Beyond PDMS: Mastering Material Biocompatibility for Next-Generation Organ-on-Chip Models

This article provides a comprehensive guide for researchers and drug development professionals on the critical challenge of material biocompatibility in organ-on-chip (OOC) technology.

Beyond PDMS: Mastering Material Biocompatibility for Next-Generation Organ-on-Chip Models

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on the critical challenge of material biocompatibility in organ-on-chip (OOC) technology. It explores foundational principles of material-tissue interactions, details current methodologies for fabrication and surface modification, addresses common troubleshooting and optimization strategies, and critically examines validation protocols for ensuring physiological relevance. The content synthesizes the latest research to offer a practical roadmap for selecting, testing, and optimizing biomaterials to create more reliable, predictive, and translatable microphysiological systems.

The Biocompatibility Imperative: Why Material Choice Defines Organ-on-Chip Success

Technical Support Center: Troubleshooting & FAQs

Topic: Assessing Material & Surface Effects in Microfluidic Organ-on-Chip (OoC) Models

FAQs and Troubleshooting Guides

Q1: My endothelial cell barrier shows unexpectedly high permeability in my PDMS-chip, even though a direct cytotoxicity assay shows >90% viability. What could be the cause and how can I investigate it? A: High permeability with high viability is a classic sign of biocompatibility issues beyond cytotoxicity. The likely culprit is leaching of uncrosslinked oligomers from the PDMS or absorption of small hydrophobic molecules (e.g., drugs) into the bulk polymer, which then slowly leach out.

- Troubleshooting Steps:

- Pre-extraction: Soak and flush the device with organic solvents (e.g., isopropanol) prior to sterilization and cell culture.

- Surface Coating Validation: Ensure your basement membrane matrix (e.g., collagen IV, Matrigel) forms a consistent layer. Use immunofluorescence staining for the specific protein (e.g., Collagen IV) to check coating uniformity.

- Functional Assay: Perform a Transepithelial/Transendothelial Electrical Resistance (TEER) assay in-line if your chip design allows it, or use an endpoint assay like fluorescence-conjugated dextran permeability.

- Experimental Protocol: Dextran Permeability Assay

- Introduce a fluorescently-tagged dextran (e.g., 70 kDa FITC-dextran) at a relevant concentration (e.g., 100 µg/mL) into the luminal (apical) channel.

- Collect effluent from the abluminal (basal) channel at set time intervals (e.g., every 20 min for 2h).

- Measure fluorescence intensity of the collected samples using a plate reader.

- Calculate the apparent permeability coefficient (P_app) using the formula:

P_app = (dC/dt) * (V / (A * C0)), where dC/dt is the flux rate, V is the basal channel volume, A is the membrane area, and C0 is the initial luminal concentration.

Q2: I observe inconsistent cell adhesion and spontaneous detachment in my liver-on-chip model when using a new commercial chip. Cytotoxicity is low. What should I check? A: This points to inadequate or non-biocompatible surface functionalization. The surface energy or specific chemical groups may not support stable protein adsorption and cell integrin binding.

- Troubleshooting Steps:

- Surface Characterization: If possible, perform contact angle measurement on the chip material to check for batch-to-batch hydrophilicity variation.

- Protein Adsorption Test: Conduct a qualitative test by flowing a fluorescently-labeled albumin solution through the channel, incubating, washing thoroughly, and imaging under a fluorescent microscope to see if the protein adsorbs uniformly.

- Alternative Coating: Implement a robust, covalent coating strategy. Use a linker like (3-Aminopropyl)triethoxysilane (APTES) followed by crosslinker glutaraldehyde to bond your extracellular matrix protein permanently.

Q3: How can I test for chronic inflammatory activation in my gut-on-chip model, which uses a novel cyclic olefin copolymer (COC)? A: Biocompatibility requires the absence of a pro-inflammatory response. Monitor the secretion of inflammatory cytokines from your intestinal epithelial and/or endothelial cells.

- Experimental Protocol: Multiplex Cytokine Profiling

- After a suitable culture period under flow (e.g., 7 days), collect effluent from the basal and apical compartments separately.

- Concentrate the effluent using centrifugal filters (e.g., 10 kDa MWCO).

- Use a multiplex bead-based immunoassay (e.g., Luminex) or ELISA to quantify key cytokines (IL-8, IL-6, IL-1β, TNF-α).

- Compare the secretion profile against cells cultured in a standard, well-plate format (static control) and a material control (e.g., tissue-culture treated polystyrene).

- Data Presentation: Cytokine Secretion Profile

Table 1: Inflammatory Cytokine Secretion (pg/mL/day) in Gut-on-Chip Models

| Chip Material | Cell Type | IL-8 | IL-6 | TNF-α |

|---|---|---|---|---|

| Polystyrene (TCPS Control) | Caco-2 epithelium | 120 ± 15 | 45 ± 8 | ND |

| PDMS (Standard) | Caco-2 epithelium | 280 ± 45 | 90 ± 12 | 5.2 ± 1.1 |

| COC (Novel) | Caco-2 epithelium | 135 ± 22 | 50 ± 9 | ND |

| PDMS + Pre-extraction | Caco-2 epithelium | 150 ± 30 | 55 ± 10 | ND |

ND: Not Detected. Data represents mean ± SD from n=3 chips.

Q4: My cardiac microtissues show reduced spontaneous beating frequency after 72 hours in the microfluidic device. How do I determine if this is a material issue or a medium/flow issue? A: Altered organ-specific function is a critical biocompatibility endpoint. A systematic material vs. environment test is needed.

- Troubleshooting Workflow:

- Control Experiment: Seed identical cardiac microtissues in a standard 96-well plate with the same medium batch. Monitor beating rate.

- Material-Only Test: Use a "static chip" setup—seed tissues in the chip but do not apply flow. Use passive diffusion for medium exchange in the reservoir. Compare beating to the well-plate control.

- Flow Rate Optimization: If the static chip shows normal beating, the issue may be shear stress. Re-introduce flow at a very low rate (e.g., 0.1 µL/min) and gradually increase.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents for Advanced Biocompatibility Assessment

| Item | Function in Biocompatibility Testing |

|---|---|

| AlamarBlue, PrestoBlue | Metabolic activity assay reagent. Measures reducing potential of cells, indicating metabolic health beyond simple membrane integrity. |

| Lactate Dehydrogenase (LDH) Kit | Measures LDH enzyme released upon membrane damage. A standard for quantifying cytotoxicity. |

| FITC or TRITC-conjugated Dextran | Sized permeability probes (e.g., 4, 20, 70 kDa) to assess barrier integrity in endothelial or epithelial layers. |

| Multiplex Cytokine Assay Panel | Enables simultaneous quantification of 10+ inflammatory markers from small volume samples to assess immune activation. |

| CellTracker Dyes (CMFDA, etc.) | Fluorescent cytoplasmic dyes for long-term cell tracking, viability assessment, and monitoring cell-cell interactions. |

| (3-Aminopropyl)triethoxysilane (APTES) | Silane coupling agent for covalently bonding biomolecules to glass, silicon, or metal oxide surfaces in chips. |

| Phalloidin (FITC/TRITC) | Stains filamentous actin (F-actin), crucial for visualizing cytoskeletal organization and stress in response to material surfaces. |

| Live/Dead Stain (Calcein AM / EthD-1) | Two-color fluorescence assay distinguishing live (green, calcein) from dead (red, ethidium homodimer) cells. |

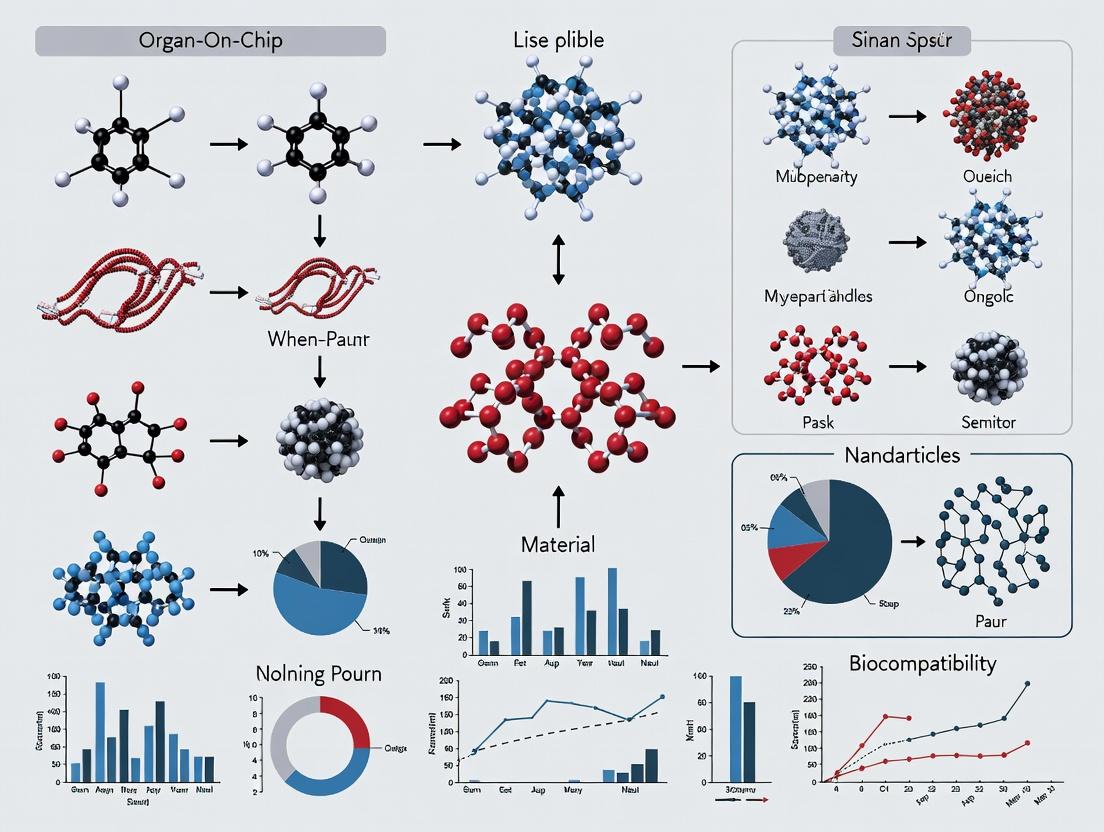

Visualization: Experimental Pathways & Workflows

Diagram 1: Material Biocompatibility Assessment Workflow

Diagram 2: Key Signaling Pathways in Cell-Material Interaction

Technical Support Center: Troubleshooting Biocompatibility in Organ-on-Chip Models

Frequently Asked Questions & Troubleshooting Guides

Q1: Our PDMS (Polydimethylsiloxane) device is absorbing small molecule drugs, skewing dose-response assays. How can we mitigate this? A: PDMS is highly porous and hydrophobic, leading to significant small molecule absorption. Implement one of these validated protocols:

- Protocol: Surface Coating with Parylene C.

- Clean and dry the fabricated PDMS device.

- Place in a vapor deposition system (e.g., Specialty Coating Systems PDS 2010).

- Deposit a 1-5 µm layer of Parylene C. Process parameters: Chamber pressure 0.1 Torr, vaporizer temp 175°C, pyrolysis furnace temp 690°C.

- Characterize coating uniformity via water contact angle (should increase from ~110° to ~90°) and FTIR for chemical signature.

- Alternative: Use a Non-Absorbing Barrier. Prime channels with a 0.1% (w/v) solution of Pluronic F-127 for 1 hour at 4°C to form a hydrophilic barrier, followed by extensive PBS rinse.

Q2: We observe poor cell adhesion on our pristine thermoplastic (PMMA/PS/COP) chips. What surface activation methods are recommended? A: Thermoplastics are inert and require surface activation to promote cell attachment.

- Protocol: Oxygen Plasma Treatment for Hydrophilicity.

- Place clean, dry thermoplastic chip in plasma cleaner chamber.

- Evacuate chamber to base pressure (<100 mTorr).

- Introduce oxygen gas at a flow rate of 20-50 sccm to maintain 200-500 mTorr.

- Apply RF power (50-100W) for 30-120 seconds.

- Critical Step: Immediately after venting the chamber, pipette your cell-compatible extracellular matrix (e.g., collagen I, fibronectin) into channels. The activated surface remains hydrophilic for <10 minutes in air.

Q3: Our photocrosslinked hydrogel (e.g., GelMA, PEGDA) structures are too weak or too dense for 3D cell culture. How do we tune mechanical properties? A: The elastic modulus (stiffness) is controlled by polymer concentration and crosslinking parameters.

- Protocol: Tuning GelMA Stiffness.

- Prepare GelMA precursor solutions at varying concentrations (e.g., 5%, 7%, 10% w/v) in PBS with 0.25% (w/v) lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) photoinitiator.

- For consistent 100 µm thick layers, use a spacer and glass coverslip.

- Crosslink using a 405 nm UV light source. Vary exposure energy: 2-10 J/cm² (e.g., 10 mW/cm² for 200-1000 seconds).

- Perform mechanical testing via microindentation or rheology. See Table 1 for expected properties.

Q4: Novel degradable polymers are releasing acidic byproducts, affecting cell viability in long-term cultures. How can this be buffered? A: This is common with polyesters like PLGA. Integrate a buffering system.

- Protocol: Incorporating HEPES Buffer into Culture Medium.

- Prepare your standard cell culture medium (e.g., DMEM).

- Add HEPES buffer at a final concentration of 25 mM.

- Adjust pH to 7.4 using NaOH.

- Note: This supplements the standard bicarbonate/CO₂ buffer system, providing stability against pH drops from degradation, especially in microenvironments with poor gas exchange.

Table 1: Key Material Properties & Biocompatibility Parameters

| Material Class | Example | Water Contact Angle (°) | Elastic Modulus | Small Molecule Absorption (Log P>2) | Primary Biocompatibility Concern | Recommended Coating/Mitigation |

|---|---|---|---|---|---|---|

| Elastomer | PDMS | 105-120 | 0.5-2 MPa | High | Hydrophobic absorption | Parylene C, Pluronic F-127 |

| Thermoplastic | PMMA | 65-80 | 2-3 GPa | Very Low | Poor cell adhesion | Oxygen Plasma + ECM |

| Thermoplastic | PS | 80-95 | 3-3.5 GPa | Very Low | Poor cell adhesion | Oxygen Plasma + ECM |

| Thermoplastic | COP | 80-90 | 2-2.5 GPa | Very Low | Autofluorescence | Gelatin/Matrigel coating |

| Hydrogel | GelMA (10%) | 10-30 (hydrated) | 5-20 kPa | Very Low | Batch-to-batch variability | Consistent UV crosslink protocol |

| Novel Polymer | PLGA (50:50) | 50-70 (dry) | 1-2 GPa | Medium | Acidic degradation products | HEPES-buffered medium |

Table 2: Surface Treatment Efficacy for Cell Adhesion (24h)

| Substrate | Treatment | Coating | Cell Type (Seeding Density) | Adhesion Efficiency (%) | Protocol Reference |

|---|---|---|---|---|---|

| Pristine PS | None | None | HUVEC (50k/cm²) | <10% | N/A |

| PS | O₂ Plasma | Collagen IV (50 µg/mL) | HUVEC (50k/cm²) | 92 ± 5% | Q2 Protocol |

| Pristine PDMS | None | Fibronectin (25 µg/mL) | Hepatocytes (100k/cm²) | 40 ± 8% | N/A |

| PDMS | Parylene C (2µm) | Fibronectin (25 µg/mL) | Hepatocytes (100k/cm²) | 85 ± 6% | Q1 Protocol |

Experimental Protocols

Protocol: Standardized Cytocompatibility Assay for Novel Polymers. Objective: Assess the impact of polymer degradation products on metabolic cell activity.

- Material Conditioning: Sterilize polymer samples (e.g., 5mm diameter discs) with 70% ethanol for 30 min. Wash 3x in sterile PBS.

- Leachate Preparation: Incubate each sample in 1 mL of complete cell culture medium (per ISO 10993-12) for 72 hours at 37°C. Use medium alone as a control.

- Cell Seeding: Seed a sensitive cell line (e.g., L929 fibroblasts or primary human fibroblasts) at 10,000 cells/well in a 96-well plate. Culture for 24 hours.

- Leachate Exposure: Aspirate medium from cells and replace with 100 µL of the prepared leachate or control medium. Incubate for 24-48 hours.

- Viability Assessment: Perform an MTT or AlamarBlue assay following manufacturer instructions. Measure absorbance/fluorescence.

- Analysis: Express viability relative to the control medium (set as 100%). A material is considered cytotoxic if viability is <70% (per ISO 10993-5).

Protocol: Assessing Protein Adsorption on Material Surfaces. Objective: Quantify nonspecific protein adsorption, a key indicator of fouling potential.

- Sample Preparation: Fabricate material samples with identical surface areas (e.g., 1 cm²). Clean and sterilize appropriately.

- Protein Solution: Prepare a 1 mg/mL solution of fluorescently tagged bovine serum albumin (BSA-FITC) in PBS.

- Incubation: Immerse each sample in 500 µL of the BSA-FITC solution. Protect from light and incubate at 37°C for 1 hour.

- Washing: Gently rinse samples 5 times in PBS to remove unbound protein.

- Elution: Place each sample in 1 mL of a 1% (w/v) SDS solution and shake vigorously for 1 hour to elute bound protein.

- Quantification: Measure the fluorescence of the eluate (ex: 495 nm, em: 519 nm). Compare against a standard curve of BSA-FITC to calculate the amount of protein adsorbed (µg/cm²).

Visualizations

Title: Biocompatibility Assessment Workflow for OOC Materials

Title: Material Selection & Mitigation Guide for OOC

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Biocompatibility Context | Example Product/Catalog # |

|---|---|---|

| Parylene C | Vapor-deposited polymer coating to create a chemically inert, non-absorbing barrier on PDMS. | Specialty Coating Systems, Daiso, or Para Tech Parylene C. |

| Pluronic F-127 | Non-ionic surfactant used to hydrophilize and passivate surfaces, reducing protein and small molecule adsorption. | Sigma-Aldrich P2443 (Poloxamer 407). |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Highly efficient, cytocompatible water-soluble photoinitiator for crosslinking hydrogels (e.g., GelMA) with visible/UV light. | Sigma-Aldrich 900889 or prepared in-lab. |

| Gelatin Methacryloyl (GelMA) | A tunable, photocrosslinkable hydrogel derived from collagen, ideal for 3D cell culture in OOC models. | Cellink GelMA, Advanced BioMatrix GelMA. |

| HEPES Buffer | A zwitterionic organic buffering agent used to maintain physiological pH in medium, countering acidic byproducts from degrading polymers. | Thermo Fisher Scientific 15630080. |

| AlamarBlue (Resazurin) | A redox indicator used to quantitatively measure cell viability and metabolic activity in cytotoxicity assays. | Thermo Fisher Scientific DAL1025. |

| Fluorescently-Tagged BSA (BSA-FITC) | Used to quantify nonspecific protein adsorption on material surfaces, a critical test for fouling potential. | Sigma-Aldrich A9771. |

| Oxygen Plasma Cleaner | System for activating thermoplastic surfaces to render them hydrophilic and amenable to protein/cell adhesion. | Harrick Plasma, Femto, or Diener Electronic systems. |

Technical Support Center

Troubleshooting Guides & FAQs

Q1: Our organ-on-chip device shows inconsistent drug response data. We suspect small molecule absorption into the chip material (e.g., PDMS). How can we confirm and quantify this? A: Inconsistent concentration due to absorption is a common issue. Perform a depletion assay.

- Protocol:

- Prepare a known concentration of your fluorescent or radio-labeled small molecule (e.g., 10 µM fluorescent dye like Rhodamine B or a drug of interest) in your standard perfusion medium.

- Perfuse the solution through your pristine, cell-free device at your standard flow rate. Collect effluent at timed intervals (e.g., every 15 min for 2 hours).

- Simultaneously, run the same solution through a chemically inert control system (e.g., glass tubing or a PTFE microfluidic chip).

- Measure the concentration in each effluent sample using a plate reader (fluorescence), LC-MS, or scintillation counter.

- Plot concentration in the effluent vs. time. A steady decline in concentration from your device, but not the inert control, confirms absorption.

- Quantitative Data Summary:

Q2: Protein fouling is clogging our microfluidic channels and creating an uncontrolled surface for cell growth. How can we measure fouling and what are effective surface treatments to prevent it? A: Fouling is measured by quantifying adsorbed protein. Prevention involves creating a hydrophilic, non-fouling barrier.

- Protocol for Quantifying Fouling (Micro-BCA Assay):

- After device perfusion with protein-containing medium (e.g., 10% serum), flush channels with PBS to remove non-adherent proteins.

- Fill channels with a commercially available micro-BCA working reagent.

- Incubate at 60°C for 1 hour. The purple reaction product intensity correlates with adsorbed protein mass.

- Collect the reagent, measure absorbance at 562 nm, and compare to a standard curve of known protein concentrations (BSA).

- Common Anti-Fouling Treatments:

Q3: How does surface hydrophobicity, often measured by water contact angle, directly correlate with protein adsorption and cell behavior in our experiments? A: Hydrophobicity drives non-specific protein adsorption, which mediates all subsequent cell-surface interactions.

- Key Relationship: Higher water contact angle (>90°) indicates hydrophobicity, which promotes rapid, denaturing adsorption of many serum proteins (e.g., albumin, fibronectin). This creates a fouled, pro-adhesive surface. Lower contact angle (<30°) indicates hydrophilicity, which resists protein adsorption, leading to less fouling and controlled cell adhesion only where specific ligands are patterned.

- Protocol for Static Water Contact Angle Measurement:

- Use a flat substrate made of the same material as your chip (e.g., PDMS slab, PS dish, COP slide).

- Ensure the surface is clean and dry.

- Using a micro-syringe, place a 2-5 µL droplet of deionized water on the surface.

- Immediately capture a side-view image with a goniometer camera.

- Use software to fit the droplet shape and calculate the angle at the three-phase (solid-liquid-vapor) contact point.

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function | Typical Use Case |

|---|---|---|

| Cyclic Olefin Polymer (COP) Chips | Alternative material with low small molecule absorption and low autofluorescence. | Replacing PDMS for critical drug transport studies or high-resolution imaging. |

| Polyethylene Glycol (PEG)-Based Cross-linker | Used to create hydrogel barriers or modify surface chemistry to resist fouling. | Creating membrane mimics or coating channels to prevent protein adhesion. |

| Fluorescent Small Molecule Tracers (e.g., Rhodamine B, Calcein) | High-visibility probes to visualize and quantify absorption and diffusion. | Performing the depletion assay to test new chip materials. |

| Micro-BCA Protein Assay Kit | Colorimetric assay for quantifying low levels of protein, suitable for microfluidics. | Measuring the degree of protein fouling on treated vs. untreated surfaces. |

| Phospholipid-PEG Conjugates | Forms stable, biomimetic, and non-fouling coatings on various surfaces. | Creating cell-membrane-like surfaces in vascular channels to prevent platelet adhesion. |

| Oxygen Plasma Cleaner | Briefly creates a hydrophilic silica-like layer on PDMS surfaces. | Pre-treatment for bonding and temporary hydrophilization before applying a more permanent coating. |

Experimental & Conceptual Diagrams

Pathway from Surface Property to OoC Failure

Troubleshooting Workflow for OoC Researchers

Technical Support Center

Troubleshooting Guide: Common Issues in Organ-on-Chip Phenotype Maintenance

Issue 1: Rapid Decline in Barrier Function (e.g., TEER)

- Q: The transepithelial/transendothelial electrical resistance (TEER) in my intestinal or blood-brain barrier model drops significantly after 3-4 days. What could be the cause?

- A: A sudden TEER decline often indicates a loss of tight junction integrity. Primary causes are:

- Material Leachates: Uncrosslinked monomers or degradation products from the chip polymer (e.g., PDMS, plastics) can be cytotoxic. Solution: Implement rigorous pre-conditioning (e.g., autoclaving, extended media incubation, or albumin coating). Consider switching to alternative materials like cyclic olefin copolymer (COC) or polystyrene.

- Shear Stress Mismatch: Incorrect fluidic flow rates. Excess shear can damage cells; too little can fail to induce proper differentiation. Solution: Recalculate and calibrate flow rates to achieve physiologically relevant shear stress (typically 0.5 - 4 dyn/cm² for endothelium). Refer to Table 1.

- Contamination: Low-level bacterial or fungal contamination. Solution: Use antibiotic/antimycotic agents during setup and perform sterility checks.

- A: A sudden TEER decline often indicates a loss of tight junction integrity. Primary causes are:

Issue 2: Altered Cellular Metabolism

- Q: My glucose consumption and lactate production rates are abnormally high/low compared to in vivo references. Is this a problem with the cells or the system?

- A: Metabolic shifts frequently reflect the cellular microenvironment.

- Hypoxic Core: In thick 3D structures, poor medium perfusion can create a hypoxic core, shifting metabolism to glycolysis. Solution: Optimize tissue seeding density and increase perfusion rate to improve oxygen/nutrient delivery. Monitor oxygen levels with sensor foils.

- Material Interaction: Some materials (like PDMS) can absorb small hydrophobic molecules (e.g., hormones, drugs), starving cells of key metabolites or signaling molecules. Solution: Pre-saturate channels by incubating with media or use non-absorbent materials. See "Research Reagent Solutions" below.

- Incorrect Differentiation: The cells may not be fully matured. Solution: Verify differentiation protocol completeness and duration. Use qPCR for metabolic enzyme markers (e.g., GLUT1, PCK1).

- A: Metabolic shifts frequently reflect the cellular microenvironment.

Issue 3: Failure to Achieve or Maintain Differentiation

- Q: My primary hepatocytes lose CYP450 expression, or my stem cell-derived cells do not reach a mature state within the chip.

- A: Differentiation is sensitive to biochemical and mechanical cues.

- Missing Soluble Factors: The microfluidic environment may dilute or sequester growth factors. Solution: Increase the concentration of critical morphogens (e.g., BMP, FGF, Wnt agonists) in your differentiation medium or use a continuous, lower-dose perfusion.

- Lack of 3D Matrix Cues: Cells plated on flat plastic may not receive proper spatial signals. Solution: Incorporate a physiologically relevant hydrogel (e.g., collagen I, Matrigel, laminin) into the culture chamber. See Table 2.

- Inadequate Co-culture Signaling: The phenotype may depend on signals from a missing partner cell type. Solution: Introduce relevant stromal or immune cells in a compartmentalized co-culture setup.

- A: Differentiation is sensitive to biochemical and mechanical cues.

Frequently Asked Questions (FAQs)

Q: How often should I change the medium in a perfused organ-on-chip system?

- A: In continuous perfusion systems, the "change" is constant. The key parameter is the refresh rate, typically calculated to replace the reservoir volume every 12-24 hours. For a 10 mL reservoir and a desired 24-hour refresh, set the flow rate to ~7 µL/min.

Q: What is the best way to validate material biocompatibility for my specific organ model?

- A: Perform a tiered assay:

- Viability: Measure ATP content or Calcein-AM staining after 72h of static material exposure.

- Function: For barrier models, measure TEER over time. For metabolic cells, assay albumin (liver) or insulin (pancreas) production.

- Genomics: Run a targeted PCR array for stress response (e.g., oxidative stress, ER stress) and phenotype-specific genes.

- A: Perform a tiered assay:

Q: Can I use standard well-plate assay kits on chip-cultured cells?

- A: Often, but with caveats. Lysate-based assays (ELISA, qPCR) are usually transferable. Live-cell imaging may require adaptation of working distances. Plate reader assays may need adjustment as cell numbers per chip are lower. Always normalize to total DNA or protein content.

Data Presentation

Table 1: Physiologically Relevant Shear Stress and Flow Rates for Common Barrier Models

| Tissue Type | Approximate Shear Stress | Calculated Flow Rate (for a 1000 µm x 100 µm channel) | Primary Function Impacted |

|---|---|---|---|

| Vascular Endothelium (Arterial) | 10 - 30 dyn/cm² | 0.5 - 1.5 mL/min | Alignment, Anti-inflammatory State |

| Vascular Endothelium (Venous) | 1 - 6 dyn/cm² | 0.05 - 0.3 mL/min | Leukocyte Adhesion |

| Intestinal Epithelium | 0.2 - 2 dyn/cm² | 0.01 - 0.1 mL/min | Villi Differentiation, Mucus Production |

| Renal Tubule Epithelium | 0.1 - 1 dyn/cm² | 0.005 - 0.05 mL/min | Ion Transport, Differentiation |

| Blood-Brain Barrier Endothelium | 0.5 - 4 dyn/cm² | 0.025 - 0.2 mL/min | Tight Junction Formation, Transporter Expression |

Table 2: Impact of Common Hydrogel Matrices on Cell Phenotype

| Hydrogel | Key Components | Typical Use | Impact on Differentiation & Function |

|---|---|---|---|

| Collagen I | Fibrillar collagen | Liver, Kidney, Fibroblast co-culture | Promotes epithelial polarity and 3D morphogenesis. |

| Matrigel | Laminin, Collagen IV, Entactin | Angiogenesis, Glandular epithelia | Induces complex tubulogenesis and gland formation. Batch variability is high. |

| Fibrin | Fibrinogen, Thrombin | Vascular models, Wound healing | Excellent for endothelial network formation; biodegradable. |

| Hyaluronic Acid (HA) | Glycosaminoglycan | Neural, Cartilage, Stromal niches | Mimics soft tissue ECM; can be functionalized with peptides. |

| Polyethylene Glycol (PEG) | Synthetic polymer | Defined, tunable mechanical studies | Bio-inert baseline; requires RGD peptide conjugation for cell adhesion. |

Experimental Protocols

Protocol: Standardized Biocompatibility Assessment of Chip Materials Objective: To evaluate the impact of a novel chip material on hepatocyte barrier function (albumin production) and metabolic competence (CYP3A4 activity).

- Material Pre-conditioning: Cut test material into 1 cm² coupons. Sterilize (ethanol or UV). Incubate in complete hepatocyte culture medium for 72 hours at 37°C to leach potential contaminants.

- Cell Seeding: Seed primary human hepatocytes (e.g., HepaRG) at 2.5 x 10⁵ cells/cm² onto collagen I-coated material coupons and a standard tissue culture plastic (TCP) control.

- Culture: Maintain in hepatocyte maintenance medium under static conditions for 48 hours.

- Functional Assays:

- Albumin ELISA: Collect 48-hour conditioned medium. Use a human albumin ELISA kit following manufacturer instructions. Normalize secretion to total cellular protein (BCA assay).

- CYP3A4 Activity (Luminogenic Assay): Incubate cells with a substrate (e.g., luciferin-IPA) for 2 hours. Measure luminescence in the medium. Treat cells on TCP with 50 µM rifampicin for 48h as a positive induction control.

- Analysis: Express data from material coupons as a percentage of the TCP control. A biocompatible material should support >70% of control albumin and CYP3A4 activity.

Protocol: Establishing a Differentiated Intestinal Barrier with Continuous Flow Objective: To culture and differentiate Caco-2 cells into a high-integrity intestinal barrier with physiological TEER values.

- Chip Preparation: Prime microfluidic channels (e.g., 1 mm wide, 100 µm high) with 50 µg/mL collagen IV in PBS for 1 hour at 37°C.

- Cell Seeding: Trypsinize and resuspend Caco-2 cells at 10 x 10⁶ cells/mL. Introduce 20 µL of suspension into the apical channel, allowing cells to attach for 20 minutes under static, inverted conditions.

- Initial Culture: Connect chip to perfusion system. Flow complete medium (DMEM + 10% FBS) through the basal channel at a low shear stress (0.02 dyn/cm²) for 48 hours.

- Differentiation & Flow Ramp-Up: Switch to differentiation medium (DMEM + 1% FBS). Gradually increase basal flow rate over 7 days to achieve a target shear of 0.5 dyn/cm². Maintain for an additional 14-21 days.

- Monitoring: Measure TEER every 2-3 days using integrated or chopstick electrodes. Expect TEER to plateau between 800 - 1500 Ω·cm² for a mature barrier.

Diagrams

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Function & Rationale | Example Use Case |

|---|---|---|

| Cyclic Olefin Copolymer (COC) | A non-absorbent, optically clear thermoplastic. Alternative to PDMS to prevent small molecule loss. | Drug absorption studies in liver-on-chip models. |

| Polydimethylsiloxane (PDMS) Pre-polymer | The standard elastomer for rapid prototyping. Must be thoroughly cured and pre-conditioned. | Fabrication of custom microfluidic device geometries. |

| Matrigel (GFR, Phenol Red-Free) | Basement membrane extract providing complex ECM for 3D growth. GFR and dye-free versions reduce interference. | Establishing tubules in kidney or angiogenesis models. |

| Transepithelial Electrical Resistance (TEER) Electrodes | Sterilizable electrodes (chopstick or integrated) to quantify tight junction integrity in real-time. | Monitoring maturation of intestinal or BBB barriers. |

| PBS with 0.1% BSA (Bovine Serum Albumin) | Pre-conditioning and blocking solution. BSA saturates hydrophobic binding sites on materials like PDMS. | Pre-treating microfluidic channels before cell seeding to prevent analyte absorption. |

| Shear Stress Calculator Spreadsheet | Tool to convert desired shear stress (dyn/cm²) into required flow rate (µL/min) based on channel geometry. | Setting up physiological flow for any new chip design. |

| Live/Dead Viability/Cytotoxicity Kit | Dual fluorescent stain (Calcein-AM/EthD-1) for immediate assessment of material toxicity. | Initial biocompatibility screening of a new 3D-printed resin. |

| CYP450-Glo Assay | Luminescent, cell-based assay to measure specific cytochrome P450 enzyme activity. | Evaluating metabolic function of hepatocytes in a chip post-drug exposure. |

Technical Support Center: Troubleshooting Biocompatibility in Organ-on-Chip Models

This support center addresses common technical challenges encountered while establishing material biocompatibility for organ-on-chip (OoC) models, a critical step in validating these platforms for regulatory acceptance and translational drug development.

Frequently Asked Questions (FAQs)

Q1: Our polydimethylsiloxane (PDMS) chip is absorbing our small-molecule drug candidate, leading to inconsistent pharmacokinetic data. How can we mitigate this? A: PDMS is highly hydrophobic and prone to absorbing small lipophilic compounds. Consider these solutions:

- Surface Coating: Apply a thin, inert coating like parylene-C via chemical vapor deposition. This creates a barrier that reduces absorption.

- Material Alternative: Transition to thermoplastic polymers (e.g., cyclo-olefin polymer/copolymer) that have lower binding properties.

- Protocol Adjustment: Pre-saturate the PDMS channels by flowing a high-concentration solution of the compound prior to the experiment, or include bovine serum albumin (BSA) in the medium to act as a carrier.

Q2: We observe inconsistent cell adhesion and viability in our 3D hydrogel culture within the chip. What are the key factors to check? A: Inconsistent 3D culture often stems from hydrogel preparation or sterilization issues.

- Crosslinking Consistency: Ensure precise control over crosslinker concentration (e.g., APS/TEMED for collagen) and gelation time/temperature.

- Sterilization Method: Avoid autoclaving or ethanol sterilization for many hydrogels, as it degrades the matrix. Use sterile filtration of precursor solutions or UV sterilization of the assembled chip.

- Degradation Test: Check for unexpected degradation of the hydrogel by your cell type over time by measuring released glycosaminoglycans or using fluorescence-tagged matrix proteins.

Q3: How do we rigorously test for leachates from our chip materials, and what are the acceptable thresholds? A: Leachate testing is mandatory for regulatory filing. Implement a two-step protocol:

- Extraction: Follow ISO 10993-12 guidelines. Immerse chip material samples in cell culture medium (surface area to volume ratio of 3 cm²/mL) and incubate at 37°C for 24-72 hours.

- Analysis: Use liquid chromatography-mass spectrometry (LC-MS) for unidentified leachates or targeted assays for known monomers (e.g., bisphenol A from plastics). Compare cytotoxicity of leachate-laden medium vs. fresh medium using a sensitive assay like ATP quantification.

Q4: Our endothelial barrier on the chip does not achieve a sufficiently high Transendothelial Electrical Resistance (TEER). What troubleshooting steps should we follow? A: Low TEER indicates a leaky, immature barrier. Address the following:

- Surface Treatment: Optimize extracellular matrix (ECM) coating (e.g., collagen IV, fibronectin) concentration and incubation time.

- Shear Stress: Apply physiological laminar flow. Barrier function often matures under continuous, appropriate shear stress (e.g., 1-10 dyn/cm² for endothelium).

- Cell Source: Confirm the quality and passage number of your primary endothelial cells. Use early passages (< P8) and pre-validate barrier formation in standard Transwell assays first.

Experimental Protocols for Key Biocompatibility Assays

Protocol 1: Direct Cytotoxicity Testing per ISO 10993-5 (Elution Test Method)

- Sample Preparation: Prepare a sterile extract of your OoC material (as in FAQ A3) using complete cell culture medium as the extraction vehicle.

- Cell Seeding: Seed relevant cells (e.g., primary hepatocytes for a liver chip) in a 96-well plate at a density of 1x10⁴ cells/well. Culture for 24 hours.

- Exposure: Replace the medium in test wells with 100 µL of the material extract. Use fresh medium as a negative control and medium with 0.1% Triton X-100 as a positive control.

- Incubation: Incubate cells with extracts for 24-48 hours at 37°C, 5% CO₂.

- Viability Assessment: Perform an MTT or PrestoBlue assay. Aspirate medium, add reagent diluted in fresh medium, incubate for 1-4 hours, and measure absorbance/fluorescence.

- Calculation: Calculate cell viability as a percentage of the negative control. A reduction in viability by more than 30% is considered a cytotoxic effect.

Protocol 2: Quantifying Adsorption of a Compound to Chip Materials

- Standard Curve: Prepare a standard curve of your test compound in the intended perfusion medium (e.g., 0.1, 1, 10, 100 µM).

- Setup: Prime your OoC device with medium according to standard protocol.

- Perfusion & Sampling: Perfuse a known concentration (C_initial) of the compound through the device at the intended flow rate. Collect effluent from the outlet at regular time intervals (e.g., every 15 min for 2 hours).

- Analysis: Quantify the compound concentration in each effluent sample (C_effluent) using HPLC or LC-MS.

- Modeling: Plot Ceffluent/Cinitial vs. time. A steady-state ratio <1 indicates adsorption. Fit data to a non-linear adsorption model to calculate the adsorption coefficient.

Data Presentation: Biocompatibility Benchmarking

Table 1: Common OoC Material Properties & Biocompatibility Considerations

| Material | Key Advantage | Primary Biocompatibility Concern | Typical Application | Recommended Mitigation Strategy |

|---|---|---|---|---|

| PDMS | Gas permeability, optical clarity | Absorption of small molecules | Barrier models, lung alveoli | Parylene coating, use of thermoplastics |

| Polycarbonate (PC) | Rigidity, low cost | Potential for BPA leaching | Fluidic layers, housings | Use medical-grade, BPA-free variants |

| Cyclo-olefin Polymer (COP) | Low autofluorescence, low binding | Hydrophobicity (requires treatment) | Microfluidic channels, mass spec integration | Oxygen plasma treatment for hydrophilicity |

| Poly(methyl methacrylate) (PMMA) | Excellent optical clarity | Susceptibility to solvent cracking | Optical detection windows | Compatible with aqueous solutions only |

| Agarose/Collagen Hydrogels | Tunable stiffness, natural ECM | Batch-to-batch variability, degradation | 3D cell encapsulation, stromal layers | Source from reliable vendors, crosslink tuning |

Table 2: Acceptable Ranges for Key OoC Validation Metrics

| Validation Metric | Target Range (General Physiology) | Method | Frequency of Testing (Recommendation) |

|---|---|---|---|

| TEER (for barriers) | >1000 Ω·cm² (e.g., BBB) 50-100 Ω·cm² (e.g., Proximal Tubule) | Integrated or chopstick electrodes | Every experiment, real-time possible |

| Albumin Production (Liver) | 5-20 µg/day/10⁶ hepatocytes | ELISA | Endpoint or daily effluent sampling |

| Glomerular Filtration Rate (Kidney) | ~100 nL/min/glomerulus | Inulin-FITC clearance assay | Endpoint or periodic challenge |

| Beat Rate (Cardiac) | 0.5-2 Hz (species dependent) | Video analysis, MEAs | Continuous monitoring |

| Lactate Dehydrogenase (LDH) Release | <10% increase over negative control | Colorimetric assay (medium) | Endpoint, or periodic for chronic studies |

Visualizations

Title: OoC Material Biocompatibility Assessment Workflow

Title: Cellular Pathways Activated by Material Leachates

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for OoC Biocompatibility Testing

| Item | Function in Biocompatibility Context | Example Product/Type |

|---|---|---|

| AlamarBlue/CellTiter-Glo | Quantifies metabolic activity/ATP content for cytotoxicity. More sensitive than MTT for long-term or 3D cultures. | Thermo Fisher Scientific, Promega |

| Recombinant Human Collagen IV | Provides a defined, consistent ECM coating for endothelial and epithelial barriers, reducing batch variability. | Advanced Biomatrix |

| Parylene-C Dimers | For creating inert, conformal vapor-deposited coatings inside PDMS devices to prevent small molecule absorption. | Specialty Coating Systems |

| Inulin-FITC | A clinically relevant filtration marker for quantifying glomerular filtration rate (GFR) in kidney chips. | Sigma-Aldrich |

| LC-MS Grade Solvents | Essential for leachate analysis and adsorption studies to avoid background contamination. | Fisher Chemical, Honeywell |

| LIVE/DEAD Viability/Cytotoxicity Kit | Dual-fluorescence staining for simultaneous visualization of live (calcein-AM) and dead (EthD-1) cells in situ. | Thermo Fisher Scientific |

| Human Cytokine Multiplex Array | Profiles a panel of inflammatory cytokines (e.g., IL-1β, IL-6, TNF-α) to assess immune activation by materials. | Bio-Rad, Millipore |

| TEER Measurement Electrodes | Ag/AgCl electrodes (chopstick or integrated) for non-destructive, real-time barrier integrity monitoring. | World Precision Instruments |

From Theory to Fabrication: Practical Strategies for Biocompatible OOC Design

Technical Support Center: Troubleshooting & FAQs

FAQ 1: My endothelial monolayer on PDMS shows poor barrier function (low TEER). What could be wrong and how can I fix it?

- Answer: This is a common issue due to PDMS's high hydrophobicity and tendency to absorb small molecules. First, ensure rigorous surface activation. Use an oxygen plasma treatment (100W, 30 seconds) followed by immediate coating with 50 µg/mL fibronectin in PBS for 1 hour at 37°C. If the problem persists, consider switching to a more hydrophilic substrate like polystyrene or a coated thermoplastic polyurethane (TPU). Pre-treating PDMS with Pluronic F-127 (0.1% w/v) can also minimize protein denaturation.

FAQ 2: My hydrogel for a liver-on-chip model degrades too quickly, losing 3D structure within 48 hours. How do I modulate stability?

- Answer: Rapid degradation typically indicates a mismatch between hydrogel crosslinking density and enzymatic activity in your cell culture. For a collagen-based hydrogel, increase the polymerization concentration from 2 mg/mL to 4-6 mg/mL. For synthetic hydrogels like PEG, you can adjust the molecular weight of the crosslinker. Use a peptide crosslinker with a sequence cleavable by MMPs (e.g., GPQGIWGQ) but increase its molar ratio from 1:1 to 2:1 (crosslinker: PEG-vinyl sulfone) during synthesis to enhance initial stability.

FAQ 3: I observe nonspecific protein adsorption on my chip's channels, causing background noise in my assays. How can I prevent this?

- Answer: Nonspecific adsorption is often a material surface chemistry issue. Implement a post-fabrication passivation protocol. For polymers like PDMS, PMMA, or COP, a continuous 2-hour flush with a 1% (w/v) solution of bovine serum albumin (BSA) or 0.1% Pluronic F-68 can block hydrophobic sites. For long-term culture, consider covalent grafting of poly(ethylene glycol) (PEG-silane for glass/oxide surfaces) to create a non-fouling brush layer.

FAQ 4: My cardiac microtissue shows weak and asynchronous beating on a polystyrene chip. Could the material stiffness be the cause?

- Answer: Absolutely. Mature cardiomyocytes require a substrate stiffness that mimics native cardiac tissue (~10-20 kPa). Standard polystyrene dishes are orders of magnitude stiffer (~3 GPa). Solution: Fabricate your chip using a soft hydrogel as the functional layer. A 7-10 mg/mL fibrin or collagen-I hydrogel cast onto anchor points can provide the necessary mechanical compliance. Alternatively, use a thin membrane of PDMS (with a 30:1 base-to-curing agent ratio for softer ~0.5-1 MPa modulus) coated with laminin.

Polymer Property Comparison Table

Table 1: Key Polymer Properties for Organ-on-Chip Applications

| Polymer | Young's Modulus (Approx.) | Key Advantages | Organ-Specific Limitations | Primary Use Case |

|---|---|---|---|---|

| Polydimethylsiloxane (PDMS) | 0.5 - 4 MPa | Gas-permeable, optically clear, easy to mold. | Hydrophobic, absorbs small drugs, not mass-producible. | Lung/Alveolus, Gut (barrier models), prototyping. |

| Polystyrene (PS) | 2 - 4 GPa | Excellent optical clarity, rigid, low-cost. | Too stiff for soft tissues, non-permeable. | Liver (metabolism studies), commercial cell culture inserts. |

| Poly(methyl methacrylate) (PMMA) | 2 - 3 GPa | Stiff, good clarity, low autofluorescence. | Brittle, poor chemical resistance. | Blood-brain barrier models (with porous membranes). |

| Cyclic Olefin Copolymer (COP) | 2 - 3 GPa | Low protein binding, high clarity, good for molding. | Low gas permeability, relatively stiff. | Kidney tubule models, commercial microfluidic devices. |

| Polyurethane (PU) / Thermoplastic PU | 5 MPa - 1 GPa | Tunable elasticity, good fatigue resistance. | Can hydrolyze, requires coating for cytocompatibility. | Heart (beating myocardium), muscle constructs. |

| Polyethylene Glycol (PEG) Hydrogel | 0.1 - 100 kPa | Bio-inert, tunable stiffness, modular biofunctionalization. | Non-adhesive without RGD peptides, can resist cell spreading. | 3D Cancer models, neural networks, stem cell niches. |

| Collagen-I Hydrogel | 0.1 - 5 kPa | Native ECM, fully biocompatible and biodegradable. | Batch variability, low mechanical strength at physiological temps. | Connective tissues, lobular liver models, stroma. |

Detailed Experimental Protocol: Evaluating Polymer Biocompatibility & Function

Protocol: Assessing Barrier Integrity on a Candidate Polymer Surface Objective: To quantitatively compare the suitability of different polymer substrates for forming a tight endothelial barrier. Materials: PDMS (Sylgard 184), COP film, 24-well plates, oxygen plasma cleaner, fibronectin, human umbilical vein endothelial cells (HUVECs), transwell inserts (optional), EVOM2 voltmeter with STX2 electrodes. Procedure:

- Fabrication: Cast PDMS (10:1 ratio) at 5 mm thickness and bond to well plates. For COP, use laser-cut film bonded via solvent welding.

- Surface Treatment: Treat PDMS with O₂ plasma (100W, 30s). Coat all substrates with 50 µg/mL fibronectin for 1h at 37°C.

- Cell Seeding: Seed HUVECs at a density of 100,000 cells/cm². Allow adhesion for 6h.

- TEER Measurement: Place electrodes on either side of the substrate/membrane. Measure Transendothelial Electrical Resistance (TEER) daily for 72h. Record values in Ω·cm².

- Data Analysis: Normalize Day 0 TEER. Plot TEER over time. A stable or increasing TEER >500 Ω·cm² indicates good barrier formation on that substrate.

Visualization: Experiment Workflow & Pathway

Workflow for Polymer Evaluation in Organ-on-Chip

Mechanotransduction from Polymer to Cell Fate

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Polymer-Based Organ-on-Chip Research

| Item | Function | Example & Notes |

|---|---|---|

| Sylgard 184 | Silicone elastomer kit for fabricating gas-permeable, flexible chips. | The standard for rapid PDMS prototyping. Use a 10:1 base:curing agent ratio for cell culture. |

| Pluronic F-127 | Non-ionic surfactant for blocking hydrophobic surfaces. | 0.1-1% solution passivates PDMS to reduce protein/cell adhesion. |

| PEG-Silane | Covalent grafting agent for creating non-fouling surfaces. | (e.g., (m)PEG-silane) Used to render glass or oxide surfaces resistant to protein adsorption. |

| Fibronectin | Extracellular matrix protein coating for cell adhesion. | Critical for endothelial and epithelial cell attachment on synthetic polymers. Use 5-50 µg/mL. |

| Type I Collagen, Rat Tail | Natural hydrogel polymer for 3D soft tissue constructs. | Neutralize on ice with NaOH/HEPES to form gels at 37°C. Concentration dictates stiffness. |

| 8-well Chambered Coverslips (µ-Slide) | Ready-made, optically superior polymer (ibiTreat) surfaces. | Polystyrene-like, plasma-treated for consistent cell culture in imaging experiments. |

| Poly-D-Lysine | Positively charged polymer coating for neuronal cell adhesion. | Essential for glial and neuron attachment, often used under laminin on stiff substrates. |

| EVOM2 with STX2 Electrodes | Voltmeter for measuring Transendothelial/Epithelial Electrical Resistance (TEER). | Gold standard for quantifying real-time barrier integrity on permeable supports. |

| RGD Peptide (GRGDSP) | Synthetic peptide for integrin-mediated cell adhesion in inert hydrogels. | Must be covalently coupled (e.g., to PEG hydrogels) to enable cell spreading and survival. |

Technical Support Center

Troubleshooting Guide: Common Issues in Surface Modification for Organ-on-Chip Models

Issue 1: Inconsistent Hydrophilicity After Plasma Treatment

- Problem: Water contact angle measurements vary across the polydimethylsiloxane (PDMS) surface after oxygen plasma treatment, leading to uneven cell adhesion in microfluidic channels.

- Diagnosis & Solution:

- Cause A: Hydrophobic recovery over time.

- Solution: Use the treated surfaces immediately (within 1 hour) for bonding or coating. For delayed use, store in deionized water or apply an intermediate hydrophilic coating post-treatment.

- Cause B: Contamination from air or handling.

- Solution: Ensure cleanroom conditions or a laminar flow hood. Use only clean, powder-free gloves and plasma-clean sample holders.

- Cause C: Uneven plasma field in the chamber.

- Solution: Do not overload the chamber. Ensure samples are placed parallel to the electrodes and rotate samples midway if the system allows.

- Cause A: Hydrophobic recovery over time.

Issue 2: Poor or Unstable Chemical Coating (e.g., PLL-g-PEG) on Plasma-Activated Surfaces

- Problem: Coating appears non-uniform under fluorescence tagging, or protein adsorption/cell attachment increases over time, indicating coating failure.

- Diagnosis & Solution:

- Cause A: Insufficient plasma activation.

- Solution: Optimize plasma parameters. Standardize treatment time (e.g., 60 seconds) and power (e.g., 50-100W). Confirm activation by achieving a water contact angle <10°.

- Cause B: Incorrect coating solution pH or ionic strength.

- Solution: Prepare coating solutions exactly as per protocol using recommended buffers (e.g., 10 mM HEPES, pH 7.4). Filter sterilize (0.22 µm) before use.

- Cause C: Inadequate rinsing post-coating.

- Solution: Rinse coated surfaces vigorously (3x5 min) with the coating buffer to remove physically adsorbed polymers.

- Cause A: Insufficient plasma activation.

Issue 3: Low Bio-functionalization Efficiency (e.g., RGD Peptide Coupling)

- Problem: Expected cellular response (e.g., spreading, integrin signaling) is not observed despite protocol adherence.

- Diagnosis & Solution:

- Cause A: Loss of reactive surface groups during storage or handling.

- Solution: For silane-based chemistry, use freshly prepared anhydrous solutions and control humidity during coupling. Coat and functionalize in a sequential, uninterrupted workflow.

- Cause B: Quenching step is inefficient, leading to non-specific binding.

- Solution: After ligand coupling, incubate surfaces with a high-concentration quenching agent (e.g., 1M ethanolamine hydrochloride for NHS esters, 100 mM glycine for aldehydes) for at least 1 hour.

- Cause C: Ligand density is outside the optimal range.

- Solution: Titrate the concentration of the bioactive ligand in the coupling solution. Use a fluorescently tagged version to quantify surface density via fluorescence microscopy or spectroscopy.

- Cause A: Loss of reactive surface groups during storage or handling.

Frequently Asked Questions (FAQs)

Q1: What is the optimal plasma treatment duration and power for PDMS to achieve stable bonding and surface activation for coatings?

A: The optimal settings depend on your specific chamber. A common starting point is 50-100W for 45-60 seconds using oxygen gas at a medium flow rate (e.g., 20 sccm). This typically creates a stable hydrophilic silica-like layer. Over-treatment (>120s at high power) can cause cracking. Always calibrate using water contact angle measurement, aiming for an immediate post-treatment angle of <10°.

Q2: How can I quantify the success of my bio-functionalization (e.g., collagen or fibronectin grafting)?

A: Several direct and indirect methods are available:

- Direct: Use fluorescently tagged proteins/peptides and measure surface fluorescence with a microscope or plate reader. Include control surfaces without coupling chemistry.

- Indirect: Perform a protein adsorption assay (e.g., BCA assay) on the coated surface. A successful bio-inert coating (like PLL-g-PEG) will show >90% reduction in albumin adsorption compared to bare PDMS.

- Functional: Seed relevant cells and measure attachment efficiency (%) at 2-4 hours or assess spreading area at 24 hours.

Q3: My organ-on-chip device has complex 3D channels. How can I ensure uniform coating throughout the entire lumen?

A: For internal channel coating, dynamic coating is essential.

- Procedure: Introduce the coating solution into the inlet port.

- Apply a slight negative pressure at the outlet or positive pressure at the inlet to prime the channels.

- Incubate statically for the required time (e.g., 1 hour for proteins).

- Crucially, flush the channels with gentle flow (e.g., 5-10 µL/min for 10 minutes) using coating buffer to remove aggregates and ensure uniform deposition. Avoid air bubbles.

Q4: Can I sterilize surfaces after bio-functionalization? What is the recommended method?

A: Sterilization must be compatible with your coating. UV sterilization (30-60 min) is generally safe for most protein and peptide coatings. Ethanol (70%) exposure can denature some proteins and is not recommended for specific ligand coatings. For chemically inert coatings (like silanes), autoclaving may be possible. The gold standard is to perform surface modification under sterile conditions using filter-sterilized solutions in a biosafety cabinet.

Table 1: Efficacy of Common Surface Modifications in Reducing Non-Specific Protein Adsorption

| Modification Technique | Substrate | Coating/ Treatment | Protein Tested | Reduction in Adsorption vs. Untreated Control | Key Measurement Method |

|---|---|---|---|---|---|

| Plasma + Graft Co-polymer | PDMS | O2 Plasma + PLL(20)-g[3.5]-PEG(2) | Fibrinogen | 95-98% | Fluorescence (FITC-label) |

| Chemical Vapor Deposition | Glass | Silane-PEG | Bovine Serum Albumin | 90-95% | Radiolabeling (I-125) |

| Bio-functionalization | PS | Collagen I (covalent) | N/A (Promoted specific binding) | - | Cell Adhesion Assay (>80% attachment) |

| Plasma Polymerization | TCPS | Acrylic Acid Plasma Polymer | Fibronectin | Controlled increase | ELISA |

Table 2: Impact of Plasma Treatment Parameters on PDMS Surface Properties

| Plasma Gas | Power (W) | Time (s) | Immediate Water Contact Angle (°) | Contact Angle After 24h (°) | Bond Strength (kPa)* |

|---|---|---|---|---|---|

| Oxygen | 50 | 30 | ~15 | ~60 | 350 |

| Oxygen | 50 | 60 | ~5 | ~45 | 480 |

| Oxygen | 100 | 30 | ~10 | ~70 | 400 |

| Oxygen | 100 | 60 | <5 | ~65 | 450 |

| Air | 50 | 60 | ~20 | ~80 | 300 |

| *Bond strength to a glass slide after immediate contact. Values are illustrative. |

Experimental Protocols

Protocol 1: Oxygen Plasma Treatment for PDMS-PDMS or PDMS-Glass Bonding

Objective: To create irreversible sealing and a hydrophilic surface on PDMS. Materials: PDMS slabs/chips, oxygen gas, plasma cleaner, glass slides or other PDMS slabs. Procedure:

- Clean PDMS and glass/PDMS counterpart with isopropanol and dry with filtered air or nitrogen.

- Place samples in the plasma chamber, ensuring surfaces to be bonded are facing up and unobstructed.

- Set parameters: Gas: O2, Flow rate: 20 sccm, Pressure: 0.3-0.6 mbar, Power: 50W, Time: 60 seconds.

- Start the process. Immediately after venting the chamber, carefully remove samples.

- For bonding: Bring the activated surfaces into conformal contact immediately. Apply gentle, even pressure. The bond is instantaneous.

- For coating: Proceed to the next coating step within 10 minutes to prevent hydrophobic recovery.

Protocol 2: Grafting of PLL-g-PEG for Creating Bio-inert Surfaces

Objective: To passivate a plasma-activated surface against non-specific protein and cell adhesion. Materials: Plasma-treated substrate, PLL(20)-g[3.5]-PEG(2) stock solution (1 mg/mL in HEPES), 10 mM HEPES buffer (pH 7.4), sterile filtration unit (0.22 µm). Procedure:

- Prepare the coating solution by diluting PLL-g-PEG stock to 0.1 mg/mL in filter-sterilized 10 mM HEPES buffer.

- Immediately after plasma treatment, place the substrate in a well or directly pipette the solution onto the surface, ensuring complete coverage.

- Incubate for 1 hour at room temperature in a humid environment to prevent evaporation.

- Rinse the surface thoroughly three times for 5 minutes each with copious amounts of HEPES buffer to remove loosely adsorbed copolymer.

- Use immediately for cell culture or store in sterile PBS for up to 24 hours at 4°C.

Protocol 3: Covalent Bio-functionalization with RGD Peptide via Sulfo-SANPAH Crosslinking

Objective: To graft the cell-adhesive peptide RGD onto a hydrogel or polymer surface. Materials: PLL-g-PEG coated or other hydroxyl/amine-rich surface, Sulfo-SANPAH, RGD peptide (e.g., GCGYGRGDSPG), PBS (pH 7.4), UV lamp (or strong visible light source). Procedure:

- Hydrate the substrate in PBS.

- Prepare a fresh 0.2 mM Sulfo-SANPAH solution in PBS.

- Apply the solution to the surface and irradiate with UV light (365 nm) for 10 minutes to activate the crosslinker.

- Rinse 3x with PBS to remove unreacted Sulfo-SANPAH.

- Apply a 0.1 mM solution of the RGD peptide in PBS and incubate overnight at 4°C or for 4 hours at room temperature.

- Rinse thoroughly with PBS. Quench any remaining active esters with 1M ethanolamine (pH 8.5) for 1 hour.

- Rinse with PBS and sterile water before cell seeding.

Diagrams

Title: Plasma Treatment & Bonding/Coating Workflow

Title: RGD-Integrin Signaling Pathway for Cell Adhesion

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Surface Modification in Organ-on-Chip Research

| Item | Function & Rationale |

|---|---|

| Oxygen Plasma Cleaner | Generates reactive oxygen species to oxidize polymer surfaces (e.g., PDMS), creating silanol (Si-OH) groups for bonding and providing anchor points for coatings. |

| PLL(20)-g[3.5]-PEG(2) | Graft copolymer. The cationic PLL backbone adsorbs to negatively charged surfaces post-plasma, while the dense PEG side chains create a hydrophilic, protein-repellent brush layer. |

| Sulfo-SANPAH (N-Sulfosuccinimidyl-6-(4'-azido-2'-nitrophenylamino)hexanoate) | Heterobifunctional crosslinker. The NHS ester reacts with amine groups on a surface, while the aryl azide (photo-activated) couples to nucleophiles on the ligand (e.g., RGD peptide). |

| RGD Peptide (e.g., GCGYGRGDSPG) | Contains the Arg-Gly-Asp sequence, the minimal cell-adhesive motif recognized by integrin receptors. The cysteine (C) or glycine (G) spacer allows for oriented coupling. |

| Filter-Sterilized HEPES Buffer (10 mM, pH 7.4) | A non-coordinating, biologically inert buffer used for preparing and rinsing coatings to maintain consistent ionic strength and pH without interfering with electrostatic adsorption. |

| Water Contact Angle Goniometer | The key instrument for quantitatively measuring surface wettability/hydrophilicity, providing immediate feedback on the success and uniformity of plasma treatment or coating application. |

| Fluorescently Tagged Proteins (e.g., FITC-BSA, Alexa-Fibrinogen) | Essential tools for visualizing and quantifying protein adsorption on modified surfaces to validate the anti-fouling performance of coatings like PLL-g-PEG. |

Technical Support Center

Troubleshooting Guides & FAQs

Q1: My collagen hydrogel is polymerizing too quickly/unpredictably inside the microfluidic device channels, leading to clogging and inconsistent scaffold density. What are the primary control parameters?

A: Rapid polymerization is a common issue influenced by temperature, pH, and ionic concentration.

- Protocol Adjustment: Pre-chill all components and the microfluidic chip on ice. Use a neutralization buffer (e.g., PBS or culture medium) at 4°C to dilute the acidic collagen stock. Initiate perfusion immediately after injection.

- Quantitative Control: The table below summarizes key parameters.

| Parameter | Recommended Range | Effect on Polymerization |

|---|---|---|

| Temperature | 4°C (Handling), 37°C (Setting) | Rate doubles with ~10°C increase. |

| Final pH | 7.2 - 7.4 (Check with pH indicator) | Polymerization fails below pH 7. |

| Collagen Concentration | 1.5 - 5.0 mg/ml | Higher concentration = faster gelation & denser matrix. |

| Ionic Strength (PBS/MEM) | 1X Concentration | Essential for fibrillogenesis; avoid dilution. |

Q2: How can I achieve consistent, bubble-free loading of viscous Matrigel into fine microfluidic architectures without damaging the hydrogel structure?

A: Bubbles compromise scaffold continuity and cell seeding.

- Detailed Protocol:

- Preparation: Keep Matrigel on ice at all times. Pre-cool syringes, tubing, and the microfluidic chip.

- Loading: Use a positive displacement pipette or a syringe pump with ice-cooled syringe. Set a slow, constant flow rate (e.g., 2-5 µL/min).

- Priming: Pre-wet all channels and inlets with ice-cold, sterile PBS to displace air.

- Curing: After loading, immediately transfer the device to a 37°C, 5% CO₂ incubator for 30-45 minutes without disturbance.

Q3: When integrating synthetic PEG-based hydrogels, my encapsulated cells show poor viability and spreading. What factors should I investigate to improve biocompatibility?

A: This points to issues with the hydrogel's biochemical and mechanical compatibility.

- Troubleshooting Steps:

- RGD Peptide Density: Ensure incorporation of cell-adhesive motifs (e.g., RGD peptides). Consult the table for reference concentrations.

- Degradation: The hydrogel must locally degrade for cells to spread. Use a matrix metalloproteinase (MMP)-sensitive crosslinker (e.g., MMP-sensitive peptide).

- Mechanical Mismatch: Modulus (stiffness) should match the target tissue (e.g., ~1 kPa for brain, ~10 kPa for muscle). Measure via rheometry.

- Cytotoxicity: Increase photoinitiator concentration, use cytocompatible types (e.g., LAP), and strictly control UV exposure time and intensity.

Q4: My scaffold delaminates from the PDMS channel walls after a few days of culture, creating an artificial gap. How can I improve scaffold-wall adhesion?

A: Delamination breaks critical cell-scaffold-device interactions.

- Protocol for Surface Functionalization:

- Plasma Treatment: Expose the assembled, dry PDMS device to oxygen plasma for 1 minute.

- Immediate Coating: Immediately perfuse the channels with a solution of 0.1% (v/v) (3-Aminopropyl)triethoxysilane (APTES) in ethanol for 20 minutes.

- Rinse and Activate: Rinse with ethanol and water, then treat with 0.5% glutaraldehyde for 30 minutes. Rinse thoroughly with sterile water.

- Scaffold Loading: This creates an aldehyde-rich surface that covalently binds amine groups in collagen or Matrigel. Load hydrogel immediately.

Key Research Reagent Solutions

| Item | Function & Rationale |

|---|---|

| High-Concentration Collagen I, Rat Tail | Gold standard for biomechanical and biocompatibility studies; allows precise tuning of concentration and stiffness. |

| Phenol Red-free Matrigel / GFR Matrigel | Absence of phenol red prevents interference with assays; Growth Factor Reduced allows controlled factor addition. |

| 8-Arm PEG-NHS Ester (MW 40kDa) | Synthetic hydrogel base with high water content and controllable functionalization for bio-orthogonal chemistry. |

| MMP-Sensitive Peptide Crosslinker (e.g., GCGPQG↓IWGQGCG) | Enables cell-mediated hydrogel remodeling and migration, critical for biocompatibility. |

| RGD Adhesion Peptide (Ac-GCGYGRGDSPG-NH₂) | Incorporates into synthetic hydrogels to provide essential integrin-binding sites for cell adhesion. |

| Lithium Phenyl-2,4,6-Trimethylbenzoylphosphinate (LAP) | A cytocompatible, water-soluble photoinitiator for UV-mediated hydrogel crosslinking with cells present. |

| (3-Aminopropyl)triethoxysilane (APTES) | Silane coupling agent for functionalizing PDMS/glass surfaces to covalently anchor hydrogels. |

| Scaffold Type | Typical Concentration Range | Polymerization/ Gelation Time | Typical Elastic Modulus (G') | Key Advantage for Biocompatibility |

|---|---|---|---|---|

| Collagen I | 1.5 - 10 mg/mL | 5 - 60 min (37°C) | 0.1 - 2 kPa | Native ECM composition; excellent for cell attachment. |

| Matrigel | 8 - 12 mg/mL | 30 - 60 min (37°C) | ~0.5 kPa | Contains basement membrane proteins; promotes complex morphology. |

| PEG-4/8 Arm | 5 - 20% (w/v) | 2 - 10 min (UV light) | 0.5 - 20 kPa | Precisely tunable mechanical and biochemical properties. |

Protocol: Assessing Scaffold Biocompatibility via Cell Viability & Morphology

Objective: Quantify the biocompatibility of integrated scaffolds within a microfluidic device by assessing encapsulated cell viability and spreading over 7 days.

Materials: Microfluidic device with integrated scaffold, cell suspension, cell culture medium, Live/Dead assay kit (Calcein AM/EthD-1), 4% paraformaldehyde, Triton X-100, actin stain (e.g., Phalloidin), nuclear stain (e.g., DAPI), confocal microscope.

Methodology:

- Cell Encapsulation: Mix cell suspension with pre-gel scaffold solution on ice. For collagen, neutralize first. Perfuse or pipette mixture into device channels.

- Gelation: Transfer device to incubator (collagen/Matrigel) or expose to UV (PEG, 365 nm, 5-10 mW/cm² for 1-2 min) for polymerization.

- Culture: Connect device to medium perfusion system or perform static medium changes every 48 hours.

- Live/Dead Staining (Day 1, 4, 7): Perfuse channels with 2 µM Calcein AM and 4 µM EthD-1 in PBS. Incubate 30-45 min at 37°C. Image at multiple locations.

- Immunofluorescence (Day 7): Fix with 4% PFA for 20 min. Permeabilize with 0.1% Triton X-100 for 10 min. Block with 1% BSA for 1 hour. Stain for F-actin and nuclei. Image via confocal microscopy.

- Analysis: Calculate viability as (Live cells / Total cells) * 100. Quantify cell spreading area and aspect ratio from actin images.

Visualizations

Scaffold Selection Logic for Biocompatibility

Protocol to Prevent Scaffold Delamination

Creating a Biocompatible Synthetic Hydrogel Network

Technical Support Center

Troubleshooting Guides & FAQs

Q1: Our primary liver hepatocytes show rapid loss of albumin synthesis and cytochrome P450 activity within 48 hours on our PDMS chip. What material-related factors should we investigate? A: This is a common issue linked to hydrophobic small molecule absorption from the culture medium into PDMS.

- Primary Cause: PDMS's high hydrophobicity absorbs critical, lipophilic hormones and growth factors, as well as drug compounds being tested, skewing results.

- Actionable Steps:

- Coat with Hydrophilic Barriers: Implement a sequential coating of Parylene C (via chemical vapor deposition) followed by covalent bonding of ECM proteins like collagen I or Matrigel. Parylene C provides a dense, pinhole-free barrier.

- Consider Alternative Polymers: Shift to more hydrophilic bulk materials like poly(methyl methacrylate) (PMMA) or cyclo-olefin polymer (COP) for chip fabrication.

- Protocol - Parylene C Coating Validation: Coat your PDMS device with a 2-5 μm Parylene C layer. Perform a fluorescent dextran (70 kDa) absorption assay. Incubate a FITC-dextran solution in the device and a glass well for 2 hours. Measure fluorescence intensity of the solutions afterward; a >90% reduction in intensity loss compared to uncoated PDMS indicates a successful barrier.

Q2: We observe inconsistent endothelial cell barrier formation (high TEER variability) in our gut-on-chip model when using collagen I gel. What optimization can we perform? A: Variability often stems from poor collagen polymerization consistency and lack of a stiff, defined membrane for cell attachment.

- Primary Cause: Traditional, thick collagen gels are mechanically soft and exhibit batch-to-batch polymerization heterogeneity.

- Actionable Steps:

- Use a Composite Membrane: Employ a porous PET membrane (1-3 μm pores, 10 μm thickness) coated with a thin, uniform layer of collagen I.

- Protocol - Thin Collagen Coating: Dilute collagen I (rat tail, high concentration) to 150 μg/mL in 0.02N acetic acid. Apply 100 μL/cm² to the PET membrane and incubate for 1 hour at 37°C. Aspirate and air-dry for 15 minutes. Rinse with PBS before seeding cells. This creates a consistent, thin, and stable substrate.

- Material Solution: Source PET membranes with treated surfaces (e.g., tissue culture-treated) to enhance collagen adhesion.

Q3: Neuronal cells in our brain-on-chip do not form extensive neurite networks on the chip substrate. Which surface modifications promote neuronal adhesion and outgrowth? A: Neurons require specific, bioactive cues beyond generic tissue culture plastics.

- Primary Cause: The chip material (e.g., PDMS, glass) lacks the necessary biochemical motifs for neuronal integrin binding.

- Actionable Steps:

- Coat with Poly-L-Lysine (PLL) & Laminin: This is the gold standard. PLL provides a cationic surface for strong cell adhesion; laminin provides integrin-specific cues for neurite outgrowth.

- Protocol: Sterilize the chip chamber. Apply 0.1 mg/mL PLL solution (in PBS) for 1 hour at 37°C. Rinse 3x with sterile water. Air-dry. Then apply laminin at 5-20 μg/mL (in PBS) and incubate for 2 hours at 37°C. Rinse with culture medium before seeding cells.

- Advanced Modification: For defined patterning, use microcontact printing to stamp laminin lines (e.g., 20 μm width) onto the substrate to guide neurite direction.

Q4: Our organ-on-chip device shows air bubble formation during medium perfusion, which damages cell monolayers. How can we prevent this? A: Bubbles often form due to temperature/pressure changes and surface property issues.

- Primary Cause: Sudden pressure drops (e.g., from syringe pump start/stop) and hydrophobic channel surfaces nucleate bubbles.

- Actionable Steps:

- Degas All Fluids: Prior to loading, degas culture medium and any other fluids in a vacuum desiccator for 30 minutes.

- Prime with Surfactant: Prime the entire fluidic path with a 0.1-0.5% Pluronic F-68 solution in PBS for 1 hour. This hydrophilic block copolymer coats channels and reduces surface tension, preventing bubble adhesion.

- Design & Operational Fix: Incorporate bubble traps into the chip design. Always operate syringe pumps in "withdraw" mode to maintain positive pressure on the fluidic path, preventing air ingress at connections.

Comparative Data on Material Performance

Table 1: Key Material Properties for Organ-on-Chip Applications

| Material | Young's Modulus (Approx.) | Gas Permeability (O₂) | Protein Absorption Tendency | Typical Fabrication Method | Best Suited For |

|---|---|---|---|---|---|

| Polydimethylsiloxane (PDMS) | 0.5 - 3 MPa | Very High | Very High (Hydrophobic) | Soft Lithography, Molding | Lung-, Barrier- models (requires coating) |

| Poly(methyl methacrylate) (PMMA) | 2 - 3 GPa | Low | Low | Laser Ablation, Milling | Liver-, Gut- models (for drug studies) |

| Cyclo-olefin polymer (COP) | 2 - 3 GPa | Low | Very Low | Injection Molding | High-throughput, absorption-sensitive assays |

| Polyethylene Terephthalate (PET) | 2 - 4 GPa | Low | Moderate (with treatment) | Commercial membranes | Barrier inserts in multi-layer chips |

| Parylene C (Coating) | 2 - 4 GPa | Moderate | Very Low | Chemical Vapor Deposition | Barrier coating for PDMS & other polymers |

Table 2: Coating Performance for Specific Cell Types

| Coating/Modification | Target Cell Type | Key Performance Metric | Result vs. Uncoated Control | Recommended Application Method |

|---|---|---|---|---|

| Collagen I (thin layer) | Intestinal Epithelium | Transepithelial Electrical Resistance (TEER) | ~300% higher, more stable | Spin-coating or air-dry on porous membrane |

| PLL + Laminin | Primary Neurons | Neurite Length & Density | ~500% increase in network density | Sequential solution coating, 1-2 hrs each |

| Matrigel | Hepatocytes | Albumin Secretion (Day 7) | ~200% increase | Cold application, gelation at 37°C |

| Pluronic F-68 Passivation | All (Anti-fouling) | Non-specific Protein Adsorption | Reduction of >70% | Perfusion of 0.1% solution for 1 hour |

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function & Rationale |

|---|---|

| Pluronic F-68 | Non-ionic surfactant used to passivate fluidic channels, reduce bubble adhesion, and minimize non-specific cell/protein adsorption. |

| Parylene C | A vapor-deposited, biocompatible polymer coating that creates an inert, pinhole-free barrier on PDMS to prevent small molecule absorption. |

| Fibronectin, Recombinant Human | Provides defined cell adhesion signals (via RGD motifs) for endothelial and epithelial cells, more consistent than animal-sourced batches. |

| Poly-L-Lysine (PLL) | A cationic polymer that coats negatively charged surfaces (glass, PDMS), enhancing initial attachment of most cell types, especially neurons. |

| Permeable PET Membranes (1μm pore) | Provide a physical, tunable barrier for co-culture models, allowing molecular exchange while separating cell compartments. |

| Degasser Module (Inline) | Removes dissolved gases from perfusion media in real-time, eliminating a primary source of bubble formation in microfluidic circuits. |

| Cytocompatible UV-Curable Adhesive | For bonding chip layers without toxicity; allows rapid prototyping and sealing of complex geometries without heat or pressure. |

| Laminin-511 (Recombinant) | A key basement membrane protein for stem cell and neuronal cultures, promoting polarized organization and long-term functionality. |

Experimental Protocols

Protocol 1: Validating Small Molecule Absorption in PDMS Chips Objective: Quantify the absorption of a test compound into chip materials. Materials: PDMS chip, glass well plate (control), fluorescent test compound (e.g., Rhodamine B), fluorescence plate reader. Steps:

- Prepare a 10 μM solution of Rhodamine B in standard culture medium.

- Add 200 μL to the inlet reservoir of the PDMS chip and to a glass well. For the chip, ensure the channels are filled and no bubbles are present.

- Incubate the systems statically at 37°C for 24 hours.

- Carefully extract the solution from both the PDMS chip reservoir and the glass well.

- Measure the fluorescence intensity (Ex/Em ~540/625 nm) of both solutions.

- Calculation: % Absorption = [1 - (IntensityPDMS / IntensityGlass)] x 100. Values >20% indicate significant absorption requiring mitigation.

Protocol 2: Establishing a Reliable Intestinal Epithelial Barrier on a Synthetic Membrane Objective: Achieve consistent, high TEER monolayers of Caco-2 or similar cells. Materials: Chip with integrated porous PET membrane, collagen I (rat tail, high conc.), acetic acid, Caco-2 cells. Steps:

- Membrane Coating: Prepare a 150 μg/mL collagen I solution in 0.02N acetic acid. Apply to the membrane and incubate 1 hr at 37°C. Aspirate and let air-dry for 15 min. Rinse with PBS.

- Cell Seeding: Trypsinize and resuspend Caco-2 cells at 1 x 10^6 cells/mL in complete medium. Seed 50-100 μL of suspension onto the coated membrane surface (apical side) to achieve ~100,000 cells/cm².

- Initial Attachment: Let the chip sit undisturbed in the incubator for 2 hours to allow cell attachment.

- Perfusion Culture: Initiate slow perfusion (50-100 μL/hr) of medium through the basolateral channel. The apical surface remains static or with a very slow flow.

- Monitoring: Measure TEER daily using integrated or external electrodes. A mature barrier typically reaches TEER >500 Ω·cm² for Caco-2 cells after 7-14 days.

Visualizations

Title: PDMS Surface Treatment Workflow for Liver Chips

Title: Neurite Outgrowth Signaling via PLL/Laminin Coating

Technical Support Center: Troubleshooting for Biocompatible Organ-on-Chip Fabrication

This support center addresses common challenges in scaling the production of biocompatible organ-on-chip (OOC) devices, framed within the thesis context of ensuring material biocompatibility while achieving high-throughput manufacturing for robust biomedical research.

Frequently Asked Questions (FAQs) & Troubleshooting

Q1: We observe increased cell death in our OOC devices when switching from manually cast PDMS to injection-molded plastic chips. What could be causing this bioincompatibility? A: This is a classic scalability conflict. Manual PDMS curing allows for thorough degassing and slow, room-temperature polymerization, minimizing residual uncrosslinked oligomers. High-temperature, high-pressure injection molding can:

- Leach additives (e.g., plasticizers, mold release agents) from thermoplastics like polystyrene (PS) or polycarbonate (PC).

- Alter surface hydrophobicity, affecting protein adsorption and cell adhesion.

- Induce residual stress in the polymer, leading to subsequent warping or leaching.

Troubleshooting Protocol:

- Pre-treatment: Implement a rigorous post-molding cleaning protocol. Sonicate chips in 70% isopropanol for 20 minutes, followed by rinsing in deionized water and a 24-hour soak in phosphate-buffered saline (PBS).

- Surface Analysis: Use water contact angle measurement to quantify hydrophobicity changes. A shift >10° from your PDMS control indicates a significant surface property change.

- Extraction Assay: Perform a cytotoxicity assay per ISO 10993-5. Incubate chip material extracts in cell culture medium for 24 hours at 37°C, then apply to cultured cells. Viability <70% compared to controls indicates significant leaching.