Lab-on-a-Chip Technology for Viral Disease Detection: A Comprehensive Review for Researchers and Developers

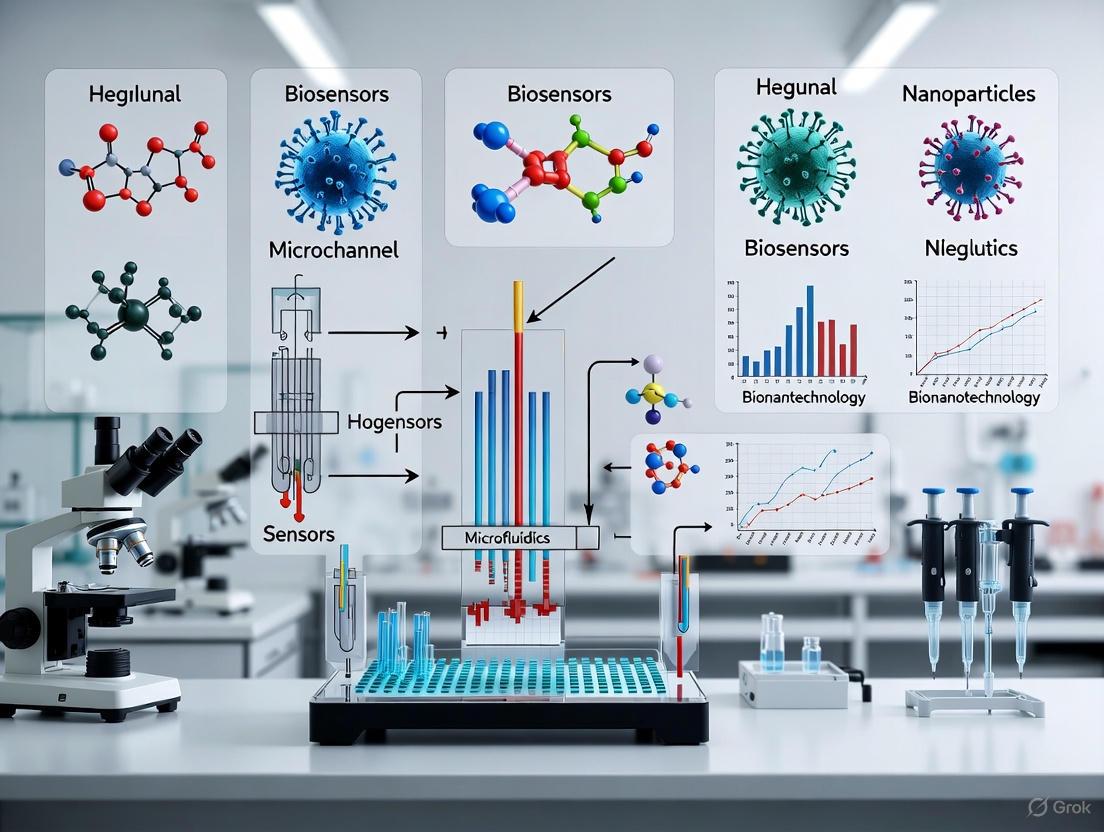

This article provides a comprehensive overview of the transformative potential of lab-on-a-chip (LOC) technology for viral diagnostics.

Lab-on-a-Chip Technology for Viral Disease Detection: A Comprehensive Review for Researchers and Developers

Abstract

This article provides a comprehensive overview of the transformative potential of lab-on-a-chip (LOC) technology for viral diagnostics. Tailored for researchers, scientists, and drug development professionals, it explores the foundational principles of microfluidic systems that enable rapid, sensitive, and point-of-care detection of pathogens like SARS-CoV-2 and Ebola. The scope covers the transition from conventional laboratory methods to innovative LOC applications, including immunoassays and nucleic acid amplification tests (NAATs). It further delves into critical troubleshooting and optimization strategies for device development, presents validation frameworks comparing LOC performance with traditional models, and discusses the future trajectory of this technology in advancing personalized medicine and pandemic preparedness.

The Fundamentals of Lab-on-a-Chip Technology and Its Rise in Virology

Lab-on-a-chip (LOC) and Micro-Total Analysis Systems (µTAS) represent transformative technologies that miniaturize and integrate entire laboratory functions onto a single chip, typically only millimeters or centimeters in size. Within viral disease detection research, these systems have evolved from devices performing single tasks to fully integrated platforms capable of complex, multi-step benchtop protocols without human intervention [1]. By incorporating intricate networks of microchannels, valves, mixers, pumps, reaction chambers, and detectors, LOC systems offer a powerful tool for rapid, sensitive, and low-cost diagnosis of pathogens at the point-of-care (POC) [1]. This capability is critical for guiding infection control, initiating targeted therapy, and preventing the spread of epidemics, especially given the persistent threat of emerging and re-emerging viruses [2].

Current Applications in Viral Disease Detection

LOC technologies are being applied to detect a wide spectrum of viruses through two primary detection methodologies: immunoassays for detecting viral antigens or antibodies, and nucleic acid (NA) amplification for detecting viral genetic material [1].

Immunoassays, such as the enzyme-linked immunosorbent assay (ELISA), are considered a gold standard for protein detection. In a microfluidic format, these assays can be performed with enhanced speed and reduced reagent consumption [1]. Nucleic acid-based techniques, including polymerase chain reaction (PCR) and isothermal amplification, are known for their high sensitivity and specificity [2]. More recently, CRISPR-Cas systems have been integrated into LOC devices for precise genetic identification [2].

The table below summarizes the performance of conventional methods versus LOC-based technologies for detecting various viral diseases:

Table 1: Comparison of Conventional and LOC-Based Viral Detection Methods

| Target Disease | Conventional Method (Time) | LOC-Based Method | Test Time (Minutes) | Limit of Detection (LOD) | References |

|---|---|---|---|---|---|

| COVID-19 | PCR (90+ min) | LoCKAmp (PCR-based) | 3 min | Not Specified | [3] |

| Ebola | Immunofluorescence, ELISA | RT-PCR on Microfluidic Chip | 30-50 min | 10 copies/μL | [1] |

| Dengue Fever | ELISA (60 min) | RT-PCR on Microfluidic Chip | 90 min | 10 copies/μL | [1] |

| Zika Fever | MAC-ELISA (60 min) | RT-PCR on Microfluidic Chip | 90 min | 10 copies/μL | [1] |

| Influenza | ELISA (180 min) | RT-LAMP on Microfluidic Chip | 40 min | 0.4 copies/μL | [1] |

These examples demonstrate the significant advantage of LOC systems in reducing diagnostic time, a critical factor during outbreaks. For instance, the LoCKAmp device developed at the University of Bath provides lab-quality PCR results in just three minutes, a dramatic improvement over conventional PCR [3]. Furthermore, the use of off-the-shelf components and printed circuit boards (PCBs) allows devices like LoCKAmp to be produced rapidly and at low cost on a mass scale, with a projected unit cost of ~£50 and disposable test cartridges for less than £0.50 [3].

Experimental Protocols

Protocol: On-Chip Nucleic Acid Amplification for SARS-CoV-2 Detection

This protocol details the operation of the LoCKAmp device for rapid genetic detection of SARS-CoV-2 from a nasal swab [3].

I. Principle The device utilizes a disposable microfluidic cartridge and a portable testing unit to perform a chemical reaction that rapidly releases and amplifies the viral genetic material. The result is detected and can be viewed via a smartphone application.

II. Equipment and Reagents

- LoCKAmp portable testing unit

- LoCKAmp disposable test cartridges

- Nasal swab sample

- Lysis buffer

- Elution buffer

- Master mix for isothermal amplification (e.g., for RT-LAMP)

- Smartphone with dedicated app

III. Procedure

- Sample Introduction: The nasal swab sample is inserted into the designated inlet of the disposable cartridge.

- On-Chip Lysis: The cartridge is loaded into the testing unit, which initiates the process. The device first performs a rapid lysis step to release the viral RNA.

- Nucleic Acid Amplification: The released genetic material is transported within the microchannels to a reaction chamber where an isothermal amplification (e.g., Loop-mediated isothermal amplification or LAMP) reaction occurs.

- Detection and Result Readout: The amplification reaction produces a fluorescent or colorimetric signal, which is detected by the unit's optical sensor. The result is transmitted to the smartphone app and displayed within three minutes.

IV. Analysis and Interpretation A positive result indicates the detection of SARS-CoV-2 genetic material in the sample. The entire process, from sample introduction to result, is completed within three minutes, making it the fastest genetic testing device reported to date [3].

Protocol: On-Chip Immunoassay for Viral Antigen Detection

This protocol outlines a general microfluidic immunoassay for detecting viral antigens, such as the Ebola virus [1].

I. Principle The assay is based on the specific binding of antibodies to viral antigens (e.g., surface proteins) present in a sample. This binding event is typically detected through an enzyme-mediated colorimetric or fluorescent reaction in a microfluidic channel.

II. Equipment and Reagents

- Microfluidic chip with pre-patterned channels

- Syringe pump or microfluidic pressure controller

- Capture antibodies (specific to the target virus)

- Sample solution

- Detection antibodies (conjugated to a reporter enzyme, e.g., HRP)

- Wash buffer

- Substrate solution (e.g., TMB for colorimetric detection)

III. Procedure

- Surface Functionalization: The microchannels are first coated with capture antibodies.

- Sample Incubation: The sample solution is flowed through the channel, allowing the viral antigens to bind to the immobilized capture antibodies.

- Washing: A wash buffer is flowed through to remove unbound materials.

- Detection Antibody Incubation: A solution containing enzyme-conjugated detection antibodies is introduced, which bind to the captured antigens, forming a "sandwich" complex.

- Second Washing: Another washing step removes unbound detection antibodies.

- Signal Development: A substrate solution is flowed into the channel. The enzyme conjugated to the detection antibody catalyzes a reaction, producing a measurable color or fluorescence change.

- Optical Readout: The signal is quantified using an integrated or external optical detector (e.g., a miniaturized spectrophotometer or fluorescence microscope).

IV. Analysis and Interpretation The intensity of the signal is proportional to the concentration of the viral antigen in the sample. The confined dimensions and laminar flow in microchannels enhance the binding kinetics, significantly reducing the total assay time compared to a conventional plate-based ELISA [1].

Visualized Workflows and Signaling Pathways

Diagram 1: LOC System Workflow

Diagram 2: LoCKAmp Rapid Test Process

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for LOC-based Viral Detection

| Item | Function | Examples / Key Characteristics |

|---|---|---|

| Microfluidic Chip | The core substrate that houses microchannels and reaction chambers. | Fabricated from PDMS, glass, or thermoplastics like PMMA via soft lithography or injection molding. |

| Capture Probes | Biological recognition elements for specific virus detection. | Antibodies (for immunoassays) or oligonucleotide primers/probes (for nucleic acid tests). |

| Lysis Reagents | To break open viral particles and release genetic material. | Chaotropic salts, detergents (e.g., Triton X-100), or enzymatic mixes. |

| Amplification Master Mix | Enzymes and reagents for nucleic acid amplification. | Contains reverse transcriptase and DNA polymerase for RT-PCR; Bst polymerase for LAMP; Cas enzymes for CRISPR-based assays. |

| Fluorescent Dyes/Reporters | For generating a detectable signal. | Intercalating dyes (SYBR Green), TaqMan probes, or enzyme substrates (TMB for HRP). |

| Surface Modification Kits | To functionalize channel surfaces for reagent immobilization. | Silanization kits for glass, or Pluronic solutions to prevent non-specific adsorption. |

| Portable Detector | For signal acquisition and quantification. | Miniature spectrophotometers, fluorescence readers, or smartphone-based optical sensors. |

Addressing the Limitations of Conventional Viral Detection Methods (Cell Culture, ELISA, PCR)

Conventional laboratory methods for viral detection, including cell culture, enzyme-linked immunosorbent assay (ELISA), and polymerase chain reaction (PCR), have long served as fundamental tools in clinical diagnostics and virology research. However, these techniques present significant limitations in responding to rapidly spreading viral outbreaks, where time, portability, and operational complexity become critical factors. Cell culture, traditionally considered the gold standard for virus isolation, is time-consuming, requiring days to weeks for results and sophisticated laboratory infrastructure [4]. ELISA, while valuable for detecting antiviral antibodies or viral antigens, can exhibit variable sensitivity and specificity and may not always indicate active infection [5] [6]. Although PCR and its quantitative variant (qPCR) offer high sensitivity and specificity for detecting viral genetic material, they rely on expensive thermocycling equipment, trained personnel, and are generally confined to laboratory settings [4] [5].

Table 1: Key Limitations of Conventional Viral Detection Methods

| Method | Key Limitations | Typical Turnaround Time | Primary Equipment Needed |

|---|---|---|---|

| Cell Culture | Long incubation time; requires viable virus; sophisticated lab infrastructure [4]. | Days to weeks [4] | Biosafety cabinets, CO₂ incubators, microscopes |

| ELISA | Detects antibodies which may not indicate active infection; can show cross-reactivity; moderate sensitivity [5] [7]. | 3-5 hours [7] | Microplate reader, incubator, washer |

| PCR/qPCR | Requires expensive equipment and trained operators; not suitable for point-of-care; risk of contamination [4] [5]. | 1-6 hours (plus sample prep) [8] | Thermal cycler (qPCR machine) |

In recent decades, lab-on-a-chip (LOC) technology has emerged as a transformative approach, overcoming these constraints by miniaturizing and integrating entire laboratory processes onto a single, miniaturized platform [4] [9] [10]. LOC systems leverage microfluidics—the science of manipulating small fluid volumes (picoliters to microliters) within micrometre-sized channels—to perform functions ranging from sample preparation and biochemical reactions to detection [9] [8] [11]. This review details how LOC platforms address the specific drawbacks of traditional viral detection methods, providing application notes and experimental protocols to guide researchers and drug development professionals in this advancing field.

Lab-on-a-Chip Solutions to Method-Specific Limitations

Overcoming the Drawbacks of Cell Culture

Traditional cell culture is impractical for rapid diagnostics. LOC technology circumvents this through direct molecular detection and the creation of advanced organ-on-a-chip models.

Application Note: From Culture to Direct Detection LOC systems bypass the need for viral propagation by directly targeting viral nucleic acids or proteins with high sensitivity. For instance, an automated multiplexing LOC system using the CRISPR/Cas13a enzyme detected Ebola virus RNA at a limit of detection (LOD) of 20 pfu/mL from 10 µL of sample in just 5 minutes [4]. This demonstrates a shift from biological amplification to enzymatic and molecular amplification directly on the chip.

Application Note: Organ-on-a-Chip for Viral Studies Where in vitro culture is needed, organ-on-a-chip (OOC) models provide a more physiologically relevant environment than static culture plates. These microfluidic devices culture living cells in continuously perfused, micrometer-sized chambers to simulate organ-level physiology [9] [12]. A meta-analysis of perfused OOC models showed that certain cell types, particularly those from blood vessel walls, the intestine, and the liver, exhibited significantly enhanced functional biomarkers under flow compared to static cultures [12]. For virology, this allows for the study of viral infection and pathogenesis in human-relevant tissues, potentially improving the predictive value of in vitro drug testing.

Enhancing the Capabilities of ELISA

LOC platforms enhance ELISA-based detection by improving its sensitivity, reducing its volume requirements, and accelerating its workflow.

Application Note: Ultra-Sensitive Digital ELISA The Single Molecule Array (SIMOA) technology represents a digital ELISA platform that can detect proteins at femtomolar concentrations [7]. By capturing individual protein molecules on antibody-coated beads and segregating them into femtoliter-sized wells, SIMOA allows for single-molecule counting, providing an average 465-fold increase in sensitivity over standard ELISA [7]. This ultra-sensitivity is crucial for detecting low-abundance viral antigens or early-stage antibody responses.

Application Note: Integrated Microfluidic Immunoassays LOC devices can integrate the multi-step workflow of an immunoassay into a single, automated chip. Paper-based microfluidic chips, which use capillary action to move fluids, have been developed for serological detection. One such platform coupled with a smartphone readout detected IgG antibodies against Ebola virus in serum with 100% sensitivity, offering a low-cost, rapid point-of-care solution [4].

Table 2: Comparison of ELISA and Advanced Immunoassay Platforms

| Parameter | Standard ELISA | Immuno-PCR (IQELISA) | SIMOA (Digital ELISA) | Paper-based LOC Immunoassay |

|---|---|---|---|---|

| Principle | Colorimetric detection [6] | DNA-barcode amplification via PCR [7] | Single-molecule detection in microwells [7] | Capillary flow, visual/phone readout [4] |

| Sample Volume | ~100 µL [7] | 10-25 µL [7] | ~125 µL [7] | < 50 µL (estimated) [4] |

| Sensitivity | 1-100 pg/mL (high) [7] | 23x higher than standard ELISA on average [7] | 465x higher than standard ELISA on average [7] | Varies; shown to match gold standard serology [4] |

| Time to Result | ~5 hours [7] | ~5.5 hours [7] | ~3 hours [7] | ~30 minutes [4] |

| Key Advantage | Low cost, widely available [7] | High sensitivity, low volume [7] | Ultra-high sensitivity, automation [7] | Extreme portability, low cost [4] |

Advancing Beyond Conventional PCR

LOC technology addresses the primary limitations of conventional PCR by miniaturizing the reaction, reducing power consumption, and dramatically speeding up the process.

Application Note: Microfluidic PCR and Isothermal Amplification Microfluidic PCR chips, often called microPCR, exploit the high surface-to-volume ratio of microchannels to achieve ultrafast thermal cycling. One system demonstrated DNA amplification in just 6 minutes by processing a 100 nL sample [8]. Furthermore, many LOCs employ isothermal amplification techniques (e.g., LAMP, RPA), which amplify nucleic acids at a constant temperature. This eliminates the need for bulky, power-intensive thermal cyclers. A paper-based microfluidic chip using reverse transcription RPA (RT-RPA) detected Ebola virus in 30 minutes with 90% sensitivity compared to RT-PCR [4].

Application Note: Sample-to-Answer Integrated Systems The highest form of integration in LOC technology is the micro-total analysis system (μTAS), which combines sample preparation, nucleic acid amplification, and detection on a single chip [9] [11]. An example is a disc-shaped centrifugal chip that automated RNA extraction and used RT-LAMP to detect four different types of Ebola virus simultaneously within 50 minutes, achieving a LOD as low as 1 copy/μL for one subtype [4].

Integrated Experimental Protocol: Paper-based Microfluidic Chip for Viral RNA Detection

This protocol outlines the procedure for detecting viral RNA using a paper-based microfluidic chip incorporating RT-RPA, adapted from published work on Ebola virus detection [4].

Research Reagent Solutions & Materials

Table 3: Essential Reagents and Materials

| Item | Function/Description |

|---|---|

| Paper-based Chip | The substrate, often patterned with hydrophobic barriers to define hydrophilic reaction zones and flow paths [4] [9]. |

| Lyophilized RT-RPA Reagents | Stable, room-temperature pellets containing reverse transcriptase, recombinase polymerase, primers, and nucleotides for isothermal amplification [4]. |

| Fluorescent DNA Probe | A sequence-specific probe (e.g., exo-probe) that is cleaved during amplification, producing a fluorescent signal [4]. |

| Sample Inactivation Buffer | A buffer to lyse the virus and inactivate nucleases while preserving RNA integrity (e.g., AVL buffer from commercial kits). |

| Positive & Negative Controls | Synthetic viral RNA and nuclease-free water to validate each assay run. |

| Portable Fluorimeter or Smartphone-based Reader | For quantitative or qualitative endpoint detection of the fluorescent signal [4]. |

Step-by-Step Workflow

- Chip Preparation: Load the paper zones of the microfluidic chip with lyophilized RT-RPA reagents and the fluorescent probe. Store in a sealed, desiccated pouch until use.

- Sample Preparation: Mix the collected sample (e.g., serum, swab eluent) with an equal volume of inactivation buffer. Incubate at room temperature for 5-10 minutes.

- Sample Introduction: Pipette 10-50 µL of the inactivated sample onto the sample inlet of the paper chip. Capillary action will transport the sample to the reaction zone(s), rehydrating the reagents.

- Isothermal Amplification: Seal the chip in a small, portable heater or incubator. Incubate at a constant temperature of 39-42°C for 15-30 minutes.

- Detection & Analysis: After incubation, place the chip in a portable fluorimeter or capture an image using a smartphone attachment. The presence of a fluorescent signal above a predetermined threshold indicates a positive result.

The following diagram illustrates the logical workflow and signaling pathway for this protocol:

The limitations of conventional viral detection methods—time, complexity, cost, and lack of portability—are being decisively addressed by lab-on-a-chip technology. By miniaturizing and integrating laboratory processes, LOC devices enable rapid, sensitive, and specific detection of viruses at the point of need, from clinical settings to remote field locations. The experimental protocols and application notes detailed herein provide a framework for researchers to leverage this innovative technology. The continued integration of LOC systems with advanced biosensors, artificial intelligence, and data analytics promises to further revolutionize viral diagnostics and outbreak response, ultimately enhancing global public health preparedness [13] [10].

Lab-on-a-Chip (LoC) technology represents a transformative approach in biomedical research and clinical diagnostics by miniaturizing and integrating complex laboratory functions onto a single, compact platform. These devices, typically measuring from millimeters to a few square centimeters, leverage the principles of microfluidics to manipulate small fluid volumes, typically between nanoliters and microliters [9]. The fundamental advantages of this technology—miniaturization, integration, speed, and low reagent consumption—collectively address critical limitations of conventional analytical methods. Within viral disease detection research, these attributes enable rapid, sensitive, and specific identification of pathogens, significantly accelerating diagnostic workflows and therapeutic development [1] [10]. This document details these core advantages in the context of protocols and applications relevant to researchers and drug development professionals.

Quantitative Advantage Analysis

The benefits of LoC technology can be quantitatively demonstrated across key performance metrics when compared to conventional laboratory methods. The following tables summarize these advantages, with specific data drawn from viral detection applications.

Table 1: Comparative Performance: LoC vs. Conventional Methods for Viral Detection

| Performance Metric | Lab-on-a-Chip Systems | Conventional Methods | Key References & Applications |

|---|---|---|---|

| Assay Time | Minutes to a few hours [10] | Several hours to days [10] | SARS-CoV-2 RNA & Ab detection in ~2 hours [14] |

| Sample Volume | Nanoliters (nL) to Microliters (μL) [9] | Milliliters (mL) [10] | Microfluidic PCR with 100 nL volume [8] |

| Detection Sensitivity | Attomolar (10⁻¹⁸ M) level for RNA [14] | Picomolar (10⁻¹² M) level for conventional PCR [1] | CRISPR-Cas12a with LAMP pre-amplification [14] |

| Limit of Detection (LOD) | 100 copies/μL for SARS-CoV-2 [11] | Varies; e.g., 10 copies/μL for conventional RT-PCR [1] | Rapid, high-sensitivity POC diagnostics [1] [11] |

Table 2: Material and Fabrication Advantages of Common LoC Substrates

| Material | Key Advantages | Primary Applications in Viral Research |

|---|---|---|

| PDMS | Optical transparency, gas permeability, biocompatibility, rapid prototyping [9] [11] | Organ-on-chip models, cell culture, prototyping of virus-host interaction studies [9] |

| Glass | Chemically inert, low autofluorescence, high thermal stability [9] [11] | High-performance nucleic acid analysis, electrophoresis, PCR [9] |

| Thermoplastics (PMMA, PS) | High-throughput fabrication, good optical properties, chemical resistance [11] [8] | Disposable, mass-produced diagnostic chips for viral detection [11] |

| Paper | Ultra-low cost, capillary-driven flow, no external pumps required [9] [11] | Low-resource point-of-care testing (POCT) for viral antigens or antibodies [9] |

Experimental Protocols for Viral Disease Detection

The following protocols illustrate how the core advantages of LoC systems are implemented in practice for viral biomarker detection.

Protocol: Concurrent Detection of SARS-CoV-2 RNA and Antibodies

This protocol, adapted from a published study [14], details the procedure for using an integrated, 3D-printed LoC device to detect both viral RNA and host antibodies against SARS-CoV-2 from saliva, demonstrating high integration and automation.

1. Principle The device automates a complex workflow that combines CRISPR-Cas12a-based enzymatic detection of viral RNA following isothermal amplification (LAMP) with a multiplexed electrochemical enzyme-linked immunosorbent assay (ELISA) for detecting anti-SARS-CoV-2 immunoglobulins. The integration of sample preparation, amplification, and detection on a single chip enables a "sample-to-answer" process in approximately two hours [14].

2. Reagents and Equipment

- LoC Device: 3D-printed microfluidic chip with integrated heating elements and an electrochemical sensor chip.

- Saliva Sample: Unprocessed human saliva.

- Lysis Buffer: Proteinase K solution.

- Amplification Reagents: LAMP master mix with primers targeting SARS-CoV-2 RNA.

- Detection Reagents: Cas12a enzyme with guide RNA (gRNA), ssDNA reporters, and ELISA reagents (anti-human IgG antibodies conjugated to horseradish peroxidase).

- Electrode Functionalization: SARS-CoV-2 Spike S1, nucleocapsid (N), and receptor-binding-domain (RBD) antigens.

- Instrumentation: Arduino-controlled peristaltic pump, potentiostat for electrochemical detection.

3. Step-by-Step Procedure A. Sample Preparation and Lysis

- Load unprocessed saliva into the dedicated sample preparation reservoir on the chip.

- The chip automatically mixes the saliva with a proteinase K solution.

- The integrated heater incubates the mixture at 55°C for 15 minutes, followed by 95°C for 5 minutes to lyse the virus and inactivate nucleases.

B. RNA Extraction and Concentration

- The microfluidic pump transports the lysed saliva over a polyethersulfone (PES) membrane within a serpentine reaction chamber.

- Viral RNA binds to the membrane, concentrating the target and removing potential inhibitors.

- The chamber is heated to 95°C for 3-5 minutes to ensure denaturation of any remaining inhibitors.

C. Nucleic Acid Amplification and Detection

- The LAMP solution is pumped from its reservoir into the reaction chamber containing the RNA-bound membrane.

- Isothermal amplification is performed at 65°C for 30 minutes.

- The amplified product is eluted and mixed with the Cas12a-gRNA complex in the CRISPR reservoir.

- If the target RNA is present, the activated Cas12a cleaves ssDNA reporters, generating an electrochemical signal measured at the sensor electrode.

D. Antibody Detection

- In parallel, a portion of the saliva sample is pumped to a separate reservoir on the electrochemical sensor chip.

- The sensor chip is functionalized with SARS-CoV-2 antigens (S1, N, RBD).

- Host antibodies (IgG) present in the sample bind to these antigens.

- Detection is achieved via a sandwich ELISA using an enzyme-labeled secondary antibody, with an electrochemical readout.

4. Data Analysis

- The electrochemical signals for both nucleic acid and antibody assays are measured simultaneously.

- The presence of viral RNA is confirmed by a signal above a predefined threshold in the CRISPR-based assay.

- The antibody titer and profile are determined by the magnitude of the signal from each antigen-coated electrode, providing a semi-quantitative serological profile.

Protocol: Microfluidic PCR for Viral RNA Detection

This protocol highlights the gains in speed and reagent reduction achieved through miniaturization of the polymerase chain reaction (PCR) [11] [8].

1. Principle Microfluidic PCR, or continuous-flow PCR, exploits the high surface-to-volume ratio of microchannels to achieve extremely rapid thermal cycling. The sample flows through a stationary temperature zones, eliminating the time required for heating and cooling blocks, thus reducing amplification time from hours to minutes [8].

2. Reagents and Equipment

- Microfluidic PCR Chip: Fabricated from silicon, glass, or PDMS with etched microchannels.

- qPCR Master Mix: Contains DNA polymerase, dNTPs, buffers, and primers specific to the target viral RNA (e.g., SARS-CoV-2, Influenza).

- Sample: Purified RNA extract.

- Instrumentation: Syringe pump for fluid propulsion, integrated or external thermocycling blocks, fluorescence detector for real-time monitoring.

3. Step-by-Step Procedure

- Step 1: A mixture of the RNA sample and qPCR master mix is loaded into the chip's injection port.

- Step 2: A syringe pump drives the mixture through a microchannel that passes through three distinct, fixed temperature zones on the chip:

- Denaturation Zone: 90–95°C

- Annealing Zone: 50–60°C

- Extension Zone: 68–72°C

- Step 3: The residence time in each zone is controlled by the channel length and flow rate, enabling complete denaturation, primer annealing, and enzyme extension in each cycle.

- Step 4: As the fluid exits the amplification channel, its fluorescence is measured in real-time, allowing for quantitative analysis of the viral load.

4. Data Analysis

- The time-to-result for a 40-cycle qPCR can be as low as 6 minutes due to the elimination of ramp times [8].

- The cycle threshold (Ct) values are determined similarly to conventional qPCR and used for viral quantification.

The Scientist's Toolkit: Essential Research Reagent Solutions

Successful implementation of LoC protocols relies on a set of key reagents and materials. The following table details these essential components and their functions in viral detection research.

Table 3: Key Research Reagent Solutions for Viral LoC Development

| Reagent / Material | Function | Application Example |

|---|---|---|

| PDMS (Polydimethylsiloxane) | Elastomeric polymer used for rapid prototyping of microfluidic devices; gas-permeable for cell culture. | Fabricating organ-on-chip models for studying virus-host interactions [9] [11]. |

| CRISPR-Cas12a/Cas13 Reagents | Programmable endonucleases that provide highly specific nucleic acid detection through collateral cleavage activity. | Ultrasensitive, attomolar-level detection of SARS-CoV-2 RNA in saliva [11] [14]. |

| LAMP (Loop-mediated Isothermal Amplification) Master Mix | Isothermal nucleic acid amplification method that operates at a constant temperature, simplifying instrument design. | Rapid amplification of viral RNA prior to CRISPR detection in point-of-care settings [14]. |

| Functionalized Magnetic Beads | Micron-sized particles coated with antibodies or oligonucleotides for target capture, separation, and concentration. | Solid-phase extraction and purification of viral RNA or antigens from complex samples like blood or saliva [14]. |

| Electrochemical Reporters (e.g., [Fe(CN)₆]³⁻/⁴⁻) | Redox-active molecules that produce a measurable current change upon binding or cleavage events. | Transducing molecular binding (antibody-antigen, CRISPR cleavage) into an electrical signal in biosensors [14]. |

| Proteinase K | Broad-spectrum serine protease used to digest contaminating proteins and inactivate nucleases in samples. | Lysing viral envelopes and degrading nucleases in unprocessed saliva samples to enable direct RNA detection [14]. |

The core advantages of LoC technology—miniaturization, integration, speed, and low reagent consumption—are not merely incremental improvements but are foundational to its potential to revolutionize viral disease research and diagnostics. The protocols and data presented demonstrate how these attributes synergize to create powerful "sample-in-answer-out" systems. For researchers and drug development professionals, leveraging these advantages enables the development of faster, more sensitive, and accessible diagnostic tools, accelerates high-throughput drug screening, and provides more physiologically relevant models of viral infection through organ-on-chip technology. As fabrication methods advance and integration with AI and data analytics deepens, the role of LoC in combating viral outbreaks and personalizing therapeutic strategies is poised for significant growth.

The Impact of Recent Viral Outbreaks (COVID-19, Ebola, Zika) on LOC Development

Recent viral outbreaks have functioned as powerful catalysts, dramatically accelerating innovation in Lab-on-a-Chip (LOC) technologies. The urgent necessity for rapid, sensitive, and portable diagnostics during the COVID-19 pandemic, Ebola epidemics, and Zika virus crisis has highlighted the limitations of conventional laboratory methods and propelled the development of integrated microfluidic solutions [1] [15]. These outbreaks have underscored the critical need for point-of-care (POC) devices that can deliver results quickly, outside of centralised labs, to facilitate timely intervention and containment.

This application note details how the specific challenges posed by these viruses have directly influenced LOC design principles, material selection, and functional integration. We provide a structured analysis of the resulting technological advances, summarized in comparative tables, and offer detailed experimental protocols that reflect the new capabilities of these platforms within the broader context of a thesis on LOC technology for viral disease detection.

Outbreak-Driven LOC Development

The distinct transmission modes, pathophysiologies, and epidemiological patterns of COVID-19, Ebola, and Zika have steered LOC development along different, requirement-specific paths. Table 1 synthesizes the core diagnostic challenges of each virus and the corresponding LOC innovations developed in response.

Table 1: Impact of Viral Outbreak Characteristics on LOC Development Focus

| Viral Outbreak | Key Diagnostic Challenges | Resulting LOC Innovations |

|---|---|---|

| COVID-19 | High transmission risk; need for mass population testing and rapid results to break chains of transmission [16]. | Integrated sample-to-answer systems for nucleic acid amplification (e.g., RT-PCR on-chip); rapid immunoassays for antigen detection; high-throughput capabilities [1] [15]. |

| Ebola Virus Disease (EVD) | Extreme lethality (CFR 50-90%); requirement for strict containment; testing in resource-limited settings [17] [18]. | LOC devices with minimal external instrumentation; robust, disposable chips to prevent cross-contamination; integration with sustainable power sources [1]. |

| Zika Virus | Association with severe congenital defects (e.g., microcephaly); need to distinguish from other flaviviruses (e.g., Dengue) due to cross-reactivity [19] [20]. | Multiplexed assays for simultaneous detection of related flaviviruses; enhanced sensitivity to detect low viral loads; research into organ-on-a-chip models to study neurodevelopmental impacts [19] [9]. |

The push for POC applications has heavily influenced the materials used in fabricating these advanced LOCs. Material selection now balances not only biocompatibility and manufacturing cost but also optical properties for detection and surface chemistry for efficient assay performance [9].

Table 2: Key Materials for Outbreak-Responsive LOC Development

| Material | Key Properties | Outbreak Application Examples |

|---|---|---|

| Polydimethylsiloxane (PDMS) | Optically transparent, gas-permeable, biocompatible, flexible. | Widely used in organ-on-chip models to study viral mechanisms, such as Zika's effect on neural tissue [19] [9]. |

| Glass | Low autofluorescence, high chemical resistance, excellent optical clarity. | Ideal for high-sensitivity fluorescence-based detection (e.g., PCR for Ebola, Zika) where low background noise is critical [9]. |

| Paper/Cellulose | Low-cost, capillary-driven flow, disposable. | Used in rapid, mass-produced lateral flow tests for COVID-19 antigen detection [9]. |

| Epoxy Resins | High mechanical strength, thermal stability, excellent chemical resistance. | Suitable for devices requiring durable, integrated components for complex, multi-step analysis [9]. |

Experimental Protocols for Advanced LOC Operation

The following protocols reflect the integrated, sample-to-answer workflows that have become the benchmark for outbreak-ready LOC systems.

Protocol: Integrated Detection of Viral RNA via On-Chip RT-LAMP

This protocol describes a method for detecting viral RNA from pathogens like SARS-CoV-2 or Zika virus using Reverse Transcription Loop-Mediated Isothermal Amplification (RT-LAMP) on a microfluidic chip, offering rapid results without the need for complex thermal cycling [1].

Research Reagent Solutions:

- Lysis/Binding Buffer: Guanidine thiocyanate-based buffer for viral inactivation and RNA release.

- Solid-Phase Extraction Beads: Silica-coated magnetic beads for purifying and concentrating RNA from the lysate.

- RT-LAMP Master Mix: Contains reverse transcriptase, Bst DNA polymerase, specific primer sets targeting viral RNA, and dNTPs.

- Fluorescent Intercalating Dye: SYBR Green or similar for real-time visual or fluorescence detection of amplification.

Methodology:

- Sample Introduction: A nasopharyngeal swab sample (100 µL) is loaded into the chip's input reservoir.

- On-Chip RNA Extraction and Purification:

- The sample is mixed with lysis/binding buffer within a microfluidic chamber.

- Silica-coated magnetic beads are introduced. RNA binds to the beads in the presence of a high-salt chaotropic agent.

- Using an integrated magnetic actuator, the beads are washed through multiple chambers with an ethanol-based wash buffer to remove contaminants.

- Purified RNA is eluted from the beads into a low-salt elution buffer (e.g., nuclease-free water) in a final reaction chamber.

- Amplification and Detection:

- The eluted RNA is mixed with the RT-LAMP master mix.

- The reaction chamber is heated to a constant isothermal temperature (60-65 °C) for 20-30 minutes.

- Amplification is monitored in real-time via an integrated fluorescence detector or confirmed by a colorimetric change visible to the naked eye.

Diagram 1: On-chip RT-LAMP workflow for viral RNA detection.

Protocol: Multiplexed Flavivirus Serological Discrimination

This protocol leverages a microfluidic immunoassay to simultaneously detect and distinguish antibodies against the Zika virus from those against related flaviviruses (e.g., Dengue), which is a major challenge in serological diagnosis [1] [20].

Research Reagent Solutions:

- Antigen-Cooped Microchannels: Microchannels functionalized with specific recombinant viral antigens (e.g., ZIKV NS1, DENV NS1).

- Sample Diluent: Buffer containing blockers (e.g., BSA) to minimize non-specific binding.

- Fluorescently-Labeled Detection Antibodies: Anti-human IgG and IgM antibodies conjugated to distinct fluorophores.

- Wash Buffer: PBS or TBS with a low-concentration detergent (e.g., Tween-20).

Methodology:

- Chip Priming: The device, pre-patterned with specific viral antigens in parallel detection zones, is primed with wash buffer.

- Sample and Incubation:

- A patient serum or plasma sample (10 µL) is diluted and introduced into the chip.

- The sample flows through the antigen-coated channels via capillary action or pressure-driven flow and incubates for 10-15 minutes to allow antigen-antibody binding.

- Washing: Unbound proteins are removed by flushing the channels with wash buffer.

- Detection:

- A mixture of fluorescently-labeled anti-human IgG (e.g., Cy5, red) and anti-human IgM (e.g., FITC, green) is introduced.

- After a second incubation and wash step, the chip is scanned with a fluorescent reader.

- Analysis: The presence and intensity of fluorescence at each antigen zone indicate the specific antibody profile of the patient, allowing for differentiation between Zika and Dengue infections.

Diagram 2: Multiplexed serological assay for flavivirus discrimination.

The Scientist's Toolkit: Essential Research Reagents

The successful implementation of the aforementioned protocols relies on a suite of key reagents. The table below details these essential components and their functions in viral detection LOCs.

Table 3: Key Research Reagent Solutions for Viral Detection LOCs

| Reagent / Material | Function in LOC Assay | Exemplary Application |

|---|---|---|

| Silica-Coated Magnetic Beads | Solid-phase matrix for nucleic acid binding, purification, and concentration via magnetic manipulation. | Extraction of viral RNA from complex samples like saliva or blood prior to RT-PCR/LAMP [21]. |

| Recombinant Viral Antigens | Capture agents immobilized on chip surfaces to bind specific antibodies from a sample. | Serological detection of past exposure to Zika or Ebola virus in multiplexed immunoassays [1]. |

| Bst DNA Polymerase | Enzyme for isothermal nucleic acid amplification (e.g., LAMP). Enables rapid amplification at constant temperature. | Point-of-care detection of SARS-CoV-2 RNA without the need for a thermal cycler [1]. |

| Fluorophore-Labeled Antibodies | Detection probes that bind to target antigens or amplified products, generating a measurable optical signal. | Quantification of viral load or detection of specific immune responses in integrated optical detection systems [1] [15]. |

| Polymerase (PDMS) | The primary elastomeric material for building flexible, transparent, and gas-permeable microfluidic channels. | Fabrication of organ-on-a-chip devices to model Zika virus infection and study neurodevelopmental defects [19] [9]. |

The relentless pressure exerted by recent viral outbreaks has been a defining force in shaping the modern LOC landscape. The demand for speed, portability, and multiplexing has driven a paradigm shift from single-function chips to fully integrated, sample-to-answer diagnostic systems. As LOC technology continues to evolve, its integration with advanced biosensors, artificial intelligence, and organ-on-a-chip models promises not only faster and more accurate pathogen detection but also a deeper understanding of viral pathogenesis itself. This progression, forged in the fires of public health emergencies, solidifies the role of LOC devices as an indispensable tool in pandemic preparedness and response.

Core Components of a Microfluidic System for Viral Detection

Lab-on-a-chip (LoC) technology represents a pioneering amalgamation of fluidics, electronics, optics, and biosensors that performs various laboratory functions on a miniaturized scale, processing small fluid volumes from 100 nL to 10 μL [9]. For viral detection, these systems consolidate multiple laboratory processes—including sampling, sample pretreatment, nucleic acid amplification, and detection—onto a single chip, minimizing reliance on bulky instrumentation and extensive manual intervention [9]. The core advantage of microfluidic systems for viral detection stems from their compactness, which offers portability, minimal consumption of samples and reagents, and significantly shorter assay times compared to conventional laboratory methods [9]. This document details the core components and experimental protocols for microfluidic systems, framed within the broader context of LoC technology for viral disease detection research.

Key System Components and Performance Metrics

Microfluidic systems for viral detection integrate several physical and biochemical components to create a functional "sample-in, answer-out" device. The table below summarizes the core components and their functions, with quantitative performance data from recent platforms.

Table 1: Core Components and Performance of Microfluidic Viral Detection Systems

| System Component | Function & Description | Example Materials & Technologies | Performance Metrics (from recent platforms) |

|---|---|---|---|

| Microfluidic Cartridge/ Chip | Disposable unit housing microchannels and chambers for fluid manipulation and reactions [22]. | Polycarbonate [23], PDMS [9], CNC-machined parts [22]; Rotary/centrifugal design for fluid control [22] [23]. | 4-8 samples per run; 16 parallel reactions [22]; Prevents nucleic acid aerosol contamination [23]. |

| Flow Management | Controls and moves liquid samples and reagents through the microchannels. | Centrifugal force (rotary platforms) [22] [23], syringe pumps [24], integrated micropumps/valves [25]; Laminar flow for predictable particle control [24]. | Flow rates in the nL/min to μL/min range (e.g., 750 nL/min for particle focusing) [24]. |

| Heating & Temperature Control | Maintains precise temperatures for nucleic acid amplification. | Thin-film metal heaters (Pt) [26], Peltier elements [26], infrared lamps/lasers [26]. | Isothermal amplification at 65°C for 30-40 min [22] [23]; Ultra-fast qPCR in <8 minutes [26]. |

| Optical Detection Module | Detects fluorescent signals from amplified viral targets in real-time. | LED excitation source, optical filters, dichroic mirror, photomultiplier tubes (PMTs) [22]; Confocal microscopy for single-particle detection [24]. | Limit of Detection (LoD): 50 copies/μL for MP DNA [22]; 10-3 ng/μL for influenza A/H1N1 [23]. |

| Reagent Storage & Preparation | Stores and prepares lyophilized or liquid reagents on-chip. | Pre-loaded lyophilized RT-LAMP beads [22] [23]; On-chip sample lysis modules [22]. | Lyophilized beads stable at room temperature; rehydrated by introduced sample [22]. |

Detailed Experimental Protocol: Multiplex RT-LAMP for Respiratory Viruses

The following protocol is adapted from recent studies for detecting respiratory pathogens like Influenza A/H1N1, A/H3N2, and B/Victoria using a rotary microfluidic platform [22] [23].

Research Reagent Solutions

Table 2: Essential Reagents for Microfluidic RT-LAMP Viral Detection

| Reagent/Material | Function in the Assay | Example Source / Specification |

|---|---|---|

| Lyo-Ready RT-LAMP Mix | Provides enzymes (Bst DNA polymerase, reverse transcriptase), buffer, and dNTPs for isothermal amplification. | Meridian Life Science Inc. [22] |

| LAMP Primers | Specifically designed inner, outer, and loop primers for target viral sequences (e.g., MP P1 gene, Influenza HA/NA genes). | Designed with PrimerExplorer V5; synthesized by commercial providers (e.g., Sangon Biotech) [22] [23]. |

| Fluorescent DNA Dye | Intercalates with double-stranded DNA amplification products, enabling real-time fluorescence detection. | Eva Green [22] or SYBR Green [26]. |

| Nucleic Acid Release Reagent | Lyses viral particles in swab samples to release RNA/DNA for direct amplification. | Tuoman Biotech [22]. |

| Microfluidic Cartridge | Integrated disposable device for sample preparation, reagent partitioning, and amplification. | Fabricated via CNC machining or injection molding [22] [23]. |

Step-by-Step Procedure

Primer Design and Preparation

- Retrieve target viral gene sequences (e.g., from NCBI database) and align them to identify conserved regions [23].

- Use PrimerExplorer V5 software to design two inner primers and two outer primers targeting 6-8 distinct regions of the conserved sequence. Design loop primers for accelerated amplification [22] [23].

- Synthesize and reconstitute primers in RNase-free water to form a primer mixture [22].

Chip Pre-loading and Preparation

Sample Introduction and Lysis

On-Chip Fluidic Control and Reaction Setup

- Place the loaded cartridge into the companion benchtop analyzer.

- The instrument initiates a low-speed spin (e.g., 1600 rpm for 30s, repeated) to eliminate bubbles and evenly mix the liquid into a distribution tank [23].

- A subsequent high-speed centrifugation step (e.g., 4500 rpm) partitions the sample into multiple reaction chambers, where it rehydrates and mixes with the lyophilized primers and reagents [22] [23].

Isothermal Amplification and Real-Time Detection

Data Analysis

- The analyzer software records real-time fluorescence intensity and calculates the amplification rate.

- A positive detection is confirmed by a characteristic sigmoidal (S-shaped) amplification curve. The threshold time (Dt) is used for quantitative analysis [23].

- Specificity can be confirmed via melting curve analysis if using intercalating dyes like Eva Green [26].

The following workflow diagram summarizes the key steps of this protocol.

System Integration and Workflow

A fully integrated microfluidic platform combines all discrete components into an automated system. The diagram below illustrates the architecture and workflow of such a system, from sample input to result output.

Implementing LOC Platforms: From Immunoassays to Genetic Detection

Sample Preparation and Integration on a Single Chip

The emergence of lab-on-a-chip (LOC) technologies represents a paradigm shift in diagnostic virology, offering the potential to consolidate entire laboratory workflows onto a single, miniaturized device. For researchers and drug development professionals, the core challenge has traditionally been the integration of sample preparation—a critical, yet often labor-intensive first step—with subsequent amplification and detection modules on a unified platform. The presence of inhibitors in crude biological samples and the need for high sensitivity demand sophisticated on-chip handling. Recent advances address these challenges by creating self-contained systems that automate fluid control and purification, bringing robust molecular diagnostics closer to point-of-care (PoC) settings and high-throughput research applications [27]. This application note details protocols centered on an autonomously loaded microfluidic platform, the VirChip, for the multiplexed detection of respiratory viral pathogens [28].

Key Technologies and Principles

The integration of sample preparation on a single chip relies on several key technological principles. Isothermal amplification methods, particularly loop-mediated isothermal amplification (LAMP), are central to this integration. Unlike traditional PCR, LAMP operates at a constant temperature (60–65 °C), eliminating the need for complex thermal cycling and reducing power consumption and instrumental complexity. This makes it ideally suited for PoC devices [28]. LAMP employs a strand-displacing DNA polymerase and four to six primers that recognize distinct regions of the target, conferring high specificity and enabling efficient amplification directly from crude samples [28].

Fluid control within the chip is another critical element. The VirChip platform utilizes a valve-free and pump-free autonomous loading mechanism based on degas-driven flow. The polydimethylsiloxane (PDMS) substrate is degassed prior to use, creating a pressure differential that draws the liquid sample into the microchambers without external equipment. This passive, self-loading feature is vital for operation in resource-limited environments [28].

Finally, spatial multiplexing is employed to enable the simultaneous detection of multiple analytes. This is achieved by fabricating an array of individual reaction chambers on the chip, each pre-loaded with primers for a specific viral target (e.g., SARS-CoV-2, influenza A, influenza B, RSV). The sample is distributed among these chambers, allowing for a single sample to be screened against a panel of pathogens concurrently [28] [29].

Integrated Experimental Protocol

This protocol describes the procedure for using the VirChip for the direct, multiplexed detection of respiratory viruses from nasal swab samples.

Research Reagent Solutions

Table 1: Essential Research Reagents for On-Chip LAMP Assays

| Reagent/Material | Function/Description | Example Source/Concentration |

|---|---|---|

| WarmStart LAMP Kit (DNA & RNA) | Provides the core enzymes (Bst 2.0 polymerase) and buffers for isothermal amplification. | New England Biolabs (E1700S) [28] |

| WarmStart RTx Reverse Transcriptase | Enables reverse transcription of viral RNA for subsequent LAMP amplification (for RNA viruses). | New England Biolabs (M0380L, 15,000 U/mL) [28] |

| Target-Specific Primers | Four to six primers per virus target designed for high specificity in LAMP reactions. | Integrated DNA Technologies [28] |

| LAMP Fluorescent Dye (e.g., EvaGreen) | Intercalating dye for real-time fluorescence detection of amplified DNA. | Jena Bioscience [28] |

| Betaine | Additive that reduces DNA secondary structure, improving amplification efficiency and yield. | Thermo Fisher Scientific [28] |

| Trehalose | Stabilizing agent for lyophilized reagents, enhancing shelf-life at room temperature. | Merck [28] |

| Sylgard 184 Elastomer Kit | PDMS polymer used for fabricating the microfluidic chip via soft lithography. | Dow Corning [28] |

Chip Fabrication Workflow

The following diagram illustrates the fabrication process for the VirChip.

Procedure:

- Master Mold Fabrication: Create a two-layer master mold featuring microchamber and flow channel designs using a maskless photolithography system (e.g., μMLA maskless mask aligner) and standard photoresist techniques [28].

- PDMS Replication: Mix the Sylgard 184 elastomer kit base and curing agent in a 10:1 ratio, pour over the master mold, and cure at elevated temperature (e.g., 65 °C for 2 hours) to create a solid PDMS replica.

- Inlet Punching: Use a 3.0 mm diameter biopsy punch to create a sample inlet port in the PDMS layer.

- Bonding and Degassing: Bond the patterned PDMS layer to a flat substrate (e.g., glass slide) using oxygen plasma treatment. Subsequently, place the assembled chip in a vacuum desiccator for degassing to enable autonomous loading.

- Reagent Pre-loading: Pipette the prepared LAMP master mix (see Section 3.3) into individual microchambers. Reagents can be used immediately or lyophilized for storage.

Assay Procedure and Workflow

The complete process, from sample introduction to result interpretation, is outlined below.

Procedure:

- LAMP Master Mix Preparation:

Prepare the reaction mix on ice. A typical 25 µL reaction contains:

- 1.5 µL of WarmStart RTx Reverse Transcriptase

- 1.0 µL of WarmStart Bst 2.0 Polymerase

- 12.5 µL of 2× LAMP Buffer

- 1.4 µL of 10 mM dNTPs

- 5.0 µL of 5 M Betaine

- 1.0 µL of LAMP Fluorescent Dye (e.g., 20× EvaGreen)

- Forward and backward inner primers (FIP/BIP, 1.6 µM each)

- Loop primers (LF/LB, 0.8 µM each)

- Outer primers (F3/B3, 0.2 µM each)

- Nuclease-free water to volume

- Note: Primers are specific to each target (e.g., SARS-CoV-2, Influenza A/B, RSV) and are loaded into separate chambers for multiplexing [28].

Sample Application and Loading: Apply 20-30 µL of a crude nasal swab sample (in viral transport media, no RNA extraction required) directly to the chip's inlet port. The degassed PDMS chip will autonomously draw the sample into the pre-loaded microchambers via passive pumping, hydrating the lyophilized reagents and initiating the reaction [28].

On-Chip Amplification and Detection: Place the loaded chip on a portable, isothermal heating block or reader at 65 °C for 30–45 minutes. Fluorescence is monitored in real-time or measured at end-point. A positive amplification curve (or a fluorescence threshold exceeding the negative control) indicates the presence of the target viral pathogen.

Performance Data and Validation

Table 2: Performance Metrics of the VirChip for Viral Pathogen Detection

| Parameter | Performance Data / Specification | Experimental Context / Notes |

|---|---|---|

| Limit of Detection (LOD) | 100 RNA copies per reaction | Demonstrated for SARS-CoV-2, Influenza A/B, and RSV targets [28] |

| Analytical Specificity | No cross-reactivity observed | Tested with patient samples positive for targeted respiratory viruses [28] |

| Sample-to-Answer Time | ~45-60 minutes | Includes autonomous loading and isothermal amplification [28] |

| Sample Input Volume | 20-30 µL | Compatible with standard nasal swab elution volumes [28] |

| Assay Multiplexing Capacity | 4-plex (demonstrated) / 16-24 chambers (design) | Simultaneous detection of SARS-CoV-2, Influenza A, Influenza B, RSV (A/B) [28] |

Discussion

The integrated protocols presented herein demonstrate that efficient sample preparation and multiplexed detection can be successfully consolidated onto a single microfluidic chip. The VirChip platform effectively addresses key bottlenecks in PoC molecular diagnostics, notably the elimination of manual RNA extraction and the need for external fluid handling equipment [28]. The use of direct crude sample input without a separate lysis or purification step significantly simplifies the workflow, reduces the risk of contamination, and shortens the total analysis time.

The degas-driven autonomous loading mechanism is a key enabling technology for deployment in resource-limited settings, as it operates without pumps or power [28]. Furthermore, the spatial multiplexing capability allows researchers to tailor the chip to specific pathogen panels, enhancing its utility for syndromic testing where clinical symptoms from multiple pathogens overlap [28] [29]. While the platform shows great promise, challenges remain in further simplifying manufacturing, ensuring long-term reagent stability, and expanding the panel to include a broader range of emerging pathogens. Future developments may incorporate electrical sensing methods for quantification and integration with smartphone-based readers to broaden accessibility and data management capabilities [29]. For the research and drug development community, such integrated systems offer a powerful tool for rapid pathogen screening, animal model testing, and expediting therapeutic discovery.

Microfluidic Immunoassays for Viral Antigen and Antibody Detection

Microfluidic immunoassays represent a transformative advancement in the detection of viral antigens and antibodies, core to the broader application of lab-on-a-chip (LoC) technology in viral disease research. By miniaturizing and integrating complex laboratory functions such as sample preparation, reagent handling, and signal detection onto a single chip, these systems enable rapid, sensitive, and automated diagnostics at the point-of-care (PoC) or in resource-limited settings [30] [1] [9]. This shift from conventional, centralized laboratory methods to compact, micro-scale devices addresses critical limitations of traditional techniques—including long processing times, high reagent consumption, and the need for specialized equipment and personnel [1] [31] [32]. For researchers and drug development professionals, mastering these protocols is essential for advancing serological studies, epidemiologic surveillance, and the development of next-generation diagnostic tools.

Key Applications and Performance Data

Microfluidic platforms have been successfully engineered to detect a wide array of viral targets, demonstrating performance comparable to, and sometimes surpassing, conventional laboratory standards. The following applications highlight the versatility and effectiveness of this technology.

Detection of SARS-CoV-2 Antigens and Antibodies: The VISTA platform is a disposable, electricity-free microfluidic chip that executes a bubbling immunoassay for SARS-CoV-2 nucleocapsid (N) antigen detection directly from patient samples in under 45 minutes. It pairs with an AI-enabled smartphone application for automated result interpretation, achieving a sensitivity on par with lab-based ELISAs and capable of detecting viral loads below 10⁴ copies mL⁻¹ [30]. For serology, a microfluidic microplate-based fluorescent ELISA (Opti IgG/M) demonstrated high diagnostic performance for detecting anti-SARS-CoV-2 IgG and IgM. It showed a positive percent agreement (PPA) of 97.1–100% for IgG and 93.7% for IgM, with specificities of 99.4% and 97.2%, respectively [33].

High-Throughput Serological Surveillance: A microfluidic nano-immunoassay (NIA) was developed for high-throughput testing of up to 1024 samples in parallel. This platform was validated using dried capillary blood microsamples collected on Mitra devices, achieving a clinical sensitivity of 95.05% and specificity of 100% for anti-SARS-CoV-2 Spike IgG, enabling decentralized sample collection and cost-effective large-scale serosurveys [34].

Detection of Other Viral Pathogens: The principles of these assays are broadly applicable. Microfluidic systems have been extensively researched and deployed for detecting pathogens such as Hepatitis C virus (HCV), influenza, HIV, and Ebola, utilizing both immunoassay and nucleic acid amplification techniques [30] [1]. For instance, integrated LoC systems can perform nucleic acid extraction and amplification for respiratory viruses from swab samples, reducing total PCR time to approximately 30 minutes [32].

Table 1: Performance Comparison of Selected Microfluidic Immunoassays

| Viral Target | Assay Platform | Biomarker Detected | Sample Type | Key Performance Metrics | Reference |

|---|---|---|---|---|---|

| SARS-CoV-2 | VISTA Microfluidic Chip | N Antigen | Patient Samples | Sensitivity par with lab ELISA; LOD <10⁴ copies mL⁻¹; <45 min | [30] |

| SARS-CoV-2 | Microfluidic Fluorescent ELISA (Opti IgG) | Anti-N IgG | Human Serum | PPA: 97.1-100%; Specificity: 99.4% | [33] |

| SARS-CoV-2 | Microfluidic Fluorescent ELISA (Opti IgM) | Anti-RBD IgM | Human Serum | PPA: 93.7%; Specificity: 97.2% | [33] |

| SARS-CoV-2 | Microfluidic Nano-Immunoassay (NIA) | Anti-Spike IgG | Dried Capillary Blood | Sensitivity: 95.05%; Specificity: 100% | [34] |

| HCV | VISTA Microfluidic Chip | Core Antigen | Patient Samples | Sensitivity on par with lab-based ELISAs | [30] |

Experimental Protocols

Protocol 1: Microfluidic Bubbling Immunoassay for Viral Antigen Detection

This protocol adapts the methodology from the VISTA cartridge for detecting viral antigens (e.g., SARS-CoV-2 N protein) using a pressure-driven, electricity-free microfluidic system [30].

Workflow Overview:

Materials:

- Microfluidic Cartridge: Disposable chip with pre-stored reagents and integrated microchannels.

- Antibody-Conjugated Magnetic Beads: Beads coated with capture antibody specific to the target antigen.

- Platinum Nanoparticle (Pt-NP) Conjugate: Detection antibody conjugated to Pt-NPs.

- Catalytic Substrate: Hydrogen peroxide (H₂O₂) solution.

- Wash Buffer: Phosphate-buffered saline (PBS) with a surfactant (e.g., Tween-20).

- Sample: Processed nasopharyngeal swab, saliva, or other relevant clinical sample.

- Smartphone with AI Application: For automated image capture and analysis.

Procedure:

- Sample Loading: Introduce the patient sample (e.g., 50-100 µL) into the sample inlet port of the microfluidic cartridge.

- On-Chip Incubation (Antigen Capture): The cartridge design allows the sample to mix with the antibody-conjugated magnetic beads. Incubate for approximately 15 minutes at room temperature to allow for the formation of antigen-antibody-bead complexes.

- Magnetic Separation and Washing: Activate an integrated magnet to immobilize the magnetic bead complexes. A pressure-driven flow then passes the wash buffer through the chamber to remove unbound proteins and sample matrix components.

- Detection Probe Incubation: Release the magnetic bead complexes and mix them with the Pt-NP-conjugated detection antibody. Incubate for another 15 minutes to form a sandwich complex (capture antibody-antigen-detection antibody-Pt-NP).

- Magnetic Washing: Re-immobilize the sandwich complexes and perform a second wash to remove excess, unbound Pt-NP conjugates.

- Signal Generation: Introduce the H₂O₂ substrate. The platinum nanoparticles catalytically decompose H₂O₂, producing oxygen bubbles.

- Result Readout: The presence and quantity of the target antigen are proportional to the number of bubbles formed. Capture an image of the reaction chamber using the smartphone application. The integrated adversarial neural network automatically analyzes the image to provide a positive/negative result or a semi-quantitative measurement.

Protocol 2: Microfluidic Microplate-Based Fluorescent ELISA for Antibody Detection

This protocol details the procedure for a high-performance, fluorescent-based microfluidic ELISA for detecting virus-specific immunoglobulins (IgG and IgM), as utilized in the Veri-Q opti system [33].

Workflow Overview:

Materials:

- Microfluidic Microplate: Opti96 plate with a network of microchannels, pre-coated with viral antigen (e.g., N protein for IgG, RBD for IgM).

- Serum Samples and Controls: Positive, negative, and calibrator controls.

- Assay Diluent: Protein-based buffer for diluting samples and reagents.

- Conjugate: Horseradish peroxidase (HRP)-labeled anti-human IgG or IgM antibody.

- Chemifluorescent Substrate: A substrate that yields a fluorescent product upon reaction with HRP.

- Wash Buffer.

- Fluorescence Plate Reader: Capable of excitation at ~530 nm and emission at ~590 nm.

Procedure:

- Initial Flush: Load 5 µL of assay diluent into the loading well to flush the system and condition the antigen-coated microchannels.

- Sample Application: Dispense 5 µL of diluted (e.g., 1:20) serum sample or control into the designated wells. The sample is drawn into the microchannels by capillary action.

- Primary Incubation: Incubate the plate for 10 minutes at room temperature. Virus-specific antibodies (if present) in the sample will bind to the immobilized antigen in the microchannels.

- Wash Step 1: Flush the microchannels with 5 µL of wash buffer to remove unbound serum proteins.

- Conjugate Application: Dispense 5 µL of the HRP-labeled secondary antibody into the wells. Incubate for 10 minutes at room temperature. The conjugate will bind to the captured human antibodies.

- Wash Step 2: Flush the microchannels with 30 µL of wash buffer to thoroughly remove any unbound conjugate.

- Signal Development: Dispense 5 µL of the chemifluorescent substrate into the wells. Incubate for 15 minutes in the dark to allow the enzymatic reaction to produce a fluorescent signal.

- Detection: Read the Relative Fluorescence Units (RFU) using a fluorescence plate reader at Ex.530 nm/Em.590 nm.

- Data Analysis: Calculate an Antibody Index for each sample (Sample RFU / Blank RFU). Interpret results per the manufacturer's cutoff (e.g., Index ≥12 positive; Index ≤6 negative).

The Scientist's Toolkit: Research Reagent Solutions

Successful implementation of microfluidic immunoassays relies on a carefully selected suite of reagents and materials. The table below outlines essential components and their critical functions in the assay workflow.

Table 2: Essential Reagents and Materials for Microfluidic Immunoassays

| Item | Function/Description | Key Considerations |

|---|---|---|

| Capture Antibody | Immobilized on solid support (beads/channel) to specifically bind target analyte. | High specificity and affinity; must be compatible with surface chemistry (e.g., passive adsorption, covalent bonding). |

| Detection Antibody | Conjugated to a label (enzyme, nanoparticle, fluorophore) for signal generation. | Binds to a different epitope than capture antibody for sandwich assays; conjugate should be stable and high-activity. |

| Magnetic Beads | Paramagnetic particles used as a mobile solid phase for efficient separation and washing. | Uniform size distribution; surface functionalized for antibody coupling (e.g., carboxyl, streptavidin). |

| Platinum Nanoparticles (Pt-NPs) | Catalytic labels that decompose H₂O₂ to generate oxygen bubbles for visual detection. | Provides electricity-free, equipment-light signal amplification [30]. |

| Fluorescent Dye/Substrate | Generates a fluorescent signal upon enzymatic reaction (e.g., with HRP). | Enables highly sensitive, quantitative detection in microfluidic fluorescent ELISAs [33]. |

| Microfluidic Chip Material (PDMS, PMMA, Glass) | The substrate of the LoC device. | Chosen based on optical clarity, biocompatibility, and fabrication needs (e.g., PDMS for prototyping, thermoplastics for mass production) [9] [11]. |

| Dried Blood Microsamplers (Mitra, HemaXis) | Devices for volumetric collection of capillary blood for decentralized sampling. | Enables stable transport and integration with sensitive microfluidic assays like NIA [34]. |

Microfluidic immunoassays provide a powerful and versatile toolkit for the sensitive and specific detection of viral antigens and antibodies. The protocols and data presented herein offer a practical foundation for researchers and drug development professionals to leverage this technology. The integration of these systems with advanced materials, decentralized sampling methods, and AI-driven analytics is poised to further revolutionize viral diagnostics and serological monitoring, solidifying the role of lab-on-a-chip technology as a cornerstone of modern biomedical research and public health response.

The integration of nucleic acid amplification tests (NAATs) with lab-on-a-chip (LOC) technologies has revolutionized point-of-care (POC) molecular diagnostics for viral diseases [1] [35]. These microfluidic platforms miniaturize and automate complex laboratory procedures, enabling rapid, sensitive, and specific detection of pathogens in resource-limited settings [35]. This article details the application and protocols for three pivotal techniques—Microfluidic PCR, Reverse Transcription Loop-Mediated Isothermal Amplification (RT-LAMP), and Recombinase Polymerase Amplification (RPA)—within microfluidic systems, providing a structured guide for researchers and drug development professionals.

The following table summarizes the core characteristics, advantages, and limitations of each technique for viral detection in microfluidic formats.

Table 1: Comparison of Key Nucleic Acid Amplification Techniques in Microfluidics

| Feature | Microfluidic PCR | Microfluidic RT-LAMP | Microfluidic RPA |

|---|---|---|---|

| Principle | Thermal cycling for DNA amplification [35] | Isothermal amplification with strand-displacing DNA polymerase [23] [35] | Isothermal amplification using recombinase-primer complexes [35] [36] |

| Typical Assay Time | 1-2 hours (includes thermal cycling) [1] | ~1 hour or less [23] | 20-40 minutes [35] [36] |

| Operating Temperature | 95°C (denaturation), 50-65°C (annealing), 72°C (extension) [35] | Constant 60-65°C [23] [35] | Constant 37-42°C [35] |

| Key Instrument Needs | Thermocycler, precise temperature control [35] | Single-temperature heater/block [23] | Low-temperature heater/block [36] |

| Detection Sensitivity | High (attomolar range) [14] | High (e.g., down to 10² copies/μL) [23] | High (picomolar to femtomolar range) [35] |

| Ease of Integration in LOC | Moderate (requires rapid thermal cycling) [35] | High (simplified thermal control) [23] [35] | High (minimal thermal control) [35] [36] |

| Primary Application | Gold standard for nucleic acid detection; quantitative analysis [35] [14] | Rapid detection of RNA viruses (e.g., Influenza, SARS-CoV-2) [23] [14] | Ultra-rapid POC diagnostics for decentralized settings [36] |

Application Notes and Experimental Protocols

Microfluidic RT-LAMP for Influenza Virus Detection

Application Note: RT-LAMP is ideal for rapid POC detection of RNA viruses like influenza. Its isothermal nature simplifies device design, and the high amplification efficiency allows for visual or fluorescent detection within 30-60 minutes [23]. A key advantage is the ability to pre-load reagents into a closed microfluidic chip, preventing nucleic acid aerosol contamination [23].

Protocol: Centrifugal Microfluidic Chip-based Detection of Influenza A/H1N1, A/H3N2, and B/Victoria [23]

- Primer Design: Design LAMP primers (inner, outer, and loop primers) targeting conserved regions of the influenza virus using software. For A/H3N2, design multiple primer sets to ensure universality across different epidemic years.

- Chip Preparation: Pre-encapsulate specific primer sets for each influenza subtype into separate reaction chambers of a polycarbonate 4-channel microfluidic chip.

- Sample Loading: Load extracted viral RNA (≥10⁻³ ng/μL for A/H1N1/A/H3N2) into the chip's sample chamber.

- Amplification & Detection:

- Place the chip in a pre-heated (65°C) detection instrument.

- Centrifuge at 1600 rpm for 30 seconds; repeat 3 times to mix and eliminate bubbles.

- Centrifuge at 4500 rpm for 30 seconds; repeat 3 times to drive the liquid into the primer-loaded reaction chambers.

- Incubate at 65°C for 40 minutes, with fluorescence read during brief rotations once per minute.

- Analysis: A typical S-shaped amplification curve indicates a positive result. The method showed high consistency with classical qPCR when tested on 296 clinical samples [23].

Microfluidic RPA for Neglected Tropical Diseases (NTDs)

Application Note: RPA's low operating temperature and rapid reaction make it perfectly suited for POC diagnostics in low-resource settings for NTDs [36]. Its freeze-dried reagents eliminate cold-chain requirements, greatly improving accessibility [36].

Protocol: General Workflow for RPA-based Pathogen Detection [35] [36]

- Sample Preparation: Minimally preparative samples are used. For viral RNA detection, incorporate reverse transcriptase for RT-RPA.

- Reconstitution: Hydrate freeze-dried RPA pellets with the prepared sample and rehydration buffer.

- Amplification: Incubate the reaction mixture at 37-42°C for 20-40 minutes within the microfluidic device. The recombinase-primer complexes scan double-stranded DNA and facilitate strand displacement synthesis.

- Detection: Amplification can be detected in real-time using fluorescent probes or at the endpoint via lateral flow strips. RPA can also be coupled with CRISPR/Cas systems for enhanced specificity [35].

Integrated Microfluidic PCR for Multiplexed Detection

Application Note: Microfluidic digital PCR (dPCR) and quantitative PCR (qPCR) enable absolute quantification of viral load and multiplexed detection. These are often implemented in digital microfluidics (DMF) based on electrowetting-on-dielectric (EWOD), where droplets are manipulated electrically to perform multiple processes automatically [35].

Protocol: Concurrent Electrochemical Detection of SARS-CoV-2 RNA and Antibodies on a Lab-on-a-Chip [14]

This protocol uses an integrated, 3D-printed LOC for simultaneous nucleic acid and antibody detection.

- Sample Input: The user manually loads unprocessed saliva into two separate reservoirs on the chip: one for RNA detection and one for antibody detection.

- RNA Workflow (Automated on-chip):

- Sample Prep: Saliva in the preparation chamber is mixed with proteinase K and heated to 55°C for 15 min, then 95°C for 5 min for virus lysis and nuclease inactivation.

- RNA Concentration: The sample is pumped over a polyethersulfone (PES) membrane in a serpentine reaction chamber, where RNA binds.

- Amplification: A LAMP solution is pumped onto the membrane and incubated at 65°C for 30 min for RNA amplification.

- CRISPR Detection: The amplicon is mixed with Cas12a-gRNA complex. If the target is present, activated Cas12a cleaves ssDNA reporters on an electrode, generating an electrochemical signal.

- Antibody Workflow: Saliva (spiked with plasma) in its reservoir is pumped over a separate electrode functionalized with SARS-CoV-2 antigens (S1, nucleocapsid, RBD). A sandwich ELISA with an enzyme-labeled secondary antibody generates an electrochemical signal in the presence of anti-SARS-CoV-2 immunoglobulins.

- Readout: Both RNA and antibody presence are determined via multiplexed electrochemical outputs within 2 hours [14].

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Reagents and Materials for Microfluidic NAAT Development

| Reagent/Material | Function | Application Notes |

|---|---|---|

| Bst DNA Polymerase | Strand-displacing enzyme for isothermal amplification [35]. | Core enzyme for LAMP reactions; used at constant 60-65°C [23] [35]. |

| Recombinase (e.g., T4 uvsX) | Binds to primers and facilitates strand invasion of dsDNA [35]. | Core component of RPA; enables amplification at 37-42°C [35] [36]. |

| Lyophilization-Ready Master Mixes | Stable, room-temperature storage of amplification reagents [37]. | Critical for POC and assay distribution without cold chain [36] [37]. |

| Cas12a Enzyme & gRNA | CRISPR-based detection system for specific nucleic acid sequence recognition [14]. | Provides high specificity for amplicon detection; used post-amplification (e.g., after LAMP) [35] [14]. |

| Polyethersulfone (PES) Membrane | Solid-phase matrix for nucleic acid binding and concentration [14]. | Used in microfluidic chips for automated RNA extraction from crude samples like saliva [14]. |

| High-Affinity Antibody Pairs | Capture and detection of target antigens in immunoassays [37]. | Used in integrated chips for serological detection (e.g., anti-SARS-CoV-2 antibodies) [14] [37]. |

Workflow and Technology Integration Diagrams

The following diagrams illustrate the logical workflow of an integrated LOC and the key characteristics of the featured NAAT techniques.

Integrated LOC Workflow for Viral RNA and Antibody Detection

NAAT Techniques and Their POC Applications

The COVID-19 pandemic highlighted critical bottlenecks in diagnostic testing, including the delay between sample collection and result delivery. While lab-based quantitative polymerase chain reaction (qPCR) tests offered high sensitivity and specificity, they required complex infrastructure, skilled personnel, and hours to process. Lab-on-a-chip (LOC) technology emerged as a promising solution, though challenges in scalable fabrication and system integration delayed widespread deployment [38].

The LoCKAmp (Lab-on-PCB for Genetic Amplification) device represents a significant advancement in this field. It is the first commercially manufactured, miniaturised lab-on-PCB device for loop-mediated isothermal amplification (LAMP) genetic detection of SARS-CoV-2 [38]. By leveraging the ubiquitous printed circuit board (PCB) manufacturing infrastructure, LoCKAmp achieves laboratory-quality genetic testing in under three minutes, offering a powerful tool for both clinical diagnostics and community-level wastewater surveillance [38] [39] [3].