Optimizing Biodegradation and Biocompatibility of Nanoparticles for Advanced Drug Delivery

This article provides a comprehensive analysis of strategies for optimizing the biodegradation and biocompatibility of nanoparticles, crucial factors for the success and safety of nanomedicines.

Optimizing Biodegradation and Biocompatibility of Nanoparticles for Advanced Drug Delivery

Abstract

This article provides a comprehensive analysis of strategies for optimizing the biodegradation and biocompatibility of nanoparticles, crucial factors for the success and safety of nanomedicines. Tailored for researchers, scientists, and drug development professionals, it synthesizes foundational principles, material selection, and design methodologies. It further explores advanced troubleshooting for common pitfalls, cutting-edge optimization techniques like AI-driven design, and rigorous validation frameworks. By integrating insights from foundational research with the latest technological advances, this review serves as a strategic guide for developing safer and more effective nanoparticle-based therapeutics, ultimately aiming to enhance clinical translation and patient outcomes.

The Core Principles: Understanding Biodegradation and Biocompatibility in Nanomaterials

Frequently Asked Questions (FAQs)

Q1: What is the Foreign Body Reaction (FBR) and why is it critical for biomaterial biocompatibility?

The Foreign Body Reaction (FBR) is a series of distinct immune and repair-like responses that occur following the implantation of a biomaterial. It is a key determinant of biocompatibility and can ultimately lead to the encapsulation of the biomaterial in a dense, largely avascular collagenous capsule, potentially causing device failure [1]. The FBR involves a series of overlapping stages [1]:

- Protein Adsorption: Immediately after implantation, proteins from blood and interstitial fluid adsorb onto the biomaterial's surface.

- Inflammatory Cell Recruitment: Inflammatory cells, first neutrophils and then macrophages, are recruited to the implantation site.

- Macrophage Fusion: Macrophages attempt to phagocytose the material and, failing that, fuse to form Foreign Body Giant Cells (FBGCs), a hallmark of the FBR [1].

- Fibrous Encapsulation: The final phase involves the deposition of extracellular matrix (ECM), primarily collagen, forming a capsule that walls off the implant from the surrounding tissue [1].

Q2: What are the primary cell types involved in the FBR?

The FBR is driven by a coordinated response from various immune cells [1]:

- Neutrophils: Among the first responders, they release cytokines after failing to phagocytose the biomaterial.

- Mast Cells: Contribute cytokines and other molecules in the early stage.

- Macrophages: The predominant drivers. They attempt phagocytosis, release enzymes and factors that contribute to persistent inflammation, and fuse to form FBGCs. Both pro-inflammatory (M1) and anti-inflammatory (M2) phenotypes play roles.

- Foreign Body Giant Cells (FBGCs): Formed by the fusion of macrophages on the biomaterial surface.

- Dendritic Cells (DCs): Bridge innate and adaptive immunity by contributing to antigen presentation and T cell priming.

- T Cells: Secrete specific cytokines; for example, TH17 cells secrete IL-17, which is implicated in the inflammatory response.

- B Cells: Recruited by factors like CXCL13 from macrophages and can enhance fibrosis.

- Natural Killer (NK) Cells: Activate macrophages via interferon-γ (IFN-γ) secretion.

Q3: How do the properties of a polymer biomaterial influence the FBR?

The physical and chemical properties of a polymer directly impact the severity and nature of the FBR [1]:

- Surface Properties & Topography: Influence the composition of adsorbed proteins, which in turn affects the types and activation states of interacting cells.

- Porosity: More porous scaffolds generally elicit less severe inflammation and a thinner fibrous encapsulation than solid biomaterials, likely due to a higher surface area-to-volume ratio [1].

- Wettability (Hydrophobicity/Hydrophilicity): Alters the affinity of proteins for the biomaterial, leading to distinct cellular responses.

- Architecture and Chemistry: Properties like morphology (amorphous, semicrystalline) and chemical composition can be engineered to dampen inflammatory responses.

Q4: What are the key differences between synthetic and natural polymers in eliciting an immune response?

While both can be used in biomaterials, they elicit different immune responses [1]:

- Natural Polymers (e.g., silk, collagen, hyaluronic acid, alginate, chitosan) generally have the advantage of eliciting little FBR, having low toxicity, and aiding in biological responses like cell signaling and adhesion [1] [2].

- Synthetic Polymers (e.g., PLA, PEG, PGA, PCL) are easily manufactured and processed but can trigger a more pronounced FBR. Studies have shown that synthetic polymers may engage adaptive immune cells (T and B cells), suggesting a cross-talk between innate and adaptive immunity that depends on the implant's nature [1].

Q5: What are the main pathways for the biodegradation of common polymers like PLA and PLGA?

Poly(lactic acid) (PLA) and Poly(lactic-co-glycolic acid) (PLGA) are FDA-approved biodegradable polymers. Their primary degradation pathway is hydrolytic degradation [3]. The process involves:

- Water Uptake: Water penetrates the polymer matrix.

- Hydrolysis of Ester Bonds: The polymer's ester bonds cleave, leading to chain scission and a reduction in molecular weight.

- Formation of Soluble Fragments: The polymer breaks down into soluble oligomers and monomers (lactic acid and glycolic acid).

- Metabolic Clearance: These acidic byproducts are metabolized via the Krebs cycle and ultimately excreted as carbon dioxide and water [3].

The degradation rate is influenced by the copolymer ratio (LA:GA), molecular weight, crystallinity, and the geometry of the device [3].

Q6: How can the biodegradation rate of a polymer be experimentally controlled or modified?

The degradation profile of a polymer can be tuned for specific applications by modifying several factors [3] [4]:

- Copolymer Composition: In PLGA, a higher glycolide content typically leads to faster degradation.

- Material Crystallinity: More crystalline regions degrade slower than amorphous regions.

- Additives and Fillers: Incorporating fillers like zinc oxide (ZnO) can directly influence the matrix degradation rate. Higher filler loadings of ZnO in PLA, for example, enhance the degradation rate and the release of ions, which governs antibacterial properties but may also augment the risk of cytotoxicity at high concentrations (e.g., 5 wt%) [4].

- Porosity and Surface Area: Materials with higher porosity and surface area degrade faster.

The table below summarizes how key parameters affect the biodegradation rate of polymers like PLA and PLGA.

| Parameter | Effect on Biodegradation Rate | Key Considerations |

|---|---|---|

| Copolymer Ratio (PLGA) | Higher glycolic acid (GA) content increases rate [3]. | Allows for precise tuning of device lifespan. |

| Crystallinity | Higher crystallinity decreases rate [3]. | Semicrystalline polymers like PCL degrade slower than amorphous PLA. |

| Molecular Weight | Higher molecular weight decreases rate [3]. | Affects initial mechanical strength and longevity. |

| Filler Addition (e.g., ZnO) | Higher filler loading can increase rate [4]. | Must be balanced with cytotoxicity risk; <2 wt% often optimal for biocompatibility [4]. |

| Material Porosity | Higher porosity and surface area increase rate [1]. | Can be engineered to promote integration and desired degradation profile. |

Troubleshooting Guides

Issue 1: Excessive or Uncontrolled Biodegradation Rate

Problem: Your nanoparticle or scaffold is degrading too quickly, leading to premature loss of mechanical integrity or a sudden, uncontrolled release of therapeutic agents.

| Possible Cause | Solution | Experimental Protocol to Test |

|---|---|---|

| Polymer is too hydrophilic or has high GA content. | Switch to a more hydrophobic polymer (e.g., PCL) or use a PLGA with a higher Lactic Acid (LA) to Glycolic Acid (GA) ratio [3]. | Conduct in vitro degradation studies in PBS (e.g., pH 7.4, 37°C). Monitor mass loss, molecular weight decrease (via GPC), and pH change of the medium over time. |

| Low molecular weight polymer. | Use a polymer with a higher initial molecular weight. | Characterize the molecular weight of your raw polymer material via Gel Permeation Chromatography (GPC) before fabrication. |

| High porosity or surface area. | Adjust fabrication parameters (e.g., electrospinning, porogen content) to reduce porosity. | Use microscopy (SEM) to characterize the morphology and surface area of your material. Compare degradation rates of low vs. high-porosity samples. |

| Acidic degradation products cause autocatalytic acceleration. | Incorporate basic salts or buffering agents into the polymer matrix to neutralize acidic byproducts [3]. | Monitor the pH of the immersion medium in a closed system. A sharp pH drop indicates autocatalysis. Test degradation with and without buffering additives. |

Issue 2: Severe Foreign Body Reaction and Excessive Fibrosis

Problem: Your implant is triggering a strong FBR, resulting in a thick, avascular fibrous capsule that isolates the device and can lead to failure.

| Possible Cause | Solution | Experimental Protocol to Test |

|---|---|---|

| Material surface is not optimized, promoting pro-inflammatory protein adsorption. | Modify surface chemistry (e.g., with PEGylation) or topography to create a more bio-inert or non-fouling surface [1] [2]. | Use in vitro protein adsorption assays (e.g., with fibrinogen) on modified vs. unmodified surfaces. Perform in vivo implantation and histologically assess capsule thickness and cellularity. |

| Macrophage polarization is skewed towards a pro-inflammatory (M1) state. | Functionalize the material with immunomodulatory agents (e.g., IL-4, IL-10) to promote a pro-healing (M2) macrophage phenotype [1] [2]. | Isolate and culture macrophages on the material. Use flow cytometry or qPCR to characterize M1 (e.g., iNOS, TNF-α) and M2 (e.g., CD206, Arg1) markers. |

| Lack of porosity or unsuitable pore size. | Fabricate a porous scaffold. Studies show porous biomaterials elicit a less severe FBR than solid ones [1]. | Fabricate scaffolds with controlled pore architectures. Implant them subcutaneously or in the target tissue and analyze the tissue in-growth and inflammatory response histologically. |

| Cytotoxicity from material or degradation products. | Ensure biocompatibility of base materials and leachables. For composites, reduce cytotoxic filler loading (e.g., for PLA-ZnO, keep ZnO <2 wt%) [4]. | Perform in vitro cytotoxicity assays (e.g., ISO 10993-5) using relevant cell lines (e.g., THP-1 macrophages, fibroblasts). Use live/dead staining and measure metabolic activity. |

Issue 3: Inconsistent or Poorly Reproducible Biodegradation Data

Problem: Results from biodegradation experiments show high variability between batches, making it difficult to draw reliable conclusions.

| Possible Cause | Solution | Experimental Protocol to Test |

|---|---|---|

| Inconsistent polymer properties between batches. | Source polymers from reputable suppliers and rigorously characterize each batch (molecular weight, polydispersity index, composition) before use [3]. | Use GPC and NMR to characterize the polymer's molecular weight, PDI, and LA:GA ratio for every new batch. |

| Variations in nanoparticle/scaffold fabrication. | Standardize and tightly control fabrication parameters (e.g., solvent evaporation rate, stir rate, temperature) [2] [3]. | Document all fabrication parameters meticulously. Use Dynamic Light Scattering (DLS) and SEM to ensure consistent size, distribution, and morphology of the final product across batches. |

| Uncontrolled environmental conditions during degradation study. | Use controlled incubators (temperature, humidity) and buffered solutions that are regularly replaced to maintain pH and ion concentration. | Follow standardized guidelines like OECD TG 309 where applicable. Use a sufficient sample size (n) and include appropriate controls in every experiment. |

The Scientist's Toolkit: Key Research Reagent Solutions

The table below lists essential materials and their functions for studying biodegradation and biocompatibility.

| Reagent/Material | Function in Research |

|---|---|

| PLA & PLGA | The benchmark biodegradable synthetic polymers for fabricating nanoparticles, microparticles, and scaffolds. Used to establish baseline degradation and FBR responses [3]. |

| Polyethylene Glycol (PEG) | Used for PEGylation to create a hydrophilic "stealth" coating on particles, reducing protein adsorption and immune recognition, thereby prolonging circulation time [2]. |

| Zinc Oxide (ZnO) Nanoparticles | A common functional filler used to impart antibacterial properties to polymers like PLA. Serves as a model to study how fillers influence degradation and cytotoxicity [4]. |

| Chitosan | A natural biodegradable polymer known for its mucoadhesive and permeation-enhancing properties. Used in wound healing, dentistry, and for studying interactions with biological tissues [2]. |

| Fibrinogen & Vitronectin | Key blood proteins that readily adsorb to biomaterials. Used in in vitro studies to understand the initial stage of the FBR and how surface properties influence protein adsorption [1]. |

| IL-4 Cytokine | A critical signaling molecule used in vitro and in vivo to induce macrophage fusion into Foreign Body Giant Cells (FBGCs) and to polarize macrophages towards an M2 phenotype [1]. |

Experimental Pathways and Workflows

Foreign Body Reaction (FBR) Cascade

The following diagram illustrates the key cellular and molecular stages of the Foreign Body Reaction to an implanted biomaterial.

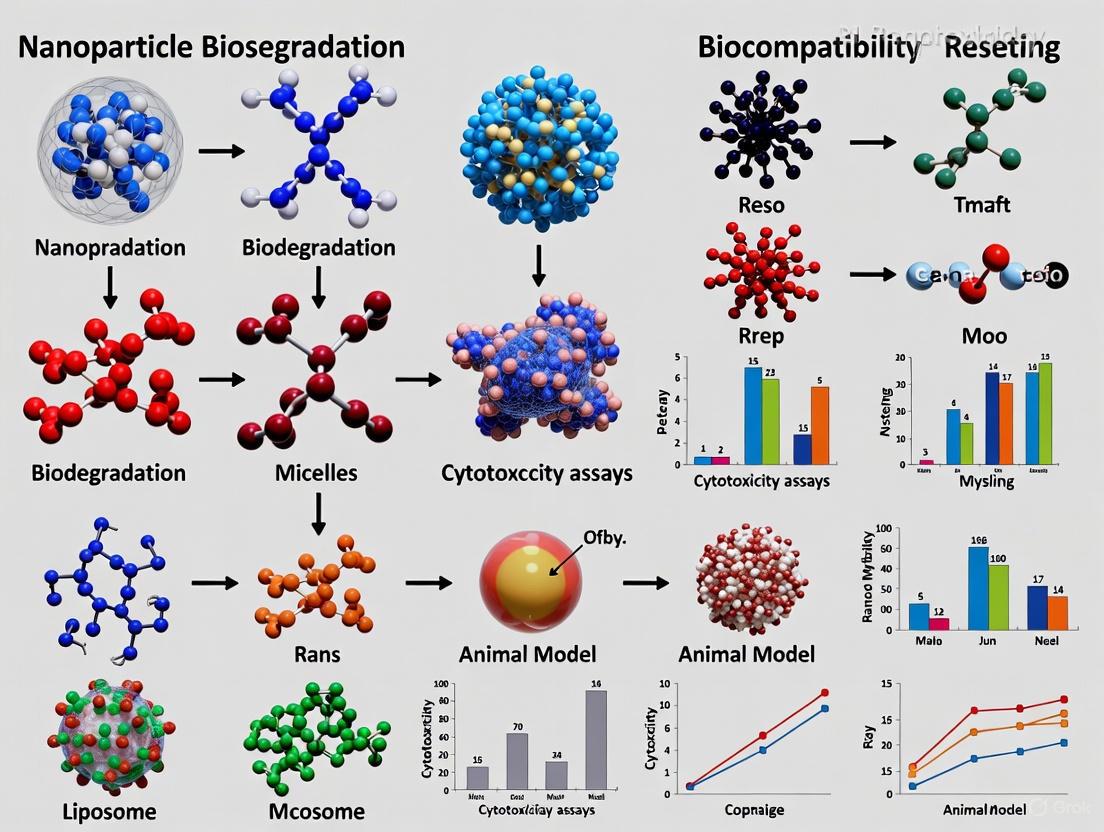

Nanoparticle Biodegradation and Immune Interaction

This workflow outlines the key stages in studying the biodegradation of a polymeric nanoparticle and its subsequent interaction with the immune system.

Frequently Asked Questions (FAQs)

Q1: How do the degradation rates of PLA and PLGA compare, and how can I select the right polymer for my desired drug release profile?

The degradation rate is a key differentiator. PLGA typically degrades faster than PLA, and its degradation kinetics can be finely tuned by adjusting the lactic acid (LA) to glycolic acid (GA) ratio. A 50:50 LA:GA ratio offers the fastest degradation [5]. PLA degrades more slowly, and its rate is significantly influenced by its crystallinity, which is controlled by the D- and L-isomer ratio. Polycaprolactone (PCL), another common biodegradable polyester, has the slowest degradation rate due to its high crystallinity and hydrophobicity, making it suitable for long-term release over several months [5].

- For fast release (days to weeks): Use PLGA with a high glycolide content (e.g., 50:50 LA:GA).

- For medium-term release (weeks to months): Use PLA or PLGA with a high lactide content (e.g., 75:25 LA:GA).

- For long-term release (several months to a year): Use PCL or high molecular weight, crystalline L-PLA [5].

Q2: What are the primary biodegradation pathways for PLA and PLGA in a biological environment?

Both PLA and PLGA primarily degrade through non-enzymatic hydrolysis of their ester bonds in the polymer backbone [5] [6]. The process is autocatalytic, as the newly formed carboxylic acid end groups accelerate the further breakdown of the polymer chains [6]. This hydrolysis occurs throughout the polymer bulk and on its surface. The oligomers and monomers (lactic acid and/or glycolic acid) produced are metabolized via the Krebs cycle into carbon dioxide and water, which are safely excreted [7] [6]. While enzymatic degradation can occur, particularly during infection or inflammation, it is not the primary mechanism in most physiological settings [6].

Q3: What innate immune responses are triggered by PLGA-based nanoparticles, and how can they be modulated for vaccine development?

PLGA nanoparticles are generally considered biocompatible, but their interaction with the immune system can be harnessed. They can be internalized by antigen-presenting cells (APCs), such as dendritic cells and macrophages [8]. When vaccine components (e.g., hapten-carrier conjugates) are displayed on the surface of PLGA nanoparticles or co-delivered with adjuvants, they can enhance the innate immune response. This includes the activation of APCs via pattern recognition receptors like Toll-like Receptors (TLRs), leading to cytokine release and subsequent initiation of a robust, targeted adaptive immune response [8]. The surface properties, size, and co-delivery of immunomodulators (e.g., TLR agonists like MPLA or R848) are key design parameters for tuning this immunostimulatory effect [8].

Q4: Our team has observed inconsistent nanoparticle biodistribution results. What are the key biological barriers for lipid-based nanocarriers (LBNs) after intravenous injection?

Intravenous administration presents several major barriers that can cause inconsistent results [9]:

- Immune Clearance: The mononuclear phagocyte system (MPS) rapidly opsonizes and clears nanoparticles from the bloodstream.

- Non-specific Distribution: Without targeting, nanoparticles can distribute throughout the body, leading to off-target effects and reduced accumulation at the target site.

- Tissue Penetration: In tumor environments, a dense extracellular matrix (ECM) and high interstitial pressure can hinder nanoparticle penetration.

- Intracellular Barriers: For drugs that require cytosolic delivery, inefficient endosomal escape after cellular uptake is a critical bottleneck [9].

Q5: Are there any known adverse immune reactions to PLA in clinical applications?

PLA has an extensive history of safe clinical use, and severe adverse reactions are rare. Most reactions are local and related to the normal foreign body response or the degradation process. There have been isolated case reports of late-onset inflammatory reactions or granuloma formation, sometimes occurring years after implantation of PLA-based orthopedic devices [10]. These are often associated with the accumulation of degradation products and are influenced by factors like implant size, location, and patient-specific immune responses [10]. Overall, PLA is considered to have favorable biocompatibility.

Troubleshooting Common Experimental Issues

Problem: Uncontrolled Burst Release from PLGA Nanoparticles

- Potential Cause: The drug is adsorbed on or near the nanoparticle surface rather than encapsulated within the polymer matrix.

- Solutions:

Problem: Rapid Clearance of Liposomes from Blood Circulation

- Potential Cause: Opsonization and recognition by the Mononuclear Phagocyte System (MPS).

- Solutions:

Problem: Inconsistent Degradation Rates of PLA Scaffards Between In Vitro and In Vivo Studies

- Potential Cause: The in vitro degradation model does not fully recapitulate the complex in vivo environment, including enzymatic activity, cellular interactions, and dynamic pH changes.

- Solutions:

- Use relevant biological media that contains enzymes like proteinase K, which is known to degrade PLA [6].

- Incorporate immune cells (e.g., macrophages) into your in vitro model to better simulate the inflammatory component of degradation [6].

- Ensure the pH and temperature of your in vitro system are carefully controlled and reflective of physiological conditions [6].

Comparative Material Properties and Data

The following tables summarize key quantitative data for the discussed materials.

| Polymer | Typical Degradation Time | Glass Transition Temp (Tg) | Melting Point (Tm) | Crystallinity | Key Degradation Mechanism |

|---|---|---|---|---|---|

| PCL | Several months to years | ≈ -60 °C | 58–61 °C | High (20-33%) | Slow bulk hydrolysis due to high hydrophobicity |

| PLA | Several months | ≈ 60 °C | 150–160 °C | Varies with isomer ratio | Hydrolysis; rate depends on crystallinity & MW |

| PLGA (50:50) | Several weeks to months | 40–60 °C | Not well-defined | Amorphous | Fastest hydrolysis; rate tunable via LA:GA ratio |

| Administration Route | Primary Physiological Barriers | Recommended Design Strategy for LBNs |

|---|---|---|

| Oral | Low gastric pH, enzymatic degradation, poor mucosal permeability, first-pass metabolism | Mucoadhesive coatings, pH-responsive lipid compositions, nanoemulsions |

| Intravenous | MPS clearance, renal clearance, non-specific distribution, tumor penetration | PEGylation ("stealth"), active targeting ligands, biomimetic coatings |

| Inhalation | Mucociliary clearance, macrophage uptake, enzymatic degradation in lungs | Optimizing particle size for alveolar deposition, sustained-release formulations |

Essential Experimental Protocols

Protocol: Formulation of PLGA Nanoparticles via Single Emulsion-Solvent Evaporation

This is a standard method for encapsulating hydrophobic drugs [7] [11].

- Dissolution: Dissolve 100 mg of PLGA polymer and your hydrophobic drug (e.g., 5-10 mg) in 5 mL of a volatile organic solvent (e.g., dichloromethane or ethyl acetate).

- Emulsification: Pour the organic solution into 20 mL of an aqueous phase containing a stabilizer (e.g., 1-2% w/v polyvinyl alcohol, PVA). Immediately emulsify using a high-speed homogenizer (e.g., 10,000 rpm for 2 minutes) to form a stable oil-in-water (o/w) emulsion.

- Solvent Evaporation: Stir the emulsion continuously at room temperature for several hours (or under reduced pressure) to allow the organic solvent to evaporate, solidifying the nanoparticles.

- Purification: Centrifuge the nanoparticle suspension at high speed (e.g., 20,000 rpm for 30 minutes) to pellet the nanoparticles. Wash the pellet with purified water to remove excess stabilizer and unencapsulated drug. Repeat centrifugation.

- Lyophilization: Resuspend the purified nanoparticles in a cryoprotectant solution (e.g., sucrose or trehalose) and freeze-dry for long-term storage.

Protocol: Assessing PLA/PLGA Degradation Kinetics In Vitro

- Sample Preparation: Pre-weigh sterile polymer films, scaffolds, or a known quantity of nanoparticles.

- Incubation: Immerse samples in phosphate-buffered saline (PBS) at pH 7.4 and maintain at 37°C under gentle agitation. Ensure a consistent volume:surface area ratio.

- Sampling: At predetermined time points (e.g., weekly), remove samples from the incubation medium in triplicate.

- Analysis:

- Mass Loss: Rinse the retrieved samples, dry them to a constant weight, and calculate the percentage of mass loss.

- Molecular Weight Change: Use Gel Permeation Chromatography (GPC) to track the decrease in average molecular weight over time.

- pH Monitoring: Measure the pH of the incubation medium, as a drop indicates the accumulation of acidic degradation products (lactic and glycolic acid) [5] [6].

Signaling Pathways and Experimental Workflows

PLGA Nanoparticle Immunostimulation Pathway for Vaccine Applications [8]

Nanoparticle Development and Testing Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Nanoparticle Biocompatibility Research

| Reagent / Material | Function / Application | Key Consideration |

|---|---|---|

| PLGA (50:50, 75:25) | Model biodegradable polymer for tunable drug release. | The LA:GA ratio directly controls degradation rate and drug release kinetics [5] [7]. |

| L-PLA & D,L-PLA | Models for studying crystallinity-dependent degradation. | L-PLA is semi-crystalline and slow-degrading; D,L-PLA is amorphous and faster-degrading [6]. |

| Polyvinyl Alcohol (PVA) | Stabilizer and surfactant in emulsion-based nanoparticle synthesis. | Critical for controlling nanoparticle size and polydispersity; residual PVA can affect surface properties [7]. |

| DSPE-PEG | Lipid-PEG conjugate for creating "stealth" liposomes/LNPs. | Shields nanoparticles from MPS, dramatically extending circulation half-life [9] [8]. |

| TLR Agonists (e.g., MPLA, R848) | Immunomodulators for vaccine adjuvantation. | When co-delivered with antigens in NPs, they potently enhance innate and adaptive immune responses [8]. |

| Proteinase K | Enzyme for modeling accelerated enzymatic degradation of PLA in vitro. | Used to simulate certain aspects of the inflammatory component of biodegradation [6]. |

Troubleshooting Guides

FAQ: How does nanoparticle size influence biological interactions and how can I control it?

Problem: Inconsistent cellular uptake, rapid clearance from the bloodstream, or unexpected toxicity in biological experiments.

Background: Nanoparticle size is a primary determinant of biological fate, governing circulation time, cellular internalization routes, and biodistribution patterns [12]. Materials at the nanoscale (typically 1-100 nm) exhibit fundamentally different properties from their bulk counterparts due to increased surface area-to-volume ratio and quantum effects [13].

Solution: Implement rigorous size control and characterization protocols.

- Target Specific Size Ranges: Aim for 10-100 nm for prolonged circulation, as particles smaller than 10 nm are rapidly cleared by renal filtration, while those larger than 100-200 nm are more quickly sequestered by the spleen and liver [14] [13].

- Employ Multiple Characterization Techniques: Use Dynamic Light Scattering (DLS) for hydrodynamic diameter, Electron Microscopy (SEM/TEM) for precise visual confirmation of core size and shape, and Gel Permeation Chromatography for size distribution [13].

- Optimize Synthesis Parameters: For polymeric nanoparticles like PLGA, control size by adjusting surfactant concentration (e.g., PVA), organic solvent evaporation rate, and homogenization/sonication energy during emulsification-solvent evaporation methods [15].

Preventive Measures:

- Monitor and control stirring rates and temperatures during synthesis.

- Use stabilizers like surfactants (e.g., Tween 80) or polymers (e.g., PEG) to prevent aggregation and maintain size distribution [16] [15].

- Characterize size in biologically relevant media (e.g., PBS, cell culture medium) as hydrodynamic size can differ from dry measurements.

FAQ: Why is surface charge (zeta potential) critical for nanoparticle stability and biointeractions?

Problem: Nanoparticle aggregation in storage or biological media, unpredictable cellular binding, or increased immunogenicity.

Background: The zeta potential indicates the surface charge of nanoparticles in suspension, determining their colloidal stability and interactions with biological components [13]. Cationic surfaces often promote cellular uptake but may increase cytotoxicity, while anionic or neutral surfaces typically exhibit longer circulation times [2].

Solution: Measure and engineer zeta potential for desired performance.

- Ensure Colloidal Stability: A zeta potential greater than ±30 mV (positive or negative) typically indicates good electrostatic stability, preventing aggregation via charge repulsion [13]. For example, a study on iron oxide nanoparticles modified with Tween 80 achieved a zeta potential of -11.4 ± 2.4 mV with significantly improved antibacterial activity and biocompatibility [16].

- Modulate Biological Interactions:

- For enhanced cellular uptake, especially in gene delivery, moderately cationic surfaces (e.g., +10 to +30 mV) are often used but require careful toxicity assessment [17] [2].

- For prolonged systemic circulation, near-neutral surfaces (e.g., via PEGylation) help evade immune recognition and reduce opsonization [14].

- Surface Modification Techniques:

- PEGylation: Covalent attachment of polyethylene glycol (PEG) creates a hydrophilic stealth layer, reducing protein adsorption and macrophage uptake [14] [2].

- Coating with Biopolymers: Use natural polymers like chitosan, which provides a positive charge and mucoadhesive properties [17].

- Ligand Conjugation: Attach targeting moieties (e.g., antibodies, peptides) for specific cell recognition, but be aware this can alter surface charge and opsonization [14].

FAQ: How can I improve the biodegradation profile and reduce the cytotoxicity of my nanoparticles?

Problem: Persistent nanoparticle accumulation, inflammatory responses, or cytotoxic effects in cell culture and animal models.

Background: Biodegradation is essential for in vivo clearance and reducing long-term toxicity. The degradation rate and byproducts determine biocompatibility and inflammatory potential [2]. For instance, while chitosan is generally biodegradable and biocompatible, some synthetic polymers or metal nanoparticles can pose persistence or ion release toxicity challenges [4] [2].

Solution: Select appropriate materials and implement surface engineering strategies.

- Choose Inherently Biodegradable Materials:

- Polymers: Use FDA-approved polymers like PLGA (Polylactic-co-glycolic acid), which hydrolyzes into metabolizable lactic and glycolic acids [15]. Natural polymers like chitosan are also biodegradable [17].

- Metal Oxides: Carefully consider dissolution rates. For example, in PLA-ZnO nanocomposites, the degradation of the polymer matrix controls the release of Zn²⁺ ions, which can cause cytotoxicity at high concentrations [4].

- Control Degradation Kinetics: Adjust polymer composition (e.g., PLA:PGA ratio in PLGA), crystallinity, and molecular weight to tune degradation rates to match therapeutic needs [15].

- Mitigate Cytotoxicity:

- For metal nanoparticles, avoid high filler loadings. Studies on PLA-ZnO showed nanocomposites with <2 wt% filler were non-cytotoxic, while 5 wt% loading showed cytotoxic effects [4].

- Use surface coatings to create a barrier that modulates ion release and reduces direct contact with cells. Tween 80 coating on green-synthesized iron oxide nanoparticles significantly enhanced their biocompatibility in skin and eye irritation tests [16].

- Avoid highly cationic surfaces unless necessary, as they can disrupt cell membranes.

Key Experimental Data Reference

Table 1: Physicochemical Properties and Corresponding Biological Outcomes of Selected Nanoparticles

| Nanoparticle Type | Size (nm) | Zeta Potential (mV) | Key Biological Finding | Reference |

|---|---|---|---|---|

| PLGA (Cur-Que-Pip) | 210.6 ± 0.22 | -8.57 ± 1.16 | Excellent biocompatibility with RAW264.7, BMSC, and MC3T3 cells; sustained drug release over 96h [15]. | |

| Iron Oxide (IONPs-GTw80) | 9.7 ± 2.1 | -11.4 ± 2.4 | >10-fold reduction in MIC against S. aureus and E. coli; confirmed biocompatibility with skin/eyes [16]. | |

| PLA-ZnO Nanocomposite | N/A | N/A | Filler loadings <2 wt%: excellent antibacterial properties and biocompatibility; 5 wt% loading: cytotoxic [4]. | |

| Chitosan NPs | Variable (based on synthesis) | Typically positive | Biocompatibility, mucoadhesion, and enhanced permeation; properties depend on molecular weight and deacetylation [17]. |

Table 2: Standardized Characterization Techniques for Key Physicochemical Properties

| Property to Characterize | Recommended Technique(s) | Key Information Provided | Experimental Consideration |

|---|---|---|---|

| Hydrodynamic Size & PDI | Dynamic Light Scattering (DLS) | Average particle size distribution and dispersion homogeneity in liquid medium. | Measure in relevant biological buffer; high PDI (>0.2) indicates polydisperse sample [16] [13]. |

| Core Size & Morphology | Transmission Electron Microscopy (TEM), Scanning Electron Microscopy (SEM) | Precise visualization of individual nanoparticle core size, shape, and structure. | Requires sample drying; may not reflect true state in solution [15] [13]. |

| Surface Charge | Zeta Potential Measurement | Electrokinetic potential at the slipping plane, predicting colloidal stability. | Measure at physiologically relevant pH and ionic strength [16] [13]. |

| Crystallinity & Composition | X-ray Diffraction (XRD), Fourier-Transform Infrared Spectroscopy (FTIR) | Crystalline structure and chemical functional groups present. | Confirms successful synthesis and identifies coating materials [16]. |

Experimental Workflows & Relationships

Diagram 1: NP Property-Biological Fate Relationship

Diagram 2: Development Workflow for Biocompatible NPs

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Nanoparticle Synthesis and Optimization

| Reagent / Material | Function / Application | Key Consideration | ||

|---|---|---|---|---|

| PLGA (50:50) | Biodegradable polymer for controlled drug delivery; hydrolyzes into metabolizable acids [15]. | Vary molecular weight and lactide:glycolide ratio to tune degradation rate and drug release profile. | ||

| Chitosan | Natural polysaccharide with inherent mucoadhesive properties and positive charge for enhanced permeation [17]. | Biocompatibility and properties depend on molecular weight and degree of deacetylation. | ||

| Polyvinyl Alcohol (PVA) | Surfactant/stabilizer used in emulsification-solvent evaporation synthesis of polymeric NPs (e.g., PLGA) [15]. | Concentration and molecular weight significantly impact nanoparticle size and polydispersity index (PDI). | ||

| Tween 80 | Non-ionic surfactant for post-synthesis stabilization; prevents aggregation and can enhance biocompatibility [16]. | An eco-friendly, biocompatible stabilizer proven to reduce particle size and cytotoxicity of metal oxide NPs. | ||

| PEG (Polyethylene Glycol) | Polymer for "stealth" coating (PEGylation); reduces opsonization and extends circulation half-life [14] [2]. | Beware of potential for anti-PEG antibodies upon repeated administration, which can trigger immune reactions. | ||

| DLS/Zeta Potential Analyzer | Instrument for critical quality attributes: hydrodynamic size, PDI, and surface charge [13]. | Essential for confirming colloidal stability (Zeta Potential > | 30 | mV) and batch-to-batch consistency. |

Troubleshooting Guides

FAQ: Nanoparticle Immune Recognition and Clearance

Why are my nanoparticles being cleared from circulation too quickly? Rapid clearance, primarily by the mononuclear phagocyte system (MPS) in the liver and spleen, is often due to unintended immune recognition [14] [18]. The "protein corona" that forms on nanoparticles in biological fluids dictates this immune interaction [18]. To troubleshoot:

- Check Surface Charge: Highly positive surfaces often cause non-specific binding and opsonization. Aim for a neutral or slightly negative ζ-potential [19] [20].

- Evaluate Stealth Coating: Ensure PEGylation density and chain length are sufficient to create an effective steric barrier. Be aware that repeated dosing can trigger anti-PEG antibodies, accelerating clearance [14] [21].

- Analyze the Protein Corona: Use techniques like SDS-PAGE or LC-MS to identify the proteins adsorbed onto your nanoparticles from plasma. A corona rich in opsonins (e.g., immunoglobulins, complement proteins) confirms immune recognition [18].

My targeted nanoparticles are not reaching their intended cells. What could be wrong? This often results from the targeting ligand being masked or its orientation being suboptimal [18].

- Ligand Accessibility: The protein corona can bury the targeting ligands, rendering them ineffective. Use a denser PEG brush or incorporate cleavable linkers that expose the ligand only in the target environment [18].

- Ligand Presentation: The spacing, orientation, and valency of the ligand are critical for efficient receptor binding. Ensure your conjugation chemistry preserves ligand activity and allows for multivalent interactions [18].

How can I prevent nanoparticle-induced inflammatory responses? Nanoparticles can unintentionally activate innate immune pathways [19] [21].

- Test for Endotoxin: Contamination with endotoxin (LPS) is a common cause of robust immune activation. Use an LAL assay to ensure your formulations are endotoxin-free.

- Screen for Inflammasome Activation: Cationic and rigid particles can activate the NLRP3 inflammasome, leading to IL-1β secretion and pyroptosis. If inflammation is observed, try formulating with more flexible, anionic materials [19] [21].

FAQ: Optimizing Biodegradation and Biocompatibility

How can I balance nanoparticle stability with biodegradability? The goal is for the nanoparticle to remain intact until it reaches its target, then safely degrade.

- Polymer Selection: For polymeric nanoparticles, use proven biodegradable polymers like PLGA, which degrades into lactic and glycolic acid. The degradation rate can be tuned by the lactic-to-glycolic acid ratio [14] [22].

- Cross-Linking Density: If using cross-linked systems, reduce the cross-linker density to facilitate easier breakdown by cellular enzymes.

- Incorporate Stimuli-Responsive Linkers: Use linkers that break under specific conditions in the target microenvironment, such as low pH (endosomes/lysosomes) or high levels of specific enzymes like matrix metalloproteinases [23].

My nanoparticle formulation shows promising in vitro results but fails in vivo. What should I investigate? This classic "translational gap" is often due to biological barriers not present in simple cell cultures [14].

- Heterogeneity of the EPR Effect: Do not rely solely on the Enhanced Permeability and Retention effect for tumor targeting. It is highly variable in human patients. Consider active targeting strategies or methods to normalize the tumor microenvironment for better delivery [14] [24].

- Assess Biodistribution: Track your nanoparticles in vivo using imaging (e.g., fluorescence, radiolabeling). You may find that the majority accumulate in the liver and spleen instead of the target tissue [22].

- Scale-Up Reproducibility: Ensure your synthesis method (e.g., microfluidics) is robust and produces consistent batches with low polydispersity when scaled up. Batch-to-batch variability is a major cause of failed translation [14] [23].

Data Presentation

Table 1: Impact of Nanoparticle Physicochemical Properties on Immune Interactions

This table summarizes key design parameters and their immunomodulatory effects to guide your experimental planning.

| Physicochemical Property | Immune Interaction & Clearance Mechanism | Suggested Optimization Strategy |

|---|---|---|

| Size [19] | < 5-10 nm: Rapid renal clearance.100-200 nm: Optimal for lymphatic drainage and uptake by APCs.> 200 nm: Preferentially cleared by spleen and liver phagocytes. | Aim for a size range of 20-150 nm for systemic circulation, adjusting based on the target tissue. |

| Surface Charge (ζ-Potential) [19] [20] | Cationic surfaces: Promote opsonization, non-specific cell uptake, and can activate inflammasomes.Neutral/Anionic surfaces: Generally exhibit longer circulation times. | Modify surfaces with PEG or zwitterionic lipids to achieve a near-neutral ζ-potential. |

| Surface Hydrophobicity [20] [18] | Hydrophobic surfaces strongly adsorb plasma proteins (opsonins), leading to MPS recognition and clearance. | Use hydrophilic polymers (PEG, Poly(oxazoline)) to create a stealth shield. |

| Shape [19] | Spherical vs. rod-shaped particles can influence the rate and mechanism of cellular uptake by phagocytes. | Spherical shapes are typically easier to fabricate and characterize for initial studies. |

| Surface Functionalization [14] [18] [21] | PEGylation reduces opsonization but can induce anti-PEG antibodies.Targeting ligands (e.g., peptides, antibodies) can enhance uptake but may also be masked by the protein corona. | Explore alternatives to PEG, such as PEG-like polymers or "self" peptides. Ensure ligands are presented with correct orientation and density. |

Table 2: Key Innate Immune Pathways Activated by Nanoparticles

This table outlines common immune pathways triggered by nanoparticles, which can be either a target for immunotherapy or an unwanted side effect.

| Immune Pathway | Key Sensor/Receptor | Downstream Effect | Nanomaterial Triggers |

|---|---|---|---|

| Complement Activation [19] [21] | C3 convertase, C5a | Opsonization, recruitment of immune cells, CARPA (pseudoallergy). | Cationic surfaces, PEG (in some cases), surface hydroxyl groups. |

| TLR Signaling [19] [21] | Toll-like Receptors (TLRs) | Production of pro-inflammatory cytokines (TNF-α, IL-6, IL-12). | Contamination with bacterial components (e.g., endotoxin), certain RNA payloads. |

| Inflammasome Activation [19] [21] | NLRP3 | Caspase-1 activation, cleavage and secretion of IL-1β and IL-18, pyroptosis. | Cationic lipids, crystalline/rigid structures, lysosomal disruption. |

| Type I Interferon Response [21] | RIG-I, MDA5, STING | Induction of interferon-stimulated genes (ISGs), antiviral state, can inhibit therapeutic mRNA translation. | Delivered nucleic acid payloads (mRNA, siRNA). |

Experimental Protocols

Protocol 1: Analyzing the Protein Corona

Objective: To isolate and identify the proteins that adsorb onto nanoparticles upon exposure to biological fluids, providing insight into their likely immune interactions and biodistribution [18].

Materials:

- Purified nanoparticle sample

- Fetal Bovine Serum (FBS) or human plasma

- Phosphate Buffered Saline (PBS)

- Ultracentrifuge or size-exclusion chromatography columns (e.g., Sepharose CL-4B)

- SDS-PAGE gel electrophoresis system

- Mass spectrometry (LC-MS/MS) facilities

Method:

- Incubation: Incubate your nanoparticles (at a concentration of 0.1-1 mg/mL) with 50-100% FBS or plasma in PBS for 1 hour at 37°C under gentle agitation.

- Isolation of Hard Corona: Separate the nanoparticle-protein complexes from unbound proteins.

- Ultracentrifugation: Centrifuge at high speed (e.g., 100,000 x g for 1 hour) to pellet the complexes. Carefully remove the supernatant.

- Size-Exclusion Chromatography: Pass the mixture through a column to separate the larger nanoparticle-corona complexes from free proteins.

- Washing: Gently wash the pellet (resuspend in PBS and re-centrifuge) or the collected fractions to remove loosely associated proteins ("soft corona").

- Elution and Analysis:

- SDS-PAGE: Dissociate the proteins from the nanoparticle surface using Laemmli buffer, boil, and run on an SDS-PAGE gel. Stain with Coomassie Blue or silver stain to visualize the protein profile.

- Mass Spectrometry: For identification, digest the proteins in-gel or in-solution with trypsin and analyze the peptides via LC-MS/MS.

Protocol 2: Evaluating In Vivo Biodistribution and Clearance

Objective: To quantitatively track the distribution and persistence of nanoparticles in an animal model over time.

Materials:

- Near-infrared (NIR) dye (e.g., DiR, Cy7) or radiolabel (e.g., ⁹⁹ᵐTc, ⁶⁴Cu)-labeled nanoparticles

- Animal model (e.g., mouse)

- In vivo imaging system (IVIS) or single-photon emission computed tomography (SPECT) scanner

- Analysis software

Method:

- Labeling: Incorporate a NIR dye or radiolabel into your nanoparticles during synthesis or via post-formulation conjugation. Purify to remove free label.

- Administration: Intravenously inject a known dose of labeled nanoparticles into the animal via the tail vein.

- Imaging: At predetermined time points (e.g., 5 min, 1 h, 4 h, 24 h, 48 h), anesthetize the animal and acquire whole-body images using IVIS or SPECT/CT.

- Ex Vivo Quantification: At the terminal time point, euthanize the animal, collect major organs (liver, spleen, kidneys, heart, lungs, tumor), and image them ex vivo for higher resolution quantification of signal intensity.

- Data Analysis: Use region-of-interest (ROI) analysis to calculate the percentage of injected dose per gram of tissue (%ID/g) for each organ. This provides a quantitative measure of biodistribution and clearance kinetics.

Mandatory Visualization

Nanoparticle Immune Recognition Pathway

Strategies to Overcome Immune Clearance

The Scientist's Toolkit: Research Reagent Solutions

This table details key materials used in advanced nanoparticle formulation to control immune interactions and biodegradability.

| Research Reagent | Function in Formulation | Key Considerations |

|---|---|---|

| PEGylated Lipids (e.g., DMG-PEG2000) [14] [21] [22] | Creates a hydrophilic steric barrier on the nanoparticle surface to reduce protein adsorption and MPS clearance. | Anti-PEG immunity can develop. Consider branching or alternatives like poly(oxazoline)s for next-gen stealth. |

| Ionizable Cationic Lipids (e.g., DLin-MC3-DMA) [14] [21] [22] | Enables encapsulation of nucleic acids (mRNA, siRNA) and facilitates endosomal escape via a charge-driven "proton sponge" effect. | The pKa should be tunable (~6.4) for neutrality in blood but positive charge in endosomes. |

| Biodegradable Polymers (e.g., PLGA) [14] [22] | Forms the nanoparticle matrix, degrading into metabolites (lactic/glycolic acid) over time, ensuring biocompatibility and clearance. | The lactide:glycolide ratio and molecular weight determine the degradation rate and drug release profile. |

| Targeting Ligands (e.g., Peptides, Antibodies, Transferrin) [18] [22] | Directs nanoparticles to specific cell surface receptors (e.g., overexpressed on cancer cells) for active targeting. | Ligand density and orientation are critical. The protein corona can mask ligands, reducing efficacy. |

| Stimuli-Responsive Linkers (e.g., pH-sensitive, enzyme-cleavable) [23] | Provides controlled release of the payload or exposure of targeting motifs in response to specific disease microenvironment triggers. | Enhances specificity and reduces off-target effects. Common triggers include low pH, MMPs, and glutathione. |

Design and Synthesis: Strategies for Engineering Optimal Nanoparticles

This guide provides technical support for researchers and drug development professionals working with nanobiomaterials. The content is framed within the broader context of optimizing nanoparticle biodegradation and biocompatibility research, offering practical solutions to common experimental challenges through FAQs and troubleshooting guides.

Material Comparison and Selection FAQs

What are the key differences between polymer, lipid, and inorganic nanoparticles?

Answer: The three material classes differ significantly in composition, properties, and ideal applications. The table below provides a comparative overview:

Table 1: Core Characteristics of Nanocarrier Materials

| Property | Polymeric Nanoparticles | Lipid-Based Nanoparticles | Inorganic Nanoparticles |

|---|---|---|---|

| Composition | Natural (e.g., chitosan, PLA) or synthetic (e.g., PLGA, PACA) polymers [25] [26] | Phospholipids, cholesterol, ionizable lipids (for LNPs) [27] [28] | Metals (e.g., Au, Ag), metal oxides (e.g., Fe₃O₄), quantum dots, silica [29] [30] |

| Biodegradability | Typically high (depends on polymer; e.g., PLGA degrades to lactic/glycolic acid) [26] | High; lipids are generally biocompatible and metabolizable [27] | Often low or non-biodegradable; potential for long-term accumulation [29] |

| Drug Loading | High capacity for hydrophobic drugs; controlled release kinetics [25] [14] | Good for hydrophilic (liposomes) and hydrophobic (LNPs) cargo [27] [28] | Variable; high surface area for conjugation or encapsulation in mesoporous structures [29] [30] |

| Key Advantages | Excellent control over drug release profile, design flexibility [14] | High biocompatibility, clinical success with mRNA vaccines, ease of production [27] [14] | Unique optical, magnetic, electronic properties for imaging & therapy (theranostics) [29] [30] |

| Primary Limitations | Risk of toxic degradation monomers, batch-to-batch variability [14] | Limited drug loading for some types, stability issues during storage [28] | Concerns over biocompatibility, potential toxicity, and slow clearance [29] [31] |

How does material selection impactin vivobiodistribution and clearance?

Answer: Material composition is a primary determinant of biodistribution. A comparative study of polymeric (poly(alkyl cyanoacrylate)) and lipid-based (Nanostructured Lipid Carriers, NLCs) nanoparticles revealed significant differences. The polymeric nanoparticles showed a more than 50-fold higher concentration ratio in organs versus blood for its cargo (cabazitaxel) compared to the dye-loaded NLCs. Furthermore, the polymeric formulation demonstrated notable accumulation in lung tissue and the brain, suggesting potential for targeting these sites [25]. Clearance is heavily influenced by surface properties; PEGylation can prolong circulation by reducing uptake by the Mononuclear Phagocyte System (MPS), but may also induce anti-PEG antibodies that accelerate clearance upon repeated administration [27] [14].

Which material is best for ensuring biocompatibility and minimizing toxicity?

Answer: There is no single "best" material; the choice depends on the application and required material properties.

- For maximum biocompatibility and metabolic clearance, lipid-based systems are often preferred due to their resemblance to biological membranes and the body's innate pathways for processing lipids [27] [28].

- For predictable, controlled biodegradation, well-established synthetic polymers like PLGA are excellent, as they hydrolyze into biologically compatible metabolites (lactic and glycolic acid) [26] [14].

- For advanced imaging or hyperthermia therapy, inorganic nanoparticles (e.g., iron oxide for MRI, gold for photothermal therapy) are indispensable, despite greater biocompatibility challenges. Their surfaces must be carefully functionalized with biocompatible coatings (e.g., polymers, silica) to improve safety [29] [30].

Troubleshooting Common Experimental Issues

Problem: My nanoparticles are exhibiting rapid clearancein vivo.

Potential Causes and Solutions:

Cause 1: Opsonization and MPS Uptake. Bare nanoparticles are quickly recognized by the immune system.

- Solution: Incorporate stealth coatings. Polyethylene Glycol (PEG) is the gold standard, but be aware of the "Accelerated Blood Clearance" (ABC) phenomenon upon repeated dosing due to anti-PEG antibodies [14]. Consider emerging alternatives like zwitterionic polymers or polysaccharides [27] [14].

- Protocol: Surface PEGylation via Post-Coating.

- Prepare nanoparticles using your standard method.

- Dissolve DSPE-PEG (or other PEG-lipid) in an appropriate solvent (e.g., ethanol) and add it to the nanoparticle suspension under gentle stirring. A typical starting molar ratio is 5-10% PEG-lipid to total lipid/polymer.

- Stir the mixture for 2-4 hours at a temperature above the phase transition of the lipids/polymer to allow for insertion/attachment.

- Purify the PEGylated nanoparticles via dialysis or tangential flow filtration to remove unbound PEG-lipid and solvent [27] [28].

Cause 2: Incorrect Nanoparticle Size or Charge.

Problem: I am experiencing low drug encapsulation efficiency.

Potential Causes and Solutions:

- Cause 1: Mismatch between Drug Properties and Nanocarrier Core.

- Cause 2: Drug Leakage During Formulation or Storage.

- Solution (for lipid systems): Add cholesterol (up to 30-40 mol%) to the lipid bilayer to improve packing and reduce membrane permeability [27]. For polymeric systems, optimize the polymer molecular weight and crystallinity to create a denser matrix [25] [14].

- Protocol: Fabrication of Polymeric Lipid Hybrid Nanoparticles (PLNs) for Enhanced Encapsulation.

- Form the polymeric core: Dissolve your polymer (e.g., PLGA) and hydrophobic drug in a water-miscible organic solvent (e.g., acetone).

- Form the lipid film: Dissolve phospholipids (e.g., DSPC) and cholesterol in chloroform in a round-bottom flask. Remove the solvent by rotary evaporation to form a thin, dry lipid film.

- Hydrate and combine: Hydrate the lipid film with an aqueous solution (e.g., PBS) to form multilamellar vesicles (liposomes). Extrude to obtain a homogeneous size.

- Nanoprecipitation: Inject the polymer-drug solution into the aqueous liposome suspension under vigorous stirring. The polymer core forms, encapsulated by a lipid monolayer shell.

- Purify the PLNs by dialysis or centrifugation to remove the organic solvent and unencapsulated drug [28].

Problem: My inorganic nanoparticles are aggregating in physiological buffers.

Potential Causes and Solutions:

- Cause: Lack of a stable steric or electrostatic coating.

- Solution: Functionalize the nanoparticle surface with stabilizing agents.

- Steric Stabilization: Coat with a layer of biocompatible polymers like PEG, chitosan, or poly(acrylic acid). This creates a repulsive barrier that prevents aggregation [29] [30].

- Electrostatic Stabilization: Adjust the pH of the suspension to ensure the surface charge (zeta potential) is sufficiently high (typically > |±30| mV) to create electrostatic repulsion between particles.

- Protocol: PEGylation of Gold Nanoparticles (AuNPs) as a Model.

- Synthesize or acquire citrate-stabilized AuNPs.

- Add an excess of methoxy-PEG-thiol (mPEG-SH) solution to the AuNP colloid. The thiol group will covalently bind to the gold surface.

- Allow the reaction to proceed for several hours at room temperature.

- Purify the PEGylated AuNPs by repeated centrifugation and redispersion in the desired buffer (e.g., PBS) to remove unbound PEG molecules [29] [30].

- Solution: Functionalize the nanoparticle surface with stabilizing agents.

Essential Experimental Workflows and Pathways

Decision Pathway for Nanomaterial Selection

This flowchart outlines a logical decision process for selecting a nanomaterial system based on application requirements.

Workflow for Assessing Biodegradation and Biocompatibility

A critical pathway for evaluating the safety and degradation profile of new nanobiomaterials.

The Scientist's Toolkit: Key Research Reagents and Materials

Table 2: Essential Reagents for Nanobiomaterial Formulation and Testing

| Reagent/Material | Function/Application | Key Considerations |

|---|---|---|

| PLGA (Poly(lactic-co-glycolic acid)) | Biodegradable polymer for controlled-release nanoparticles [26] [14] | Vary lactide:glycolide ratio and MW to tune degradation rate and drug release kinetics. |

| DSPC (1,2-distearoyl-sn-glycero-3-phosphocholine) | Phospholipid for constructing stable lipid bilayers in liposomes and hybrid systems [27] [28] | High phase transition temperature (~55°C) enhances bilayer stability at 37°C. |

| Cholesterol | Incorporated into lipid bilayers to improve packing, stability, and drug retention [27] | Typically used at 30-45 mol% relative to phospholipids. |

| DSPE-PEG | PEG-lipid conjugate for creating "stealth" coatings to prolong circulation time [27] [28] | Molar ratio of 5-10% is common. Beware of ABC phenomenon with repeated dosing. |

| Ionizable Cationic Lipids (e.g., DLin-MC3-DMA) | Key component of LNPs for encapsulating nucleic acids; promotes endosomal escape [27] [14] | pKa should be tuned to be neutral at physiological pH but charged in acidic endosomes. |

| Citrate-Capped Gold Nanoparticles | Model inorganic nanoparticles for functionalization, photothermal therapy, and imaging [29] [30] | The citrate layer allows for easy ligand exchange with thiolated molecules (e.g., PEG). |

| MTT Reagent (3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide) | Standard colorimetric assay for measuring cell viability and nanoparticle cytotoxicity [26] | Measure mitochondrial activity; confirm results with other assays (e.g., ATP assay). |

Frequently Asked Questions (FAQs)

Q1: How can I control the degradation rate of a magnesium-based orthopedic implant to match the bone healing process? Alloying is a primary strategy to control the degradation rate. For instance, adding Strontium (Sr) and Manganese (Mn) to magnesium (Mg) can significantly reduce the corrosion rate. Research on Mg-0.3Sr-0.4Mn alloys demonstrated a corrosion rate of 0.39 mm/year, a 54% reduction compared to the binary Mg-0.3Sr alloy, making it more suitable for the healing timeline [32]. The degradation is also controlled by microstructure engineering; grain refinement through processes like hot extrusion can enhance corrosion resistance, but excessive refinement may compromise it, so an optimal balance is essential [32].

Q2: What are the common causes of nanoparticle aggregation during conjugation, and how can it be prevented? Aggregation often occurs when the nanoparticle concentration is too high [33]. To prevent this, follow recommended concentration guidelines and use a sonicator to disperse nanoparticles evenly before starting the conjugation process [33]. Furthermore, ensuring an optimal pH (typically around 7-8 for antibody conjugation with gold nanoparticles) and using high-purity nanoparticles without contaminants can also improve dispersion and prevent aggregation [33].

Q3: My layer-by-layer (LbL) nanoparticle assembly is inefficient and leads to material loss. Are there more robust synthesis methods? Yes, traditional LbL assembly involving batch-wise polymer adsorption and purification can be time-consuming and result in nanoparticle loss. A modern solution is microfluidic-mediated LbL assembly. This method uses commercially available bifurcating mixer cartridges to mix nanoparticles with polyelectrolytes precisely. It allows for assembly using titrated polymer-to-NP ratios without needing excess polymer, thereby eliminating the time-consuming purification step and greatly increasing throughput while avoiding material loss [34].

Q4: How can I improve the shelf life and stability of my diagnostic nanoparticle conjugates? The stability of conjugates is essential for diagnostic kits. A key tip is to incorporate stabilizing agents, such as BSA or PEG, after conjugation. These stabilizers are compatible with various nanoparticle types and help prolong the conjugate's shelf life. Furthermore, correct storage is critical; conjugates should typically be refrigerated at 4°C for optimal stability [33].

Q5: What in vivo biocompatibility results have been seen with newer Mg-based nanocomposites? Recent in vivo studies on magnesium-based metal matrix nanocomposites (MMNCs) are promising. When MMNC pins were implanted into rat femoral defects and monitored for 3 months, they showed no or minimal hydrogen gas evolution and a minimal fibrotic body response compared to controls. Critically, the implants demonstrated osteointegration and new bone formation, indicating excellent biocompatibility and integration with the host bone tissue [35].

Troubleshooting Guides

Troubleshooting Nanoparticle Conjugation for Diagnostics

| Problem | Possible Cause | Solution |

|---|---|---|

| Low Binding Efficiency | Sub-optimal pH of conjugation buffer [33]. | Adjust pH to 7-8 for antibody-gold nanoparticle conjugation. Use dedicated conjugation buffers. |

| Nanoparticle Aggregation | Concentration of nanoparticles is too high [33]. | Follow recommended concentration guidelines; use a sonicator to disperse nanoparticles before conjugation. |

| Non-specific Binding | Lack of blocking agents leads to attachment to unintended molecules [33]. | Use blocking agents like BSA or PEG after conjugation to prevent false-positive results. |

| Short Conjugate Shelf Life | Unstable conjugates degrade over time [33]. | Incorporate stabilizing agents and store conjugates at 4°C. |

| Unreliable Assay Results | Use of degraded nanoparticles or contaminated reagents [33]. | Use high-purity nanoparticles and conduct regular quality checks on all reagents. |

Troubleshooting Microfluidic Synthesis of Nanoparticles

| Problem | Possible Cause | Solution |

|---|---|---|

| Broad Size Distribution | Inefficient mixing in simple T-junction or Y-shaped mixers [36]. | Use advanced micromixer geometries (e.g., spiral, staggered herringbone) to induce chaotic advection for uniform mixing [36]. |

| Low Throughput | Manual or batch-scale processes for LbL assembly [34]. | Implement continuous-flow microfluidic systems for high-throughput synthesis, which allows for constant pumping and mixing [34] [36]. |

| Particle Loss During Purification | Traditional purification methods like tangential flow filtration in LbL assembly [34]. | Adopt microfluidic-mediated LbL assembly that uses precise polymer-to-NP ratios, eliminating the need for excess polymer and subsequent purification steps [34]. |

| Poor Reproducibility | Inconsistent reaction conditions in bulk methods [36]. | Leverage the precise control over flow rates, concentration, and temperature offered by continuous-flow microfluidics to ensure batch-to-batch consistency [36]. |

| Alloy Composition | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Corrosion Rate (mm/year) | Cell Viability | Key Findings |

|---|---|---|---|---|---|

| Mg-0.3Sr (SM0) | ~160 | ~217 | 0.85 | >90% | Baseline alloy. |

| Mg-0.3Sr-0.4Mn (SM04) | 205 | 242 | 0.39 | >90% | Optimal performance: 28% ↑YS, 54% ↓corrosion, 2.46x higher ALP activity. |

| Mg-0.3Sr-1.2Mn (SM12) | Data in source | Data in source | Data in source | Data in source | Excessive Mn may weaken corrosion resistance. |

| Mg-0.3Sr-2.0Mn (SM20) | Data in source | Data in source | Data in source | Data in source | Further grain refinement but potential compromise on properties. |

| Aspect | Detail |

|---|---|

| Definition | An automated method to test thousands to millions of samples quickly. |

| Throughput | Can process over 10,000 samples in a single day. |

| Key Tool | Uses robotics and automated liquid handling. |

| Plate Formats | 96, 384, or 1536 mini-wells. |

| Data Quality Check | Z'-factor (a value above 0.5 is generally good). |

| Primary Application | Over 80% of small-molecule FDA-approved drugs were discovered via HTS. |

Detailed Experimental Protocols

This protocol details the synthesis of bioactive glass-ceramic nanoparticles used as reinforcement in magnesium nanocomposites.

- Dissolution: Dissolve 2.1 g of calcium nitrate tetrahydrate (

Ca(NO₃)₂·4H₂O) and 2.0 g of magnesium chloride hexahydrate (MgCl₂·6H₂O) in 200-proof ethanol. - Stirring: Stir the solution at 250 rpm for 30 minutes at room temperature.

- Gel Formation: Add 20 mL of tetraethyl orthosilicate (

SiC₈H₂₀O₄) to the solution. Stir at 450 rpm for 24 hours at 80°C until a gel is formed. - Drying: Transfer the gel to an oven and dry at 100°C for 5 days to obtain a xerogel.

- Milling: Grind the dried xerogel into a fine powder using a mortar and pestle.

- Calcination: Calcinate the powder in a furnace at 850°C for 2 hours with a heating rate of 25°C per minute to form crystalline diopside nanoparticles.

This protocol describes a scalable method for surface modification of nanoparticles using microfluidics.

- Chip Preparation: Set up a commercially available microfluidic (MCF) system with bifurcating mixer cartridges.

- Solution Preparation: Prepare solutions of nanoparticles and polyelectrolytes (e.g., polymers with opposite charge to the NPs).

- Assembly: Co-inject the NP and polyelectrolyte solutions into the MCF chip. The precise mixing in the microchannels allows for polymer deposition onto the nanoparticle surface.

- Collection: The resulting LbL-NPs are collected from the outlet stream. A key advantage is that this method uses titrated polymer-to-NP weight equivalent ratios, which typically requires no further purification to remove excess polymer.

This protocol outlines the process for creating a biodegradable Mg alloy composite.

- Melting: Place Magnesium (balance, 96.2 wt%), Scandium (3 wt%), and diopside nanoparticles (0.5 wt%) in a graphite crucible. Heat to 930°C under an argon atmosphere to prevent oxidation.

- Alloying: Add Strontium (0.3 wt%) last to the melt to minimize its oxidation.

- Stirring and Slag Removal: Manually stir the melt with a graphite rod for 30 seconds. Remove any slag (oxide inclusions) from the surface.

- Ultrasound Treatment (UST): Increase the melt temperature to 980°C. Insert a preheated ceramic sonotrode (e.g., Hielscher UP200st) and perform ultrasound treatment for 1 minute using a cycle of 6 seconds on and 4 seconds off, at 50% amplitude. This disperses nanoparticles and refines the microstructure.

- Casting and Rolling: Pour the processed melt into a preheated sand mold. Subsequently, hot-roll the cast material to further refine its microstructure and properties.

Experimental Workflows and Pathways

The Scientist's Toolkit: Essential Research Reagents & Materials

Key Materials for Biocompatible Mg Alloy and Nanoparticle Research

| Item | Function / Role in Research |

|---|---|

| Magnesium (Mg) | Base material for biodegradable implants; has an elastic modulus (41-45 GPa) similar to bone, reducing stress shielding [35] [32]. |

| Strontium (Sr) | Alloying element for Mg; refines grains, improves corrosion resistance, and promotes osteoblast activity for new bone formation [35] [32]. |

| Manganese (Mn) | Alloying element for Mg; enhances strength and corrosion resistance by forming protective oxide films and stabilizing iron impurities [32]. |

| Scandium (Sc) | Alloying element for Mg; enhances mechanical and degradation properties by altering grain structure and forming a protective oxide layer [35]. |

| Diopside (CaMgSi₂O₆) | Bioactive glass-ceramic nanoparticle; used as reinforcement in composites. Its components (Ca, Si) play roles in bone and cartilage development [35]. |

| Tetraethyl orthosilicate | Silicon precursor used in the sol-gel synthesis of diopside nanoparticles [35]. |

| Polyelectrolytes | Polymers used in Layer-by-Layer (LbL) assembly to coat nanoparticles, enabling targeted drug delivery and improved pharmacokinetics [34]. |

| Blocking Agents (BSA, PEG) | Used after nanoparticle conjugation to prevent non-specific binding in diagnostic assays, reducing false-positive results [33]. |

| Stabilizing Agents | Used to prolong the shelf life and enhance the reproducibility of diagnostic nanoparticle conjugates [33]. |

Technical Support Center

Troubleshooting Guide: Common Experimental Issues

PEGylation Challenges

Table: Troubleshooting PEGylation Problems

| Problem | Potential Causes | Solutions | Preventive Measures |

|---|---|---|---|

| Uncontrolled Aggregation | Insufficient PEG surface density; inappropriate PEG molecular weight [37] | Optimize PEG-to-nanoparticle ratio; increase PEG chain length [37] | Perform stability tests in biologically relevant media (e.g., plasma) [38] |

| Loss of Targeting Ability | PEG chains sterically blocking ligand binding sites [39] | Use heterobifunctional PEG spacers; optimize ligand conjugation after PEGylation [39] | Conduct binding assays with target receptors during development |

| Immune Recognition (Anti-PEG IgM) | PEG conformation not providing effective steric shielding [37] | Employ branched PEG structures; optimize surface grafting density [37] | Test in vivo for accelerated blood clearance (ABC phenomenon) |

| Batch-to-Batch Variability | Inconsistent reaction conditions; inadequate purification [38] [39] | Standardize synthesis protocols; implement rigorous characterization [38] | Establish quality control checks for size, polydispersity, and surface charge |

Q: After PEGylating my iron oxide nanoparticles, I still observe aggregation in serum-containing media. What might be wrong?

A: This is a common issue where the PEG coating may be insufficient or unstable. First, verify your PEG density and molecular weight using TGA or NMR. Higher molecular weight PEG (e.g., 5k Da) often provides better steric stabilization. Second, ensure the PEG is covalently conjugated, not just adsorbed. Finally, always test stability in the specific biological medium you plan to use, as the formation of a biomolecular corona can destabilize particles [38] [37].

Q: My PEGylated nanoparticles are designed for active targeting, but cellular uptake is lower than expected. How can I troubleshoot this?

A: The "PEG dilemma" is a known challenge where PEG can sterically hinder the interaction between targeting ligands and their receptors [39]. Consider these approaches: 1) Use cleavable PEG linkers that dissociate in the tumor microenvironment (e.g., pH-sensitive bonds). 2) Optimize the spatial arrangement by co-conjugating PEG and ligands in a controlled manner. 3) Validate ligand accessibility with surface plasmon resonance (SPR) or isothermal titration calorimetry (ITC) before proceeding to cellular assays.

Ligand Conjugation Issues

Table: Ligand Conjugation Optimization Parameters

| Parameter | Optimal Range | Characterization Method | Impact on Biocompatibility |

|---|---|---|---|

| Ligand Density | Variable by application (e.g., 5-50 ligands/particle) [39] | Fluorescence tagging, HPLC, ESR | High density can cause non-specific uptake; low density reduces efficacy [39] |

| Orientation/Activity | >80% retention of binding activity | Surface Plasmon Resonance (SPR) | Incorrect orientation blocks binding sites, reducing targeting efficiency |

| Conjugation Chemistry | Site-specific (e.g., cysteine-maleimide) preferred | Ellman's assay, MALDI-TOF | Non-specific conjugation can inactivate ligands or cause crosslinking |

| Final Validation | Cellular uptake in target vs. non-target cells | Flow cytometry, confocal microscopy | Confirms functional targeting and predicts in vivo performance [40] |

Q: My ligand-conjugated nanoparticles show high non-specific uptake in non-target cells. How can I improve specificity?

A: Non-specific uptake often results from residual charge or improper surface passivation. Ensure your nanoparticles are sufficiently PEGylated before ligand attachment to minimize non-specific interactions. Check the surface charge (zeta potential); near-neutral charges (slightly negative) typically reduce non-specific uptake. Also, verify ligand specificity by testing against cell lines with low receptor expression [39] [40].

Q: The conjugation efficiency of my antibody fragment to nanoparticles is consistently low. What conjugation strategies can I try?

A: Low efficiency can stem from several factors. First, ensure your nanoparticles have adequate functional groups for conjugation. Second, consider using heterobifunctional crosslinkers (e.g., SMCC for amine-to-thiol conjugation) for controlled, site-specific attachment. Third, optimize the reaction pH, time, and molar ratios. Finally, implement a size-exclusion chromatography step to efficiently remove unconjugated ligands, which is crucial for accurate dosing and interpretation of results [39].

Biomimetic Cell Membrane Coating Difficulties

Q: The cell membrane coating on my polymeric nanoparticles appears incomplete and unstable. How can I optimize this process?

A: Incomplete coating often results from improper membrane vesicle preparation or fusion conditions. First, ensure you are using sufficient membrane protein-to-nanoparticle ratio (typically 1:1 protein-to-particle weight ratio). Second, optimize the extrusion parameters (pore size, number of passes). Third, characterize the coated particles with multiple techniques: TEM for visual confirmation, dynamic light scattering (DLS) for size, and western blotting to verify the presence of key membrane proteins. The coating integrity is crucial for achieving true biomimetic properties [40].

Q: My red blood cell membrane-coated nanoparticles are still being cleared by the immune system faster than expected. What could be the issue?

A: Rapid clearance suggests either coating instability or missing "self-markers." Verify that your source membranes contain crucial "don't eat me" signals like CD47, which is essential for evading phagocytosis. Ensure the coating process preserves these proteins' structure and functionality. Test coating stability in blood plasma by incubating particles and monitoring size and protein retention over time. Consider incorporating additional stealth components like minimal PEG to stabilize the membrane coating if necessary [40].

Experimental Protocols & Methodologies

Protocol 1: Assessing Biocompatibility and Cytotoxicity

Principle: Evaluate nanoparticle safety through a tiered testing approach using in vitro models, as recommended by ISO/TR 10993-22 for biological evaluation of nanomaterial-containing medical devices [41].

Procedure:

- Sample Preparation: Prepare nanoparticle dispersions in relevant biological media (e.g., cell culture medium with serum). Do not filter the samples after preparation, as this would remove the nanoparticles. For devices with nanostructured surfaces, use surface-based extraction ratios per ISO 10993-12 [41].

- Dosimetry Considerations: Define dose using multiple metrics: mass concentration (µg/mL), surface area (cm²/mL), and particle number (# particles/mL). Account for in vitro sedimentation, diffusion, and dosimetry (ISDD) to calculate the delivered dose to cells [42].

- Cytotoxicity Testing:

- Use multiple assay types (e.g., MTS, ATP content, LDH release) to overcome potential nanoparticle-assay interferences [41].

- Test on both phagocytic (e.g., macrophages) and non-phagocytic cell lines relevant to the exposure route.

- Incubate cells with nanoparticles for 24-72 hours and measure viability/cytotoxicity relative to untreated controls.

- Hemocompatibility Assessment:

- Evaluate complement system activation, a critical endpoint for intravenously administered nanomaterials [41].

- Assess interactions with platelets and coagulation factors.

- Data Interpretation: A reduction in cell viability to <70-80% of the control is typically considered a sign of potential cytotoxicity. Always confirm findings with multiple, orthogonal assays.

Protocol 2: Endotoxin Testing for Nanoparticles

Principle: Detect and quantify bacterial endotoxin contamination using the Limulus Amoebocyte Lysate (LAL) assay, crucial as endotoxin can mask the true biocompatibility of the formulation [38].

Procedure:

- Sample Handling: Work under sterile, pyrogen-free conditions. Use LAL-grade water for all buffers and dilutions.

- Assay Selection and Interference Testing:

- Choose an appropriate LAL format (chromogenic, turbidity, or gel-clot). Colored nanoparticles can interfere with chromogenic assays, while turbid formulations interfere with turbidity assays [38].

- Perform an Inhibition/Enhancement Control (IEC) by spiking a known amount of endotoxin into your nanoparticle sample. The recovery should be within 50-200% to validate the assay.

- If interference occurs, employ a different LAL format or use techniques like the recombinant Factor C assay, which is not affected by beta-glucans [38].

- Testing: Follow the manufacturer's protocol for the selected LAL assay. The USP limit for intravenously administered formulations is 5 Endotoxin Units (EU)/kg body weight/hour [38].

- Alternative Methods: If LAL assays are not feasible, consider the macrophage activation test or rabbit pyrogen test for detecting pyrogenic contaminants.

The Scientist's Toolkit: Research Reagent Solutions

Table: Essential Reagents for Biocompatibility Enhancement Studies

| Reagent / Material | Function / Application | Key Considerations |

|---|---|---|

| Methoxy-PEG-NHS Ester | Covalently attaches PEG to amine groups on nanoparticles, creating a steric "stealth" layer. | Vary chain length (2k-20k Da) to optimize shielding; use excess molar ratios to ensure high surface density [37]. |

| Heterobifunctional Crosslinkers | Enables controlled, site-specific conjugation of targeting ligands (e.g., antibodies, peptides). | Choose linkers with appropriate reactivity (e.g., Maleimide-PEG-NHS for thiol-amine coupling); consider cleavable linkers for intracellular release [39]. |

| Limulus Amoebocyte Lysate | Detects and quantifies endotoxin contamination in nanoparticle formulations. | Always perform an Inhibition/Enhancement Control (IEC) to rule out nanoparticle-induced assay interference [38]. |

| Fetal Bovine Serum | Used to form a biomolecular corona on nanoparticles for in vitro studies under physiologically relevant conditions. | The protein corona formed can significantly alter cellular uptake and toxicity profiles [42]. |

| Cell Lines (Macrophages, Hepatic, etc.) | Models for assessing cytotoxicity, immune response, and organ-specific toxicity. | Use multiple relevant cell types, including phagocytic cells; consider 3D or co-culture models for advanced testing [41] [43]. |

| Dynamic Light Scattering Instrument | Measures hydrodynamic size, size distribution (PDI), and zeta potential of nanoparticles. | Always measure these parameters in both simple buffers and biologically relevant media (e.g., plasma) to assess stability [38]. |

Experimental Workflow & Signaling Pathways

Nanoparticle Biocompatibility Optimization Workflow

The following diagram outlines a systematic workflow for developing and troubleshooting biocompatible nanoparticles, integrating the three key techniques.

Diagram 1: Systematic workflow for developing and troubleshooting biocompatible nanoparticles, integrating characterization and validation checkpoints.

Nanoparticle-Targeted Therapy Mechanism

This diagram illustrates the sequential biological mechanism of how targeted nanoparticles interact with tumor cells, from circulation to intracellular drug release.

Diagram 2: Sequential biological mechanism of targeted nanoparticle therapy, from administration to intracellular action.