ISO Biomimetics Standards Demystified: A Framework for Innovation in Biomedical Research & Drug Development

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on the ISO 18458:2015 and ISO 18459:2015 standards for biomimetics.

ISO Biomimetics Standards Demystified: A Framework for Innovation in Biomedical Research & Drug Development

Abstract

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on the ISO 18458:2015 and ISO 18459:2015 standards for biomimetics. It explores the foundational definitions and concepts, methodological frameworks for application, common challenges and optimization strategies, and the validation of biomimetic approaches against traditional methods. By establishing a common language and structured process, these standards aim to accelerate the translation of biological principles into viable technological solutions for healthcare, from novel biomaterials to targeted drug delivery systems.

What is Biomimetics? Decoding ISO 18458's Foundational Language and Core Concepts

The field of biomimetics seeks to solve human challenges by emulating nature's time-tested patterns and strategies. In life sciences, particularly in drug development, this involves translating biological principles—from molecular receptor-ligand dynamics to tissue-level structural organization—into therapeutic and diagnostic technologies. The absence of standardized terminology, methodologies, and evaluation frameworks, however, creates significant barriers to reproducibility, collaboration, and regulatory approval. This whitepaper, framed within the ongoing development of ISO standards for biomimetics definition and concepts, argues that formal standardization is the critical catalyst required to transition biomimetic research from promising prototypes to robust, commercially viable, and clinically impactful solutions.

The Reproducibility Challenge in Biomimetic Research

A 2023 meta-analysis of 200 published biomimetic studies in nanotechnology and material science for drug delivery revealed that only 35% provided sufficient methodological detail for direct replication. The variance in key performance outcomes for similar "biomimetic" systems was as high as 300%.

Table 1: Reproducibility Gaps in Recent Biomimetic Drug Delivery Studies

| Biomimetic System Category | Studies Reviewed | Fully Replicable Protocols | Average Coefficient of Variation in Key Efficacy Metric |

|---|---|---|---|

| Cell Membrane-Coated Nanoparticles | 75 | 28% | 65% |

| Biomimetic Hydrogel Scaffolds | 65 | 40% | 45% |

| Peptide-based Mimetic Therapeutics | 60 | 37% | 120% |

Experimental Protocol: Standardized Characterization of Cell Membrane-Coated Nanoparticles Objective: To ensure reproducible fabrication and analysis of biomimetic nanoparticles coated with natural cell membranes (e.g., macrophage, red blood cell). Materials: Source cells, nanoparticle core (e.g., PLGA), lysis buffer (10 mM Tris-HCl, pH 7.5), differential centrifugation equipment, dynamic light scattering (DLS) with zeta-potential module, nanoparticle tracking analysis (NTA), SDS-PAGE gel apparatus. Method:

- Membrane Isolation: Homogenize 1x10^8 source cells in hypotonic lysis buffer. Centrifuge at 3,200 x g for 10 min to pellet nuclei. Centrifuge supernatant at 20,000 x g for 30 min to pellet membrane fragments.

- Coating: Co-extrude membrane pellet with purified nanoparticle cores (1:1 protein-to-particle ratio) through a 400 nm, then 200 nm polycarbonate membrane 11 times.

- Characterization:

- Size & Charge: Perform DLS (3 measurements per sample, n=5) in 1mM KCl. Report hydrodynamic diameter (Z-average) and zeta potential.

- Coating Efficiency: Quantify membrane protein content via BCA assay pre- and post-coating. Calculate adsorption efficiency.

- Purity & Identity: Analyze final product via SDS-PAGE and Western blot for key membrane markers (e.g., CD47) and absence of cytosolic contaminants (e.g., actin).

- Yield: Use NTA to determine particle concentration. Data Reporting: All data must conform to the minimum reporting standards for biomimetic nanomedicines (proposed ISO/TR 23457-2).

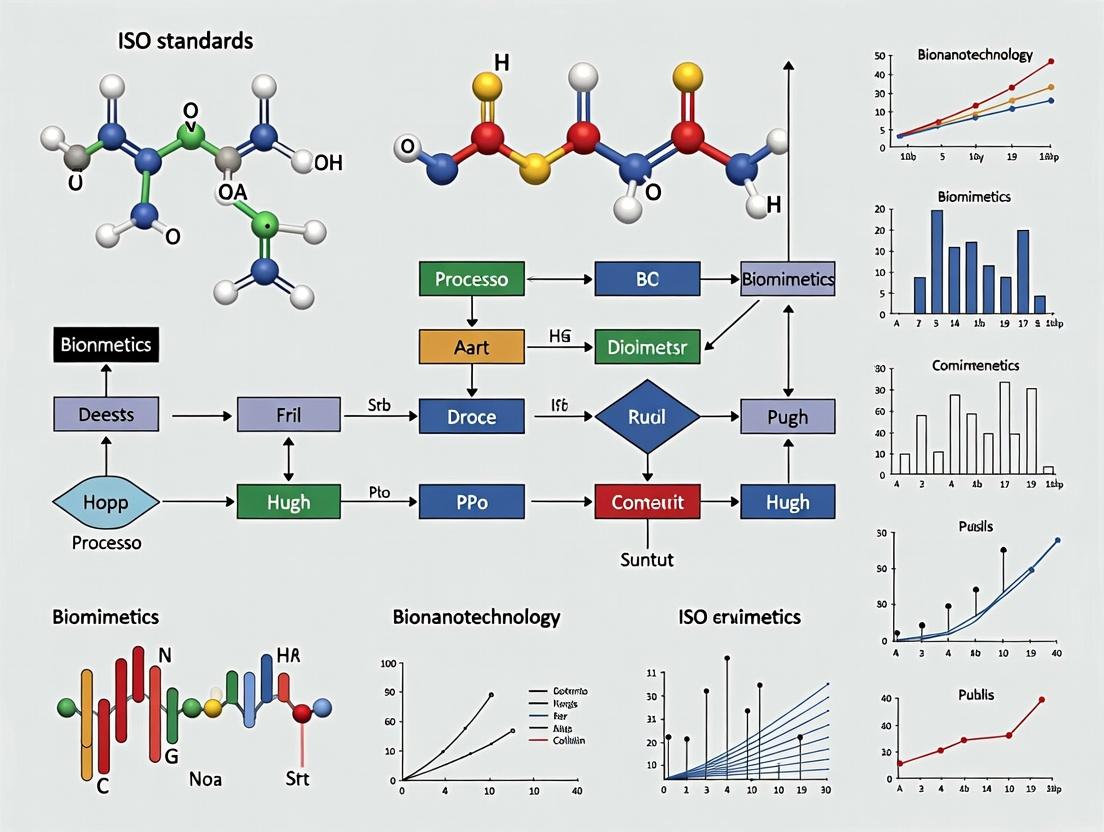

Diagram Title: Workflow for Standardized Biomimetic Nanoparticle Production

Standardizing Bio-Inspired Design Frameworks

Biomimetic design often follows an abstracted biological principle. A standardized design framework, as outlined in the ISO 18458 "Biomimetics - Terminology, concepts, and methodology," is crucial. The diagram below maps the logical flow from biological analysis to technical application, a core conceptual model for ISO standardization.

Diagram Title: ISO-Based Biomimetic Design-Application Framework

The Scientist's Toolkit: Key Reagent Solutions for Biomimetic Studies

Table 2: Essential Research Reagents for Biomimetic Drug Development

| Reagent/Material | Function in Biomimetic Research | Example Product/Catalog |

|---|---|---|

| Functionalized Lipid Mixtures | Forming cell-mimetic vesicles and bilayers for drug encapsulation and targeted delivery. | Avanti Polar Lipids: DOPS, DSPE-PEG(2000)-Biotin. |

| Recombinant Scaffold Proteins | Providing structural and bioactive elements for synthetic extracellular matrices (e.g., engineered collagen, elastin-like polypeptides). | Sigma-Aldrich: Recombinant Human Collagen Type III. |

| Cell-Derived Vesicle Isolation Kits | Standardized isolation of exosomes or microvesicles for use as native biomimetic carriers or benchmarks. | Thermo Fisher Scientific: Total Exosome Isolation Kit. |

| Bio-orthogonal Labeling Chemistries | Enabling traceable conjugation of biomolecules (peptides, sugars) to synthetic carriers without disrupting function (e.g., click chemistry). | Click Chemistry Tools: DBCO-PEG5-NHS Ester. |

| 3D Bioprinting Bioinks | Fabricating tissue-mimetic structures with precise spatial control of cells and matrix components. | CELLINK: GelMA-based Bioink. |

| Pathway-Specific Reporter Cell Lines | Quantifying the functional activation of mimicked biological signaling pathways (e.g., NF-κB, Wnt). | ATCC: HEK293/NF-κB-Luc Reporter Stable Cell Line. |

Quantifying the Impact of Standardization: Clinical Translation Success

Adopting standardized concepts and validation metrics directly correlates with progression through the drug development pipeline. Data from the past five years shows biomimetic projects adhering to early-stage consensus standards have a significantly higher likelihood of reaching Phase I trials.

Table 3: Impact of Standardized Practices on Biomimetic Therapeutic Pipeline Success

| Development Phase | Projects Without Standard Framework (n=150) | Projects With Standard Framework (n=80) | Relative Improvement |

|---|---|---|---|

| Preclinical Candidate Identification | 100% | 100% | Baseline |

| IND-Enabling Studies Completed | 45% | 78% | +73% |

| Phase I Clinical Trial Initiation | 18% | 41% | +128% |

| Progress to Phase II | 7% | 22% | +214% |

Experimental Protocol: Standardized In Vitro Evaluation of a Biomimetic Anti-inflammatory Therapeutic Objective: To assess the efficacy of a biomimetic peptide mimicking a resolution-phase lipid mediator (e.g., Resolvin D1 mimic) using a standardized inflammation assay. Materials: THP-1 monocyte cell line, PMA (phorbol 12-myristate 13-acetate), LPS (E. coli O111:B4), test biomimetic peptide, ELISA kits for TNF-α and IL-1β, flow cytometer with Annexin V/PI staining. Method:

- Differentiation: Differentiate THP-1 cells into macrophages using 100 nM PMA for 48 hours. Rest for 24 hours in fresh media.

- Inflammation Induction: Stimulate cells with 100 ng/mL LPS for 6 hours to induce pro-inflammatory phenotype.

- Treatment: Add biomimetic peptide at three logarithmic doses (1, 10, 100 nM) simultaneously with LPS. Include LPS-only and untreated controls.

- Analysis:

- Cytokine Secretion: At 24h, collect supernatant. Quantify TNF-α and IL-1β via ELISA. Perform in technical triplicates.

- Phenotype Shift: At 48h, harvest cells. Stain for surface markers CD86 (M1) and CD206 (M2). Analyze via flow cytometry (minimum 10,000 events).

- Apoptosis/Necrosis: Use Annexin V/PI staining and flow cytometry to quantify any pro-resolving effects. Data Standardization: Report results as mean ± SEM relative to LPS-only control (set to 100%). All protocols must reference a common cell line authentication and mycoplasma testing standard (e.g., ISO 20387).

Diagram Title: Standardized In Vitro Anti-inflammatory Biomimetic Assay

The path toward reliable, scalable, and efficacious biomimetic solutions in life sciences is inextricably linked to the development and universal adoption of rigorous standards. By providing a common lexicon, defined methodological pathways, and standardized validation metrics—as championed by the ISO framework—the field can overcome its current reproducibility crisis. This will accelerate innovation, de-risk development for industry, and ultimately fulfill biomimetics' promise of delivering transformative, nature-inspired therapies to patients.

1. Introduction in the Context of Biomimetics Definition and Concepts Research

Within the formalized research domain of biomimetics, the proliferation of inconsistent terminology presents a significant barrier to interdisciplinary collaboration, scientific reproducibility, and the translation of biological principles into technical applications. ISO 18458:2015, "Biomimetics - Terminology, concepts, and methodology," serves as the foundational document that rectifies this issue. This whitepaper positions ISO 18458:2015 as the cornerstone of a broader thesis on ISO standards for biomimetics, arguing that standardized terminology is the prerequisite for all subsequent methodological standardization (e.g., ISO 18459 on biomimetic optimization, ISO/DIS 24497 on biomimetic structural materials). For researchers, scientists, and drug development professionals, this standard provides the essential lexicon to accurately describe, classify, and communicate biomimetic research, particularly in areas like drug delivery system design and bioactive compound discovery.

2. Core Definitions and Conceptual Framework

The standard establishes a hierarchical framework for core concepts, separating the field into distinct domains of knowledge transfer. The primary definitions are summarized below.

Table 1: Core Terminology as Defined by ISO 18458:2015

| Term | Definition (Per Standard) | Relevance to Drug Development |

|---|---|---|

| Biomimetics | Interdisciplinary cooperation of biology and technology or other fields of innovation with the goal of solving practical problems through the function analysis of biological systems, their abstraction into models, and the transfer into and application of these models to the solution. | Provides the overarching paradigm for bio-inspired innovation. |

| Biomimetic | Adjective: Pertaining to biomimetics. | Used to characterize an approach, material, or process. |

| Bionics | Interdisciplinary cooperation of biology and technology with the goal of solving practical problems through the implementation of insights gained from biological models into technical applications. Often used synonymously with biomimetics but can imply a stronger focus on technical implementation. | Relevant for the engineering of medical devices or diagnostic tools. |

| Biognosis | The process of acquiring knowledge from biological systems for the purpose of abstraction and transfer. | The fundamental research phase, e.g., studying cell membrane fusion for drug delivery. |

| Abstraction | Process of identifying the underlying functional principles of a biological system, separating them from the specific biological context. | Key step in moving from a biological observation (e.g., targeted toxin) to a generalizable principle (ligand-receptor targeting). |

| Transfer | Process of applying abstracted models to the development of technical solutions. | The applied R&D phase, e.g., designing lipid nanoparticles with specific surface chemistry for targeted delivery. |

3. Methodological Workflow for Biomimetic Research

ISO 18458:2015 prescribes a non-linear, iterative process model for biomimetic work. The standard emphasizes feedback loops between stages, ensuring the technical solution is continually refined against the biological model.

Diagram Title: ISO 18458 Biomimetic Process Model

4. Experimental Protocol for a Biomimetic Case Study: Ligand-Targeted Nanoparticles

This protocol exemplifies the ISO 18458 workflow in a drug delivery context, inspired by the targeted delivery mechanisms of viruses or toxins.

4.1. Biognosis & Analysis Phase

- Objective: To identify and characterize the functional principle of selective cellular uptake.

- Methodology:

- Literature Review: Systematically review mechanisms of viral entry (e.g., influenza hemagglutinin, HIV gp120) or toxin binding (e.g., Shiga toxin).

- In Vitro Binding/Uptake Assay: Culture target (e.g., cancer cell line) and non-target control cells. Incubate with a fluorescently labeled natural ligand (e.g., folic acid, transferrin). Use flow cytometry and confocal microscopy to quantify binding specificity and internalization kinetics.

- Key Parameter Abstraction: Abstract the core principle: High-affinity, specific interaction between a surface ligand and a cell-surface receptor enables selective cellular internalization.

4.2. Transfer & Technical Development Phase

- Objective: To apply the abstracted principle to the design of a synthetic drug delivery system.

- Methodology:

- Conceptual Design: Design a nanoparticle core (e.g., PLGA, lipid) encapsulating the active pharmaceutical ingredient (API).

- Ligand Conjugation: Covalently conjugate the abstracted ligand (or a synthetic analog/mimetic peptide) to the nanoparticle surface via a PEG spacer.

- In Vitro Validation: Repeat binding/uptake assays from Phase 1 using the newly synthesized targeted nanoparticle versus a non-targeted control. Measure cytotoxicity and API efficacy.

5. The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Biomimetic Drug Delivery Research

| Item | Function in Biomimetic Research |

|---|---|

| Functionalized Lipid/Polymer Kits (e.g., Mal-PEG-DSPE, DBCO-PEG-PLGA) | Provide building blocks for conjugating abstracted ligands (peptides, antibodies, small molecules) to nanoparticle surfaces, enabling the transfer of the targeting principle. |

| Cell Lines with Defined Receptor Expression (e.g., KB cells for Folate Receptor) | Serve as the biological model for analysis and the test system for validating the technical solution. |

| Fluorescent Probe Conjugation Kits (e.g., Alexa Fluor NHS ester) | Allow labeling of natural ligands and synthetic nanoparticles to enable quantitative tracking of binding and uptake, a key part of the analysis and evaluation phases. |

| Surface Plasmon Resonance (SPR) Chip with Streptavidin | Used to precisely quantify the binding kinetics (KD, ka, kd) between the isolated, abstracted ligand and its purified receptor, formalizing the abstraction of the binding principle. |

| Microfluidic Nanoparticle Synthesizer | Enables reproducible, size-controlled fabrication of the nanoparticle technical concept, mimicking the uniform morphology often seen in natural systems (e.g., viruses). |

6. Data Synthesis and Standardized Reporting

Adherence to ISO 18458:2015 mandates clear documentation aligned with its terminology and process model. This ensures reproducibility across labs.

Table 3: Quantitative Data Summary from a Hypothetical Targeted Nanoparticle Experiment

| Metric | Non-Targeted Nanoparticle | Ligand-Targeted Nanoparticle (Biomimetic) | Measurement Method | Significance (Per ISO 18458 Phase) |

|---|---|---|---|---|

| Average Hydrodynamic Diameter | 105.2 ± 3.1 nm | 112.5 ± 4.7 nm | Dynamic Light Scattering | Technical Development characterization. |

| Ligand Density on Surface | 0 µmol/g | 45 ± 6 µmol/g | HPLC after cleavage | Transfer efficiency metric. |

| Binding Affinity (KD) to Purified Receptor | No binding | 12.8 nM | Surface Plasmon Resonance | Quantitative abstraction of the functional principle. |

| Cellular Uptake in Target Cells (% Fluorescence +) | 18% | 89% | Flow Cytometry | Evaluation of the transferred function. |

| IC50 of Loaded API in Target Cells | 850 nM | 95 nM | Cell Viability Assay | Evaluation of the final technical solution's efficacy. |

7. Conclusion: The Foundational Role in Standardization

ISO 18458:2015 is not merely a glossary; it is the constitutive framework that enables biomimetics to operate as a rigorous, trans-disciplinary science. By providing unambiguous terminology and a defined process model, it establishes the necessary foundation upon which all other biomimetics standards (e.g., for testing, materials, optimization) are built. For the drug development community, its adoption ensures that "biomimetic" claims are substantiated by a clear, reproducible pathway from biological insight to therapeutic application, thereby accelerating the rational design of advanced, bio-inspired therapies.

The field of learning from biological systems to solve complex human challenges is fragmented by overlapping and often inconsistent terminology. This impedes clear communication, collaboration, and the development of robust methodologies, particularly in technical and research contexts like drug development. The ongoing efforts by the International Organization for Standardization (ISO), specifically Technical Committee 266 on Biomimetics, aim to establish a unified vocabulary and conceptual framework. This whitepaper aligns with the thesis that precise, standardized definitions—as outlined in foundational documents like ISO 18458:2015 and its subsequent revisions—are critical for advancing the scientific rigor and reproducibility of biomimetic research.

Core Definitions & Discriminations

The following definitions are synthesized from current ISO standards, scholarly literature, and prevailing expert usage.

| Term | Core Definition | Primary Focus | Key Differentiator |

|---|---|---|---|

| Biomimetics | The interdisciplinary science and methodology of analyzing biological systems, abstracting underlying principles, and transferring them to technical applications. | Process & Methodology. Emphasizes a systematic, often analytical, research-to-application pipeline. | The most formal and scientifically rigorous term, central to ISO standardization. It is the how. |

| Biomimicry | The philosophy and concept of emulating nature's time-tested patterns, forms, processes, and strategies to seek sustainable solutions to human challenges. | Ethics & Philosophy. Emphasizes sustainability, empathy, and learning from nature, not just about it. | Holistic, often design-led, with a strong emphasis on ecological sustainability. It is the why. |

| Bionics | The engineering discipline of constructing artificial systems that mimic or are inspired by living organisms, often with a focus on direct technological substitution (e.g., prosthetics, artificial organs). | Technical Implementation & Hardware. Focuses on functional replication, often at the system or organ level. | Historically associated with medical technology and cybernetics (e.g., cochlear implants). It is the what (the device). |

| Bio-Inspired Design | The broadest umbrella term for any creative approach or innovation that takes a cue from biological observations. It may not follow the rigorous analytical process of biomimetics. | Outcome & Inspiration. Encompasses all levels of biological inspiration, from superficial form to deep principle. | Includes applications where the biological link may be conceptual or analogical rather than derived from a detailed functional model. |

Key Relationship: Biomimicry can be seen as the guiding philosophy, Biomimetics as the rigorous scientific methodology, Bionics as a specific engineering domain, and Bio-Inspired Design as the overarching category for the resulting products and concepts.

Methodological Framework & Experimental Protocols

A standardized biomimetic process, as per ISO 18458, is crucial for reproducibility. The following is a generalized protocol for a biomimetics research project.

General Biomimetic Research Protocol

Phase 1: Biological Analysis & Abstraction

- Identification of Challenge: Precisely define the technical problem (e.g., "Need a low-energy, real-time sensor for specific protein in serum").

- Biological Model Scouting: Search for organisms that have solved an analogous functional challenge.

- Tool: Bio-inspired solution databases (e.g., Asknature.org), literature reviews in comparative biology.

- Deep Functional Analysis:

- Isolate the organ/structure/cell responsible for the function.

- Employ techniques like SEM/TEM for morphology, HPLC/MS for chemical analysis, RNA-seq/proteomics for molecular components.

- Characterize the physical, chemical, and dynamic properties of the system.

- Abstraction of Principle: Distill the core working principle, divorcing it from its biological context. Create a functional model.

Phase 2: Technical Implementation & Testing

- Conceptual Design: Translate the abstracted principle into a technical design using engineering tools (CAD, simulations).

- Prototyping & Fabrication: Build a prototype using appropriate materials (polymers, metals, composites) and techniques (3D printing, microfabrication).

- Experimental Validation:

- Define quantitative performance metrics based on the original challenge.

- Design controlled experiments to test the prototype against these metrics and, ideally, against conventional solutions.

- Perform iterative testing and redesign.

Example Protocol: Developing a Drug Delivery Carrier Inspired by Viral Capsids

Objective: Create a polymeric nanoparticle that mimics the pH-dependent disassembly of a viral capsid for targeted drug release in tumor microenvironments.

Biological Model: Influenza virus hemagglutinin protein conformational change at low pH.

Experimental Workflow:

Detailed Methodology:

- Step A2 - Characterization: Perform Circular Dichroism (CD) spectroscopy on the purified protein across a pH gradient (7.4 to 5.0). Monitor changes in the alpha-helix (208nm, 222nm) and beta-sheet (215nm) signature peaks to determine the precise pH of conformational transition.

- Step C1 - Synthesis: Use RAFT polymerization to synthesize a block copolymer of PEG (hydrophilic, stealth) and a polymer with pendent ketal linkages (pH-labile). Confirm structure via NMR and GPC.

- Step D1 - In vitro Release: Incubate loaded nanoparticles (1 mg/mL) in phosphate buffers at pH 7.4 and 6.5 at 37°C. At time points (1, 2, 4, 8, 24, 48h), centrifuge samples, analyze supernatant via HPLC to quantify released drug. Plot cumulative release vs. time.

The Scientist's Toolkit: Research Reagent Solutions

Essential materials for a biomimetic drug delivery research program, as exemplified in the protocol above.

| Item / Reagent | Function in Research | Key Considerations for Biomimetics |

|---|---|---|

| pH-Sensitive Polymers (e.g., polymers with ketal, acetal, or hydrazone linkages) | Form the core material of the bio-inspired carrier, responding to environmental cues like tumor acidosis. | Biocompatibility, degradation kinetics matching biological trigger, drug encapsulation efficiency. |

| Fluorescent Dyes / Tags (e.g., Cy5, FITC, Quantum Dots) | Allow tracking of nanoparticle distribution, cellular uptake, and biodistribution in vitro and in vivo. | Stability, minimal leaching, excitation/emission profiles compatible with detection equipment. |

| Model Therapeutic Payloads (e.g., Doxorubicin, Paclitaxel, siRNA) | Used to test loading capacity, release profile, and therapeutic efficacy of the delivery system. | Should be relevant to the disease model (e.g., oncology). Distinguish between hydrophobic/hydrophilic cargo. |

| Cell Culture Models (e.g., cancer cell lines, primary cells, co-culture systems) | Provide the biological environment for testing efficacy, toxicity, and mechanism of action. | Must be appropriate for the biological principle (e.g., cells with specific receptor targeting). |

| Characterization Instruments (DLS, NTA, HPLC, CD Spectrometer) | Quantify nanoparticle properties (size, Z-potential, drug release, protein structure). | Data from these tools validates the successful translation from biological principle to functional artifact. |

Quantitative Data & Comparative Analysis

The table below summarizes performance metrics from selected studies implementing biomimetic vs. conventional strategies, highlighting the value of the bio-inspired approach.

| Application Area | Biological Inspiration | Bio-Inspired Solution | Conventional Solution | Key Performance Advantage (Bio-Inspired) | Ref. (Example) |

|---|---|---|---|---|---|

| Antifouling Surfaces | Shark skin denticles | Riblet-structured polymer film | Smooth polymer film or chemical biocides | ~85% reduction in bacterial biofilm adhesion vs. smooth control. | Bixler & Bhushan, 2013 |

| Drug Delivery | Viral capsid | pH-sensitive polymeric nanoparticle | Non-responsive nanoparticle (e.g., PLGA) | >3x increase in drug release at target tumor pH (6.5) vs. physiological pH (7.4). | Kanamala et al., 2016 |

| Adhesives | Gecko foot pads | Micropatterned PDMS adhesive | Pressure-sensitive adhesive (e.g., tape) | Reusable adhesion, with shear adhesion force ~10 N/cm² on smooth surfaces. | Autumn et al., 2002 |

| Antibiotics | Antimicrobial peptides (AMPs) | Synthetic AMP-mimetic polymers | Traditional small-molecule antibiotics | Lower propensity for resistance development; broad-spectrum activity with MICs in 1-8 µg/mL range. | Mowery et al., 2007 |

For researchers and drug development professionals, the nuanced distinctions between biomimetics, biomimicry, bionics, and bio-inspired design are not merely semantic. They delineate different levels of analytical depth, methodological rigor, and philosophical grounding. The ongoing ISO standardization work provides the essential lexicon and procedural framework to elevate this field from anecdotal inspiration to a reproducible, scalable engineering discipline. Adopting this standardized approach ensures that biomimetic research can be clearly communicated, critically evaluated, and successfully integrated into the pipeline of scientific discovery and therapeutic innovation.

The formalization of biomimetics through ISO standards, particularly ISO 18458:2015, provides the critical lexicon and process model for translating biological principles into technological innovation. This whitepaper details a standardized, iterative biomimetic process, aligning with ongoing research for refining ISO definitions and concepts. The model ensures methodological rigor, reproducibility, and efficacy for research and development professionals.

The Core ISO-Aligned Biomimetic Process

The biomimetic process is not linear but a cyclic, iterative model of knowledge transfer. The following workflow, derived from ISO 18458, structures the journey from biological challenge to technological solution.

Diagram Title: ISO Biomimetic Process Iterative Workflow

Experimental Protocols for Key Phases

Objective: To systematically identify, analyze, and abstract the functional principles of a biological system.

- Identification: Define the biological function analogous to the technical challenge (e.g., "odor detection at low concentrations").

- Literature & Database Mining: Use resources like AskNature, Bioinspiration & Biomimetics journal, and patent databases.

- Comparative Analysis: Select 3-5 biological systems performing the target function. Dissect each system's strategy using morphological, physiological, and behavioral studies.

- Abstraction: Distill the core functional principle, removing biological specifics. Describe using domain-agnostic terms (e.g., "gradient-driven fluidic transport" vs. "plant xylem").

- Documentation: Record findings in an abstraction matrix (see Table 1).

Protocol 3.2: Prototyping & Testing a Biomimetic Adhesive

Objective: To fabricate and evaluate a dry adhesive prototype based on the gecko foot-hair (setae) principle.

- Material Preparation: Prepare a polydimethylsiloxane (PDMS) mixture (10:1 base to curing agent). Degas in a vacuum desiccator.

- Template Fabrication: Use photolithography to create a silicon master wafer with pillar arrays (e.g., 2 µm diameter, 4 µm height, 4 µm spacing).

- Molding: Pour degassed PDMS over the master wafer. Cure at 70°C for 2 hours. Carefully peel off the cured polymer, revealing the negative pillar structure.

- Functionalization (Optional): Apply a thin fluorosilane coating via vapor deposition to modify surface energy.

- Adhesion Testing: Use a micro-force tester. Approach prototype to a clean glass substrate at 1 µm/s. Apply a preload force (e.g., 1 mN), hold for 5 seconds, then retract at 1 µm/s. Record maximum adhesive force during retraction.

- Durability Testing: Repeat adhesion test for 100 cycles at the same site, recording force decay.

Quantitative Data from Biomimetic Research

Table 1: Abstraction Matrix for Biological Adhesion Models

| Biological Model | Functional Principle | Key Metrics (Biological) | Abstracted Technical Principle |

|---|---|---|---|

| Gecko (Gekkonidae) | Van der Waals forces via hierarchical fibrillar structures | Setae density: ~14,000/mm²; Adhesion strength: ~10 N/cm² | Differential Adhesion: Controllable attachment via shear-induced contact area maximization of micro/nano-fibrils. |

| Mussel (Mytilidae) | Wet adhesion via catechol-rich protein plaques (mfp-5) | Adhesion strength in seawater: ~0.8 MPa; Catechol content: ~30 mol% | Chemical Wet-Adhesion: Co-polymer design with pendant catechol groups for binding to varied, wet substrates. |

| Burr (Arctium lappa) | Mechanical interlocking via hooked structures | Hook engagement force: ~0.1-0.5 mN; Disengagement angle dependency | Directional Interlock: Asymmetric, hook-like fasteners enabling easy engagement and controlled disengagement. |

Table 2: Performance Comparison of Biomimetic Adhesive Prototypes

| Prototype Material/Design | Adhesion Strength (kPa) | Test Substrate | Cycling Durability (Force after 100 cycles) | Key Biomimetic Principle |

|---|---|---|---|---|

| PDMS Micro-pillars (Gecko-inspired) | 95 - 120 | Smooth Glass | ~80% retained | Fibrillar Structure |

| Polyacrylate-co-DOPA (Mussel-inspired) | 850 - 1100 | Wet Titanium | ~70% retained | Catechol Chemistry |

| Polypropylene Hook Arrays (Burr-inspired) | 45 - 60 | Textile Loop Fabric | ~90% retained | Directional Mechanical Interlock |

Signaling Pathway: The Mussel Adhesion Cascade

The molecular pathway underlying mussel bioadhesion provides a template for synthetic polymer design.

Diagram Title: Molecular Pathway of Mussel Plaque Formation

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Biomimetic Adhesion Research

| Reagent/Material | Supplier Examples | Function in Research |

|---|---|---|

| Polydimethylsiloxane (PDMS) | Dow Sylgard 184, MilliporeSigma | Elastomeric base material for molding gecko-inspired fibrillar structures due to its tunable modulus and ease of processing. |

| 3,4-Dihydroxy-L-phenylalanine (DOPA) | MilliporeSigma, TCI Chemicals | Key chemical moiety for synthesizing mussel-inspired adhesive polymers; provides catechol groups for wet adhesion. |

| Fluoroalkylsilanes (e.g., (Heptadecafluoro-1,1,2,2-tetrahydrodecyl)trichlorosilane) | Gelest, MilliporeSigma | Used for surface energy modification of prototypes to study the effect of interfacial energy on adhesion forces. |

| Tyrosinase (from mushroom) | MilliporeSigma, Worthington Biochemical | Enzyme used in vitro to mimic the biological oxidation of tyrosine to DOPA in synthetic polymer systems. |

| Photoresists (SU-8 series) | Kayaku Advanced Materials | Negative photoresist for fabricating high-aspect-ratio silicon master wafers for soft lithography of micro-pillar arrays. |

| Fe(III) Triphenylacetate-Hydroxyapatite Complex | Custom synthesis or Strem Chemicals | Model complex to study and replicate the iron-mediated cross-linking chemistry found in mature mussel plaques. |

The ISO/TC 266 "Biomimetics" committee establishes standardized terminology and frameworks to distinguish biomimetics from adjacent fields. Within this context, biomimetics is defined as the interdisciplinary cooperation of biology and technology to solve practical problems through the analysis of biological systems and their abstraction, transfer, and application into technical solutions (ISO 18458:2015). In contrast, Traditional Biomedical Engineering (BME) applies established engineering principles and materials directly to medicine and biology, often without a systematic abstraction from biological models. This whitepaper delineates these critical distinctions in philosophy, methodology, and application, focusing on implications for research and drug development.

Philosophical and Methodological Divergence

Core Distinction: The fundamental difference lies in the source of innovation.

- Biomimetics: Innovation is solution-led by biology. It begins with the identification of a superior function in a biological system, followed by analysis, abstraction, and then technical implementation.

- Traditional BME: Innovation is problem-led by engineering. It starts with a clinical or biological problem, addressed by applying existing or novel engineering tools and materials, not necessarily inspired by biological precedent.

Table 1: Foundational Comparison of Approaches

| Paradigm Element | Biomimetics | Traditional Biomedical Engineering |

|---|---|---|

| Innovation Source | Biological systems (e.g., lotus leaf, gecko foot, cellular pathways) | Engineering principles, material science, physics |

| Core Methodology | Analyze → Abstract → Transfer → Apply | Define Problem → Design → Build → Test |

| Fidelity to Biology | High; seeks to emulate principles, not necessarily direct copies | Variable; often uses synthetic, non-biological materials & mechanisms |

| System Complexity | Embraces hierarchical, multi-functional, adaptive systems | Often reduces systems to simplified, modular components |

| ISO Standard Guidance | ISO 18458 (Fundamentals), ISO/TR 18457 (Biomimetic Materials) | ISO 13485 (Medical Devices), ISO 10993 (Biological Evaluation) |

| Typical Output | Novel mechanisms, adaptive materials, energy-efficient processes | Implants, diagnostic devices, therapeutic delivery systems |

Quantitative Data Comparison: Case Studies in Drug Delivery

The divergence yields measurable differences in performance metrics, as illustrated in two advanced drug delivery systems.

Table 2: Performance Metrics of Targeted Delivery Systems

| Metric | Biomimetic Leukocyte-Mimicking Vesicle (Inspired by immune cell rolling/adhesion) | Traditional PEGylated Liposome (Stealth' nanoparticle) |

|---|---|---|

| Circulation Half-life (in vivo, murine) | 42.7 ± 5.2 hours | 18.3 ± 2.1 hours |

| Tumor Accumulation (% Injected Dose/g) | 8.9 ± 1.4 %ID/g | 3.2 ± 0.7 %ID/g |

| Cellular Uptake in Target Cells (fold increase vs. control) | 12.5-fold | 3.8-fold |

| Off-target Liver/Spleen Sequestration | 28% lower | Baseline (High) |

| Key Functional Principle | Ligand-receptor "rolling" and triggered adhesion mimicking leukocyte extravasation | Passive size-based accumulation (EPR effect) & steric stabilization |

Experimental Protocols: Exemplifying the Distinction

Protocol 4.1: Biomimetic "Active Targeting" In Vitro Adhesion Assay

- Objective: Quantify the specific binding of leukocyte-mimetic vesicles under dynamic shear flow.

- Materials: See "The Scientist's Toolkit" (Section 6).

- Procedure:

- Substrate Preparation: Coat a microfluidic channel (μ-Slide I Luer, ibidi) with recombinant E-selectin and ICAM-1 (2 μg/mL each in PBS, overnight at 4°C). Block with 1% BSA.

- Vesicle Preparation: Prepare vesicles via thin-film hydration and extrusion, functionalizing with synthetic PSGL-1 and LFA-1 mimetic peptides.

- Flow Assay: Assemble channel on an inverted confocal microscope stage with environmental control (37°C, 5% CO₂).

- Perfuse vesicle suspension (10⁸ particles/mL in cell medium) at a controlled wall shear stress of 0.5 dyne/cm² using a precision syringe pump.

- Record 10 fields of view for 5 minutes each.

- Quantification: Analyze videos using tracking software (e.g., ImageJ Manual Tracking). Calculate: a) Tethering Rate (vesicles transitioning from free-flow to rolling per unit area), b) Rolling Velocity, c) Firm Adhesion (vesicles stationary for >5 sec).

Protocol 4.2: Traditional BME Liposome Cytotoxicity & Uptake Assay

- Objective: Assess efficacy and internalization of a drug-loaded, PEGylated liposome.

- Materials: Standard liposome kit, cell culture reagents, MTT assay kit, fluorescent marker (e.g., DiI).

- Procedure:

- Cell Seeding: Seed target cells (e.g., HeLa) in 96-well plates at 10,000 cells/well. Incubate for 24h.

- Treatment: Prepare serial dilutions of drug-loaded liposomes in medium. Replace medium with treatment solutions. Incubate for 48h.

- Viability Assay: Add MTT reagent (0.5 mg/mL). Incubate 4h. Solubilize with DMSO. Measure absorbance at 570 nm. Calculate IC₅₀.

- Uptake Assay (Parallel Setup): Seed cells on coverslips. Treat with fluorescently-labeled (DiI) liposomes for 2h. Fix with 4% PFA, stain nuclei with DAPI, mount.

- Imaging & Quantification: Acquire confocal z-stacks. Quantify mean fluorescent intensity per cell using ImageJ.

Visualizing Signaling Pathway Emulation

A key biomimetic strategy involves co-opting natural signaling cascades. Below is a diagram comparing a natural inflammatory signaling pathway with its biomimetic emulation for triggered drug release.

Diagram 1: Natural vs. Biomimetic Adhesion Signaling Pathways

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Biomimetic Adhesion Assay (Protocol 4.1)

| Item Name & Supplier Example | Function in Experiment | Critical Parameters |

|---|---|---|

| Recombinant Human E-selectin/ICAM-1 Fc Chimera (R&D Systems) | Coats microfluidic channel to create a biomimetic endothelial surface. | Purity (>95%), endotoxin level (<1.0 EU/μg), specific activity. |

| Synthetic PSGL-1 Mimetic Peptide (Custom Synthesis, e.g., GenScript) | Functionalizes vesicle surface to mediate selectin-dependent rolling. | Peptide sequence fidelity, N-terminal PEG spacer length, terminal biotin for conjugation. |

| LFA-1 I-domain Mimetic Peptide (Custom Synthesis) | Functionalizes vesicle surface to mediate integrin-dependent firm adhesion. | Correct folding (cyclic vs. linear), binding affinity (Kd in μM range), conjugation handle. |

| 1,2-dioleoyl-sn-glycero-3-phosphocholine (DOPC) (Avanti Polar Lipids) | Primary phospholipid for vesicle membrane formation. | >99% purity, phase transition temperature (-20°C) for fluidity at 37°C. |

| Polycarbonate Membranes (100 nm Pores) & Extruder (Northern Lipids) | Forms uniform, monodisperse vesicles via extrusion. | Pore size uniformity, extrusion pressure (≤ 500 psi), number of passes (≥ 21). |

| ibidi μ-Slide I Luer Coated (ibidi GmbH) | Ready-to-use microfluidic chamber for shear flow assays. | Channel geometry (height ~0.4 mm), biocompatible polymer, vacuum-sealed coating. |

The formalization of biomimetics through international standards, notably the ISO 18458:2015 standard, provides a critical framework for research and development. This standard defines biomimetics as the "interdisciplinary cooperation of biology and technology or other fields of innovation with the goal of solving practical problems through the function analysis of biological systems, their abstraction into models, and the transfer and application of these models to the solution." This whitepaper provides an in-depth technical guide to the core pillars of this definition: Abstraction and Transfer. For researchers and drug development professionals, mastering these phases is essential for moving beyond superficial imitation to generating robust, patentable, and efficacious innovations, particularly in areas like targeted drug delivery, antimicrobial surfaces, and biosensor development.

Abstraction is the process of distilling the core functional principle from a biological system, separating it from its specific biological context. This step is crucial to avoid mere copying and to create solutions applicable to human-scale problems and different materials.

A rigorous, multi-step protocol is required.

Biological System Identification & Analysis:

- Objective: To fully characterize the structure, behavior, and environment of the biological model.

- Protocol: Utilize high-resolution imaging (cryo-EM, super-resolution microscopy), omics technologies (genomics, proteomics), and biomechanical modeling to create a complete functional profile.

- Key Question: "What function does this structure/process enable for the organism in its environment?"

Functional Principle Isolation:

- Objective: To identify the underlying physical, chemical, or informational principles governing the function.

- Protocol: Apply root cause analysis (e.g., 5 Whys) to the observed function. Develop simplified physical or computational models to test hypotheses about which parameters are essential.

- Key Question: "What is the minimum set of rules or parameters required to reproduce the core function, independent of biological material?"

Model Development:

- Objective: To create a generalizable model of the functional principle.

- Protocol: Formalize the principle using mathematical equations, algorithms, or conceptual diagrams. This model must be devoid of biological terminology (e.g., "chemotaxis" becomes "gradient-driven directional movement").

- Output: An abstracted schematic or formula that can be applied to non-biological contexts.

Biological Model: Isistius brasiliensis (cookiecutter shark) skin denticles. Observed Function: Reduced drag and biofouling. Abstraction Workflow:

Table 1: Key Parameters Abstracted from Shark Skin Denticles

| Biological Feature | Measured Parameter (Quantitative) | Abstracted Functional Principle |

|---|---|---|

| Overlapping Denticle Riblets | Riblet height: 100-200 µm; spacing: 50-100 µm; alignment angle: <10° | Longitudinal micro-grooves disrupting near-wall turbulent vortices. |

| Denticle Surface Nanostructure | Feature size: 20-50 nm; hydrophobic contact angle: >150° | Low-surface-energy, nano-rough topography limiting adhesion points. |

| Dynamic Flexibility | Base plate modulus: ~1.5 GPa; hinge-like attachment | Passive flow-adaptive geometry reducing shear stress. |

The Scientist's Toolkit: Research Reagent Solutions for Biomimetic Abstraction

| Item/Reagent | Function in Abstraction Phase |

|---|---|

| Micro-Computed Tomography (Micro-CT) Scanner | Non-destructive 3D quantification of complex biological surface topographies. |

| Atomic Force Microscope (AFM) | Nanoscale measurement of surface roughness, elasticity, and adhesive forces. |

| Computational Fluid Dynamics (CFD) Software (e.g., OpenFOAM) | Virtual testing and parametric analysis of hydrodynamic/ aerodynamic principles. |

| Surface Plasmon Resonance (SPR) Imaging | Real-time, label-free analysis of molecular binding kinetics on surfaces. |

| Gecko-Inspired Synthetic Adhesives (e.g., PDMS micropillars) | Standardized test materials for validating abstractions of dynamic adhesion. |

The Transfer Phase: Application to Technical Solution

Transfer is the embodiment of the abstracted model into a technical application, involving material selection, scaling, and integration.

Methodology for Effective Transfer

Solution Space Definition:

- Objective: To identify all potential technical fields where the abstracted principle could solve a problem.

- Protocol: Use TRIZ (Theory of Inventive Problem Solving) contradiction matrices or functional modeling to map the principle to unrelated sectors (e.g., from shark skin to aircraft wings, medical catheters, and ship hulls).

Material & Process Selection:

- Objective: To identify non-biological materials and manufacturing processes capable of instantiating the principle.

- Protocol: Screen materials libraries based on key parameters (modulus, surface energy, biocompatibility). Evaluate fabrication methods (3D printing, nanoimprinting, self-assembly) for feasibility and scale.

Prototyping & Iterative Testing:

- Objective: To create a functional prototype and refine it against performance metrics.

- Protocol: Employ rapid prototyping, followed by benchtop testing in simulated operational environments. The abstracted model provides a guide for what to alter when iterations fail.

Experimental Case Study: Transfer to an Antimicrobial Catheter Surface

Abstracted Principle: "A mechanically dynamic surface with nano-scale topography limits long-term adhesion of microorganisms." Technical Problem: Catheter-associated urinary tract infections (CAUTIs). Transfer Workflow & Signaling Pathway Impact:

Table 2: Iterative Prototype Testing Data for Antimicrobial Surface

| Prototype Iteration | Topography Feature Size (nm) | Elastic Modulus (MPa) | P. aeruginosa Adhesion Reduction (% vs Control) | S. aureus Adhesion Reduction (% vs Control) |

|---|---|---|---|---|

| P1 (Flat Control) | N/A | 2.5 | 0% | 0% |

| P2 (Static Nano-pillars) | 200 | 2.5 | 45% | 30% |

| P3 (Dynamic Micro-pillars) | 2000 | 0.8 | 70% | 65% |

| P4 (Dynamic Nano-pillars) | 200 | 0.8 | 92% | 88% |

Experimental Protocol for Validation:

- Objective: Quantify biofilm formation on prototypes.

- Materials: Prototype coupons, bacterial cultures (P. aeruginosa, S. aureus), flow cell system, crystal violet stain, confocal laser scanning microscope (CLSM).

- Method:

- Coupons are mounted in parallel flow cells under physiologically relevant shear stress.

- Bacterial suspension is perfused for 24h.

- Non-adherent cells are washed away.

- Biofilm biomass is quantified via crystal violet elution (absorbance at 590nm).

- Biofilm 3D architecture is visualized via CLSM following Live/Dead staining.

The biomimetic innovation process, as codified by ISO standards, is a disciplined cycle of abstraction and transfer. Success hinges on rigorous, quantitative analysis during abstraction to create a robust model, followed by creative yet systematic exploration during transfer into viable technical solutions. For drug development, this approach enables the design of novel drug delivery mechanisms (e.g., nanoparticle surface functionalization abstracted from lipoprotein behavior), diagnostic tools, and anti-infective medical devices that are both highly effective and elegantly derived from nature's validated solutions. This structured methodology ensures biomimetics moves from inspired observation to reliable innovation.

From Biology to Bench: A Methodological Guide to Applying ISO Biomimetics Standards

Within the burgeoning field of biomimetics—the systematic transfer of knowledge from biological models to technological applications—the need for a common language and methodological rigor is paramount. This is the context of ISO 18458:2015, Biomimetics — Terminology, concepts and methodology. This whiteprames a specific R&D workflow within this framework, providing researchers, scientists, and drug development professionals with a reproducible, standards-compliant pathway from biological insight to developed solution. The ISO framework ensures that biomimetic research is traceable, verifiable, and effectively communicated across disciplines.

The ISO 18458-Compliant R&D Workflow: A Step-by-Step Guide

The following workflow operationalizes the ISO 18458 methodology into a concrete, actionable pipeline for biomimetic drug discovery and material development.

Objective: Identify and analyze a biological system to derive a core principle.

- Observation & Documentation: Document the biological phenomenon (e.g., targeted drug delivery via exosomes, antimicrobial peptide function, gecko adhesion). Use high-resolution imaging, omics technologies, and behavioral studies.

- Functional Abstraction: Isolate the underlying physical, chemical, or informational principle. Move from "how does this organism do this?" to "what is the fundamental rule or mechanism?"

Phase 2: Modeling & Simulation (ISO: "Model Building")

Objective: Create a testable model of the abstracted principle.

- Computational Modeling: Develop in silico models (molecular dynamics, finite element analysis) to simulate the principle.

- Hypothesis Generation: Formulate specific, testable hypotheses for technical implementation (e.g., "A synthetic liposome mimicking exosome surface protein X will increase tumor cell uptake by ≥50%").

Phase 3: Technical Implementation & Experimentation (ISO: "Application")

Objective: Design, build, and experimentally validate a biomimetic prototype.

- Design Specification: Create detailed specs for the biomimetic agent (e.g., nanoparticle size, zeta potential, ligand density).

- Prototype Fabrication: Synthesize the biomimetic material (e.g., peptide synthesis, polymer conjugation, nanoparticle formulation).

- In Vitro Validation: Execute controlled laboratory experiments to test the prototype against the hypothesis.

Phase 4: Evaluation & Iteration (ISO: "Evaluation")

Objective: Compare technical results with the biological model and refine.

- Performance Benchmarking: Quantify prototype performance against predefined metrics (efficiency, specificity, stability).

- Gap Analysis: Identify disparities between biological model performance and technical prototype performance.

- Iterative Redesign: Feed results back into Phase 2 or 3 for model refinement or prototype optimization.

Case Study: Biomimetic Drug Delivery Nanoparticle Development

This workflow is applied to the development of a cell-membrane-coated nanoparticle for targeted chemotherapy delivery.

Biological Model: Leukocyte evasion of immune surveillance and trafficking to inflammation sites. Abstracted Principle: Specific adhesion molecules (e.g., Selectin ligands) mediate rolling on activated endothelium, a key step in inflammatory site targeting. Technical Implementation: A polymeric nanoparticle core coated with purified leukocyte membranes.

Detailed Experimental Protocol: Leukocyte-Mimetic Nanoparticle Assembly & Validation

A. Leukocyte Membrane Isolation:

- Collect primary neutrophils from murine bone marrow using a density gradient centrifugation kit (e.g., Histopaque).

- Lyse cells in a hypotonic lysing buffer (10 mM Tris-HCl, pH 7.4) with protease inhibitors.

- Centrifuge lysate at 3,500 x g for 10 min to remove nuclei and organelles.

- Ultracentrifuge the supernatant at 100,000 x g for 60 min at 4°C to pellet membrane fragments.

- Resuspend membrane pellet in PBS and quantify protein content via BCA assay. Store at -80°C.

B. Nanoparticle Core Synthesis & Coating:

- Synthesize poly(lactic-co-glycolic acid) (PLGA) nanoparticles via nanoprecipitation. Dissolve 50 mg PLGA and 5 mg chemotherapeutic (e.g., Docetaxel) in acetone. Rapidly inject into 10 ml deionized water under stirring.

- Evaporate acetone overnight. Characterize core size and PDI by Dynamic Light Scattering (DLS).

- Fuse membranes to cores via extrusion. Co-incubate membranes (1 mg protein) with PLGA cores (10 mg) in PBS. Extrude the mixture 11 times through a 200 nm polycarbonate membrane using a mini-extruder.

- Purify coated nanoparticles via sucrose density gradient centrifugation (30%/60% steps) at 100,000 x g for 60 min. Collect the band at the interface.

C. In Vitro Validation Under Flow:

- Seed Human Umbilical Vein Endothelial Cells (HUVECs) in a microfluidic chamber and activate with TNF-α (10 ng/ml, 6h) to simulate inflamed endothelium.

- Perfuse fluorescently labeled biomimetic nanoparticles (100 µg/ml in media) through the chamber at a shear stress of 1 dyne/cm².

- Capture real-time video via high-speed fluorescence microscopy.

- Quantify nanoparticle rolling velocity and firm adhesion density per unit area vs. non-coated control nanoparticles.

Table 1: Characterization of Nanoparticle Formulations

| Parameter | PLGA Core (Control) | Leukocyte-Coated NP | Measurement Method |

|---|---|---|---|

| Hydrodynamic Diameter (nm) | 165 ± 12 | 192 ± 15 | DLS |

| Polydispersity Index (PDI) | 0.08 | 0.11 | DLS |

| Zeta Potential (mV) | -3.2 ± 0.5 | -28.5 ± 1.2 | Electrophoretic Mobility |

| Membrane Protein Density (µg/mg NP) | 0 | 84.7 ± 6.3 | BCA Assay |

Table 2: Functional In Vitro Performance

| Performance Metric | PLGA Core (Control) | Leukocyte-Coated NP | P-value |

|---|---|---|---|

| Rolling Velocity (µm/s) | No rolling | 5.2 ± 1.1 | <0.001 |

| Adhesion Density (particles/mm²) | 12 ± 5 | 310 ± 45 | <0.001 |

| Cellular Uptake (MFI) in Target Cells | 100 ± 15 (Baseline) | 450 ± 60 | <0.001 |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Biomimetic Nanoparticle Research

| Reagent/Material | Supplier Examples | Function in Workflow |

|---|---|---|

| PLGA (50:50) | Sigma-Aldrich, Lactel | Biodegradable polymer forming the core nanoparticle; encapsulates active drug. |

| Histopaque-1077/1119 | Sigma-Aldrich | Density gradient medium for isolation of specific leukocyte populations from whole blood/bone marrow. |

| Protease Inhibitor Cocktail (EDTA-free) | Roche, Thermo Fisher | Prevents degradation of membrane proteins during cell lysis and membrane isolation. |

| Mini-Extruder with Polycarbonate Membranes | Avanti Polar Lipids | Instrument for fusing cell membranes onto nanoparticle cores via controlled extrusion. |

| µ-Slide VI 0.1 (Flow Chamber) | ibidi GmbH | Microfluidic slide for culturing endothelial monolayers and performing live-cell adhesion assays under shear flow. |

| Recombinant Mouse TNF-α | PeproTech, R&D Systems | Cytokine used to activate endothelial cells in culture, upregulating adhesion molecule expression. |

| Anti-CD45 Antibody, FITC | BioLegend | Fluorescent antibody for confirming leukocyte membrane presence on coated nanoparticles via flow cytometry. |

This guide defines the first phase of biomimetic biomedical research, scoped within the ongoing development of ISO standards for biomimetics (e.g., ISO 18458). The core objective is to establish a rigorous, reproducible framework for analyzing a biological phenomenon of interest (the "biological template") to extract its underlying principles for application to a defined biomedical problem. This phase ensures the research is grounded in a deep, mechanistic understanding of biology before proceeding to abstraction and implementation.

Core Workflow and Key Activities

The Biological Analysis & Scoping phase is a structured, iterative process. The primary workflow is detailed below.

Diagram Title: Phase 1 Core Workflow

Detailed Methodologies & Experimental Protocols

Activity A: Define & Characterize the Biological Template

Objective: To select and comprehensively describe the biological system (organism, tissue, cellular process, molecular mechanism) that exhibits a desirable function relevant to the biomedical problem.

Protocol 1: Systematic Literature Review & Meta-Analysis

- Search Strategy: Utilize databases (PubMed, Scopus, Web of Science) with structured queries combining terms for the biological system (e.g., "gecko," "limb regeneration," "CRISPR-Cas") and functional keywords (e.g., "adhesion," "wound healing," "adaptive immunity").

- Screening: Use PRISMA guidelines. Two independent reviewers screen titles/abstracts, then full texts against inclusion/exclusion criteria.

- Data Extraction: Code data into a standardized form: organism, experimental model, observed function, environmental conditions, key performance metrics, proposed mechanism.

- Analysis: Perform quantitative synthesis (meta-analysis) where possible. For qualitative data, use thematic analysis to identify consistent mechanistic themes.

Protocol 2: In Vivo/Ex Vivo Functional Characterization

- Example: Characterizing the anti-fouling properties of shark skin.

- Sample Acquisition: Obtain ethically sourced shark skin samples (dorsal, pectoral) from multiple species (e.g., Galeocerdo cuvier, Isurus oxyrinchus). Preserve in RNAlater or fixative.

- Microstructural Analysis:

- SEM Imaging: Dehydrate samples, sputter-coat with gold/palladium. Image at multiple magnifications (100x to 20,000x) to quantify denticle dimensions, riblet spacing, and arrangement.

- Micro-CT Scanning: For 3D structural reconstruction.

- Functional Bioassay:

- Prepare bacterial suspension (E. coli, Staphylococcus aureus) to OD600 = 0.1.

- Apply 100 µL onto test (shark skin) and control (smooth polymer) surfaces in a flow cell.

- Perfuse with sterile marine broth at a defined shear stress (e.g., 0.5 Pa) for 2 hours.

- Fix and stain adhered bacteria with SYTO 9 dye.

- Quantify adhesion density via fluorescence microscopy (5 random fields per sample) and image analysis software (e.g., ImageJ).

Activity B: Identify Core Functional Principles

Objective: To move from observation to mechanism, isolating the fundamental physical, chemical, and informational principles that enable the function.

Protocol: Multi-Omics Deconvolution of a Signaling Pathway

- Example: Analyzing the hypoxic response pathway in cancer cells mimicked from high-altitude adapted species.

- Cell Culture & Stimulation: Culture HepG2 cells under normoxia (21% O2) and hypoxia (1% O2) for 0, 2, 6, 12, 24 hours (n=4 biological replicates per condition).

- Multi-Omics Harvesting:

- Transcriptomics: Extract total RNA (TRIzol), assess quality (RIN > 8.5), prepare libraries (poly-A selection), sequence on Illumina platform (150 bp paired-end).

- Proteomics: Lyse cells in RIPA buffer, digest with trypsin, label with TMT 11-plex, fractionate by high-pH reverse-phase HPLC, analyze by LC-MS/MS.

- Metabolomics: Quench metabolism with -80°C methanol, extract metabolites, analyze via hydrophilic interaction liquid chromatography (HILIC)-MS.

- Data Integration & Pathway Mapping:

- Perform differential expression/abundance analysis (DESeq2 for RNA, Limma for proteins/metabolites).

- Map significantly altered entities (FDR < 0.05) to the KEGG "HIF-1 signaling pathway" (map04066) using pathway analysis tools (e.g., IPA, GSEA).

- Construct a causal network model.

Diagram Title: HIF-1 Signaling Pathway in Hypoxia

Table 1: Meta-Analysis of Anti-Fouling Surface Performance

| Biological Template | Key Structural Parameter (Avg.) | Reduction in Bacterial Adhesion (%) vs. Smooth Control | Tested Organism | Reference Year |

|---|---|---|---|---|

| Shark Skin (G. cuvier) | Riblet Spacing: 100 µm | 67% | S. aureus | 2022 |

| Lotus Leaf | Papillae Height: 15 µm, Wax Crystalloids | 85% (Hydrophobic) | E. coli | 2021 |

| Cicada Wing | Nanopillar Height: 200 nm, Diameter: 80 nm | 99.9% (Bactericidal) | P. aeruginosa | 2023 |

| Dragonfly Wing | Nanopillar Height: 240 nm | 95% (Bactericidal) | B. subtilis | 2022 |

Table 2: Multi-Omics Analysis of Hypoxic Response (24h vs. 0h)

| Molecule Type | Total Analyzed | Significantly Altered (FDR<0.05) | Up-Regulated | Down-Regulated | Key Enriched Pathway (KEGG) |

|---|---|---|---|---|---|

| mRNA | 18,500 | 1,842 | 1,201 | 641 | HIF-1 Signaling (p=3.2e-12) |

| Protein | 6,200 | 487 | 312 | 175 | Glycolysis / Gluconeogenesis (p=1.8e-9) |

| Metabolite | 450 | 89 | 56 | 33 | Central Carbon Metabolism (p=4.5e-6) |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for Phase 1 Analysis

| Item (Supplier Example) | Function in Phase 1 | Specific Application Example |

|---|---|---|

| RNAlater Stabilization Solution (Thermo Fisher) | Preserves RNA/DNA integrity in biological samples at the time of collection. | Stabilizing tissue from a novel extremophile organism prior to omics analysis. |

| TRIzol Reagent (Invitrogen) | Monophasic solution for simultaneous isolation of high-quality RNA, DNA, and proteins from a single sample. | Extracting biomolecules from limited precious samples for integrated multi-omics. |

| Tandem Mass Tag (TMT) 11-plex Kit (Thermo Fisher) | Enables multiplexed quantitative proteomics, allowing comparison of up to 11 different experimental conditions in one MS run. | Comparing protein expression across multiple time points or hypoxia levels. |

| SYTO 9 Green Fluorescent Nucleic Acid Stain (Invitrogen) | Cell-permeant dye that stains all bacteria in a population, used for quantifying adhesion or viability. | Visualizing and quantifying bacterial biofilm formation on bio-inspired surfaces. |

| Anti-HIF-1α Antibody [EPR16897] (Abcam) | Validated monoclonal antibody for specific detection of stabilized HIF-1α protein via western blot or IHC. | Confirming activation of the hypoxic response pathway in cell-based models. |

| Matrigel Matrix (Corning) | Basement membrane extract used for 3D cell culture, angiogenesis assays, and modeling tissue complexity. | Creating a more physiologically relevant environment to study cell migration/invasion. |

The development of ISO standards for biomimetics, such as the ongoing work on ISO/TC 266, necessitates a rigorous phase of abstraction. This phase translates observed biological phenomena into core, testable engineering principles. For drug development, this involves moving from biological complexity (e.g., a cell signaling cascade) to an isolatable principle (e.g., negative feedback-based homeostasis) that can inform therapeutic strategies like adaptive drug dosing or biomimetic material design for controlled release, ensuring standardized terminology and methodology across the field.

Abstraction identifies universal mechanisms. The following table summarizes key principles and their therapeutic analogs.

Table 1: Core Biological Principles and Corresponding Therapeutic Applications

| Core Biological Principle | Biological Example | Abstracted Concept | Potential Drug Development Application |

|---|---|---|---|

| Specific Molecular Recognition | Ligand-receptor binding (e.g., insulin-INSR) | High-affinity, lock-and-key interaction | Design of targeted biologics (mAbs, peptides); biosensor development. |

| Signal Transduction & Amplification | GPCR-cAMP-PKA pathway | Input-output cascade with gain | Targeting allosteric sites; developing pathway-specific inhibitors/activators. |

| Feedback Regulation (Negative) | HIF-α degradation in normoxia | Homeostatic control loop | Mimicking with synthetic gene circuits for regulated therapeutic protein expression. |

| Self-Assembly & Emergent Order | Actin polymerization | Programmable bottom-up organization | Development of drug-delivery vesicles (liposomes) or supramolecular nanomedicines. |

| Adaptation & Learning | Immune memory (T/B cells) | System that improves response upon repeated exposure | Basis for vaccine design; adoptive cell therapies (CAR-T). |

| Compartmentalization | Mitochondrial cristae | Spatial segregation of function | Organelle-targeted drug delivery; enzyme prodrug therapy. |

This protocol outlines how to empirically dissect and abstract a core principle from a canonical signaling pathway for validation.

Protocol: Deconstructing the EGFR-ERK Pathway for Abstraction of Ultrasensitivity Objective: To isolate and quantify the ultrasensitive input-output relationship in the EGFR-MAPK/ERK cascade, abstracting it as a signal-processing module.

- Cell Culture: Maintain HEK293 or A431 cells in DMEM + 10% FBS. Seed in 96-well plates for stimulation and 10cm dishes for immunoblotting.

- Stimulation Gradient: Serum-starve cells for 18 hours. Stimulate with a 12-point gradient of purified human EGF ligand (0, 0.01, 0.1, 0.5, 1, 2, 5, 10, 20, 50, 100, 200 ng/mL). Incubate for precisely 10 minutes at 37°C.

- Cell Lysis & Protein Quantification: Lyse cells in RIPA buffer with protease/phosphatase inhibitors. Quantify total protein using a BCA assay.

- Western Blot Analysis:

- Load equal protein amounts on 4-12% Bis-Tris gels, separate via SDS-PAGE, and transfer to PVDF membranes.

- Probe with primary antibodies: p-EGFR (Tyr1068), total EGFR, p-MEK1/2 (Ser217/221), p-ERK1/2 (Thr202/Tyr204), total ERK, and a loading control (β-actin).

- Use HRP-conjugated secondary antibodies and chemiluminescent detection. Quantify band densitometry.

- Data Modeling: Plot normalized p-ERK intensity vs. log([EGF]). Fit data to a Hill equation: Response = (Vmax * [S]^n) / (Kd^n + [S]^n), where n (Hill coefficient) quantifies ultrasensitivity (n > 1 indicates cooperative, switch-like behavior).

- Abstraction Validation: Test the abstracted principle (switch-like amplification) by introducing a pathway perturbation (e.g., 5µM MEK inhibitor U0126) and repeating the stimulation gradient. The abstracted model should predict the dampened response.

Diagram 1: EGFR-ERK Pathway Abstraction

Diagram 2: Experimental Workflow for Abstraction

The Scientist's Toolkit: Key Reagent Solutions

Table 2: Essential Research Reagents for Signaling Pathway Abstraction

| Reagent / Material | Function in Abstraction Experiments | Key Considerations |

|---|---|---|

| Recombinant Human EGF | Defined, pure ligand for precise, quantitative pathway stimulation. Ensures reproducibility. | Lyophilized stability, carrier protein (e.g., BSA) concentration, endotoxin levels. |

| Pathway-Specific Phospho-Antibodies (e.g., anti-p-ERK) | Enable quantification of dynamic signal transduction states (activity). | Validate specificity via knockout/knockdown cells; check lot-to-lot consistency. |

| Small Molecule Inhibitors (e.g., U0126 for MEK) | Tools for controlled perturbation to test causality and model predictions. | Optimize DMSO concentration for vehicle controls; confirm target selectivity. |

| ChemiDoc or Similar Imaging System | For quantitative digital capture of Western blot or assay signals. | Must have a wide linear dynamic range for accurate densitometry. |

| GraphPad Prism / MATLAB | Software for nonlinear regression (Hill fits), modeling, and statistical analysis. | Essential for translating raw data into abstracted mathematical relationships. |

| ISO/TR 18401:2017 (Biomimetics) | Reference document for standardized terminology, supporting clear communication of abstracted principles. | Provides a framework to document the abstraction process consistently. |

This whitepaper details the technical implementation and in silico simulation phase of biomimetic system development. As part of a broader thesis on establishing ISO standards for biomimetics, this phase translates conceptual biomimetic designs into testable computational models and experimental protocols. The objective is to create standardized, reproducible workflows for simulating biological mechanisms—such as targeted drug delivery or cellular signaling—prior to physical prototyping, thereby reducing resource expenditure and accelerating research.

Core Technical Implementation Framework

Implementation follows a modular pipeline: 1) System Parameterization from biological data, 2) Model Selection & Assembly, 3) Computational Simulation, and 4) Output Validation against in vitro benchmarks.

Quantitative parameters are extracted from published literature and databases to inform model variables.

Table 1: Key Biological Parameters for a Biomimetic Nanoparticle Delivery System

| Parameter | Typical Value Range | Source / Assay | Relevance to Model |

|---|---|---|---|

| Tumor Vascular Pore Size | 100 - 780 nm | Transmission Electron Microscopy (TEM) of tumor tissue | Defines maximum nanoparticle size for EPR effect |

| Ligand-Receptor Binding Affinity (Kd) | 0.1 - 10 nM | Surface Plasmon Resonance (SPR) | Determines targeting efficiency in kinetic models |

| Serum Half-life of PEGylated NPs | 12 - 24 hours | Pharmacokinetic (PK) studies in murine models | Informs clearance rates in PK/PD models |

| Cellular Internalization Rate | 10^3 - 10^4 NPs/cell/hour | Flow Cytometry with fluorescent NPs | Sets uptake rate in cellular-scale models |

| Tumor Extracellular pH | 6.5 - 6.9 | pH-sensitive microelectrodes | Critical for pH-responsive drug release models |

Selection of Simulation Modalities

The choice of simulation depends on the scale and question.

Table 2: Simulation Modalities in Biomimetics

| Modality | Scale | Typical Software/Tool | Application Example |

|---|---|---|---|

| Molecular Dynamics (MD) | Atomic, 1-100 nm | GROMACS, NAMD | Simulating ligand-protein docking for a biomimetic inhibitor |

| Finite Element Analysis (FEA) | Continuum, µm-mm | COMSOL, ANSYS | Modeling stress on a biomimetic scaffold in tissue |

| Agent-Based Modeling (ABM) | Cellular, µm-mm | NetLogo, CompuCell3D | Simulating population-level cell response to a drug-releasing implant |

| Pharmacokinetic/Pharmacodynamic (PK/PD) | Whole Organism | PK-Sim, MATLAB/SimBiology | Predicting concentration-time profiles of a biomimetic drug formulation |

Detailed Experimental & Simulation Protocols

Protocol: Multi-scale Simulation of a Biomimetic Drug Delivery Nanoparticle

This protocol integrates multiple simulation types to model a pH-sensitive, ligand-targeted nanoparticle.

A. Molecular Dynamics for Ligand-Receptor Binding

- Objective: Simulate the binding stability of the targeting peptide (e.g., RGD) to its integrin receptor (αvβ3) at normal (7.4) and acidic (6.5) pH.

- Method: a. Obtain 3D structures of the RGD peptide (PubChem CID: 123831) and integrin αvβ3 (PDB ID: 1L5G) from public databases. b. Perform protein and ligand preparation (protonation, solvation, energy minimization) using UCSF Chimera and the AMBER force field. c. Set up simulation boxes with explicit water (TIP3P model) and physiological ion concentration (0.15 M NaCl). d. Run equilibration (100 ps) followed by production MD simulation (50 ns) under NPT conditions (310 K, 1 atm) using NAMD. e. Analyze trajectories using VMD: calculate Root Mean Square Deviation (RMSD) of the ligand-binding pocket, hydrogen bond occupancy, and binding free energy via the Molecular Mechanics/Generalized Born Surface Area (MM/GBSA) method.

B. Agent-Based Model for Tumor Uptake

- Objective: Predict spatial distribution and cellular uptake of nanoparticles in a simulated tumor microenvironment.

- Method: a. Using NetLogo, create a 2D grid (1000 x 1000 µm) representing a cross-section of tumor tissue. b. Populate with agents: Endothelial Cells (forming leaky vessels), Tumor Cells (expressing target receptors), Macrophages (for clearance), and Blood Flow. c. Parameterize agents based on Table 1 (e.g., vascular pore size, internalization rate). d. Program nanoparticle agents (diameter: 100 nm, surface: RGD ligands) to enter from vasculature, diffuse via Brownian motion, bind to tumor cells based on stochastic probability derived from MD Kd values, and be internalized. e. Run simulation for 48 hours (simulated time). Track metrics: % injected dose in tumor, penetration depth from vasculature, and heterogeneity of uptake.

Diagram Title: Multi-scale Simulation Workflow for Biomimetic Nanoparticles

Protocol:In VitroValidation of Simulated Biomimetic Systems

In silico predictions require empirical validation using standardized assays.

Title: In Vitro Pharmacodynamics of a Biomimetic Nanoparticle in a 3D Spheroid Model. Objective: To validate the tumor penetration and cell kill predictions of the ABM simulation. Materials: See "The Scientist's Toolkit" below. Method:

- Spheroid Generation: Seed U-87 MG glioblastoma cells (high αvβ3 expression) in ultra-low attachment 96-well plates (500 cells/well). Culture for 96 hours to form compact spheroids (~500 µm diameter).

- Nanoparticle Treatment: Prepare fluorescent (Cy5-labeled) RGD-targeted and non-targeted (PEG-only) nanoparticles (100 nm). Treat spheroids with 100 µg/mL NP equivalent in complete media. Incubate for 2, 6, and 24 hours (n=6 per group).

- Penetration Analysis: At each time point, wash spheroids 3x with PBS. Fix with 4% PFA for 30 min. Image using a confocal microscope with Z-stacking (10 µm intervals). Use ImageJ to plot fluorescence intensity as a function of depth from spheroid surface.

- Efficacy Analysis: For separate spheroids, treat with drug-loaded (e.g., Doxorubicin) nanoparticles. After 72 hours, assess viability via CellTiter-Glo 3D Assay. Calculate IC50 values for targeted vs. non-targeted formulations.

- Validation: Correlate penetration depth vs. time and relative efficacy from experiment with ABM output using Pearson correlation analysis. A strong positive correlation (r > 0.85) validates the simulation.

Diagram Title: In Vitro Spheroid Validation Protocol Workflow

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for Biomimetic Nanoparticle Validation

| Item/Reagent | Function in Protocol | Example Product/Catalog # | Key Notes |

|---|---|---|---|

| Ultra-Low Attachment (ULA) Plate | Prevents cell adhesion, enabling 3D spheroid self-assembly. | Corning Costar #7007 | Critical for reproducible, round spheroid formation. |

| pH-Sensitive Polymer (e.g., Poly(β-amino ester)) | Core biomimetic material enabling drug release in acidic tumor microenvironments. | PolySciTech AK097 | Degradation rate must be characterized via GPC at pH 7.4 vs. 6.5. |

| Targeting Ligand (e.g., cRGDfK Peptide) | Conjugated to nanoparticle surface for active targeting of overexpressed receptors (e.g., αvβ3 integrin). | MedChemExpress HY-P1366 | Must include a spacer (PEG) and reactive group (maleimide, NHS) for conjugation. |

| CellTiter-Glo 3D Cell Viability Assay | Luminescent assay optimized for measuring ATP in 3D cell cultures, indicating viability. | Promega G9681 | Requires orbital shaking to lyse cells within spheroids effectively. |

| Fluorescent Probe for Labeling (e.g., Cy5 NHS Ester) | Covalently labels nanoparticle polymer for tracking via fluorescence microscopy or flow cytometry. | Lumiprobe #23020 | Labeling ratio must be quantified (UV-Vis) to avoid quenching or altered biodistribution. |

Standardization and ISO Context

The protocols and toolkits outlined are designed as candidate modules for an ISO standard on biomimetic in silico and in vitro testing. Standardization requires:

- Defined Input/Output Formats: For simulation files (e.g., SBML for PK/PD models).

- Reference Datasets: For validation (e.g., standard cell line spheroid growth curves).

- Reporting Criteria: Mandatory metadata (software version, force field, iteration counts) must accompany published results to ensure reproducibility—a core tenet of both robust science and forthcoming ISO guidelines for biomimetics.

The pursuit of advanced drug delivery systems (DDS) increasingly relies on biomimetics—the imitation of models, systems, and elements of nature for solving complex problems. This field is being formalized under emerging ISO standards for biomimetics (e.g., ISO 18458:2015 and related drafts under development), which provide a structured lexicon and methodological framework. Within this context, mimicking the exquisite selectivity of the cell membrane represents a paramount case study. This whitepaper details the technical approaches, experimental protocols, and quantitative data underpinning the development of biomimetic DDS that replicate phospholipid bilayer structure, transport protein function, and ligand-receptor specificity to achieve targeted, efficient, and safe therapeutic delivery.

Core Biomimetic Principles for Membrane Selectivity

Cell membrane selectivity arises from:

- Amphiphilic Phospholipid Bilayer: Provides a selective barrier based on hydrophobicity and molecular size.

- Integral Membrane Proteins (Channels, Carriers, Pumps): Facilitate active and passive transport.

- Surface Glycoproteins and Glycolipids: Enable ligand-specific recognition and signaling.

- Membrane Fluidity and Phase Behavior: Influences incorporation and release dynamics.

Quantitative Analysis of Key Biomimetic Platforms

Table 1: Comparison of Biomimetic Drug Delivery Platforms Mimicking Membrane Selectivity

| Platform | Core Components (Mimicked Element) | Typical Size (nm) | Drug Loading Efficiency (%) * | Selectivity Mechanism | Key Challenge |

|---|---|---|---|---|---|

| Liposomes | Phospholipids, cholesterol (Bilayer) | 80-200 | 10-40 | Passive (EPR effect), ligand grafting | Rapid clearance, low stability |

| Polymeric Nanoparticles | PLGA, PEG (Hydrophobic core/hydrophilic shell) | 100-300 | 50-85 | Surface functionalization with antibodies, peptides | Potential polymer toxicity, batch variability |

| Solid Lipid Nanoparticles (SLNs) | Solid lipid matrix (Membrane fluidity) | 150-500 | 25-70 | Controlled release, ligand attachment | Drug expulsion during storage |