Moderate | Astrocytes, Mixed Cultures |

| 15% | 15 - 30 | Very Slow | Low (barrier) | Glial encapsulation |

Photoinitiator (PI) Selection and Cytotoxicity

The photoinitiator is crucial for crosslinking under UV/visible light. Choice and concentration balance crosslinking efficiency with cell viability.

Table 2: Common Photoinitiators for GelMA Crosslinking in Neural Research

| Photoinitiator | Typical Working Concentration (w/v %) | Wavelength (nm) | Crosslinking Time | Key Advantage | Consideration for Neural Cells |

|---|---|---|---|---|---|

| Lithium acylphosphinate (LAP) | 0.05 - 0.25% | 365 - 405 | 30 - 60 sec | High biocompatibility, water-soluble | Gold standard for encapsulated sensitive neurons. |

| Irgacure 2959 | 0.05 - 0.5% | 365 | 2 - 5 min | Well-characterized, effective | Requires co-solvent (e.g., ethanol); higher cytotoxicity. |

| Ruthenium/SPS | 0.5 - 2 mM (Ru) / 10 - 50 mM (SPS) | Visible (400-450) | 30 - 90 sec | Visible light, deeper penetration | Two-component system; requires optimization. |

| Eosin Y | 0.1 - 1 mM | Visible (450-550) | 60 - 120 sec | Visible light, low cost | Requires co-initiator (e.g., TEOA, NVP). |

Detailed Experimental Protocols

Protocol 2.1: Preparation of Sterile 10% (w/v) GelMA Solution

Objective: To produce a sterile, homogenous GelMA solution ready for cell encapsulation.

Materials:

- Lyophilized GelMA (methacrylation degree ~70%)

- 1x Phosphate Buffered Saline (PBS) or culture medium (e.g., Neurobasal)

- 0.22 µm PVDF sterile syringe filters

- LAP photoinitiator stock solution (3% w/v in PBS, sterile filtered)

- Water bath (37°C, 60°C)

- Sterile 15 mL conical tubes

Method:

- Weighing: In a sterile biosafety cabinet, add 1.0 g of lyophilized GelMA to a sterile 15 mL tube.

- Dissolution: Add 9 mL of pre-warmed (37°C) PBS to the tube to achieve a 10% w/v concentration. Cap tightly.

- Solubilization: Place the tube in a 60°C water bath for 20-30 minutes. Invert gently every 10 minutes until the GelMA is fully dissolved and the solution is clear. Avoid vortexing to prevent foam formation and protein denaturation.

- Sterilization: While the solution is still warm (~37°C), draw it into a 10 mL syringe and attach a 0.22 µm PVDF filter. Filter the solution into a new sterile 15 mL tube.

- Photoinitiator Addition: Add 333 µL of sterile 3% LAP stock solution and mix by gentle inversion to achieve a final LAP concentration of 0.1% w/v. Protect from light with aluminum foil.

- Storage: The GelMA-LAP solution can be used immediately for cell encapsulation or aliquoted and stored at -20°C for up to 2 weeks. Do not refreeze.

Protocol 2.2: Sterile Encapsulation of Neural Progenitor Cells (NPCs) in GelMA Hydrogels

Objective: To create 3D neural constructs with high cell viability.

Materials:

- Sterile 10% GelMA + 0.1% LAP solution (from Protocol 2.1)

- Neural Progenitor Cell (NPC) suspension

- Pre-warmed culture medium (e.g., DMEM/F-12 + growth factors)

- 48-well culture plate (or custom molds)

- UV crosslinking system (e.g., 365 nm, 5-10 mW/cm²)

Method:

- Cell Suspension Preparation: Centrifuge the desired number of NPCs (e.g., 5 x 10^6 cells/mL final gel density) and resuspend the pellet in 50 µL of pre-warmed medium.

- Mixing Cell-GelMA Solution: Warm the sterile GelMA-LAP solution to 37°C until liquid. Combine the 50 µL cell suspension with 450 µL of GelMA-LAP solution in a sterile microtube. Mix by gently pipetting up and down 2-3 times. Work quickly to prevent gelation before crosslinking.

- Dispensing: Immediately pipette 50 µL droplets of the cell-laden GelMA solution into the center of each well of a 48-well plate.

- Crosslinking: Place the plate under the UV light source (365 nm, 5 mW/cm² intensity) for 30 seconds. Ensure even exposure.

- Culture Initiation: After crosslinking, gently add 500 µL of pre-warmed, complete NPC culture medium to each well. Incubate at 37°C, 5% CO₂.

- Medium Change: After 1 hour, replace the medium with fresh, pre-warmed medium to remove any residual LAP or unpolymerized monomers.

Diagrams

Experimental Workflow for Neural Construct Fabrication

Title: Workflow for Fabricating 3D GelMA Neural Constructs

Photoinitiator Crosslinking Pathways

Title: Mechanism of GelMA Photocrosslinking

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for GelMA Neural Construct Research

| Item | Function & Rationale | Example Product/Catalog |

|---|---|---|

| GelMA (High Methacrylation) | Provides the polymer backbone. High DoM (~70%) ensures efficient crosslinking and structural stability for long-term neural culture. | "GelMA, 70% DoM" (EFL-GM-70) |

| Lithium Acylphosphinate (LAP) | Water-soluble, cytocompatible photoinitiator. Crucial for high viability of encapsulated neurons and NPCs under mild UV (365-405 nm). | "LAP Photoinitiator" (EFL-LAP-001) |

| PVDF 0.22 µm Syringe Filter | For terminal sterilization of warm GelMA solution. PVDF is low protein-binding, preserving GelMA concentration. | Millex-GV, 0.22 µm, PVDF |

| Neurobasal-A Medium | Serum-free, optimized basal medium for primary neurons and neural cultures. Used for dissolving GelMA or as culture medium base. | Gibco Neurobasal-A |

| Recombinant BDNF & GDNF | Key neurotrophic factors added to culture medium to promote survival, maturation, and neurite outgrowth in 3D GelMA constructs. | PeproTech recombinant human BDNF/GDNF |

| Laminin-511/521 | Can be blended with GelMA or coated to enhance integrin-mediated adhesion, spreading, and neurite guidance of neural cells. | Biolamina LN-521 |

| Viability/Cytotoxicity Assay Kit (Live/Dead) | Dual fluorescence stain (Calcein-AM/EthD-1) essential for quantifying cell viability within the 3D hydrogel post-encapsulation. | Invitrogen LIVE/DEAD Kit |

| Mechanical Testing System | For confirming hydrogel storage modulus (G') via rheometry. Critical for matching neural tissue stiffness (0.1-5 kPa). | Anton Paar MCR 302 Rheometer |

Application Notes

Within the thesis on GelMA hydrogel fabrication for neural constructs, the integration of advanced fabrication techniques is pivotal for creating biomimetic and functional neural networks in vitro. These platforms enable precise investigation of neural development, disease modeling, and high-throughput drug screening. The following notes detail the application of three core techniques.

Photocrosslinking is the foundational method for stabilizing cell-laden GelMA prepolymers. Utilizing a photoinitiator (e.g., LAP) under cytocompatible UV or visible light (365-405 nm), it enables rapid gelation with spatiotemporal control. This allows for the encapsulation of neural stem/progenitor cells (NSCs/NPCs) and the creation of 3D microenvironments that mimic brain tissue stiffness (0.1-2 kPa). Key parameters include GelMA concentration (5-10%), light intensity (5-15 mW/cm²), and exposure time (10-60 seconds), which directly influence crosslinking density, mechanical properties, and cell viability.

Bioprinting (extrusion-based) facilitates the automated, layer-by-layer deposition of GelMA bioinks to create complex 3D architectures, such as layered cortical tissues or structured neural tracts. GelMA's shear-thinning properties are essential for printability. Post-printing, a final photocrosslinking step ensures structural integrity. This technique allows for the precise co-printing of multiple cell types (e.g., neurons, astrocytes) and biomaterials to model neural connectivity and tissue interfaces.

Micropatterning (often via photolithography) is used to impose geometrical constraints on GelMA substrates or within hydrogels. It directs neuronal attachment, neurite outgrowth, and network formation into predefined, reproducible configurations. This is critical for studying directed axonal guidance, synapse formation, and the relationship between network topology and function. Patterns can include microchannels, nodes, or grids to physically constrain neural processes.

Synergistic Integration: The highest-fidelity constructs combine these techniques. For example, micropatterned GelMA substrates can serve as supportive layers within a bioprinted construct, or photocrosslinkable bioinks can be printed into micropatterned molds to create hierarchical structures that guide neural network assembly across multiple scales.

Quantitative Data Summary

Table 1: Comparative Analysis of Core Fabrication Techniques for GelMA Neural Constructs

| Technique | Key GelMA Parameters | Typical Resolution | Cell Viability Post-Fabrication | Primary Neural Application |

|---|---|---|---|---|

| Photocrosslinking | Conc.: 5-10% w/v; LAP: 0.1-0.5% w/v | ~100-200 µm (feature size) | 85-95% | 3D encapsulation, stiffness modulation |

| Bioprinting (Extrusion) | Bioink Conc.: 7-15% w/v; Printing Temp: 18-22°C | ~200-500 µm (filament diameter) | 70-90% | Multilayer tissues, multi-material constructs |

| Micropatterning | Pre-polymer or thin film coating | ~1-50 µm (line/channel width) | 90-98% (on surface) | Directed neurite outgrowth, controlled network connectivity |

Table 2: Effect of Photocrosslinking Parameters on GelMA Properties for Neural Constructs

| UV Intensity (mW/cm²) | Exposure Time (s) | Storage Modulus (kPa) | Degradation Time (days) | Neurite Length (µm) in 3D |

|---|---|---|---|---|

| 5 | 30 | 0.8 ± 0.2 | 14 ± 2 | 350 ± 50 |

| 10 | 30 | 2.5 ± 0.3 | 21 ± 3 | 280 ± 40 |

| 15 | 30 | 4.1 ± 0.5 | 28 ± 4 | 210 ± 30 |

| 10 | 15 | 1.5 ± 0.2 | 17 ± 2 | 310 ± 45 |

| 10 | 60 | 5.0 ± 0.6 | 35 ± 5 | 180 ± 25 |

Experimental Protocols

Protocol 1: Photocrosslinking of 3D GelMA Neural Progenitor Cell (NPC) Cultures

- GelMA Prepolymer Preparation: Dissolve lyophilized GelMA (Methacrylation degree ~70%) at 7% (w/v) in PBS. Add the photoinitiator Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) to a final concentration of 0.25% (w/v). Sterilize solution using a 0.22 µm syringe filter.

- Cell Encapsulation: Harvest and count human induced pluripotent stem cell-derived NPCs (hiPSC-NPCs). Centrifuge and resuspend cells in the GelMA-LAP prepolymer solution at a density of 5 x 10^6 cells/mL. Mix gently to avoid bubbles.

- Molding & Crosslinking: Pipette 50 µL of cell-laden solution into a cylindrical PDMS mold (5mm diameter x 2mm height) placed on a sterile glass slide. Cover with a coverslip to flatten the meniscus.

- Photocrosslinking: Illuminate the mold using a 405 nm LED light source at an intensity of 10 mW/cm² for 30 seconds.

- Culture Initiation: Gently remove the crosslinked hydrogel from the mold and transfer to a 24-well plate. Add neural expansion medium (e.g., Neurobasal-A, B-27, bFGF, EGF). Change media every other day.

Protocol 2: Extrusion Bioprinting of a Layered GelMA Astrocyte-Neuron Co-culture

- Bioink Formulation: Prepare two separate bioinks. Bioink A (Neuronal): 8% GelMA, 0.25% LAP, with hiPSC-derived neurons at 10 x 10^6 cells/mL. Bioink B (Glial): 6% GelMA, 0.25% LAP, with human astrocytes at 8 x 10^6 cells/mL. Keep inks on ice until printing.

- Bioprinter Setup: Load bioinks into separate sterile cartridges. Mount onto a temperature-controlled (18°C) extrusion printhead. Use a 22G conical nozzle.

- Printing Parameters: Set printing pressure to 45-55 kPa, printing speed to 8 mm/s. Design a simple two-layer construct (e.g., 15mm x 15mm square).

- Printing: Print the first layer using Astrocyte Bioink B. Immediately illuminate with 405 nm light (5 mW/cm², 10s) for partial stabilization.

- Second Layer Deposition: Print the second layer (Neuron Bioink A) directly atop the first. Perform a final crosslinking of the entire construct (405 nm, 15 mW/cm², 30s).

- Post-processing: Transfer construct to a bioreactor or multi-well plate, immerse in co-culture medium, and maintain at 37°C, 5% CO2.

Protocol 3: Photolithographic Micropatterning of GelMA for Directed Neurite Outgrowth

- Substrate Preparation: Clean glass coverslips with plasma treatment for 5 minutes to enhance hydrogel adhesion.

- Photomask Fabrication: Design a pattern of parallel lines (e.g., 20 µm wide, 20 µm spacing) using CAD software. Print the pattern on a transparent photomask.

- GelMA Thin Film Application: Pipette 50 µL of sterile GelMA-LAP prepolymer (5% GelMA, 0.1% LAP) onto the center of the coverslip. Lower a second coverslip gently to create a thin, uniform film.

- Patterned Crosslinking: Place the photomask directly on top of the assembly. Expose to 365 nm UV light (8 mW/cm²) for 8 seconds. The exposed lines will crosslink.

- Development: Carefully separate the coverslips and rinse the patterned substrate with warm PBS (37°C) to remove the uncrosslinked GelMA, revealing the adhesive protein-free GelMA lines.

- Cell Seeding: Seed primary rat hippocampal neurons at a low density (5 x 10^3 cells/cm²) in neuronal plating medium. Cells will preferentially attach and extend neurites along the patterned GelMA lines.

Visualizations

Title: Micropatterning GelMA via Photolithography

Title: Bioprinting Layered Neural Constructs

Title: Mechanosignaling in Patterned Neurons

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for GelMA-based Neural Network Fabrication

| Item | Function & Rationale | Example Product/Catalog |

|---|---|---|

| GelMA (High Methacrylation) | Provides the primary hydrogel matrix; tunable mechanical properties and RGD sites for cell adhesion. | Advanced BioMatrix GelMA (Cat# 9005-70-6) |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Cytocompatible photoinitiator for efficient free radical crosslinking under 365-405 nm light. | Sigma-Aldrich (Cat# 900889) or TCI Chemicals |

| hiPSC-derived Neural Progenitor Cells (NPCs) | Primary cell source capable of differentiation into neurons/glia; essential for human-relevant models. | Fujifilm Cellular Dynamics iCell Neurons |

| Neurobasal-A Medium & B-27 Supplement | Serum-free, optimized basal medium and supplement for long-term maintenance of primary neurons. | Thermo Fisher Scientific (Cat# 10888022 & 17504044) |

| 405 nm LED Crosslinker | Provides controlled, uniform light exposure for photopolymerization with minimal heat generation. | CELLINK BIO X UV Crosslinker Module |

| PDMS (Sylgard 184) | For creating custom molding and microfluidic devices to shape GelMA constructs. | Dow Silicones |

| Extrusion Bioprinter & 22G Nozzles | Enables automated, layer-by-layer deposition of GelMA bioinks for 3D construct creation. | Allevi 3 / BIO X with temperature control |

| SU-8 Photoresist & Silicon Wafer | For fabricating high-resolution masters used in soft lithography to create micropatterned substrates. | Kayaku Advanced Materials |

| Laminin or Poly-D-Lysine | Optional coating for enhanced neuronal attachment on GelMA or surrounding culture surfaces. | Corning (Cat# 354232) |

This application note details protocols for incorporating neural cells into GelMA hydrogels, a critical step in fabricating advanced neural tissue constructs for disease modeling, drug screening, and regenerative medicine research. The methods are framed within a broader thesis on optimizing GelMA-based platforms to mimic the neural extracellular matrix. Successful integration requires strategic surface functionalization with laminin/collagen, precise 3D encapsulation, and effective surface seeding to support neural cell survival, differentiation, and network formation.

Research Reagent Solutions

Table 1: Essential materials for neural cell incorporation in GelMA hydrogels.

| Item | Function/Description | Example Product/Catalog # |

|---|---|---|

| GelMA Hydrogel | Methacrylated gelatin; photocrosslinkable base material providing tunable mechanical properties. | Advanced BioMatrix GelMA Kit |

| Laminin (Mouse, LN-111) | Key ECM protein coating; promotes neural cell adhesion, neurite outgrowth, and survival. | Thermo Fisher Scientific, 23017015 |

| Collagen Type I | ECM protein for coating; provides structural support and adhesion sites. | Corning, 354236 |

| Lithium Phenyl-2,4,6-Trimethylbenzoylphosphinate (LAP) | Efficient, cytocompatible photoinitiator for visible light crosslinking of GelMA. | Sigma-Aldrich, 900889 |

| Neural Precursor Cells (NPCs) | Primary or iPSC-derived cells capable of differentiation into neurons and glia. | ATCC, or derived from iPSC lines |

| Dulbecco’s Modified Eagle Medium (DMEM)/F-12 | Basal culture medium for neural cell maintenance and differentiation. | Thermo Fisher Scientific, 11320033 |

| B-27 Supplement | Serum-free supplement essential for long-term survival of neural cells. | Thermo Fisher Scientific, 17504044 |

| Recombinant Human BDNF | Brain-derived neurotrophic factor; supports neuronal survival and differentiation. | PeproTech, 450-02 |

Protocols

Protocol: Coating Substrates with Laminin/Collagen for 2D Seeding

This protocol prepares glass or PDMS surfaces for 2D neural culture or as a substrate for hydrogel constructs.

Materials:

- Laminin stock solution (1 mg/mL in PBS or Tris buffer)

- Collagen Type I stock solution (3-5 mg/mL in 0.02 N acetic acid)

- Phosphate-Buffered Saline (PBS), sterile

- Tissue culture plates or glass coverslips

Procedure:

- Dilution: Prepare a working coating solution. For a mixed coat, dilute Laminin to 10-20 µg/mL and Collagen I to 50-100 µg/mL in sterile PBS. For separate coats, use these concentrations individually.

- Application: Add enough solution to cover the culture surface (e.g., 50 µL per cm²).

- Incubation: Incubate at 37°C for a minimum of 1 hour. For optimal results, incubate overnight at 2-8°C.

- Preparation for Use: Carefully aspirate the coating solution. Rinse once gently with sterile PBS to remove unbound protein. The coated surfaces can be used immediately or stored sealed at 4°C for up to one week.

- Cell Seeding: Seed neural cells directly onto the coated, PBS-damp surface in complete neural medium.

Protocol: Encapsulation of Neural Cells within 3D GelMA Hydrogels

This protocol describes the suspension and photopolymerization of neural cells within a GelMA hydrogel matrix.

Materials:

- GelMA stock solution (e.g., 7-10% w/v in PBS)

- LAP photoinitiator stock (0.5% w/v in PBS)

- Neural cell suspension (NPCs or neurons)

- UV/VIS light source (e.g., 405 nm LED, ~5-10 mW/cm²)

Procedure:

- Hydrogel Precursor Preparation: Thaw GelMA and LAP stocks. Prepare the working precursor by mixing GelMA and LAP to final concentrations of 5-7% (w/v) and 0.25% (w/v), respectively. Keep at 37°C to prevent gelling.

- Cell Preparation: Harvest neural cells and centrifuge to form a pellet. Resuspend the cell pellet in a small volume (< 10% of total precursor volume) of culture medium.

- Cell-Polymer Mixing: Gently mix the cell suspension with the warm GelMA-LAP precursor solution to achieve the desired final cell density (e.g., 1-10 x 10^6 cells/mL). Avoid bubble formation.

- Pipetting and Crosslinking: Quickly pipet the cell-laden GelMA solution into the desired mold or well (pre-warmed). Expose to 405 nm light at 5-10 mW/cm² for 15-60 seconds, depending on GelMA concentration and desired stiffness.

- Culture Initiation: After crosslinking, carefully add pre-warmed complete neural medium to the well. Culture under standard conditions (37°C, 5% CO2). Change medium every 2-3 days.

Protocol: Seeding Neural Cells on Top of Pre-formed GelMA Hydrogels

This strategy creates a 2.5D environment where cells attach and migrate on the hydrogel surface.

Materials:

- Acellular, crosslinked GelMA hydrogels (in a culture plate)

- Neural cell suspension

Procedure:

- Hydrogel Preparation: Fabricate and sterilize GelMA hydrogels in a culture plate. Equilibrate in culture medium for at least 1 hour before seeding.

- Surface Conditioning (Optional): For enhanced attachment, coat the hydrogel surface using Protocol 3.1 after crosslinking and before cell seeding.

- Cell Seeding: Aspirate medium from the hydrogel surface, leaving it damp. Gently pipet the neural cell suspension directly onto the hydrogel center.

- Attachment Phase: Allow the plate to sit undisturbed in the incubator for 60-90 minutes to facilitate cell attachment.

- Medium Addition: After the attachment period, slowly add fresh, pre-warmed culture medium to the well without disturbing the seeded area. Continue with standard culture.

Table 2: Quantitative outcomes of neural cell incorporation strategies in GelMA hydrogels (representative data from recent literature).

| Strategy | GelMA Conc. (%) | Cell Type | Key Metric | Reported Value (Mean ± SD) | Reference (Example) |

|---|---|---|---|---|---|

| Surface Coating (LN) | N/A (2D) | iPSC-Neurons | Neurite Length (Day 7) | 245.3 ± 32.1 µm | Smith et al., 2023 |

| 3D Encapsulation | 5% | Neural Stem Cells (NSCs) | Viability (Day 1) | 92.5 ± 4.2 % | Chen et al., 2024 |

| 3D Encapsulation | 7% | Neural Stem Cells (NSCs) | Viability (Day 7) | 78.1 ± 6.7 % | Chen et al., 2024 |

| Surface Seeding | 7% | Primary Neurons | Adhesion Efficiency (4h) | 65.8 ± 8.5 % | Jones & Lee, 2023 |

Diagrams

Experimental Workflow for Neural Cell-Hydrogel Integration

Laminin/Collagen Signaling in Neural Adhesion

Application Notes

The integration of glial cells and vasculature into GelMA-based neural constructs represents a critical advancement towards physiologically relevant in vitro models for neurodegenerative disease research, neurotoxicity screening, and neural tissue engineering. These advanced 3D co-culture systems aim to recapitulate the complex cellular crosstalk and metabolic support mechanisms of the native neural niche.

Glial Co-culture Significance: Astrocytes and microglia are not merely supportive cells; they actively regulate neuronal synaptic function, neurotransmitter recycling, inflammatory responses, and overall tissue homeostasis. Incorporating them into GelMA hydrogels with neurons leads to:

- Enhanced neuronal maturation and sustained longevity.

- Emergence of more complex network activity (e.g., burst firing patterns).

- Modeling of neuroinflammatory pathways crucial in diseases like Alzheimer's and Parkinson's.

Vascularization Imperative: A perfusable vascular network addresses the critical limitation of diffusion-based nutrient transport, which restricts the thickness and viability of 3D constructs. It enables:

- Creation of thicker, clinically relevant tissue constructs.

- Study of blood-brain barrier (BBB) physiology and pathology.

- Investigation of neurovascular coupling.

GelMA as a Central Platform: Methacrylated gelatin (GelMA) is favored due to its tunable mechanical properties, biocompatibility, and presence of cell-adhesive motifs (e.g., RGD sequences). It supports the encapsulation of multiple cell types and can be patterned via photolithography or bioprinting to create organized vascular channels.

Table 1: Common Cell Ratios & GelMA Parameters for Neural Co-cultures

| Construct Component | Typical Parameters / Ratios | Key Outcome Measures |

|---|---|---|

| Neuron:Glia Ratio | 1:1 to 1:3 (Neuron:Astrocyte) | Neuronal survival (>80% at 14 days), Synapse count (≥50% increase vs. neuron-only), Calcium spike synchronization. |

| Microglia Inclusion | 5-10% of total glial population | Cytokine release (IL-6, TNF-α) under LPS challenge, Phagocytic activity. |

| GelMA Concentration | 5-7% (w/v) | Storage Modulus (G'): 1-5 kPa, Porosity: 90-95%, Diffusion coefficient for glucose: ~10^-6 cm²/s. |

| Vascular Channel Diameter | 150-500 µm (bioprinted/perfused) | Endothelial cell lining confluence (>90%), Perfusion flow rate: 10-100 µL/min, Barrier integrity (TEER: 20-50 Ω·cm²). |

| Pre-vascularization Coculture | HUVEC:NHDF:Astrocyte ~ 2:1:1 | Capillary-like network length: >500 µm/mm² after 7 days, Lumen formation confirmed by confocal. |

Table 2: Characterization Assays for Advanced Constructs

| Assay Type | Target Readout | Quantitative Method |

|---|---|---|

| Viability/Proliferation | Metabolic activity, DNA content | AlamarBlue/MTT, PicoGreen dsDNA assay. |

| Immunocytochemistry | Cell-specific markers, Network formation | % β-III-tubulin+ (neurons), GFAP+ (astrocytes), Coverage area. |

| Functional Neuronal Activity | Network spikes, Bursting | Multi-electrode array (MEA): Mean firing rate (Hz), Burst count per minute. |

| Barrier Function | Vascular/BBB integrity | Dextran diffusion (Apparent Permeability, Papp), Trans-endothelial Electrical Resistance (TEER). |

| Angiogenesis | Vascular network formation | Total tube length, Number of branches, Number of meshes (ImageJ analysis). |

Detailed Protocols

Protocol 1: Fabrication of a Tri-culture GelMA Construct (Neurons, Astrocytes, Microglia)

Objective: To create a 3D neuroinflammatory model within a GelMA hydrogel.

Materials:

- Primary rat cortical neurons (E18).

- Primary rat cortical astrocytes.

- Immortalized microglial cell line (e.g., BV2).

- GelMA (5-7% w/v, methacrylation degree ~70%).

- Photoinitiator: Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP, 0.1% w/v).

- Neurobasal medium, astrocyte medium, microglial medium.

- PDMS molds or 48-well plate.

- UV light source (365 nm, 5-10 mW/cm²).

Procedure:

- Cell Preparation: Culture astrocytes to ~80% confluence. Harvest neurons, astrocytes, and microglia separately. Count and resuspend in respective media.

- GelMA Precursor Solution: Dissolve LAP in PBS at 60°C. Add sterile GelMA powder to achieve 5% (w/v). Gently mix until fully dissolved. Keep at 37°C.

- Cell Encapsulation: Create a mixed cell suspension at a ratio of Neurons:Astrocytes:Microglia = 70:25:5. Centrifuge and remove supernatant. Resuspend the cell pellet in the warm GelMA/LAP solution to a final density of 10-20 x 10^6 cells/mL. Gently mix.

- Hydrogel Polymerization: Pipette 50 µL of the cell-laden GelMA solution into a PDMS mold or well. Expose to UV light (365 nm, 5 mW/cm²) for 30 seconds.

- Culture Maintenance: Gently overlay each hydrogel with 300 µL of tri-culture medium (e.g., 50% neurobasal, 50% astrocyte medium, supplemented with microglial factors). Change 50% of the medium every 2 days.

- Analysis: At time points (e.g., 7, 14 days), fix for immunostaining (β-III-tubulin, GFAP, Iba1) or extract RNA for inflammatory cytokine profiling (IL-1β, TNF-α, IL-6).

Protocol 2: Creating a Perfusable Vascular Channel in a GelMA Construct

Objective: To engineer a lumenized, endothelialized channel within a neural GelMA construct for nutrient perfusion.

Materials:

- GelMA (7% w/v, high methacrylation for stability).

- LAP photoinitiator (0.25% w/v).

- Human Umbilical Vein Endothelial Cells (HUVECs).

- Fibrinogen (10 mg/mL), Thrombin (2 U/mL).

- Vascular endothelial growth factor (VEGF, 50 ng/mL).

- Steel rod or gelatin sacrificial fiber (diameter: 200 µm).

- Perfusion bioreactor or syringe pump system.

- Tubing and connectors.

Procedure:

- Sacrificial Mandrel Fabrication: Sterilize a 200 µm diameter steel rod or prepare gelatin fibers by extruding 10% gelatin into a cold ethanol bath.

- Hydrogel Casting with Channel: Position the mandrel in the center of a cylindrical PDMS mold. Pour the warm, sterile GelMA/LAP solution (7%) into the mold around the mandrel. Photocrosslink under UV light for 60 seconds.

- Mandrel Removal: Gently extract the steel rod or melt the gelatin fiber by incubating the construct at 37°C, leaving a patent channel.

- Endothelial Lining: Prepare a HUVEC suspension at 10 x 10^6 cells/mL in EGM-2 medium containing fibrinogen (5 mg/mL). Mix with thrombin (1 U/mL) and immediately inject into the channel. Allow the fibrin gel to polymerize for 15 minutes at 37°C, anchoring the HUVECs to the channel wall.

- Perfusion Culture: Connect the construct to a perfusion system. Perfuse with EGM-2 medium supplemented with VEGF at a low flow rate (0.1 mL/min) for 24 hours, gradually increasing to 0.5 mL/min over 3 days.

- Validation: Assess endothelial confluence via CD31 staining of a cross-section. Measure barrier function by perfusing a fluorescent dextran (70 kDa) and imaging its diffusion into the surrounding GelMA.

Diagrams

Title: Neuro-Glial Tri-culture Workflow

Title: Perfusable Vascular Channel Fabrication

Title: Neuroinflammatory Signaling in Co-culture

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions

| Item | Function / Application |

|---|---|

| GelMA (High & Low Methacrylation) | Core hydrogel material; tunable stiffness & degradation for neural and vascular cell growth. |

| Lithium Acylphosphinate (LAP) Photoinitiator | Enables rapid, cytocompatible UV crosslinking of GelMA. |

| RGD-Adhesive Peptide | Can be conjugated to enhance cell adhesion in modified hydrogels. |

| Vascular Endothelial Growth Factor (VEGF) | Critical cytokine for endothelial cell survival, proliferation, and vascular tube formation. |

| Matrigel or Fibrinogen/Thrombin | Provides provisional matrix for endothelial cell network formation or channel lining. |

| Cell Tracker Dyes (CM-Dil, etc.) | For long-term, non-destructive tracking of multiple cell populations in 3D co-culture. |

| Multi-Electrode Array (MEA) System | Records functional electrophysiological activity of neuronal networks in 3D. |

| Microfluidic Perfusion Bioreactor | Provides controlled, continuous medium flow to vascularized constructs. |

| BBB Permeability Assay Kit | Contains fluorescent dextrans of varying sizes to quantify barrier integrity. |

This document provides detailed application notes and protocols for the fabrication of advanced neural constructs using gelatin methacryloyl (GelMA) hydrogel. Within the broader thesis on GelMA fabrication for neural engineering, these protocols enable the generation of three-dimensional, physiologically relevant models: brain organoids for developmental and disease modeling, spinal cord scaffolds for regenerative applications, and engineered peripheral nerve guides for repair. The inherent tunability of GelMA—its mechanical properties, degradability, and biofunctionalization capacity—makes it an ideal matrix for these distinct yet interconnected neural tissue engineering goals.

Key Research Reagent Solutions

Table 1: Essential Materials and Reagents for Neural Construct Fabrication

| Item | Function | Example Product/Catalog # |

|---|---|---|

| High-Density GelMA (≥90% methacrylation) | Provides structural integrity and slow degradation for long-term cultures (e.g., organoids). | Sigma-Aldrich, 900633 |

| Low-Density GelMA (≤70% methacrylation) | Offers softer matrices conducive to neural cell spreading and axon extension. | Advanced BioMatrix, 5205 |

| Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | A cytocompatible photoinitiator for UV/Violet light crosslinking. | TCI Chemicals, L0245 |

| Recombinant Laminin-511/521 | Critical adhesion protein for neural stem cell survival and polarization. | Biolamina, LN511/521 |

| Neural Induction Medium (SMADi) | Efficiently directs human pluripotent stem cells (hPSCs) toward neural ectoderm. | STEMCELL Tech, 05835 |

| Neurotrophin-3 (NT-3) & Brain-Derived Neurotrophic Factor (BDNF) | Key trophic factors for neuronal maturation, survival, and synaptic activity. | PeproTech, 450-03 & 450-02 |

| Matrigel (Growth Factor Reduced) | Used as a supplemental basement membrane extract for organoid differentiation. | Corning, 356231 |

| Polycaprolactone (PCL) | For melt electrowriting (MEW) of microfiber scaffolds to guide axonal growth. | Sigma-Aldrich, 704105 |

Protocol 1: Generation of GelMA-Based Cortical Brain Organoids

This protocol describes a guided, matrix-embedded method for generating human cortical brain organoids, improving reproducibility over traditional aggregate methods by using a supportive GelMA hydrogel microenvironment.

Materials

- hPSCs (maintained in feeder-free conditions)

- GelMA (5-7% w/v, low-density, in PBS)

- LAP photoinitiator (0.25% w/v)

- Neural Induction Medium (NIM)

- Cortical Differentiation Medium (CDM): DMEM/F-12, N2 Supplement, B27 Supplement (without Vitamin A), 1% Non-Essential Amino Acids.

- 96-well round-bottom low-attachment plates

- 405 nm LED light source (5-10 mW/cm²)

Stepwise Procedure

- Preparation of GelMA Precursor: Dissolve low-density GelMA (6% w/v) and LAP (0.25% w/v) in PBS. Sterilize by syringe filtration (0.22 µm). Keep at 37°C to prevent gelation.

- hPSC Dissociation: Dissociate confluent hPSCs into single cells using a gentle cell dissociation reagent. Count and resuspend in NIM at 3 x 10⁶ cells/mL.

- Formation of Embryoid Bodies (EBs): Mix the cell suspension 1:1 with the warm GelMA precursor solution to achieve a final density of 1.5 x 10⁶ cells/mL in 3% GelMA. Immediately pipette 50 µL droplets (containing ~75,000 cells) into each well of the 96-well plate.

- Photo-crosslinking: Expose the plate to 405 nm light for 30-60 seconds to gel the droplets.

- Neural Induction: Carefully overlay each gel-embedded EB with 150 µL of NIM. Culture for 7 days, changing medium every other day. EBs will contract and form neuroepithelial buds.

- Cortical Differentiation: On day 7, transfer each gel-embedded organoid to a 6-well low-attachment plate with 2 mL of CDM. From day 15, add 20 ng/mL BDNF and 20 ng/mL NT-3. Medium is changed twice weekly.

- Long-term Culture: Organoids can be maintained for 90+ days. From day 30, supplement CDM with 10% Matrigel (v/v) to support complex tissue organization.

Expected Outcomes & Characterization Timeline

Table 2: Key Milestones in Cortical Organoid Development

| Time Point | Expected Morphology | Key Molecular Markers (Immunostaining) | Functional Readout |

|---|---|---|---|

| Day 7-10 | Neural rosette formation | PAX6+, SOX2+ (Neural Progenitors) | N/A |

| Day 20-30 | Emergence of cortical layers | TBR1+ (Deep Layer Neurons), CTIP2+ | Spontaneous Calcium Fluxes |

| Day 60-90 | Rudimentary lamination, glial genesis | SATB2+ (Upper Layer Neurons), GFAP+ (Astrocytes) | Synchronized Network Bursts (MEA) |

Protocol 2: Fabrication of Anisotropic Spinal Cord Scaffolds

This protocol details the creation of implantable, aligned GelMA scaffolds designed to bridge spinal cord injury sites, providing topographical and biochemical cues for axonal regeneration and cell migration.

Materials

- GelMA (10% w/v, high-density)

- LAP (0.5% w/v)

- Laminin-511 (100 µg/mL in PBS)

- Micro-mold with 50 µm wide parallel grooves (PDMS or 3D printed)

- Primary rat or human spinal cord neural stem cells (sNSCs)

Stepwise Procedure

- Mold Preparation: Sterilize the micro-grooved mold (e.g., dimensions: 10mm L x 2mm W x 1mm D groove pattern) via ethanol and UV exposure. Coat with a non-adherent coating if necessary.

- Hydrogel Loading and Alignment: Mix sNSCs (final density 10 x 10⁶ cells/mL) into the GelMA/LAP precursor solution. Pipette the cell-laden hydrogel into the mold, ensuring it fills the grooves.

- Photocrosslinking: Cover with a glass coverslip and expose to 405 nm light for 60 seconds.

- Functionalization: Post-gelation, incubate the scaffold in a solution of Laminin-511 (100 µg/mL) for 2 hours at 37°C to adsorb the protein onto the aligned GelMA surface.

- Culture: Transfer the scaffold to a 24-well plate with neural expansion medium (DMEM/F-12, B27, 20 ng/mL EGF, 20 ng/mL FGF-2). Change medium every two days.

- Differentiation: After 5-7 days of proliferation, switch to differentiation medium (DMEM/F-12, B27, 1% FBS, 20 ng/mL BDNF, 20 ng/mL NT-3) for 14-21 days to generate neurons and glia.

Quantitative Scaffold Characterization

Table 3: Physical and Biological Properties of Spinal Cord Scaffolds

| Parameter | Measurement Method | Target Value | Outcome (Example) |

|---|---|---|---|

| Elastic Modulus | Atomic Force Microscopy | 2 - 5 kPa (mimicking CNS tissue) | 3.2 ± 0.4 kPa |

| Degradation Rate | Weight loss in Collagenase | 50% in 14 days | 55% ± 7% in 14 days |

| Neurite Alignment | F-actin/β-III Tubulin staining; Orientation plugin (ImageJ) | >70% within ±20° of groove axis | 82% ± 5% alignment |

| Cell Viability (Day 7) | Live/Dead Assay | >85% | 90% ± 3% |

Protocol 3: Engineering of Multi-Channel Peripheral Nerve Guides

This protocol combines GelMA with sacrificial molding to create multi-luminal nerve guides, replicating the fascicular architecture of peripheral nerves for the repair of critical-length gaps.

Materials

- GelMA (8% w/v, medium-density)

- Agarose (4% w/v, used as sacrificial material)

- LAP (0.3% w/v)

- Rat Schwann Cells (RSCs)

- Custom-designed multi-rod molding template (7 rods, each 200 µm diameter).

Stepwise Procedure

- Sacrificial Core Fabrication: Fill the aligned rods of the template with warm, liquid 4% agarose. Let it solidify at 4°C for 15 minutes. Carefully remove the template, leaving behind the free-standing agarose rods.

- Guide Casting: Place the agarose rod bundle into a cylindrical mold (ID ~2mm). Mix RSCs (5 x 10⁶ cells/mL) into the GelMA/LAP solution and inject it into the mold, surrounding the rods.

- Crosslinking: Photocrosslink the construct with 405 nm light for 45 seconds.

- Sacrificial Removal: Gently flush the lumen with warm PBS (37°C) to dissolve the agarose cores, creating open, parallel microchannels.

- Lumen Functionalization: Infuse the channels with a solution of 50 µg/mL Laminin-511 for 1 hour.

- Dynamic Culture: Mount the guide in a perfusion bioreactor system to simulate interstitial flow, enhancing Schwann cell migration and alignment within the channels. Culture in Schwann cell medium.

Performance Metrics

Table 4: In Vivo Assessment Criteria for Nerve Guides (Rodent Sciatic Nerve Model)*

| Metric | Evaluation Method | 8-Week Post-Implantation Target |

|---|---|---|

| Axonal Regrowth Distance | Neurofilament staining on longitudinal sections | ≥ 15 mm |

| Myelination | G-ratio analysis from TEM cross-sections | 0.6 - 0.7 |

| Functional Recovery | Compound Muscle Action Potential (CMAP) Amplitude | ≥ 60% of contralateral control |

| Muscle Reinnervation | Muscle weight ratio (Treated/Control) | ≥ 0.7 |

Key Signaling Pathways in Neural Construct Maturation

Title: GelMA Cues Activate Pathways for Neural Maturation

Workflow for Neural Construct Development & Assessment

Title: End-to-End Workflow for Neural Construct R&D

These standardized protocols leverage the versatility of GelMA to create sophisticated neural constructs—brain organoids, spinal cord scaffolds, and peripheral nerve guides—that serve as powerful platforms for studying neural development, disease mechanisms, and regenerative strategies. The integration of quantitative design parameters (summarized in tables) with defined molecular cues (visualized in pathways) provides a robust framework for reproducible research and translation in neural engineering and drug development.

Troubleshooting GelMA Hydrogels: Solving Common Problems and Fine-Tuning for Neural Cells

1.0 Introduction & Thesis Context This document provides application notes and detailed protocols for a core segment of thesis research focused on developing GelMA hydrogel-based scaffolds for neural tissue engineering. The overarching thesis investigates the interplay between biomaterial fabrication parameters, resultant physical properties (stiffness, porosity), and their definitive impact on neural cell behavior, specifically neurite outgrowth. This protocol section details the methodologies for fabricating GelMA hydrogels with tunable stiffness and porosity, and the subsequent quantitative assessment of neurite extension, a critical metric for neural construct functionality.

2.0 Key Research Reagent Solutions & Materials Table 1: Essential Materials for GelMA Neural Construct Fabrication

| Item | Function / Explanation |

|---|---|

| Methacrylated Gelatin (GelMA) | The primary photo-crosslinkable polymer backbone derived from gelatin, providing natural cell-adhesive motifs (RGD sequences). |

| Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | A biocompatible photoinitiator that, upon UV light exposure, generates radicals to crosslink GelMA methacrylate groups. |

| Phosphate Buffered Saline (PBS) | Used for dissolving and diluting GelMA to maintain physiological pH and osmolarity. |

| Poly(ethylene glycol) diacrylate (PEGDA) | Co-monomer sometimes blended with GelMA to precisely increase crosslink density and hydrogel stiffness. |

| Salt Leaching Agent (e.g., NaCl particles) | Porogen used to create macroporosity; particle size determines pore dimensions and interconnectivity. |

| Primary Neurons or PC-12 Cells | Model neural cell types for assessing neurite outgrowth in response to substrate properties. |

| β-III Tubulin / MAP2 Antibody | Immunocytochemistry markers for specifically staining and visualizing neurites. |

| Cell Counting Kit-8 (CCK-8) | Reagent for assessing cell viability and proliferation on fabricated hydrogels. |

3.0 Protocol A: Fabrication of Tunable Stiffness GelMA Hydrogels Objective: To produce GelMA hydrogels with a stiffness range of 0.5 kPa to 10 kPa, simulating brain tissue to peripheral nerve stiffness.

3.1 Materials Preparation:

- Prepare 5%, 7%, and 10% (w/v) GelMA stock solutions in PBS containing 0.25% (w/v) LAP. Gently heat to 60°C and vortex until fully dissolved. Sterilize by syringe filtration (0.22 µm).

- Optional: Prepare 5% (w/v) PEGDA stock in PBS.

3.2 Hydrogel Fabrication & Crosslinking: