From Design to Reality: How Self-Assembling Biomimetic Materials Are Revolutionizing 3D Bioprinting

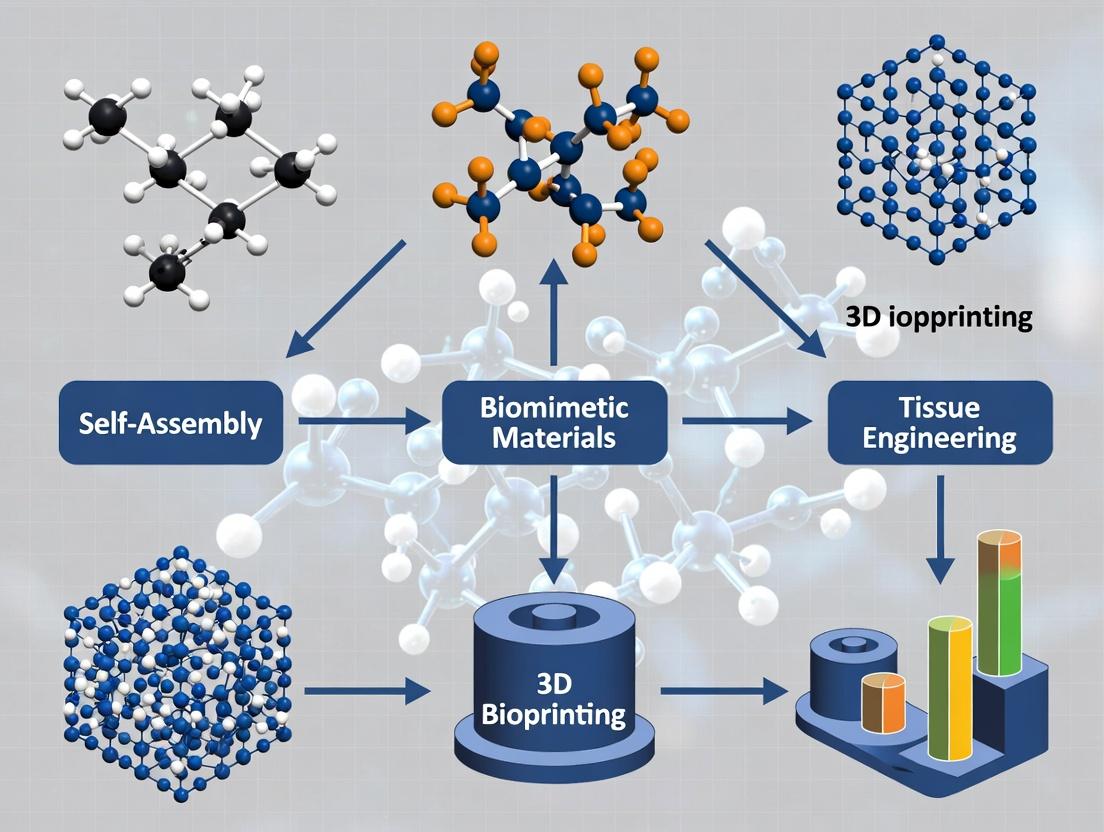

This comprehensive review examines the transformative role of self-assembling biomimetic materials in advancing 3D bioprinting applications.

From Design to Reality: How Self-Assembling Biomimetic Materials Are Revolutionizing 3D Bioprinting

Abstract

This comprehensive review examines the transformative role of self-assembling biomimetic materials in advancing 3D bioprinting applications. We explore the foundational principles of bioinspired molecular design, detailing key material classes like peptides, proteins, and DNA nanostructures. Methodological approaches for integrating these dynamic materials into bioprinting workflows are analyzed, including layer-by-layer and co-printing strategies. The article critically addresses common challenges in structural integrity, cellular integration, and printing fidelity, presenting optimization techniques. Finally, we evaluate current validation benchmarks and comparative performance against traditional hydrogels, concluding with future implications for tissue engineering, disease modeling, and personalized drug development.

The Blueprint of Life: Core Principles of Self-Assembling Biomimetic Materials for Biofabrication

Self-assembly is a process where components, pre-programmed via molecular and supramolecular interactions, autonomously organize into ordered, functional structures without external guidance. In 3D bioprinting, harnessing this intrinsic biological principle enables the fabrication of biomimetic tissues with hierarchical complexity that rival native extracellular matrices. This application note details protocols and analytical methods for leveraging self-assembling peptides and polymer systems in bioprinting applications for drug screening and tissue engineering.

Core Self-Assembly Mechanisms & Molecular Triggers

Self-assembly in biomaterials is governed by precise, non-covalent interactions. Key triggers include:

- pH Change: Alters charge states of amino acid side chains, triggering hydrophobic collapse or beta-sheet formation.

- Ionic Strength: Screens electrostatic repulsion, allowing attractive forces (e.g., van der Waals, π-π stacking) to dominate.

- Enzymatic Cleavage: Reveals cryptic self-assembling domains from precursor molecules.

- Thermal Induction: Modulates solubility and kinetic energy to favor ordered aggregation.

- Molecular Recognition: Specific lock-and-key interactions (e.g., biotin-streptavidin, DNA hybridization).

Quantitative Comparison of Common Self-Assembling Systems

Table 1: Characteristics of Key Self-Assembling Biomaterial Systems

| System / Acronym | Core Building Block | Primary Trigger | Typical Fiber Diameter | Storage Modulus (G') | Key Applications in Bioprinting |

|---|---|---|---|---|---|

| RADA16-I | Peptide (Ac-RADARADARADARADA-CONH₂) | Ionic Strength / pH | 10-20 nm | 1-10 kPa | Neural repair, cell encapsulation bioink |

| Q11 | Peptide (QQKFQFQFEQQ) | Ionic Strength | 5-15 nm | 0.5-5 kPa | Vaccine delivery, sustained release scaffolds |

| Peptide Amphiphiles (PAs) | Peptide conjugated to alkyl tail | pH | 6-10 nm | 2-15 kPa | Bone regeneration, vascularization |

| Elastin-Like Polypeptides (ELPs) | Protein polymer (VPGXG)n | Temperature (T>LCST) | 50-500 nm | 0.1-2 kPa | Drug delivery, thermally responsive inks |

| Hyaluronic Acid (HA) / Heparin Systems | Glycosaminoglycans | Electrostatic Coacervation | 100-1000 nm | 0.01-1 kPa | Growth factor binding, viscoelastic bioinks |

Application Notes & Protocols

Protocol: Formulation and Printability Assessment of a RADA16-I-Based Bioink

Aim: To prepare a self-assembling peptide hydrogel bioink suitable for extrusion bioprinting and characterize its rheological and mechanical properties.

Materials (Research Reagent Solutions):

- RADA16-I Peptide Powder: Synthetic, >95% purity. The core self-assembling unit.

- Sucrose (10% w/v in PBS): Provides osmolarity and printability enhancement via viscosity modulation.

- Sterile PBS (1x, pH 7.4): Ionic trigger and solvent. Filter sterilized (0.22 µm).

- Cell Suspension (e.g., NIH/3T3 fibroblasts): Model cell line for viability assessment.

- Sterile Sodium Hydroxide (10 mM) and HCl (10 mM): For fine pH adjustment.

- Sterile Syringe (3 mL) and Blunt-end Nozzle (22-27G): For ink extrusion.

Method:

- Peptide Solution Preparation:

- Dissolve RADA16-I powder in sterile, deionized water to a final concentration of 1.0% (w/v). Vortex for 30 seconds.

- Adjust the pH to 7.4 using small volumes of 10 mM NaOH or HCl. Sterilize by passing through a 0.22 µm syringe filter. Store on ice to prevent premature assembly.

- Bioink Formulation:

- Mix the sterile 1% RADA16-I solution with an equal volume of 10% sucrose in PBS. This yields a final bioink of 0.5% RADA16-I, 5% sucrose in 0.5x PBS.

- For cell-laden printing, centrifuge your cell pellet, resuspend in a small volume of 10% sucrose/PBS, and gently mix with the RADA16-I solution to the desired final cell density (e.g., 1-5 x 10^6 cells/mL).

- Gelation & Printing:

- Transfer bioink to a sterile syringe fitted with a nozzle.

- The increase in ionic strength upon mixing triggers self-assembly. Incubate the loaded syringe at 37°C for 5-7 minutes to initiate gelation.

- Print using an extrusion bioprinter. Recommended parameters: Pressure 15-25 kPa, speed 5-10 mm/s, layer height 0.15-0.2 mm.

- Post-Printing Stabilization:

- Immediately after printing, immerse the construct in complete cell culture media. The media further triggers assembly and provides nutrients.

- Incubate at 37°C, 5% CO₂ for 30 minutes to form a stable hydrogel.

Assessment:

- Rheology: Perform time sweep (oscillation, 1% strain, 1 rad/s) to monitor storage (G') and loss (G'') modulus evolution after ionic trigger.

- Printability: Calculate filament collapse and spreading ratio from top-view images of a printed grid.

- Cell Viability: Assess using Live/Dead assay at 1, 24, and 72 hours post-print.

Protocol: Co-Assembly System for Growth Factor Delivery

Aim: To create a heparin-binding peptide amphiphile (PA) co-assembling system for the sustained presentation of Vascular Endothelial Growth Factor (VEGF).

Materials (Research Reagent Solutions):

- Heparin-Binding PA (HB-PA): e.g., C16-VVVAAAEEEK-(PEG)₄-KKKKLRAL peptide. Contains alkyl tail (C16), matrix-binding domain, heparin-binding sequence.

- Standard PA (S-PA): C16-VVVAAAGGG. Provides structural backbone.

- Heparin Sodium Salt: Sulfated glycosaminoglycan for growth factor binding.

- Recombinant Human VEGF₁₆₅: Target growth factor.

- DMEM/F-12 Medium: For cell culture assays.

Method:

- Micelle Preparation:

- Dissolve HB-PA and S-PA separately in ultrapure water at 1% (w/v) by brief sonication (5 min, water bath sonicator).

- Mix solutions to achieve a final ratio of 1:9 (HB-PA:S-PA). This ensures sparse presentation of heparin-binding sites.

- Growth Factor Loading:

- Prepare a solution of heparin (100 µg/mL) in PBS.

- Add VEGF to the heparin solution at a molar ratio of 1:1 (VEGF:Heparin). Incubate for 15 min at RT to form complex.

- Gently mix the VEGF-Heparin complex with the mixed PA solution. Final VEGF concentration should be 50 ng/mL in the total mixture.

- Gelation:

- Adjust pH to 7.4 with NaOH. Add cell culture medium (1:1 v/v) to provide physiological ions.

- Incubate at 37°C for 1 hour. A self-supporting hydrogel will form via β-sheet assembly of the PA fibers, incorporating the VEGF-Heparin complex.

- Application: The gel can be used as a pre-formed matrix in a well plate for cell migration assays or incorporated as a sacrificial bioink component during multi-material bioprinting.

Assessment:

- Release Kinetics: Use ELISA to quantify VEGF release into supernatant over 14 days.

- Bioactivity: Perform human umbilical vein endothelial cell (HUVEC) tubulogenesis assay on Matrigel in the presence of the release supernatant.

The Scientist's Toolkit

Table 2: Essential Research Reagents for Self-Assembly Bioprinting

| Reagent / Material | Function & Role in Self-Assembly | Example Supplier / Catalog Consideration |

|---|---|---|

| Self-Assembling Peptides (RADA16-I, Q11, KLD-12) | Core structural component; forms nanofibrous hydrogel matrix via β-sheet formation. | Bachem, CPC Scientific, Genscript (Custom Synthesis) |

| Peptide Amphiphile (PA) Kits | Simplified access to alkyl-tailed peptides for rapid nanofiber formation. | Sigma-Aldrich (Custom Design), Ambiopharm |

| Recombinant Growth Factors (VEGF, BMP-2, FGF-2) | Bioactive cargo for controlled release; often binds to self-assembled structures. | PeproTech, R&D Systems |

| Heparin Sodium Salt | Polyanionic glycosaminoglycan; mediates growth factor binding and release kinetics. | Sigma-Aldrich, Merck |

| Rheometer with Peltier Plate | Critical for characterizing gelation kinetics (time sweep) and viscoelastic properties. | TA Instruments, Anton Paar |

| Extrusion Bioprinter (Temperature-Controlled) | Enables deposition of self-assembling bioinks under sterile, parametrically controlled conditions. | Allevi, CELLINK, REGEMAT 3D |

| Live/Dead Viability/Cytotoxicity Kit | Standard for assessing cell health post-encapsulation and printing. | Thermo Fisher Scientific (L3224) |

Visualizing Pathways and Workflows

Title: Self-Assembly Pathway from Molecules to Bioprint

Title: Experimental Workflow for Self-Assembling Bioink

Peptide-Based Bioinks for 3D Bioprinting

Recent advancements focus on self-assembling peptides (SAPs) like RADA16-I and ionic-complementary peptides. These form nanofibrous hydrogel scaffolds that mimic the extracellular matrix (ECM).

Table 1: Performance Metrics of Key Peptide Bioinks

| Material (Example) | Gelation Mechanism | Storage Modulus (G') | Typical Gelation Time | Key Application in 3D Bioprinting |

|---|---|---|---|---|

| RADA16-I | Ionic Strength/pH | 1-5 kPa | 30-60 sec | Neural tissue models |

| KLD-12 (KLDLKLDLKLDL) | Ionic Strength | 2-4 kPa | < 5 min | Chondrocyte encapsulation |

| MAX8 (β-hairpin) | Thermo/Photo-triggered | 10-20 kPa | Seconds (UV) | High-resolution cell-laden constructs |

| Elastin-like Polypeptides (ELPs) | Inverse Temperature Transition | 0.5-2 kPa | Minutes (37°C) | Vascularized constructs |

Protein-Based Constructs

Recombinant proteins (e.g., silk fibroin, collagen, resilin) offer precise control over mechanical and biochemical properties.

Table 2: Engineered Protein Biomaterials for Bioprinting

| Protein | Crosslinking Method | Tensile Strength | Cell Adhesion Motif | Bioprinting Relevance |

|---|---|---|---|---|

| Recombinant Spider Silk | Enzymatic (HRP), Sonication | 100-500 MPa | RGD incorporation | Mechanically robust scaffolds |

| Recombinant Collagen | Chemical (Genipin) | 1-10 MPa | Native sequence | Dermal/osseous tissue models |

| Fibrinogen | Enzymatic (Thrombin) | 0.05-0.2 MPa | Native sequence | Vascularized tissue, wound models |

| Resilin-like Polymers | Photo-click (Tyrosine) | 0.1-1 MPa | Optional | Elastic cartilage models |

DNA Nanostructures as Functional Elements

DNA origami and tiles provide nanoscale control for spatial patterning of signals.

Table 3: DNA Nanostructure Applications in 3D Bioprinting

| Nanostructure Type | Typical Size (nm) | Functionalization | Role in Bioprinted Construct | Reference Yield (%) |

|---|---|---|---|---|

| DNA Origami (6-helix bundle) | ~10 x 100 | Thiol, Biotin | Crosslinker for hydrogel reinforcement | ~85% |

| Tetrahedral DNA Framework | ~5-10 | Aptamers, VEGF | Spatially controlled growth factor presentation | >90% |

| DNA Hydrogel Tiles | 100-1000 | ssDNA overhangs | Sacrificial lattice for microvasculature | 70-80% |

Synthetic Polymers: Precision and Tunability

Synthetic polymers (e.g., PEG, PLGA, PNIPAM) offer reproducible, tunable properties often combined with natural materials.

Table 4: Key Synthetic Polymers in Advanced Bioinks

| Polymer | Functional Group | Typical MW (kDa) | Degradation Time | Key Advantage |

|---|---|---|---|---|

| PEG (4-arm) | Acrylate, Maleimide, NHS | 10-40 | Tunable (weeks-years) | Bioorthogonal crosslinking |

| PLGA | Carboxyl, Ester | 50-100 | 4-8 weeks (tunable) | FDA-approved, controlled release |

| PNIPAM | Acrylamide | 20-100 | Non-degradable | Thermoresponsive (LCST ~32°C) |

| PVA | Hydroxyl | 30-100 | Slow | High elasticity, support baths |

Detailed Experimental Protocols

Protocol: Forming a Peptide-Polymer Hybrid Bioink for Vascular Bioprinting

Aim: To create a printable, peptide-crosslinked hydrogel supporting endothelial network formation. Materials: RGDS-modified 4-arm PEG-SVA (20 kDa), KLD-12 peptide (Ac-KLDLKLDLKLDL-CONH2), HUVECs, Phosphate Buffered Saline (PBS), Sterile NaHCO₃ (0.1M).

Procedure:

- Peptide Solution Prep: Dissolve KLD-12 peptide in sterile 0.1M NaHCO₃ at 1% (w/v). Sterilize by filtration (0.22 µm). Keep on ice.

- Polymer Solution Prep: Dissolve 4-arm PEG-SVA (RGDS-modified) in PBS at 10% (w/v).

- Bioink Formulation: In a sterile 1:1 volume ratio, mix the peptide and polymer solutions directly in the bioprinter cartridge. Gently pipette to mix. Final concentrations: 0.5% KLD-12, 5% PEG.

- Crosslinking & Printing: Load the cartridge into a pneumatic extrusion bioprinter (20-22°C). Print into a support bath or onto a heated stage (37°C) to initiate rapid peptide self-assembly and Michael addition crosslinking.

- Post-Printing Cure: Incubate the printed construct at 37°C, 5% CO₂ for 20 minutes to complete gelation.

- Cell Encapsulation (Alternative): For cell-laden prints, suspend HUVECs in the PEG solution prior to mixing. Mix with peptide solution immediately before loading into the cartridge to minimize pre-gelation.

Protocol: Incorporating DNA Origami as Reinforcing Agents in Collagen Bioinks

Aim: To enhance the mechanical resilience of a soft collagen matrix using DNA nanostructures. Materials: Type I Collagen (rat tail, 5 mg/mL), DNA Origami 6-helix bundles (functionalized with NHS esters), EDC/NHS crosslinking solution, DMEM (10x, no phenol red).

Procedure:

- DNA Origami Activation: Resuspend NHS-functionalized DNA origami in 0.1M MES buffer, pH 6.0. Add a fresh EDC/NHS mixture (final 50mM/25mM) and incubate at RT for 15 min. Purify using a 100kDa MWCO spin filter into PBS.

- Neutralization of Collagen: On ice, mix: 800 µL collagen, 100 µL 10x DMEM, 50 µL 0.1M NaOH. Gently vortex.

- Bioink Formulation: Add 50 µL of activated DNA origami solution (final concentration ~50 nM) to the neutralized collagen. Mix gently by inversion. Keep on ice until printing.

- Printing: Using a microextrusion printer with a cooled stage (4°C), deposit the bioink.

- Crosslinking: Post-print, expose the construct to 365 nm UV light (5 mW/cm², 2 min) to initiate covalent amide bond formation between collagen amines and activated DNA origami.

- Incubation: Transfer to cell culture medium and incubate at 37°C for 1 hour for final fibrillogenesis.

The Scientist's Toolkit: Research Reagent Solutions

Table 5: Essential Reagents for Biomaterial-Based 3D Bioprinting Research

| Item/Reagent | Supplier Examples | Function & Brief Explanation |

|---|---|---|

| 4-arm PEG-Acrylate (20kDa) | JenKem, Laysan Bio | Provides a synthetic, hydrophilic backbone for bioorthogonal (e.g., photo) crosslinking. High tunability. |

| RADA16-I Peptide | Bachem, Genscript | Self-assembles into stable nanofibers upon exposure to physiological ionic strength. Serves as a synthetic ECM. |

| Recombinant Human Collagen I | Fibralign, Jellatech | Animal-free, consistent source of a major ECM protein for bioinks, reducing batch variability. |

| NHS-PEG-Maleimide | Thermo Fisher, Sigma | Heterobifunctional crosslinker for coupling peptides (via cysteine) to polymers/proteins (via amines). |

| DNA Origami Scaffold (M13mp18) | tilibit nanosystems | Long single-stranded DNA scaffold for folding into precise 2D/3D nanostructures for spatial patterning. |

| Ruthenium/SPS Photoinitiator | Sigma-Aldrich | Visible light (450 nm) photoinitiator system for cell-friendly crosslinking of tyramine or thiol groups. |

| Gelatin Methacryloyl (GelMA) | Advanced BioMatrix, Allevi | Photocrosslinkable derivative of gelatin; combines natural cell adhesion motifs with synthetic control. |

| Carbopol-based Support Bath | Sigma-Aldrich (Carbopol 974P) | Yield-stress fluid used as a suspension medium for printing intricate, low-viscosity bioinks. |

Diagrams

Diagram Title: Peptide-Polymer Hybrid Bioink Crosslinking Workflow

Diagram Title: DNA-Collagen Composite Bioink Fabrication Process

Application Notes

Biomimicry of the native ECM is a foundational goal in 3D bioprinting and tissue engineering. The ECM provides a complex, tissue-specific milieu of biochemical, topological, and mechanical cues that direct cellular behaviors such as adhesion, proliferation, migration, and differentiation. Replicating these cues within self-assembling biomimetic materials is critical for constructing functional, physiologically relevant tissue models for drug development and regenerative medicine.

Key Replicable ECM Cues:

- Biochemical Composition: Incorporation of adhesive ligands (e.g., RGD peptides), glycosaminoglycans (GAGs) like hyaluronic acid, and growth factor binding sites.

- Topographical & Structural Features: Emulation of fiber diameter, porosity, and alignment present in native fibrillar networks (collagen, fibronectin).

- Mechanical Properties: Tuning of viscoelasticity, stiffness (elastic modulus), and stress relaxation to match target tissues (e.g., brain ~0.1-1 kPa, muscle ~8-17 kPa, bone ~15-30 MPa).

- Dynamic & Responsive Behavior: Designing materials that degrade or change properties in response to cell-secreted enzymes (e.g., matrix metalloproteinases - MMPs) or allow user-triggered stiffening/softening.

Quantitative Data on Native ECM and Biomimetic Replicas

Table 1: Mechanical and Compositional Properties of Native Tissues

| Tissue Type | Approximate Elastic Modulus | Dominant ECM Components | Characteristic Fiber Diameter | Key Bioactive Ligands |

|---|---|---|---|---|

| Brain | 0.1 - 1 kPa | Hyaluronic Acid, CSPGs | N/A (porous hydrogel) | IKVAV, RGD |

| Skin (Dermis) | 2 - 20 kPa | Collagen I, Elastin | 1 - 10 μm | RGD, DGEA |

| Cardiac Muscle | 8 - 17 kPa | Collagen I, III, Laminin | 1 - 3 μm | RGD, YIGSR |

| Articular Cartilage | 0.2 - 2 MPa | Collagen II, Aggrecan | 20 - 80 nm | RGD |

| Cortical Bone | 15 - 30 GPa | Collagen I, Hydroxyapatite | 50 - 500 nm (mineral) | RGD, GFOGER |

Table 2: Common Biomimetic Hydrogel Systems for 3D Bioprinting

| Material System | Crosslinking Mechanism | Tunable Stiffness Range | Key Biomimetic Features | Typical Biofunctionalization |

|---|---|---|---|---|

| Fibrin | Enzymatic (Thrombin) | 0.1 - 5 kPa | Natural cell-binding domains, proteolytic remodeling | Native integrin binding |

| Collagen I | Thermally-driven self-assembly & pH | 0.1 - 5 kPa | Native fibrillar architecture, integrin binding sites | Blending with other collagens |

| Alginate | Ionic (Ca2+) | 1 - 100 kPa | Rapid gelation, high print fidelity | RGD peptide coupling |

| Hyaluronic Acid (MeHA) | Photo-crosslinking (e.g., 365-405 nm UV) | 0.5 - 50 kPa | CD44 receptor binding, MMP-degradable sequences | RGD, MMP peptides, heparin for GF binding |

| Polyethylene Glycol (PEG) | Photo-crosslinking or Michael Addition | 0.2 - 100 kPa | "Blank slate" for precise biofunctionalization, protease sensitivity | Custom peptides (RGD, MMP-sensitive) |

Experimental Protocols

Protocol 1: Formulation and 3D Bioprinting of a MMP-Sensitive, RGD-Functionalized Hyaluronic Acid Bioink

Objective: To create a biomimetic, cell-laden hydrogel that replicates ECM's degradability and adhesivity for soft tissue modeling.

Materials:

- Methacrylated Hyaluronic Acid (MeHA, 5-20% w/v in PBS).

- Photoinitiator: Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP, 0.05% w/v).

- Peptides: GCGYGRGDSPG (RGD, 1 mM stock in water), GCRDVPMS↓MRGGDRCG (MMP-sensitive crosslinker, 2 mM stock). (↓ indicates cleavage site).

- Phosphate Buffered Saline (PBS), pH 7.4.

- Primary cells (e.g., human fibroblasts, 5 million cells/mL).

- Extrusion bioprinter with a 22G-27G blunt needle and a 405 nm UV light source (5-10 mW/cm²).

Procedure:

- Bioink Preparation: Dissolve MeHA in PBS to the desired final concentration (e.g., 2% w/v). Protect from light.

- Functionalization: Add LAP (0.05% final w/v), RGD peptide (0.5-1.0 mM final), and MMP-sensitive peptide (1-2 mM final) to the MeHA solution. Mix gently but thoroughly.

- Cell Incorporation: Centrifuge cell pellet. Resuspend cells in a small volume of bioink (10% of total final volume). Gently mix this cell suspension with the remaining bioink to achieve the final cell density.

- Printing: Load bioink into a sterile syringe. Mount onto the bioprinter. Set print parameters: Pressure 15-25 kPa, speed 5-10 mm/s, layer height 0.15-0.25 mm.

- Crosslinking: After deposition of each layer, apply a brief pulse of 405 nm UV light (5-10 seconds, 5 mW/cm²) for partial stabilization. After the final layer is printed, apply a final crosslinking step (30-60 seconds) to ensure complete gelation.

- Post-processing: Transfer constructs to cell culture medium and incubate at 37°C, 5% CO₂. Change medium every 2-3 days.

Protocol 2: Assessing Cell Morphogenesis and Matrix Remodeling in 3D Biomimetic Constructs

Objective: To quantify cell spreading, viability, and proteolytic remodeling within the 3D biomimetic ECM over time.

Materials:

- 3D bioprinted constructs from Protocol 1.

- Cell culture medium with/without pharmacological inhibitors (e.g., MMP inhibitor GM6001, 10 μM).

- Live/Dead Viability/Cytotoxicity Kit (Calcein AM/EthD-1).

- 4% Paraformaldehyde (PFA) in PBS.

- 0.1% Triton X-100 in PBS.

- Phalloidin (for F-actin) and DAPI (for nuclei) stains.

- Blocking buffer (5% BSA in PBS).

Procedure:

- Time-Course Imaging: At days 1, 3, 7, and 14, harvest constructs (n=3 per time point).

- Viability Assay: Incubate one construct per group in Calcein AM (2 μM) and EthD-1 (4 μM) in PBS for 45 min at 37°C. Rinse with PBS. Image using confocal microscopy (488/515 nm for Calcein, 528/617 nm for EthD-1). Calculate viability as (Live cells / Total cells) * 100%.

- Immunofluorescence Staining: Fix remaining constructs in 4% PFA for 45 min at 4°C. Permeabilize with 0.1% Triton X-100 for 30 min. Block with 5% BSA for 2 hours. Incubate with primary antibody (e.g., anti-integrin β1) overnight at 4°C. Wash and incubate with fluorescent secondary antibody, Phalloidin, and DAPI for 2 hours at RT. Wash thoroughly.

- Confocal Microscopy & Analysis: Acquire z-stacks. Use image analysis software (e.g., FIJI/ImageJ) to measure:

- Cell Spreading: 3D volume and surface area of individual cells.

- Process Length: For elongated cells (e.g., mesenchymal), measure the longest cellular extension.

- Proteolytic Zone: Area of fluorescence clearance around cells indicating MMP-mediated degradation (for constructs with fluorescently-tagged hydrogel).

Diagrams

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Biomimetic ECM Research

| Item | Function & Relevance | Example Supplier / Cat. No. (Illustrative) |

|---|---|---|

| Methacrylated Hyaluronic Acid (MeHA) | Photo-crosslinkable polymer backbone mimicking GAG-rich ECM; allows tunable stiffness and biofunctionalization. | "Glycosil" (Advanced BioMatrix) or in-house synthesis. |

| RGD Peptide (GCGYGRGDSPG) | Provides primary cell adhesion ligand found in fibronectin and other ECM proteins; essential for integrin-mediated attachment. | PepTech, AnaSpec. Custom synthesis from peptide vendors. |

| MMP-Sensitive Peptide Crosslinker (e.g., GCRDVPMS↓MRGGDRCG) | Enables cell-mediated proteolytic remodeling of the hydrogel, mimicking dynamic ECM turnover. | Genscript, Bachem. |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Cytocompatible photoinitiator for rapid free-radical crosslinking with 365-405 nm light; crucial for bioprinting. | Sigma-Aldrich, 900889. |

| Recombinant Human Laminin-521 | Native basement membrane protein providing potent adhesive and differentiation cues for stem/progenitor cells. | BioLamina, LN521. |

| Type I Collagen, High Concentration (>8 mg/mL) | The most abundant natural ECM protein; forms fibrillar networks via self-assembly at physiological pH/temp. | Corning, 354249 (rat tail). |

| Small Molecule MMP Inhibitor (GM6001/Ilomastat) | Pharmacological tool to validate the role of MMP-mediated degradation in cell spreading and invasion. | Tocris, 2983. |

| Fluorescent Microspheres (e.g., 0.5 μm, red/green) | Embedded as fiducial markers for traction force microscopy to quantify cell-generated contractile forces. | Thermo Fisher, F881x series. |

| Rho-associated Kinase (ROCK) Inhibitor (Y-27632) | Used to modulate cellular contractility, a key readout of mechanotransduction from biomimetic matrix stiffness. | Selleckchem, S1049. |

In 3D bioprinting, achieving precise spatial and temporal control over material assembly is paramount for constructing complex, biomimetic tissues. Molecular triggers—pH, temperature, ionic strength, and light—offer a powerful toolkit for guiding the in situ self-assembly of bioinks, enabling the creation of dynamic, functional constructs. This application note details protocols for leveraging these triggers within a bioprinting workflow, framed within research on self-assembling, biomimetic materials for advanced drug screening and disease modeling platforms.

Research Reagent Solutions & Essential Materials

| Item/Category | Function in Triggered Self-Assembly | Example Product/Specification |

|---|---|---|

| pH-Responsive Polymer | Undergoes conformational or solubility changes at specific pH values, enabling layer-specific or microenvironment-triggered gelation. | Alginate-diethylaminoethyl (Alg-DEAE); pKa ~6.5. |

| Thermo-responsive Bioink | Transitions from sol to gel upon temperature change (e.g., heating to 37°C), providing gentle cell encapsulation. | Gelatin Methacryloyl (GelMA) blended with Poly(N-isopropylacrylamide) (PNIPAAm); LCST ~32°C. |

| Ion Source | Provides divalent cations to crosslink ionic polymers (e.g., alginate), enabling rapid, cytocompatible post-print stabilization. | Calcium Chloride (CaCl₂) or Calcium Sulfate (CaSO₄) slurry; 100-200 mM stock. |

| Photoinitiator | Generates radicals upon light exposure to initiate crosslinking in photopolymerizable bioinks (e.g., GelMA, PEGDA). | Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP); 0.1% w/v in bioink. |

| Visible/Light Source | Provides specific wavelength (λ) to activate photoinitiators or photoswitches with high spatiotemporal control. | 405 nm or 365 nm LED curing system; intensity 5-20 mW/cm². |

| Buffer System | Maintains or creates localized pH environments to trigger pH-sensitive assembly without global cytotoxicity. | HEPES (pH 6.8-8.2) or Acetate (pH 4.0-5.5) buffers at 1M stock. |

| Ionic Strength Modulator | Alters solution salt concentration to screen electrostatic interactions, triggering assembly/disassembly of polyelectrolytes. | Sodium Chloride (NaCl) solution; 0.1-2.0 M. |

Application Notes & Protocols

Protocol 1: pH-Triggered Sequential Layering of a Vascular-like Structure

Objective: To bioprint a coaxial tube using a pH-triggered, self-assembling peptide bioink (e.g., RAD16-II) that gels at neutral pH. Materials: Acidic bioink solution (pH 4.0, 1% w/v RAD16-II in sterile water), neutralizing buffer (PBS, pH 7.4), coaxial printhead, bioprinter. Procedure:

- Load the acidic peptide solution into the inner cartridge of a coaxial printhead.

- Load the neutral PBS buffer into the outer sheath cartridge.

- Set bioprinter parameters: pressure 15-25 kPa, print speed 8 mm/s, nozzle diameter 22G.

- Print directly into a culture medium or PBS bath (pH 7.4). The instantaneous diffusion of the outer buffer neutralizes the peptide stream, triggering its self-assembly into a stable gel filament.

- Layer filaments to form a tubular structure. Incubate the final construct in culture medium for 1 hour to complete assembly. Data: The resulting filaments have a mean diameter of 450 ± 50 µm and storage modulus (G') of 2.5 ± 0.3 kPa at pH 7.4.

Protocol 2: Thermo-Ionic Crosslinking of an Alginate-GelMA Composite Bioink

Objective: To utilize a combined temperature trigger and ionic crosslink for printing a shape-stable, cell-laden construct. Materials: Bioink (3% w/v Alginate, 7% w/v GelMA, cells), CaCl₂ solution (100 mM), cooled print bed (20°C). Procedure:

- Prepare bioink and maintain at 20°C to keep GelMA in liquid state.

- Print onto a print bed maintained at 20°C.

- Immediately post-print, expose the construct to a nebulized mist of 100 mM CaCl₂ for 60 seconds to ionically crosslink the alginate.

- Transfer construct to an incubator at 37°C for 15 minutes to trigger thermal gelation of GelMA.

- Wash with culture medium to remove excess Ca²⁺. Data: Dual-crosslinked constructs show significantly improved shape fidelity (94% ± 2%) compared to ionic crosslink alone (78% ± 5%) after 24 hours in culture.

Protocol 3: Light-Triggered Spatiotemporal Patterning of Biochemical Cues

Objective: To photopattern RGD adhesion peptides within a printed PEGDA hydrogel to create controlled heterogeneity. Materials: Bioink (4-arm PEG-Acrylate, 5 mM, thiol-containing RGD peptide, 0.1% LAP), photomask, 405 nm light source. Procedure:

- Print a base hydrogel construct using PEGDA bioink and standard 405 nm exposure (10 s, 10 mW/cm²).

- Prepare a solution of RGD peptide (1 mM) and LAP (0.05%) in PBS.

- Infuse the solution into the hydrated printed construct.

- Apply a photomask defining the desired adhesion pattern and expose to 405 nm light (5 s, 5 mW/cm²).

- Wash thoroughly to remove unreacted peptides. Data: Photopatterned regions show a 3-fold increase in primary human fibroblast adhesion density compared to non-exposed regions.

Table 1: Characteristic Responsive Ranges of Common Trigger Mechanisms

| Trigger | Typical Responsive Range | Example Material | Response Time | Key Application in Bioprinting |

|---|---|---|---|---|

| pH | Transition pH 5.0 - 7.0 | Chitosan/β-GP | 30 s - 2 min | Layer-specific gelation, drug release niches. |

| Temperature | LCST: 25°C - 32°C | PNIPAAm, Elastin-like polypeptides | 10 s - 1 min | Cell-friendly gelation at 37°C, sacrificial supports. |

| Ionic Strength | [Ca²⁺] > 20 mM | Alginate, Fibrinogen/Thrombin | < 1 s | Instant post-print stabilization, shear-thinning inks. |

| Light (405 nm) | Intensity: 5-50 mW/cm² | GelMA, PEGDA, Photoswitches | 1 - 60 s | High-resolution spatial patterning, sequential curing. |

Table 2: Mechanical Properties of Trigger-Crosslinked Hydrogels

| Crosslinking Trigger | Bioink Formulation | Storage Modulus G' (kPa) | Gelation Time (s) | Reference Cell Viability (Day 1) |

|---|---|---|---|---|

| pH (to 7.4) | RAD16-I Peptide | 1.8 ± 0.2 | 30 - 60 | >95% |

| Temperature (to 37°C) | PNIPAAm-HPMC | 4.5 ± 0.5 | 40 - 90 | 92% ± 3% |

| Ionic (Ca²⁺) | 2% Alginate | 12.0 ± 2.0 | < 5 | 88% ± 5% |

| Light (405 nm) | 5% GelMA | 8.0 ± 1.5 | 10 - 30 | 90% ± 4% |

| Dual (Ionic + Light) | Alginate-GelMA | 15.0 ± 2.5 | < 5 + 30 | 85% ± 3% |

Diagrams

Diagram Title: Workflow for pH-triggered peptide self-assembly during bioprinting.

Diagram Title: Logical pathway from trigger to bioprinting application.

Within the expanding domain of 3D bioprinting for tissue engineering and drug screening, the limitations of static, inert scaffolds are increasingly apparent. This document, framed within a thesis on self-assembling biomimetic materials, details the pivotal advantages of dynamic scaffolds—those engineered to respond to environmental cues and present bioactive signals in a spatiotemporally controlled manner. Unlike static constructs, dynamic platforms can mimic the ever-changing in vivo extracellular matrix (ECM), guiding complex cellular processes like morphogenesis, differentiation, and tissue repair with superior fidelity.

Key Comparative Advantages

The transition from static to dynamic scaffolds is driven by the need for systems that not only support but actively instruct cellular behavior. The core advantages are quantified in Table 1.

Table 1: Quantitative Comparison of Static vs. Dynamic/Bioactive Scaffolds

| Parameter | Static Scaffolds | Dynamic/Bioactive Scaffolds | Source/Model System |

|---|---|---|---|

| Cell Viability (%) at Day 7 | 65-75% | 85-95% | Alginate vs. RGD-modified Alginate Hydrogel (Chondrocytes) |

| Angiogenic Sprout Length (µm) | ~50-100 | ~200-400 | HUVECs in Fibrin vs. MMP-Degradable Peptide Hydrogel |

| Osteogenic Differentiation (ALP Activity, U/mg) | 1.0 (Baseline) | 2.5 - 4.0 | hMSCs in PLA vs. BMP-2 Releasing PLGA Microsphere Scaffold |

| Drug Screening Z'-Factor | 0.3 - 0.5 | 0.5 - 0.8 | Static Spheroid vs. Bioprinted Vascularized Dynamic Model |

| Matrix Remodeling Rate (∆ Modulus/week) | ~5% decrease | 15-30% increase | Collagen Gel vs. Hyaluronic Acid with Cell-Mediated Crosslinking |

Mechanisms of Dynamic Responsiveness

Dynamic responsiveness is typically engineered through:

- Enzyme-Responsive Elements: Incorporation of peptide crosslinkers cleavable by cell-secreted matrix metalloproteinases (MMPs).

- Stimuli-Responsive Polymers: Use of polymers that change properties (swelling, degradation) in response to pH, temperature, or light.

- Mechano-Responsive Design: Scaffolds with tailored viscoelasticity that soften or stiffen in response to cellular traction forces.

Mechanisms of Engineered Bioactivity

Bioactivity is enhanced through:

- Covalent Immobilization: Tethering of adhesion peptides (e.g., RGD, IKVAV) or growth factors.

- Controlled Release Systems: Integration of microspheres or nanoparticles for sustained or triggered release of morphogens.

- Dynamic Presentation: Use of photolabile or enzymatically cleavable linkers to reveal cryptic bioactive sites on demand.

Detailed Experimental Protocols

Protocol 2.1: Fabrication of an MMP-Degradable, RGD-Functionalized Hyaluronic Acid (HA) Hydrogel for 3D Bioprinting

This protocol outlines the synthesis of a bioink that combines dynamic degradability with integrin-mediated bioactivity.

A. Materials: Research Reagent Solutions

| Item | Function | Example Product/Catalog # |

|---|---|---|

| Thiolated Hyaluronic Acid (HA-SH) | Base polymer backbone, provides biocompatibility and tunable rheology. | Glycosil (BioTime Inc.) or synthesized in-lab. |

| MMP-Sensitive Peptide Crosslinker (KCGPQG↓IWGQCK) | Provides cell-mediated degradability. The ↓ indicates the MMP cleavage site. | Custom synthesis from peptide vendors (e.g., GenScript). |

| RGD Peptide Acrylate (Ac-GRGDSP) | Confers integrin-binding bioactivity to support cell adhesion. | Peptides International or custom synthesis. |

| Photoinitiator (Lithium Phenyl-2,4,6-Trimethylbenzoylphosphinate, LAP) | Enables rapid, cytocompatible crosslinking via visible light (405-420 nm). | Sigma-Aldrich or prepared as per Fairbanks et al., 2009. |

| Phosphate Buffered Saline (PBS), pH 7.4 | Reaction buffer and cell suspension medium. | Thermo Fisher Scientific. |

| 3D Bioprinter with Light Projection/Extrusion Head | For precise spatial deposition and crosslinking of the bioink. | Cellink BIO X or equivalent. |

B. Procedure:

- Precursor Solution Preparation:

- Dissolve HA-SH in PBS to a final concentration of 2% (w/v).

- Dissolve the MMP-sensitive peptide crosslinker in PBS to a concentration of 5 mM.

- Dissolve Ac-GRGDSP peptide in PBS to a concentration of 2 mM.

- Dissolve LAP in PBS to a concentration of 0.05% (w/v). Protect from light.

Bioink Formulation (Aseptic Technique):

- Mix the following components in a sterile vial: 1 mL HA-SH solution, 100 µL Ac-GRGDSP solution, 200 µL MMP-peptide solution, and 50 µL LAP solution.

- Gently vortex to achieve a homogenous mixture. Keep on ice and protected from light until printing.

3D Bioprinting and Crosslinking:

- Load the bioink into a sterile printing cartridge. For cell-laden printing, mix cells (e.g., human mesenchymal stem cells, hMSCs) into the bioink at 1-10 x 10^6 cells/mL prior to loading.

- Set the bioprinter stage temperature to 4-10°C.

- Print using a pneumatic or screw-driven extruder with a 22-27G nozzle. Apply 405 nm light (5-10 mW/cm²) continuously during deposition or in layers post-printing to achieve full crosslinking (typically 30-60 seconds exposure per layer).

- Transfer the printed construct to cell culture medium.

Protocol 2.2: Assessing Dynamic Remodeling and Bioactivity

This protocol describes methods to quantify cellular remodeling and bioactive signaling in the dynamic hydrogel.

A. Quantitative Degradation & Remodeling Assay:

- Fabricate acellular hydrogel discs (e.g., 8mm diameter x 1mm height).

- Immerse in culture medium containing 100 ng/mL of active MMP-2/MMP-9 or conditioned medium from relevant cells.

- At time points (0, 1, 3, 7 days), retrieve samples (n=5), blot dry, and weigh (Wt).

- Lyophilize samples and record dry weight (Wd). Calculate mass loss:

% Mass Remaining = (Wd_t / Wd_0) * 100. - Plot degradation kinetics against a static (non-MMP sensitive) hydrogel control.

B. Analysis of Bioactivity via Integrin-Mediated Signaling:

- Seed cells (e.g., hMSCs) on 2D films or within 3D gels functionalized with RGD vs. a non-adhesive control (e.g., RDG).

- At 6h and 24h, lyse cells and perform a Western Blot for phosphorylated Focal Adhesion Kinase (pFAK Y397) and total FAK.

- Normalize pFAK intensity to total FAK. A significant increase in the RGD group indicates successful activation of integrin-mediated signaling pathways.

Visualizations

DOT Diagram Scripts

Bioprinting with Dynamic Ink: Integrating Self-Assembly into Fabrication Pipelines

Within a broader thesis exploring 3D bioprinting applications of self-assembling biomimetic materials, a central challenge is formulating bioinks that satisfy two conflicting demands: printability (extrusion, structural fidelity) and post-printing self-assembly (biological remodeling, tissue maturation). This document provides application notes and detailed protocols for developing and characterizing such bioinks.

Key Material Systems and Quantitative Data

Table 1: Common Bioink Material Systems and Properties

| Material Base | Typical Conc. (%) | Gelation Mechanism | Key Advantage for Printability | Key Advantage for Self-Assembly | Representative Cell Viability (%) | Reference Year |

|---|---|---|---|---|---|---|

| Alginate | 1.5 - 3.0 | Ionic (Ca²⁺) | Excellent shear-thinning, rapid crosslinking | Low; inert, limited biological cues | 70-85 | 2023 |

| Gelatin Methacryloyl (GelMA) | 5.0 - 15.0 | Photo-polymerization | Tunable viscoelasticity, good shape fidelity | Contains RGD motifs, cell-adhesive, enzymatically degradable | 80-95 | 2024 |

| Hyaluronic Acid (MeHA) | 1.0 - 3.0 | Photo-polymerization | Adjustable viscosity | Native ECM component, supports mesenchymal condensation | 75-90 | 2023 |

| Fibrinogen/Thrombin | 10 - 30 mg/ml | Enzymatic (Thrombin) | Can be blended for printability | Natural clotting cascade, high bioactivity, rapid cell infiltration | 85-95 | 2024 |

| Decellularized ECM (dECM) | 3.0 - 6.0 | Thermo-gelation/Photo-crosslink | Challenging; often blended | Full biomimetic cue repertoire, ideal for self-organization | 65-80 | 2023 |

| Peptide (RADA16-I) | 0.5 - 1.5 | Ionic/pH-triggered self-assembly | Poor structural fidelity alone | Extreme biomimicry, nanofiber presentation of signals | 90-98 | 2024 |

Table 2: Printability vs. Self-Assembly Assessment Metrics

| Metric Category | Specific Parameter | How Measured | Target for Printability | Target for Self-Assembly |

|---|---|---|---|---|

| Rheology | Shear-thinning index (n) | Rotational rheometer | n < 1 (pseudoplastic) | Less critical post-print |

| Yield stress (Pa) | Rotational rheometer | 50 - 500 Pa | Low for remodeling | |

| Printability | Filament Collapse Score (1-5) | Microscopy of grid structure | 1 (No collapse) | May sacrifice for bioactivity |

| Strand Diameter Fidelity (%) | (Nozzle D/Printed D)*100 | >90% | Less critical | |

| Biological | Post-Print Cell Viability (Day 1) | Live/Dead assay | >70% | >80% |

| Matrix Remodeling (Day 7) | Collagen staining area | Not applicable | >150% increase | |

| Gene Marker Upregulation | qPCR (e.g., FN1, ACTA2) | Baseline | 3-5 fold increase |

Experimental Protocols

Protocol 3.1: Formulation of a Dual-Crosslinking GelMA-Alginate Bioink

Objective: Create a bioink with initial printability via alginate ionic crosslinking and long-term self-assembly via GelMA RGD presentation and degradability.

Materials:

- GelMA (5-10% w/v in PBS)

- Sodium Alginate (high G-content, 1-2% w/v in PBS)

- Photoinitiator (LAP, 0.1% w/v)

- CaCl₂ solution (100 mM, sterile)

- Cell suspension (e.g., human mesenchymal stem cells, hMSCs)

Procedure:

- Preparation: Dissolve GelMA and alginate separately in PBS at 40°C. Sterilize using 0.22 µm filters. Mix solutions to final desired ratios (e.g., 7% GelMA / 1% Alginate). Add LAP and dissolve completely. Keep at 37°C.

- Cell Incorporation: Pellet hMSCs (1x10⁶ cells/mL target in bioink). Resuspend pellet in small volume of bioink precursor, then mix gently with the bulk. Avoid bubble formation.

- Printing: Load bioink into syringe. Use a 22-27G nozzle. Set stage temperature to 10-15°C for viscosity. Print into a pre-designed lattice structure.

- Immediate Post-Print Crosslinking: Immediately mist- or submerge-print with 100 mM CaCl₂ solution for 60 seconds to ionically crosslink alginate.

- Secondary Crosslinking: Rinse briefly with PBS. Expose construct to 405 nm UV light (10 mW/cm²) for 30-60 seconds to photocrosslink GelMA.

- Culture: Transfer to cell culture medium. Change medium every 2-3 days.

Protocol 3.2: Assessing Post-Printing Self-Assembly via Spheroid Formation

Objective: Quantify the self-assembly capacity of a bioink by monitoring encapsulated cell reorganization.

Materials:

- Printed cell-laden construct (from Protocol 3.1)

- Culture medium

- Paraformaldehyde (4%)

- Triton X-100 (0.1%)

- Phalloidin (actin stain) and DAPI (nuclear stain)

Procedure:

- Culture: Maintain printed constructs in standard culture conditions (37°C, 5% CO₂) for up to 14 days.

- Time-Point Fixation: At days 1, 7, and 14, extract samples and fix in 4% PFA for 45 minutes at RT.

- Permeabilization and Staining: Wash 3x with PBS. Permeabilize with 0.1% Triton X-100 for 20 min. Block with 3% BSA for 1 hr. Incubate with Phalloidin (1:500) for 2 hrs and DAPI (1:1000) for 5 min.

- Imaging and Analysis: Confocal microscopy. Use image analysis software (e.g., Fiji) to: a. Measure spheroid diameter (>50 spheroids/sample). b. Quantify cell-cell contact (co-localization of actin at junctions). c. Calculate porosity/condensation of the matrix over time.

- Statistical Analysis: Report mean ± SD. Use ANOVA to compare time points.

Visualizations

Bioink Design Logic

Title: Bioink Design Conflict and Resolution Pathway

Dual-Crosslinking Workflow

Title: Bioink Dual-Crosslinking and Self-Assembly Workflow

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions

| Reagent/Material | Function in Bioink Formulation | Example Product/Catalog Number | Key Consideration |

|---|---|---|---|

| GelMA | Provides photocrosslinkable, cell-adhesive network. Crucial for self-assembly. | Advanced BioMatrix GelMA Kit | Degree of functionalization (DoF) affects mechanics & degradation. |

| LAP Photoinitiator | Initiates radical polymerization of GelMA under cytocompatible UV/VIS light. | Sigma-Aldrich, 900889 | Use at low concentrations (0.05-0.2%) to minimize cytotoxicity. |

| High-G Alginate | Provides immediate ionic crosslink for printability and shape retention. | NovaMatrix Pronova SLG100 | G-content determines stiffness and stability of ionic network. |

| RGD Peptide | Can be grafted into inert hydrogels (e.g., PEG) to promote integrin binding and self-assembly. | Peptides International, custom synthesis | Density must be optimized for specific cell type. |

| Matrix Metalloproteinase (MMP) Sensitive Peptide | Incorporated into crosslinkers to enable cell-mediated degradation and remodeling. | Bachem, crosslinker-Peptide | Sequence (e.g., GPQGIWGQ) must match cellular MMP profile. |

| Nanoclay (Laponite XLG) | Rheological modifier to enhance shear-thinning and yield stress for printability. | BYK, Laponite XLG | Can interfere with some fluorescence assays; requires rinsing. |

| Support Bath (Carbopol) | Enables printing of low-viscosity self-assembling inks via FRESH printing. | Lubrizol, Carbopol 980 | Must be formulated at precise pH for gelation and later removal. |

Application Notes

This document details application notes and protocols for three primary bioprinting modalities, contextualized within a thesis on 3D bioprinting applications of self-assembling biomimetic materials. The focus is on creating functional, multicellular tissue constructs for research and drug development.

Extrusion-Based Bioprinting

Application: Ideal for printing high-viscosity bioinks containing self-assembling peptides, cell spheroids, and tissue strands. Best suited for creating large, dense tissue constructs and organ-scale scaffolds. Critical for depositing materials that undergo shear-thinning, enabling precise filament formation. Key Considerations: Shear stress during extrusion can impact cell viability. Optimization of pressure, nozzle diameter, and temperature is essential for maintaining bioink integrity and cell function.

Light-Based Bioprinting (Stereolithography - SLA & Digital Light Processing - DLP)

Application: Excellent for fabricating high-resolution, complex 3D architectures from photopolymerizable hydrogels (e.g., GelMA, PEGDA). Enables the encapsulation of cells within finely tuned, biomimetic microenvironments that guide self-assembly. DLP offers faster print times for an entire layer. Key Considerations: Cytocompatibility of photoinitiators (e.g., LAP, Irgacure 2959) and UV/blue light exposure duration must be meticulously controlled to minimize phototoxicity.

Hybrid Bioprinting Approaches

Application: Combines extrusion and light-based techniques in a single print job. For instance, extrusion can deposit cellular components and supportive materials, while subsequent light-based curing provides structural refinement and stabilization. This is pivotal for creating heterogeneous, multi-material constructs that mimic native tissue interfaces. Key Considerations: Requires precise spatial and temporal coordination between different printheads and curing systems. Bioink chemistries must be compatible across modalities.

Table 1: Comparative Quantitative Data of Bioprinting Modalities

| Parameter | Extrusion-Based | Light-Based (SLA/DLP) | Hybrid Approach |

|---|---|---|---|

| Typical Resolution | 100 - 500 µm | 10 - 150 µm | 50 - 300 µm |

| Print Speed | 1 - 10 mm³/s | 5 - 50 mm³/s (layer) | Varies by component |

| Cell Viability Post-Print | 70% - 90% | 80% - 95% | 75% - 92% |

| Bioink Viscosity Range | 30 - 6x10⁷ mPa·s | 1 - 300 mPa·s | Multi-range |

| Key Material Limitation | Shear-thinning behavior required | Photopolymerization required | Cross-modality compatibility |

Experimental Protocols

Protocol 1: Extrusion Bioprinting of a Self-Assembling Peptide Hydrogel Containing HepG2 Cells

Aim: To fabricate a 3D liver tissue model for drug metabolism studies.

Materials: See "The Scientist's Toolkit" (Table 2).

Method:

- Bioink Preparation: Resuspend the self-assembling peptide powder in sterile cell culture medium at 4°C to a final concentration of 1% (w/v). Allow to equilibrate overnight at 4°C.

- Cell Harvesting: Trypsinize a confluent T75 flask of HepG2 cells. Centrifuge at 300 x g for 5 minutes.

- Cell Encapsulation: Gently mix the cell pellet with the chilled peptide solution to a final density of 5 x 10⁶ cells/mL. Keep the bioink on ice to prevent premature gelation.

- Bioprinter Setup: Load bioink into a sterile, temperature-controlled (4°C) syringe. Assemble a conical nozzle (22G, 410 µm diameter). Set the print stage temperature to 37°C.

- Printing Parameters: Set extrusion pressure to 15-25 kPa, print speed to 8 mm/s, and layer height to 300 µm. Use a pre-designed 10 mm x 10 mm grid structure.

- Crosslinking & Culture: Post-print, incubate the construct at 37°C, 5% CO₂ for 30 minutes to induce thermal gelation. Add complete culture medium and culture for up to 21 days, assessing functionality.

Protocol 2: DLP Bioprinting of a Vascularized GelMA Construct

Aim: To create a perfusable endothelialized channel within a cell-laden hydrogel.

Materials: See "The Scientist's Toolkit" (Table 2).

Method:

- Bioink Formulation: Prepare 7% (w/v) GelMA solution in PBS with 0.25% (w/v) LAP photoinitiator. Filter sterilize.

- Cell Incorporation: Mix human umbilical vein endothelial cells (HUVECs) at 1 x 10⁷ cells/mL into the GelMA-LAP solution. Keep in the dark.

- DLP Setup: Load the bioink into the printing reservoir. Import the 3D model of a branched channel network (diameter: 500 µm).

- Printing Parameters: Set layer thickness to 50 µm. Project each layer for 3-5 seconds (405 nm light, 20 mW/cm²).

- Post-Print Processing: Wash the printed construct twice in PBS to remove unreacted components. Transfer to EGM-2 medium.

- Perfusion Culture: Seed HUVECs into the lumen of the channel and mount the construct in a bioreactor for dynamic perfusion culture to mature the endothelium.

Protocol 3: Hybrid Print of an Osteochondral Interface

Aim: To fabricate a gradient tissue construct mimicking the bone-cartilage junction.

Method:

- Step 1 - Bone Compartment (Extrusion): Print a polycaprolactone (PCL) scaffold infused with a suspension of mesenchymal stem cells (MSCs) in a collagen-nanohydroxyapatite bioink. Use a 25G nozzle at 120°C for PCL and a coaxial nozzle for the cell-laden bioink.

- Step 2 - Interface Stabilization (Light-Based): Immediately after depositing the osteogenic region, use a digital micromirror device to project a gradient pattern of UV light (365 nm, 15 mW/cm², 10s) onto a layer of photopolymerizable hyaluronic acid methacrylate (HAMA) containing chondrogenic factors, creating a stiffness gradient.

- Step 3 - Cartilage Compartment (Extrusion): Print the chondrogenic bioink (HAMA with MSCs and TGF-β3) onto the stabilized interface region.

- Step 4 - Final Cure (Light-Based): Perform a final global light exposure (405 nm, 10 mW/cm², 30s) to crosslink the entire cartilage compartment.

- Culture: Maintain the hybrid construct in a dual-chamber bioreactor providing osteogenic and chondrogenic media to their respective compartments.

Diagrams

Extrusion Bioprinting Workflow

Cell Signaling in Self-Assembly

Logic for Hybrid Approach Selection

The Scientist's Toolkit

Table 2: Key Research Reagent Solutions for Bioprinting with Self-Assembling Materials

| Item | Function in Research | Example Product/Catalog |

|---|---|---|

| Self-Assembling Peptides | Form nanofibrous scaffolds that mimic extracellular matrix (ECM), promoting 3D cell organization and signaling. | Peptide (RADA16-I), Custom designer peptides. |

| Methacrylated Gelatin (GelMA) | Photopolymerizable hydrogel derived from collagen; provides tunable mechanical properties and cell-adhesive motifs. | GelMA, Lyophilized powder. |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | A cytocompatible photoinitiator for visible/UV light crosslinking of hydrogels with high efficiency and low toxicity. | LAP Photoinitiator. |

| Polycaprolactone (PCL) | A biodegradable, thermoplastic polymer used in extrusion printing to provide immediate structural integrity to soft constructs. | Medical-grade PCL pellets. |

| Hyaluronic Acid Methacrylate (HAMA) | A photopolymerizable derivative of hyaluronic acid; used for cartilage bioprinting and creating hydration gradients. | HAMA, 100 kDa. |

| Dual-Chamber Bioreactor | Enables independent perfusion of different media to distinct regions of a hybrid construct (e.g., osteochondral model). | Custom or commercial perfusion systems. |

| Cellular Assay Kits | For quantifying post-print cell viability (Live/Dead), metabolic activity (AlamarBlue), and tissue-specific markers (ELISA/qPCR). | Live/Dead Viability/Cytotoxicity Kit. |

Layer-by-Layer Assembly vs. Co-Printing of Materials and Cells

Within the broader thesis on the 3D bioprinting applications of self-assembling biomimetic materials, two dominant paradigms exist for fabricating cellularized constructs: Layer-by-Layer (LbL) Assembly and Co-Printing. LbL involves the sequential, spatially segregated deposition of biomaterial scaffolds and living cells, allowing for precise, independent control over each component. Co-printing, in contrast, involves the simultaneous deposition of cells and biomaterials from a single, homogenous or composite bioink. The choice between these strategies fundamentally impacts the structural fidelity, cellular microenvironment, biological functionality, and translational potential of the engineered tissue. This application note provides a comparative analysis, detailed protocols, and a research toolkit for implementing these techniques.

Comparative Analysis & Quantitative Data

Table 1: Comparative Analysis of LbL Assembly vs. Co-Printing

| Feature | Layer-by-Layer (LbL) Assembly | Co-Printing (Simultaneous) |

|---|---|---|

| Core Principle | Sequential, alternate deposition of material layers and cell layers. | Simultaneous deposition of cells suspended within a biomaterial ink. |

| Spatial Control | Very High. Enables precise, heterogenous patterning of materials and cells in the Z-axis. | Moderate to High. Depends on printhead design; better for homogeneous distribution. |

| Structural Integrity | Often higher, due to independent optimization of support layers. | Can be limited by bioink rheology and cell-induced degradation. |

| Cell Density | Can achieve very high densities in specific layers. | Limited by bioink printability (typically 1-20 x 10^6 cells/mL). |

| Cell Viability Post-Print | Typically >90-95%, as cells avoid harsh crosslinking or shear stresses. | Variable (70-95%), dependent on bioink shear-thinning and crosslinking mechanics. |

| Fabrication Speed | Slower, due to multiple steps and potential curing/drying intervals. | Faster, single-step deposition process. |

| Complexity of Setup | High. Often requires multi-printhead systems or alternating print/aspiration steps. | Lower. Standard single or multi-material bioprinter configuration. |

| Exemplary Applications | Vascularized tissues, osteochondral interfaces, multi-layered skin models. | Bulk tissue fabrication, organoids, homogeneous parenchymal tissues. |

Table 2: Quantitative Performance Metrics from Recent Studies (2023-2024)

| Metric | LbL Assembly (Avg. Reported) | Co-Printing (Avg. Reported) | Measurement Method |

|---|---|---|---|

| Print Fidelity (Line Width Accuracy) | ± 15 µm | ± 25 µm | Microscopic image analysis |

| Max Achievable Cell Density | 5 x 10^7 cells/mL (in cell layer) | 2 x 10^7 cells/mL (in bioink) | Hemocytometer/flow cytometry |

| Post-Print Viability (Day 1) | 94% ± 3% | 85% ± 5% | Live/Dead assay (Calcein AM/EthD-1) |

| Initial Metabolic Activity (Day 3) | 100% (baseline) | 120% ± 15% (often higher due to stress response) | AlamarBlue/MTT assay |

| Elastic Modulus of Construct | 50 ± 20 kPa (tunable per layer) | 15 ± 5 kPa (homogeneous) | Uniaxial compression test |

Experimental Protocols

Protocol 3.1: Layer-by-Layer Assembly of a Bilayered Vascular Channel

Objective: To fabricate a perfusable channel with an inner endothelial layer and an outer stromal layer using sequential printing.

Materials: See "The Scientist's Toolkit" (Section 5).

Procedure:

- Design & Slicing: Design a hollow tubular structure (Ø 2 mm). Slice into two interlocked parts: a sacrificial Pluronic F127 core and the surrounding scaffold.

- Print Sacrificial Core: Using a cooled printhead (18°C), extrude 30% w/v Pluronic F127 ink to form the core. Maintain stage at 4°C to prevent dissolution.

- Deposit Outer Stromal Layer: Switch to a gelatin-methacryloyl (GelMA)/alginate composite bioink. Print the first scaffold layer around the core. Immediately crosslink with a 100 mJ/cm² 405 nm UV light pulse.

- Seed Endothelial Cells: Aspirate the liquefied Pluronic core at 4°C to create a lumen. Immediately inject a high-density (10^7 cells/mL) suspension of HUVECs in a temperature-sensitive, non-adhesive hydrogel (e.g., Puramatrix) into the lumen. Incubate at 37°C for 30 min to gel.

- Deposit Final Outer Layer: Print a final layer of the GelMA/alginate composite over the initial layer to encapsulate the channel. Perform a final global UV crosslink (500 mJ/cm²).

- Culture & Perfusion: Transfer construct to bioreactor and initiate perfusion culture with endothelial growth medium (EGM-2).

Protocol 3.2: Co-Printing of a Hepatic Spheroid-Laden Construct

Objective: To simultaneously print hepatocyte spheroids within a supportive hydrogel matrix for liver tissue modeling.

Materials: See "The Scientist's Toolkit" (Section 5).

Procedure:

- Bioink Preparation:

- Matrix Bioink: Prepare 5% w/v alginate and 5% w/v gelatin in PBS. Sterile filter. Add 0.5% w/v LAP photoinitiator.

- Cell Component: Form HepG2 spheroids (approx. 150 µm diameter) via hanging drop or ULA plates. Gently mix spheroids into the matrix bioink at a density of 50 spheroids/mL ink.

- Printing Parameters: Load bioink into a temperature-controlled (22°C) syringe printhead. Use a tapered nozzle (Ø 400 µm). Set pressure to 25-30 kPa, print speed to 8 mm/s.

- Co-Printing: Print the desired lattice structure (e.g., 10x10x2 mm grid). Simultaneously with deposition, irradiate the printed filament with a integrated 405 nm LED source (50 mJ/cm²) for immediate partial gelation.

- Ionic Crosslinking: Post-print, immerse the entire construct in a 100 mM CaCl₂ solution for 5 minutes to complete alginate crosslinking.

- Post-Print Culture: Rinse with warm PBS and transfer to hepatocyte culture medium. Assess viability and albumin secretion at days 1, 3, and 7.

Visualizations

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagent Solutions for LbL and Co-Printing

| Item | Function & Rationale | Example Product/Catalog (Representative) |

|---|---|---|

| Temperature-Sensitive Sacrificial Ink | Creates void channels or spaces in LbL printing. Liquefies upon cooling for gentle removal without damaging delicate cell layers. | Pluronic F-127 (Sigma P2443) - 20-30% w/v in cold cell culture medium. |

| Photocrosslinkable Hydrogel | Provides structural integrity and allows rapid, layer-specific stabilization during both LbL and Co-Printing. | Gelatin-Methacryloyl (GelMA) (EngelCell or Advanced BioMatrix) - 5-15% w/v with 0.25% LAP. |

| Ionic Crosslinker | Provides secondary, gentle crosslinking for alginate-based bioinks, enhancing mechanical stability post-print. | Calcium Chloride (CaCl₂) Solution (Sigma C7902) - 50-200 mM in PBS. |

| Bioactive Peptide Adhesion Ligand | Modifies inert hydrogels to promote specific cell adhesion, spreading, and signaling in both techniques. | RGD Peptide (Peptides International) - Conjugated to polymer backbone at 0.5-2 mM concentration. |

| Shear-Thinning Viscosity Modifier | Enhances extrudability of co-printing bioinks and protects cells from shear stress. Improves shape fidelity. | Nanocellulose (Cellink) or Hyaluronic Acid (Creative PEGWorks) - 0.1-1% w/v. |

| Viability/Cytotoxicity Assay Kit | Standardized method to quantify cell survival and death post-printing for protocol optimization. | LIVE/DEAD Viability/Cytotoxicity Kit (Thermo Fisher L3224) - Calcein AM (live) & EthD-1 (dead). |

| Perfusion Bioreactor System | Enables dynamic culture of printed constructs, essential for maturing vascularized LbL structures. | BOSE ElectroForce BioDynamic or custom-built system with flow control. |

Application Notes

The convergence of vascularized tissue constructs and engineered neural networks represents a frontier in 3D bioprinting, driven by the development of self-assembling biomimetic materials. This integration is critical for advancing complex tissue models for drug discovery and understanding neurodegenerative diseases. The core challenge is fabricating a perfusable vascular network that can sustain dense, metabolically active neural tissues and facilitate functional neurovascular coupling.

Key Advances in Biomimetic Materials

Recent research has yielded materials that undergo programmable self-assembly to form hierarchical structures. These materials, often peptide-based or hybrid polymer hydrogels, are designed with specific ligands (e.g., RGD, IKVAV) to guide endothelial and neural cell organization. Their mechanical and biochemical properties can be tuned to match the soft brain parenchyma while providing structural support for capillary-like networks.

Functional Integration Metrics

The success of integrated constructs is evaluated through multi-parametric assessments. Key quantitative outcomes from recent studies are summarized below.

Table 1: Quantitative Metrics for Integrated Neurovascular Constructs

| Metric Category | Typical Target/Result | Measurement Technique |

|---|---|---|

| Vascular Network Maturity | Lumen diameter: 15-50 µm; Perfusion rate: 0.1-1 mL/min | Confocal microscopy, Micro-CT, Tracer perfusion |

| Neural Network Activity | Mean firing rate: 5-15 Hz; Burst synchronization: >60% | Multi-electrode array (MEA), Calcium imaging |

| Barrier Function | TEER: 40-80 Ω·cm²; Dextran (70 kDa) permeability: < 5x10⁻⁷ cm/s | Trans-endothelial electrical resistance, Tracer flux |

| Cell Viability | >90% at Day 14 | Live/Dead assay, ATP quantification |

| Neurovascular Coupling | ~3 sec delay from neural stimulus to vascular diameter change (+15%) | Simultaneous MEA and live imaging |

Application in Drug Development

These constructs provide a physiologically relevant platform for neuropharmacology and toxicology. They enable the study of blood-brain barrier (BBB) permeation, neurotoxicity, and the efficacy of drugs for conditions like Alzheimer's disease in a human-cell-based, 3D context. The inclusion of a perfusable vasculature allows for longer-term culture and the testing of systemic drug delivery routes.

Experimental Protocols

Protocol 1: Bioprinting a Neurovascular Unit Model

Objective: To fabricate a 3D construct containing a perfusable endothelial vessel surrounded by a neural spheroid compartment.

Materials & Pre-Bioprinting:

- Cell Sources: Human induced pluripotent stem cell (iPSC)-derived brain microvascular endothelial cells (iBMECs), iPSC-derived neural progenitor cells (NPCs), and primary human astrocytes.

- Bioinks:

- Vascular Bioink: 8 mg/mL fibrinogen, 3 mg/mL collagen I, 1x10⁶ iBMECs/mL, supplemented with 50 ng/mL VEGF.

- Neural Bioink: 1.5% (w/v) alginate, 3 mg/mL laminin, 2x10⁶ NPCs/mL, 1x10⁶ astrocytes/mL.

- Preparation: Prepare bioinks sterilely. Maintain cells in expansion media until printing. Load bioinks into separate sterile cartridges.

Bioprinting Process:

- Use a coaxial extrusion printhead on a pneumatic bioprinter.

- Print the vascular channel: Co-extrude the vascular bioink (core) with a CaCl₂ crosslinking solution (shell, 100 mM) into a pre-designed channel mold (Ø 1.5 mm) within a support bath. Print at 22°C, 15 kPa pressure.

- Incubate the printed channel at 37°C for 30 minutes to allow fibrin polymerization.

- Switch to a standard nozzle (22G). Infill the surrounding space in the construct with the neural bioink, printing at 10 kPa.

- Immerse the entire construct in a CaCl₂ bath (50 mM) for 5 min to crosslink the alginate.

Post-Printing Culture & Maturation:

- Transfer construct to a dynamic perfusion bioreactor.

- Culture Media: Use a 1:1 mix of endothelial growth medium (EGM-2) and neural differentiation medium (NDM), with 250 µM cAMP and 100 nM retinoic acid to promote maturity.

- Perfusion: Initiate flow at Day 3. Start with a low shear stress of 0.5 dyne/cm², gradually increasing to 2 dyne/cm² over 7 days.

- Culture for 14-21 days, with medium changes every 2 days.

Protocol 2: Assessing Neurovascular Coupling

Objective: To measure functional connectivity where neural activity triggers vascular responses.

Procedure:

- At Day 14, transfer the matured construct to a perfusion chamber on a confocal microscope equipped with an MEA stage.

- Load the vascular lumen with a fluorescent dye (e.g., FITC-dextran, 70 kDa) and incubate the neural compartment with a calcium indicator (e.g., Fluo-4 AM).

- Acquire a baseline recording (60 sec) of vascular diameter and neural calcium fluorescence.

- Stimulation: Use the MEA to deliver a biphasic electrical pulse train (20 Hz, 0.5 ms pulse width, 2 sec duration) to a localized region of the neural network.

- Simultaneous Recording: Record for 120 sec post-stimulation.

- Track changes in vascular diameter in capillaries within 200 µm of the stimulation site.

- Record calcium wave propagation across the neural network.

- Analysis: Calculate the time delay between the peak neural activity and the onset of vasodilation/constriction. Normalize diameter changes as a percentage of baseline.

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Reagent Solutions for Neurovascular Construct Research

| Reagent/Material | Function |

|---|---|

| Peptide Hydrogel (e.g., Puramatrix) | Self-assembling nanofibrous scaffold presenting cell-adhesion motifs; mimics neural ECM. |

| RGD & IKVAV Peptide Motifs | Chemically grafted to hydrogels to promote specific endothelial and neural cell adhesion. |

| VEGF-165 & BDNF Growth Factors | VEGF induces endothelial tubulogenesis; BDNF supports neuronal survival and differentiation. |

| Matrix Metalloproteinase (MMP)-Sensitive Crosslinkers | Enable cell-mediated remodeling of the hydrogel, crucial for network invasion and maturation. |

| FITC- or TRITC-labeled Dextrans (4-150 kDa) | Tracers to assess vascular permeability and barrier integrity. |

| Calcium Indicators (Fluo-4, Cal-520 AM) | Cell-permeable dyes for real-time visualization of neural activity (calcium transients). |

| Tissue Plasminogen Activator (tPA) | Used in post-printing to gently degrade fibrin for easy retrieval of constructs from support baths. |

Visualizations

Neurovascular Coupling Signaling Pathway

Neurovascular Construct Bioprinting Workflow

The integration of 3D bioprinting with self-assembling biomimetic materials has enabled the fabrication of sophisticated, physiologically relevant microtissues. This progress provides the foundational architecture for next-generation Organ-on-a-Chip (OoC) platforms. When engineered for high-throughput (HT) operation, these systems transition from bespoke research tools to powerful drug screening platforms capable of predicting human response with greater accuracy than traditional 2D cultures or animal models. This application note details protocols and considerations for implementing HT OoC systems derived from 3D bioprinted constructs for preclinical drug development.

Table 1: Comparison of High-Throughput OoC Platform Formats

| Platform Feature | Microfluidic Plate (e.g., 96-chip array) | Perfused Bioprinted Construct Array | Spheroid/Microtissue Agarose Trap Array |

|---|---|---|---|

| Throughput (Chips per run) | 48 - 96+ | 24 - 48 | 96 - 384+ |

| Tissue Complexity | Moderate (2-3 cell types, layered) | High (3D architecture, vascular channels) | Moderate (3D aggregates, limited structure) |

| Liquid Handling Compatibility | Full automation | Limited (size constraints) | Full automation |

| Perfusion Capability | Yes (on-chip pumps or rocker) | Yes (integrated bioreactor) | Limited (diffusion dominant) |

| Primary Readout Types | TEER, secreted markers, imaging | Contractility, biomarker release, omics | Viability, ATP content, imaging |

| Typical Assay Duration | 1-7 days | 7-28 days | 3-14 days |

| Approximate Cost per Data Point | High | Very High | Moderate |

Table 2: Performance Metrics of Bioprinted OoCs in Drug Screening (Recent Studies)

| Organ Model | Bioprinting Material | Drug Tested | Key Metric | Result vs. 2D Culture | Reference Year |

|---|---|---|---|---|---|

| Liver | Gelatin methacryloyl (GelMA) / Hepatic spheroids | Acetaminophen | Albumin secretion, CYP450 activity | 3-5x higher IC50, aligned with clinical toxicity | 2023 |

| Cardiac | Fibrin-based bioink / iPSC-CMs | Doxorubicin | Beat rate, viability, troponin release | Detected chronic toxicity at 10x lower conc. | 2024 |

| Blood-Brain Barrier | Collagen I / hBMECs, Astrocytes | Cisplatin, Temozolomide | TEER, permeability coefficient | Barrier integrity effects 100x more sensitive | 2023 |

| Tumor (Breast) | Alginate-GelMA / CAFs, Tumor cells | Paclitaxel, Selumetinib | Invasion area, cytokine profiling | Identified pro-invasive drug effect missed in 2D | 2024 |

Detailed Experimental Protocols

Protocol 1: Fabrication of a High-Throughput Bioprinted Liver-Chip Array

Objective: To create a 24-unit array of perfusable liver sinusoid models for hepatotoxicity screening.

Materials: See "The Scientist's Toolkit" below.

Methodology:

- Chip Fabrication: Microfabricate or procure a 24-unit polystyrene chip plate with each unit containing two medium channels separated by a porous membrane (e.g., 7 µm pores).

- Bioink Preparation: Prepare two bioinks:

- Parenchymal Bioink: Mix primary human hepatocytes (10 million/mL) with GelMA (8% w/v) containing liver ECM peptides (0.5 mg/mL) and photoinitiator (0.1% w/v LAP).

- Vascular Bioink: Mix human liver sinusoidal endothelial cells (HLSECs, 15 million/mL) and human hepatic stellate cells (2 million/mL) in GelMA (5% w/v).

- 3D Bioprinting:

- Load bioinks into separate temperature-controlled printheads (18-22°C).

- Using a multi-material extrusion printer, print a 500 µm diameter parenchymal cord into the bottom channel of each chip unit.

- Immediately crosslink each cord with 405 nm light (10 sec, 10 mW/cm²).

- Print a corresponding endothelial-lined channel (300 µm diameter) in the top channel, ensuring alignment with the parenchymal cord below. Crosslink.

- Chip Maturation: Connect the chip plate to a pneumatic perfusion system. Circulate hepatocyte maintenance medium (bottom channel) and endothelial medium (top channel) at a shear stress of 0.5 dyne/cm² for 5-7 days. Monitor albumin and urea production.

- Drug Screening: After maturation, switch to a serum-free assay medium. Introduce test compounds (e.g., 8-point dose response in triplicate) via the vascular (top) channel. Perfuse for 72 hours.

- Endpoint Analysis:

- Collect effluent daily for LDH, albumin, and cytokine (e.g., IL-8) analysis via ELISA/ multiplex assays.

- On Day 3, stain chips live/dead (Calcein-AM/EthD-1) and fix for immunostaining (ZO-1, CYP3A4, CD31).

- Quantify viability, canalicular network area, and endothelial integrity via high-content imaging.

Protocol 2: High-Throughput Screening on a Cardiac Microtissue Platform

Objective: To assess compound effects on contractility and viability in 96 bioprinted cardiac microtissues simultaneously.

Methodology:

- Microtissue Array Fabrication: Use a non-adhesive agarose micro-mold (96-well, each well with two posts). Prepare a cardiac bioink of iPSC-derived cardiomyocytes (iPSC-CMs) and cardiac fibroblasts (3:1 ratio) in a composite bioink of fibrinogen (5 mg/mL) and hyaluronic acid (1% w/v).

- Bioprinting & Self-Assembly: Dispense 10 µL of bioink into each well of the mold. Add thrombin solution (2 U/mL) to crosslink fibrin. Within 24 hours, tissues self-assemble and attach to the posts, creating suspended, spontaneously beating microtissues.

- Platform Integration: Transfer the entire agarose mold into a standard 96-well plate compatible with an automated imaging and analysis system.

- Pharmacological Screening:

- Baseline recording: Using a video-based motion capture system, record 30-second videos of each well to establish baseline beat rate, amplitude, and regularity.

- Compound addition: Using an automated liquid handler, add positive controls (e.g., Isoproterenol, E-4031) and test compounds to respective wells.

- Kinetic Monitoring: Record contractility parameters at 1h, 24h, 48h, and 72h post-treatment.

- Viability Assessment: At 72h, add ATP content reagent (e.g., CellTiter-Glo 3D) to each well to quantify viability via luminescence. Normalize ATP to baseline controls.

- Data Analysis: Calculate changes in beat rate, contraction force (from displacement), and irregularity metrics (like FFT analysis). Generate dose-response curves for functional and viability endpoints.

Visualization of Workflows and Pathways

Title: HT Bioprinted Organ Chip Screening Workflow

Title: Drug-Induced Liver Injury Pathways on Chip

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for HT OoC Research

| Item | Function & Rationale | Example Product/Type |

|---|---|---|

| Self-Assembling Bioink | Provides a biomimetic, printable matrix that supports cell-cell interactions and tissue maturation. Critical for structural fidelity. | GelMA, Fibrinogen-HA composites, Peptide amphiphiles (PAs), Collagen I. |

| ECM-Mimetic Peptides | Enhances bioactivity of scaffolds; promotes specific cell adhesion, differentiation, and function (e.g., liver-specific peptides). | RGD, GFOGER, Laminin-derived peptides (e.g., YIGSR). |

| Multi-Channel Perfusion System | Automates medium delivery and waste removal for chip arrays; enables precise control of shear stress and compound dosing. | Pneumatic or syringe pump arrays (e.g., 24-96 channel systems). |

| Automated Liquid Handler | Essential for reproducible compound dosing, medium changes, and sample collection across high-density platforms. | Integrated systems (e.g., Biomek, Mantis). |

| High-Content Imaging System | Captures spatially resolved, kinetic data from multiple chips/wells (cell viability, morphology, protein expression). | Confocal or widefield imagers with environmental control (e.g., ImageXpress, Opera). |

| In-situ Electrode Arrays | Monitors transepithelial/endothelial electrical resistance (TEER) in real-time as a barrier integrity metric. | Integrated or insertable electrodes for microplates. |

| Multiplex Secretome Assay | Quantifies a panel of biomarkers (cytokines, organ-specific proteins) from small-volume effluent samples. | Luminex xMAP or MSD ELISA panels. |

| Metabolite Flux Assays | Measures real-time metabolic shifts (glycolysis, mitochondrial respiration) within tissues using sensor cartridges. | Seahorse XF Analyzer with microplate adaptors. |

Overcoming Fabrication Hurdles: Solving Key Challenges in Biomimetic Bioprinting

Within the broader thesis on 3D bioprinting applications of self-assembling biomimetic materials research, a central challenge is the gelation-kinetics paradox. Rapid gelation kinetics favor structural integrity post-deposition, yet they impede extrudability, causing nozzle clogging and reducing print fidelity. Conversely, slow gelation kinetics enable smooth extrusion and high printability but lead to poor shape fidelity and structural collapse. This application note details protocols and analytical frameworks to resolve this paradox by precisely tuning the crosslinking trigger mechanisms—thermal, ionic, photo-initiated, and enzymatic—for optimized bioink performance.

Table 1: Comparative Analysis of Crosslinking Mechanisms for Bioinks

| Crosslinking Mechanism | Typical Gelation Time (tgel) | Storage Modulus (G') Post-Gelation (Pa) | Critical Shear Rate for Extrusion (s⁻¹) | Shape Fidelity Score (1-5) | Key Material Example |

|---|---|---|---|---|---|

| Thermal (Thermoreversible) | 10-300 s | 100 - 5,000 | 10 - 100 | 2-3 | Pluronic F127, Collagen |

| Ionic (Diffusion-Based) | 1 - 60 s | 1,000 - 20,000 | 1 - 50 | 4-5 | Alginate-CaCl2, Gellan Gum |

| Photo-Initiated (UV) | 0.1 - 10 s | 2,000 - 50,000+ | 100 - 1,000+ | 4-5 | GelMA, PEGDA |

| Enzymatic (e.g., HRP) | 5 - 120 s | 500 - 15,000 | 50 - 500 | 3-4 | Hyaluronic Acid-Tyramine, Fibrin |

| Supramolecular Self-Assembly | Seconds to Minutes | 50 - 2,000 | 0.1 - 10 | 1-3 | Peptide Amphiphiles, Silk Fibroin |

Table 2: Impact of Gelation Time on Printability Metrics