Polydopamine Coating for Membrane Hydrophilicity Enhancement: Mechanisms, Applications, and Biomedical Prospects

This article provides a comprehensive analysis of polydopamine (PDA) as a versatile surface modification tool for enhancing membrane hydrophilicity, a critical property in biomedical and drug development applications.

Polydopamine Coating for Membrane Hydrophilicity Enhancement: Mechanisms, Applications, and Biomedical Prospects

Abstract

This article provides a comprehensive analysis of polydopamine (PDA) as a versatile surface modification tool for enhancing membrane hydrophilicity, a critical property in biomedical and drug development applications. It explores the foundational chemistry and mechanisms behind PDA's strong adhesive and hydrophilic properties, detailing practical methodologies for coating application on various polymeric substrates. The content further addresses key challenges in process optimization and long-term stability, while validating performance through comparative analysis of hydrophilicity, antifouling resistance, and thermal stability against unmodified membranes. Aimed at researchers and drug development professionals, this review synthesizes current research to guide the implementation of PDA coatings in developing advanced membrane-based technologies.

The Science of Polydopamine: Unraveling the Chemistry Behind Superior Membrane Hydrophilicity

The remarkable ability of mussels to adhere to virtually any surface in wet, saline environments has inspired a transformative advancement in materials science. This biological adhesion is primarily mediated by mussel foot proteins (Mfps), which are rich in the post-translationally modified amino acid 3,4-dihydroxyphenylalanine (DOPA) [1]. The catechol functional groups within DOPA are crucial for robust interfacial binding. In 2007, researchers demonstrated that dopamine, an analog of L-Dopa, undergoes self-polymerization to form polydopamine (PDA), a versatile coating that mimics the adhesive properties of mussel proteins [2] [3]. This discovery unlocked a simple, one-step method for depositing thin, adherent films on a vast repertoire of material surfaces, overcoming the limitations of previous surface modification techniques that often required specific substrate chemistries or harsh conditions [2] [4].

In the context of membrane technology, particularly for water treatment and biomedical applications, surface hydrophilicity is a critical parameter that influences performance, fouling resistance, and longevity. PDA coatings have emerged as a powerful tool for enhancing membrane hydrophilicity, thereby improving water flux and antifouling properties [5]. This application note details the natural blueprint of mussel adhesion, the formation and deposition of PDA, and provides detailed protocols for its application in membrane surface engineering, specifically for hydrophilicity enhancement.

The Natural Blueprint: From Mussel Proteins to Polydopamine

Mussel Foot Proteins and their Adhesive Mechanisms

Mussels secrete a variety of Mfps to form a holdfast, or byssus, which anchors them to surfaces. Key adhesive proteins include Mfp-3, Mfp-5, and Mfp-6, which are located at the interface between the plaque and the substrate and contain a high mole percentage of DOPA (approximately 20-28 mol%) [1]. The catechol moiety of DOPA enables adhesion through multiple mechanisms:

- Complexation with Metal Ions: Catechols can form strong coordination bonds with metal oxides present on mineral surfaces.

- Hydrogen Bonding: The hydroxyl groups on catechol can form hydrogen bonds with organic and inorganic substrates.

- Cation-π Interactions: The aromatic ring of DOPA can interact with positively charged surfaces.

- Oxidative Cross-linking: DOPA can be oxidized to form quinones, which can undergo cross-linking reactions, strengthening the adhesive plaque [1] [6].

The versatility of these interactions allows mussels to adhere to diverse surfaces, from rocks to ship hulls.

Polydopamine as a Biomimetic Polymer

PDA is synthesized through the oxidative polymerization of dopamine in a weak alkaline aqueous solution (typically pH 8.5). While the precise molecular structure of PDA remains a subject of ongoing research, it is accepted that its formation involves both covalent polymerization and non-covalent self-assembly [3] [4]. The process begins with the oxidation of dopamine to dopaminequinone, followed by intramolecular cyclization, rearrangement, and further oxidation to form 5,6-dihydroxyindole (DHI) and its derivatives [3]. These species then polymerize and/or self-assemble into a dark brown, melanin-like material that retains the key catechol and amine functional groups of its biological counterpart.

The resulting PDA coating is universally adherent and provides a platform rich in functional groups, making it an ideal primer layer for secondary reactions or for directly modifying surface properties like hydrophilicity [2] [7].

Table 1: Key Functional Groups in Polydopamine and their Roles in Adhesion and Hydrophilicity

| Functional Group | Role in Adhesion | Role in Hydrophilicity Enhancement |

|---|---|---|

| Catechol (C₆H₄(OH)₂) | Forms coordination bonds with metal ions, hydrogen bonds, and undergoes π-interactions. | Increases surface energy and water interaction via hydrogen bonding. |

| Amino (-NH₂) | Contributes to electrostatic interactions and covalent grafting of molecules. | Can be protonated to create a positively charged, hydrophilic surface. |

| Quinone (C₆H₄O₂) | Formed from catechol oxidation; participates in Michael addition or Schiff base reactions. | Can be reduced back to catechol, maintaining a hydrophilic character. |

| Imine (-C=N-) | Results from reactions between quinones and amines; contributes to polymer structure. | Influences the electronic structure and polarity of the surface. |

Polydopamine for Membrane Hydrophilicity Enhancement

Mechanism of Hydrophilicity Improvement

The deposition of a PDA coating significantly alters the surface physicochemical properties of a membrane. The multitude of polar functional groups, particularly catechol and amine groups, on the PDA surface dramatically increases the surface energy and hydrophilicity [5] [3]. This is quantitatively measured by a decrease in the water contact angle. Studies have shown that a mere 30-second deposition of PDA can reduce the water contact angle of a polyethersulfone (PES) microfiltration membrane from 69.2° to 58.6°, with the angle decreasing further as coating time increases [5]. This enhanced hydrophilicity is crucial for water-based filtration processes as it promotes water permeation and reduces the adsorption of hydrophobic foulants.

Impact on Membrane Performance

The application of PDA coatings on membranes leads to tangible performance benefits, as demonstrated in recent studies:

Table 2: Impact of PDA Coating on Microfiltration Membrane Performance [5]

| Membrane Type (Pre-casting Time) | Mean Surface Pore Size (nm) | Coating Condition | Water Contact Angle (°) | Pure Water Flux (LMH/bar) | Sucrose Rejection (%) |

|---|---|---|---|---|---|

| M3 (3 seconds) | ~300 | Uncoated | 69.2 | 1977 | 37.4 |

| M3 (3 seconds) | ~300 | PDA-Coated (0.5 h) | 58.6 | 1152 | 58.3 |

| M60 (60 seconds) | ~300 | Uncoated | 75.4 | 1656 | 48.9 |

| M60 (60 seconds) | ~300 | PDA-Coated (0.5 h) | 64.5 | 976 | 71.3 |

| M15 (15 seconds) | ~450 | Uncoated | 73.3 | 3358 | 18.8 |

| M15 (15 seconds) | ~450 | PDA-Coated (0.5 h) | 65.4 | 1879 | 29.5 |

Data from this study reveals two key findings:

- Enhanced Rejection: On membranes with smaller surface pore sizes (~300 nm), the PDA coating acts as a hydraulic resistant layer, narrowing the pore entrances and significantly increasing sucrose rejection [5].

- Flux Reduction: The deposition of PDA inevitably leads to some degree of pore blocking or narrowing, resulting in a reduction of pure water flux. The trade-off between improved selectivity (rejection) and reduced permeability must be carefully balanced for the target application [5].

Furthermore, the hydrophilicity imparted by PDA improves antifouling performance. The hydrated layer formed on the hydrophilic surface acts as a barrier, repelling the adhesion of organic foulants, oils, and proteins [5] [8].

Experimental Protocols

Standard Protocol for PDA Coating on Flat-Sheet Membranes

This protocol describes the deposition of a PDA coating on a polymeric microfiltration membrane to enhance its surface hydrophilicity [5].

Materials:

- Dopamine hydrochloride (≥98.0%, Solarbio)

- TRIS-HCl buffer (Ultrapure grade, Solarbio), 10 mM, pH 8.5

- Polyethersulfone (PES) microfiltration membrane (or other polymeric membrane)

- Deionized water

- Sonicator bath

Equipment:

- Beaker or glass reaction vessel

- Magnetic stirrer and stir bar

- Laboratory oven (optional, for temperature control)

Procedure:

- Membrane Pre-treatment: Cut the pristine PES membrane into desired dimensions. Rinse thoroughly with deionized water and sonicate for 10 minutes to remove any preservatives or contaminants. Dry the membrane at room temperature.

- Solution Preparation: Dissolve dopamine hydrochloride in the 10 mM TRIS-HCl buffer (pH 8.5) to a final concentration of 2 mg/mL. Stir gently to ensure complete dissolution.

- Coating Process: Immerse the pre-treated membrane into the dopamine solution. Ensure the membrane is fully submerged and that no air bubbles are trapped on the surface.

- Polymerization: Allow the reaction to proceed for a predetermined time (e.g., 0.5 to 4 hours) at room temperature (25°C) with gentle agitation (e.g., 60 rpm). The solution will gradually darken, turning from colorless to dark brown.

- Termination and Washing: Carefully remove the membrane from the dopamine solution. Rinse it copiously with deionized water and sonicate for 5-10 minutes to remove any loosely adsorbed PDA particles or oligomers.

- Drying: Dry the coated membrane at room temperature or in a vacuum oven at 40°C for further characterization and use.

Notes:

- The thickness and density of the PDA coating can be controlled by varying the deposition time, dopamine concentration, and reaction temperature [5] [9].

- To minimize internal pore blockage, consider shorter coating times or lower dopamine concentrations if high water flux is a priority.

Protocol for Accelerated PDA Coating Using an Oxidant

The standard PDA deposition process can be slow. This protocol uses sodium periodate (NaIO₄) as an oxidant to significantly accelerate the polymerization rate and achieve a thicker, more hydrophilic film [2].

Materials:

- Dopamine hydrochloride

- TRIS-HCl buffer (10 mM, pH 8.5) or other suitable buffer

- Sodium periodate (NaIO₄)

- Deionized water

Procedure:

- Solution Preparation: Prepare a dopamine solution (2 mg/mL) in the TRIS-HCl buffer.

- Oxidant Addition: Add solid sodium periodate to the dopamine solution to a final concentration of 10 mM. Stir briefly to dissolve.

- Coating Process: Immediately immerse the substrate into the solution. The polymerization will proceed rapidly.

- Termination and Washing: After the desired coating time (typically 10 minutes to 2 hours), remove the substrate and wash thoroughly with deionized water.

Notes:

- PDA films formed with NaIO₄ as an oxidant exhibit faster growth and can reach a thickness close to 100 nm in about 2 hours. They also display markedly improved hydrophilicity compared to films formed using dissolved O₂ as the sole oxidant [2].

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagent Solutions for Polydopamine Coating Research

| Reagent / Material | Function / Role | Typical Usage & Notes |

|---|---|---|

| Dopamine Hydrochloride | Monomer precursor for PDA formation. | Typically used at 0.5-4 mg/mL in buffer. Protect from light and oxygen to prevent premature oxidation. |

| TRIS-HCl Buffer (pH 8.5) | Provides an alkaline environment for dopamine oxidation and self-polymerization. | 10 mM concentration is standard. Mimics the pH of seawater where mussels adhere. |

| Sodium Periodate (NaIO₄) | Strong oxidant to accelerate dopamine polymerization. | Allows for rapid film growth and can enhance film hydrophilicity [2]. |

| Ammonium Persulfate | Alternative strong oxidant for PDA synthesis. | Another common oxidant used to speed up the reaction kinetics [2]. |

| Polyethersulfone (PES) Membrane | A common hydrophobic polymer substrate for modification. | Shows significant hydrophilicity improvement after PDA coating [5]. |

| Sodium Hydroxide (NaOH) | Catalyst for PDA nanoparticle synthesis. | Used in ethanol-water mixtures to control the size of PDA nanospheres [9]. |

Visualization of Concepts and Workflows

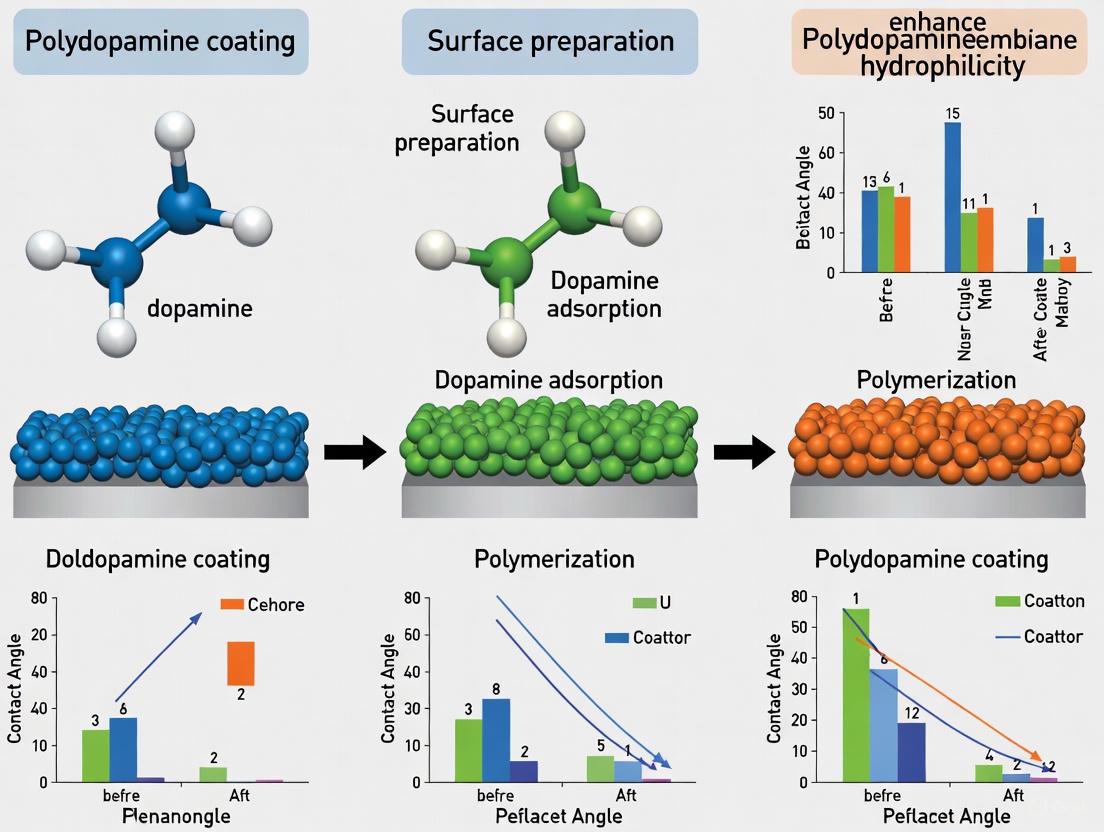

Mussel Adhesion and Polydopamine Coating Mechanism

Diagram Title: From Mussel Adhesion to Biomimetic PDA Coating

Experimental Workflow for Membrane Hydrophilicity Enhancement

Diagram Title: PDA Hydrophilicity Enhancement Workflow

Polydopamine (PDA), a synthetic analogue of melanin inspired by mussel adhesion proteins, has emerged as a versatile platform for surface modification and functionalization across diverse scientific fields. Its significance is particularly pronounced in membrane science, where PDA coatings offer a robust and straightforward method for enhancing surface hydrophilicity. The inherent hydrophobic nature of many synthetic membranes, such as polyamide (PA) and polyvinyl chloride (PVC), leads to issues like fouling, reduced flux, and undesirable biological interactions in biomedical applications [10] [11]. PDA modification addresses these challenges by introducing a hydrophilic, adhesive, and chemically functional layer that can permanently alter surface properties without compromising the bulk material. This application note details the chemical mechanisms underlying dopamine polymerization and provides standardized protocols for applying these principles to membrane hydrophilicity enhancement, serving as a critical resource for researchers and drug development professionals working in this domain.

Chemical Mechanisms of Dopamine Polymerization

The formation of polydopamine is a complex process involving the oxidative self-polymerization of dopamine. The molecular structure of dopamine, featuring catechol and primary amine functional groups, is key to its behavior [12]. This process can proceed in a weakly alkaline environment (typically pH 8.5) even without additional oxidants, though the reaction rate can be significantly accelerated by their presence [13] [12].

The widely accepted mechanism, illustrated in Figure 1, begins with the oxidation of dopamine to dopaminequinone. This is followed by a series of intramolecular cyclization, oxidation, and isomerization steps leading to the formation of 5,6-dihydroxyindole (DHI) [12] [14]. Subsequent oxidation of DHI generates radical species that undergo random polymerization and cross-linking. The final PDA structure is not a simple linear polymer but is best described as a complex heterogeneous mixture of cross-linked oligomers, primarily comprising units of DHI and uncyclized dopamine, which form supramolecular aggregates through various covalent and non-covalent interactions [12] [15].

Figure 1: Pathway of Polydopamine Formation

The strong adhesion of PDA to virtually any substrate arises from multiple synergistic interactions. As shown in Figure 2, the catechol groups in the polymer can form hydrogen bonds with surface hydroxyls or amines, undergo coordination bonds with metal ions on or from the substrate, and participate in covalent bonding via Michael-type addition or Schiff base reactions with nucleophilic surface groups [12] [14] [11]. Furthermore, π-π stacking interactions between the indole rings in PDA and aromatic structures on the substrate surface, such as in polyester textiles or certain polymer membranes, contribute significantly to adhesion stability [12] [14]. This multifaceted adhesion mechanism ensures the formation of a stable, conformal coating that is resistant to delamination.

Figure 2: Adhesion Mechanisms of Polydopamine

Quantitative Data on PDA-Modified Surfaces

The impact of PDA modification on material properties can be quantitatively assessed through various metrics. Table 1 summarizes key performance data from recent studies on hydrophilicity enhancement, demonstrating the significant improvements achievable through PDA coating and co-deposition strategies.

Table 1: Hydrophilicity and Performance Enhancement via PDA Modification

| Substrate Material | Modification Method | Key Performance Metric | Result (Before → After Modification) | Reference |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Co-deposition with Hyperbranched Polylysine (HBPL) | Water Contact Angle | Significantly reduced to 43.2° | [11] |

| Polyamide (PA) Composite Membrane | Coating with GO-TiO₂ nanocomposite | Membrane Flux (Permeability) | Increased from 28% to 61% | [10] |

| Commercial PA Membrane (Filmtec TW30) | Coating with TiO₂ nanoparticles | Maintained Flux Ratio (Antifouling) | Clearly improved, especially under UV | [10] |

| Three Coal Types (Lignite, Bituminous, Anthracite) | PDA/Polyacrylamide (PAM) Co-deposition | Coal Quality Indicators (Moisture, Ash, etc.) | Changes < 1%, minimal impact on bulk properties | [13] |

| Textiles for Oil/Water Separation | PDA-based functionalization | Oil Permeation Flux / Separation Efficiency | Up to 4000 L m⁻² h⁻¹ / >99.9% | [12] |

Beyond hydrophilicity, PDA modification influences thermal and chemical stability, which is critical for membrane applications involving sterilization or harsh operational environments. Simultaneous thermal analysis of PDA/PAM-modified coal samples demonstrated that the hydrophilic modification had a negligible effect on the thermal behavior of the substrate, with changes in moisture, ash, volatile matter, and fixed carbon content all remaining within 1% [13]. Furthermore, the stability of PDA coatings under extreme pH conditions can be significantly enhanced. For example, the incorporation of hyperbranched polylysine (HBPL) with PDA drastically reduced the detachment of the coating from PVC surfaces when exposed to 1.0 M NaOH solutions compared to PDA alone [11].

Experimental Protocols

Standard Protocol for PDA Coating via Solution Immersion

This is the foundational method for depositing a PDA coating on a surface to enhance hydrophilicity.

4.1.1 Research Reagent Solutions

Table 2: Essential Reagents for Standard PDA Coating

| Reagent/Material | Function/Explanation | Typical Specification |

|---|---|---|

| Dopamine Hydrochloride | Monomer precursor for PDA film formation. | Purity ≥ 98% |

| Tris(hydroxymethyl)aminomethane (Tris) | Buffer to maintain a stable, weakly alkaline pH (8.5-8.8) for polymerization. | Analytical Grade |

| Hydrochloric Acid (HCl) or Sodium Hydroxide (NaOH) | To adjust the pH of the Tris-buffer solution to the target value. | 0.1 - 1.0 M solutions |

| Deionized (DI) Water | Solvent for all aqueous solutions. | High resistivity (e.g., >18 MΩ·cm) |

| Target Substrate (e.g., PA, PVC membrane) | The material to be modified. | Cleaned and cut to desired size |

4.1.2 Step-by-Step Procedure

- Solution Preparation: Prepare a 10 mM Tris-buffer solution (0.05 mol L⁻¹) using DI water. Adjust the pH to 8.5 using HCl or NaOH, verified with a calibrated pH meter [14] [11].

- Dopamine Addition: Add dopamine hydrochloride to the Tris-buffer to achieve a concentration of 2 mg/mL (≈10.5 mM). Stir briefly to ensure complete dissolution. Note: The solution will initially be clear but will gradually darken due to oxidation.

- Substrate Immersion: Immediately immerse the pre-cleaned substrate into the dopamine solution, ensuring it is fully submerged. Avoid overlapping or crowding of samples.

- Polymerization Reaction: Allow the reaction to proceed for a defined period (typically 4-24 hours) at room temperature (25-35°C) with constant, gentle agitation (e.g., on a rocking shaker or with magnetic stirring) [13] [14].

- Termination and Rinsing: After the desired coating time, remove the substrate from the solution. Rise it thoroughly with copious amounts of DI water and/or gently sonicate in DI water to remove any loosely adhered PDA particles.

- Drying: Dry the coated substrate under a stream of inert gas (e.g., N₂) or in a ambient air oven at a mild temperature (e.g., 40°C) for 8 hours [14].

Advanced Protocol: PDA/Polyacrylamide Co-deposition

This protocol describes a co-deposition strategy to create a highly hydrophilic surface on hydrophobic materials like coal for dust suppression, a concept transferable to hydrophobic polymer membranes [13].

4.2.1 Reagent Solutions

- Dopamine (DA) and Polyacrylamide (PAM): Serve as the primary coating materials.

- Copper Sulfate (CuSO₄) and Hydrogen Peroxide (H₂O₂, 30.0%): Act as triggering agents to accelerate the oxidation and self-polymerization rate of DA [13].

4.2.2 Step-by-Step Procedure

- Deposition Liquid Synthesis: Prepare an aqueous solution containing both Dopamine (DA) and Polyacrylamide (PAM).

- Reaction Triggering: Add Copper Sulfate (CuSO₄) and Hydrogen Peroxide (H₂O₂) to the DA/PAM solution to initiate and accelerate the polymerization and co-deposition process.

- Substrate Treatment: Immerse the substrate in the deposition liquid for a set duration to allow for the formation of the PDA/PAM composite coating.

- Rinsing and Drying: Remove the substrate, rinse with DI water, and dry. This method has been shown to significantly enhance the wetting effect on inherently hydrophobic surfaces [13].

Advanced Protocol: PDA with Hyperbranched Polylysine (HBPL)

This protocol significantly improves the stability of the hydrophilic coating, especially under alkaline conditions, which is a known weakness of pure PDA films [11].

4.3.1 Reagent Solutions

- Hyperbranched Polylysine (HBPL): Synthesized via melt phase polycondensation of L-lysine hydrochloride [11].

- Dopamine Hydrochloride and Tris-buffer: As in the standard protocol.

4.3.2 Step-by-Step Procedure (Simultaneous Co-deposition)

- HBPL Solution Preparation: Synthesize or acquire HBPL and prepare an aqueous solution.

- Mixed Solution Preparation: Prepare a Tris-buffer solution (pH 8.5) containing both dopamine hydrochloride and HBPL. A mass ratio of DA/HBPL of approximately 1:1 has been found to be effective [11].

- Co-deposition: Immerse the substrate in the DA/HBPL/Tris solution for 24 hours to allow for simultaneous deposition and cross-linking.

- Post-treatment: Remove, rinse, and dry the substrate as before. The resulting PVC-pDA/HBPL film demonstrates enhanced hydrophilicity (water contact angle of 43.2°) and superior stability in strong base compared to PVC-pDA alone [11].

The workflow for selecting and executing these protocols is summarized in Figure 3.

Figure 3: Experimental Protocol Selection

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for PDA Hydrophilicity Enhancement

| Reagent / Material | Core Function | Application Notes & Rationale |

|---|---|---|

| Dopamine Hydrochloride | Fundamental monomer for PDA film formation. | Purity is critical for reproducible polymerization kinetics and film quality. |

| Tris-HCl Buffer (pH 8.5) | Provides optimal alkaline environment for auto-oxidation and self-polymerization. | The standard and most reliable buffer system for PDA deposition. |

| Copper Sulfate (CuSO₄) / Hydrogen Peroxide (H₂O₂) | Oxidant trigger system to accelerate polymerization. | Reduces coating time significantly; useful for rapid prototyping [13]. |

| Polyacrylamide (PAM) | Hydrophilic polymer for co-deposition. | Introduces additional water-absorbing groups, creating a super-hydrophilic surface [13]. |

| Hyperbranched Polylysine (HBPL) | Multifunctional macromer for co-deposition. | Enhances deposition mass, stability in alkaline environments, and provides amino groups for further functionalization [11]. |

| Polyvinyl Chloride (PVC) / Polyamide (PA) | Common hydrophobic substrate materials. | Representative model systems for demonstrating hydrophilicity enhancement in biomedical and filtration applications [10] [11]. |

The functional groups inherent to polydopamine (PDA)—catechol, amine, and quinone—are the fundamental drivers of its surface hydrophilicity. In the context of membrane modification, this hydrophilicity is paramount, as it directly enhances water permeability and imparts robust antifouling properties [16] [17]. The inspiration for PDA is drawn from mussel adhesive proteins, which are renowned for their exceptional adhesion in wet environments, a characteristic attributed to their high content of catecholic 3,4-dihydroxy-L-phenylalanine (DOPA) and amine-rich lysine residues [16]. This review delineates the specific role of each functional group in modulating hydrophilic behavior and provides detailed protocols for leveraging these properties in membrane surface engineering, forming a core chapter of a broader thesis on advancing membrane technology through bio-inspired coatings.

The Hydrophilic Triad: Structure and Function

The surface hydrophilicity of polydopamine is an emergent property resulting from the synergistic interaction of its constituent functional groups. The following table summarizes the distinct contributions of catechol, amine, and quinone units.

Table 1: Key Functional Groups in Polydopamine and Their Roles in Hydrophilicity

| Functional Group | Chemical Nature | Primary Role in Hydrophilicity | Additional Contributions |

|---|---|---|---|

| Catechol (3,4-dihydroxybenzene) | Two adjacent hydroxyl groups on an aromatic ring [16]. | Serves as a potent hydrogen bond donor and acceptor, strongly binding water molecules [17]. | Provides strong adhesion to substrates via metal coordination, hydrogen bonding, and π–π interactions [16] [12]. |

| Amine (Primary/Secondary) | Nitrogen-based groups (-NH₂, -NH-) [16]. | Enhances surface energy and hydrophilicity; can be protonated to form cationic, hydrophilic surfaces [17] [18]. | Critical for cohesion and film growth through amine-quinone interplay; enables secondary reactions with other molecules [19] [18]. |

| Quinone | Oxidized form of catechol (cyclic di-ketone) [19]. | Its electron-deficient nature increases surface polarity, enhancing affinity for polar water molecules [17]. | Acts as a reactive handle for Michael addition or Schiff base reactions with nucleophiles (e.g., thiols, amines) for functionalization [17] [19]. |

The interplay between these groups is dynamic. The alkaline environment used for PDA synthesis oxidizes catechol to quinone, and the amine groups are integral to the polymerization process, forming a complex, cross-linked network that is rich in hydrophilic moieties [16] [18]. The resulting surface is highly hydrated, which forms a physical and energetic barrier that prevents the adhesion of hydrophobic foulants like oils, proteins, and microbes [17].

Quantitative Impact on Membrane Performance

The introduction of PDA's hydrophilic functional groups onto membrane surfaces leads to measurable improvements in key performance metrics. The following table consolidates quantitative data from various studies on PDA-modified membranes.

Table 2: Quantitative Performance Metrics of PDA-Modified Membranes

| Membrane Substrate | Modification Type | Key Performance Change | Reference |

|---|---|---|---|

| Polyethersulfone (PES) Ultrafiltration | Two-step PDA modification (blending + coating) [20]. | Pure water flux increased from 15 to 50 L/m²·h (over 3x improvement) [20]. | [20] |

| Polyethersulfone (PES) | PDA coating as an adhesive layer for TiO₂ nanoparticles [5]. | Achieved ~82% rejection of Bovine Serum Albumin (BSA) [5]. | |

| Polypropylene Microfiltration (PPMM) | Co-deposition of PDA/PEI followed by TiO₂ embedding [21]. | Water flux surged from 605 to 5720 L m⁻² h⁻¹ (LMH) under 0.1 MPa [21]. | [21] |

| Microfiltration (MF) PES Membranes | PDA coating on membranes with controlled pore sizes [5]. | Coating on tighter pores (~300 nm) enhanced sucrose rejection without severe flux decline [5]. | |

| Polyethersulfone (PES) | Two-step PDA modification [20]. | Significant improvement in anti-fouling resistance against humic acid [20]. | [20] |

The relationship between surface chemistry and performance is further visualized below, illustrating how the fundamental properties of PDA's functional groups translate into measurable membrane enhancements.

Experimental Protocols for Membrane Hydrophilization

Standard Protocol for PDA Dip-Coating on Membrane Surfaces

This is the most prevalent method for applying a hydrophilic PDA coating to various membrane substrates [16] [17].

Research Reagent Solutions:

- Dopamine Hydrochloride: The precursor monomer for PDA formation.

- Tris-HCl Buffer (10 mM, pH 8.5): The standard alkaline buffer to trigger the oxidative self-polymerization of dopamine. Tris(hydroxymethyl)aminomethane is dissolved in purified water, and the pH is adjusted to 8.5 using HCl.

- Purified Water: Used for all solution preparation and subsequent rinsing steps.

Step-by-Step Procedure:

- Solution Preparation: Dissolve dopamine hydrochloride in the Tris-HCl buffer to a final concentration of 2 mg/mL [20]. The solution will appear clear initially but will gradually darken as polymerization begins.

- Substrate Immersion: Fully immerse the pre-cleaned and wetted membrane substrate into the freshly prepared dopamine solution. Ensure the entire surface is in contact with the solution, avoiding air bubbles.

- Reaction Incubation: Allow the reaction to proceed for a predetermined coating time, typically 4 to 24 hours, under constant, mild agitation (e.g., on a shaking platform) at room temperature [16] [20]. The coating thickness and surface roughness increase with time.

- Termination and Rinsing: After the coating period, remove the membrane from the solution and rinse it thoroughly with copious amounts of purified water. Gentle sonication in a water bath can be used to remove loosely adhered PDA particles [20].

- Drying and Storage: The modified membrane can be stored in purified water at 4°C or air-dried for further characterization and use.

Two-Step Modification for Enhanced Performance

This protocol involves blending dopamine into the membrane casting solution followed by a post-casting polymerization step, which can lead to a more uniform distribution of hydrophilic groups and improved flux [20].

Research Reagent Solutions:

- Polyethersulfone (PES): Base polymer for the membrane.

- N-methyl-2-pyrrolidone (NMP): Solvent for the dope solution.

- Dopamine Hydrochloride: Additive for blending.

- Tris-HCl Buffer (10 mM, pH 8.5): For the post-casting polymerization step.

Step-by-Step Procedure:

- Dope Solution Preparation: Prepare a standard PES dope solution in NMP (e.g., 17.5 wt%). Add dopamine hydrochloride to the dope solution and stir until completely dissolved. Dopamine concentrations of 0.5 to 4 wt% (relative to the total solution) have been effectively used [20].

- Membrane Casting: Cast the homogeneous dope solution onto a clean glass plate using a doctor blade and immediately immerse it into a purified water coagulation bath. This initiates phase separation, forming the solid membrane structure with embedded dopamine.

- Post-Casting Polymerization: Remove the nascent membrane from the water bath and immerse it in a Tris-HCl buffer solution (pH 8.5) for 5 to 36 hours [20]. This step polymerizes the embedded dopamine, forming a stable, hydrophilic PDA network within the membrane matrix.

- Post-treatment: Rinse the final membrane thoroughly with water to remove residual buffer salts and any unreacted compounds.

The experimental workflow for these two primary methods is summarized in the following diagram:

The Scientist's Toolkit: Key Reagents and Materials

Table 3: Essential Research Reagents for PDA-Based Hydrophilization

| Reagent/Material | Function/Description | Typical Usage in Protocols |

|---|---|---|

| Dopamine Hydrochloride | The essential monomer precursor that self-polymerizes to form polydopamine [16]. | Standard coating solution: 2 mg/mL in Tris buffer, pH 8.5 [20]. |

| Tris-HCl Buffer | A weak alkaline buffer (pH ~8.5) that dissolves dopamine and initiates its autoxidation and polymerization [16] [17]. | Used at 10 mM concentration as the standard solvent for dip-coating [20]. |

| Polyethersulfone (PES) | A common hydrophobic polymer used for manufacturing ultrafiltration and microfiltration membranes [5] [20]. | Serves as the primary substrate for modification; typically used at 15-20 wt% in dope solutions [20]. |

| N-methyl-2-pyrrolidone (NMP) | A polar aprotic solvent used to dissolve polymer resins like PES for membrane casting [20]. | The primary solvent in the dope solution for two-step modification protocols [20]. |

The hydrophilic character of polydopamine is not the result of a single functional group but a synergistic effect orchestrated by the catechol, amine, and quinone units. The catechol groups provide a powerful hydrogen-bonding capability, the amines increase surface energy and enable cross-linking, and the quinones enhance polarity and provide reactive sites for further customization. As demonstrated by the provided protocols and quantitative data, harnessing the chemistry of these groups allows researchers to reliably transform hydrophobic membrane surfaces into highly hydrophilic ones, leading to tangible gains in water flux and antifouling performance. This fundamental understanding is crucial for the rational design of next-generation, high-performance separation membranes.

Polydopamine (PDA), a bioinspired polymer mimicking mussel adhesion proteins, has emerged as a revolutionary surface modification tool in membrane technology. Since its introduction for surface functionalization in 2007, PDA has garnered significant scientific interest due to its exceptional universal adhesion properties, which enable robust coating formation on virtually any substrate surface [22] [23]. This adhesive capability arises from PDA's complex chemical structure rich in catechol, amine, and imine functional groups, which facilitate diverse interaction mechanisms including hydrogen bonding, metal coordination, π-π stacking, and covalent bonding [12] [22].

In the context of membrane modification, PDA coatings offer a versatile strategy for enhancing surface hydrophilicity, improving antifouling resistance, and introducing functional groups for further modification. The technology is particularly valuable for addressing the inherent hydrophobicity of common polymeric membrane materials such as polyethersulfone (PES), polyvinylidene fluoride (PVDF), polypropylene (PP), and polysulfone (PSf), which are prone to organic fouling during operation [24] [23]. This application note systematically examines PDA compatibility with these diverse membrane substrates, providing structured quantitative data, detailed experimental protocols, and practical guidance for researchers pursuing membrane hydrophilicity enhancement through PDA coating.

PDA Compatibility and Performance Across Membrane Substrates

Extensive research has demonstrated PDA's successful deposition on numerous polymeric membrane substrates, significantly altering their surface properties and separation performance. The following sections and comparative tables summarize key findings regarding PDA compatibility and its effects on different membrane materials.

Table 1: PDA Coating Compatibility and Performance on Different Membrane Substrates

| Membrane Substrate | Hydrophilicity Improvement (Contact Angle Reduction) | Key Demonstrated Benefits | Research Context & Notes |

|---|---|---|---|

| Polyethersulfone (PES) | ~20-30° reduction [24] | Enhanced hydrophilicity, improved antifouling properties, functionalization platform [21] [25] | Often modified via blending with PDA-coated nanoparticles (e.g., MoS₂@PDA) to improve compatibility and dye separation [25]. |

| Polyvinylidene Fluoride (PVDF) | ~20-30° reduction [24] | Improved antifouling properties, underwater superoleophobicity for oil/water separation [12] [24] | Successfully modified via one-step non-solvent induced phase separation (NIPS) with PDA [24]. |

| Polypropylene (PP) | Significant improvement demonstrated [23] | Excellent antifouling membranes achieved via PDA co-deposition [23] | Rapid deposition achieved using CuSO₄/H₂O₂ as an inducer (40 min) [23]. |

| Polysulfone (PSf) | High improvement potential [21] | Enhanced hydrophilicity and antifouling ability [21] | Recognized as a candidate for PDA modification, though specific contact angle data less cited than PES/PVDF. |

| Polyethylene (PE) | High improvement potential [23] | Effective surface hydrophilic modification [23] | Successfully modified via traditional dopamine deposition [23]. |

| Polytetrafluoroethylene (PTFE) | ~20-30° reduction [24] | Enhanced surface hydrophilicity [24] [23] | Notable for being modified despite its extreme hydrophobicity and chemical resistance. |

Table 2: Water Flux and Separation Performance Changes Post-PDA Modification

| Membrane Substrate | Pure Water Flux Change | Sepunction Performance | Application Context |

|---|---|---|---|

| PVDF Ultrafiltration | ~40% reduction reported after traditional PDA coating [24] | High separation efficiency (>99.9%) for oil/water mixtures [12] | Trade-off exists between hydrophilicity and permeability; blend membranes avoid pore blockage [24]. |

| PES Tight Ultrafiltration | 42.0 L m⁻² h⁻¹ bar⁻¹ (with MoS₂@PDA) [25] | Excellent dye rejection (98.17-99.88% for Janus Green B) [25] | MWCO can be finely tuned by adjusting MoS₂@PDA concentration [25]. |

| PP Microfiltration | Significant increase from 605 to 5720 LMH (with PDA/PEI & TiO₂) [21] | Enhanced performance in dynamic protein filtration [21] | Demonstrates performance enhancement possible with optimized PDA co-deposition. |

The universal adhesion of PDA stems from its multifaceted interaction mechanisms with substrate surfaces. As illustrated in the diagram below, these interactions include covalent bonding, metal coordination, hydrogen bonding, and π-π stacking, which collectively enable strong adhesion to diverse membrane materials.

Experimental Protocols for PDA Deposition on Membrane Substrates

Traditional Deposition Method

The conventional approach for PDA deposition involves simple immersion of membrane substrates in an alkaline dopamine solution under aerobic conditions [23].

Materials Required:

- Dopamine hydrochloride

- Tris(hydroxymethyl)aminomethane (Tris-base)

- Hydrochloric acid (HCl) for pH adjustment

- Deionized water

- Target membrane substrates (PES, PVDF, PP, PSf)

- Basic laboratory equipment: beakers, magnetic stirrer, pH meter

Step-by-Step Procedure:

- Solution Preparation: Prepare a 10 mM Tris-HCl buffer solution (pH ≈ 8.5) by dissolving Tris-base in deionized water and adjusting pH with HCl.

- Dopamine Solution: Dissolve dopamine hydrochloride in the Tris-Huffer at a concentration of 2 mg/mL under constant stirring.

- Membrane Pre-treatment: Cut membrane samples to desired size and pre-wet with ethanol/water if highly hydrophobic. Rinse thoroughly with deionized water.

- Deposition Process: Immerse membrane substrates completely in the dopamine solution. Ensure full surface exposure by separating stacked membranes.

- Reaction Conditions: Allow reaction to proceed for 24-48 hours at room temperature (25-35°C) with continuous gentle agitation to ensure oxygen supply.

- Post-treatment: Remove membranes from solution and rinse thoroughly with deionized water to remove loosely adhered PDA particles.

- Drying: Air-dry the modified membranes at room temperature or in a desiccator before characterization and use.

Key Considerations: This method produces homogeneous coatings but requires extended deposition times (24-48 hours). Coating thickness increases with deposition time and dopamine concentration [23].

Oxidant-Induced Rapid Deposition

To address the lengthy deposition time of traditional methods, oxidants can be incorporated to accelerate PDA polymerization.

Materials Required:

- Dopamine hydrochloride

- Copper sulfate (CuSO₄) and hydrogen peroxide (H₂O₂) as oxidation system

- Or alternative oxidants: ammonium persulfate, sodium periodate

- Deionized water

- Target membrane substrates

- Basic laboratory equipment

Step-by-Step Procedure:

- Oxidant Solution: Prepare an aqueous solution containing both dopamine hydrochloride (2 mg/mL) and CuSO₄/H₂O₂ (typically 0.01 M CuSO₄ and 0.1 M H₂O₂).

- Membrane Preparation: Cut and pre-wet membrane samples as described in Section 3.1.

- Deposition Process: Immerse membranes in the dopamine/oxidant solution at room temperature.

- Reaction Time: Allow reaction to proceed for significantly reduced time (40 minutes to 4 hours depending on desired coating thickness).

- Rinsing and Drying: Remove membranes, rinse thoroughly with deionized water, and air-dry.

Key Considerations: This method reduces deposition time from days to hours while maintaining coating quality. The added Cu²⁺ may impart additional antibacterial properties to the modified membranes [23].

One-Step Phase Inversion with PDA Integration

For PVDF and PES membranes, PDA can be incorporated directly during membrane fabrication via non-solvent induced phase separation (NIPS).

Materials Required:

- Polymer resin (PVDF or PES)

- Dopamine hydrochloride

- Solvent (typically N,N-Dimethylacetamide - DMAc)

- Sodium hypochlorite (NaClO) solution as oxidative coagulant

- Basic laboratory equipment: casting knife, glass plates, coagulation bath

Step-by-Step Procedure:

- Casting Solution: Dissolve PVDF or PES polymer (15-18 wt%) and dopamine hydrochloride (0.5-1.0 wt%) in DMAc solvent. Stir until completely dissolved.

- Membrane Casting: Cast the polymer-dopamine solution onto a non-woven fabric support using a casting knife with controlled gap thickness (200 μm).

- Phase Inversion: Immerse the cast film immediately into a coagulation bath containing dilute NaClO solution (0.5-1.0 g/L).

- PDA Formation: During phase separation, NaClO oxidizes dopamine to form PDA integrated within the membrane matrix.

- Membrane Post-treatment: Keep membranes in deionized water for 24 hours to remove residual solvent, then air-dry.

Key Considerations: This approach achieves uniform PDA distribution throughout membrane cross-section without causing pore blockage, effectively enhancing hydrophilicity while maintaining water flux [24].

The following workflow diagram illustrates the key methodological pathways for applying PDA coatings to membrane substrates, highlighting the procedural steps and decision points for each approach.

The Scientist's Toolkit: Essential Research Reagents

Table 3: Essential Reagents for PDA Membrane Modification Research

| Reagent/Chemical | Function/Application | Research Notes |

|---|---|---|

| Dopamine Hydrochloride | PDA precursor monomer | Storage: -20°C, protected from light and moisture; primary reagent for all PDA coating methods [24] [23]. |

| Tris(hydroxymethyl)aminomethane (Tris-base) | Buffer component (pH 8.5) for traditional deposition | Creates optimal alkaline environment for dopamine oxidation and polymerization [12] [23]. |

| Copper Sulfate (CuSO₄)/Hydrogen Peroxide (H₂O₂) | Oxidation system for rapid deposition | Significantly reduces coating time; Cu²⁺ may impart antibacterial properties [23]. |

| Sodium Hypochlorite (NaClO) | Oxidizing coagulant for one-step phase inversion | Enables PDA formation during membrane fabrication; concentration typically 0.5-1.0 g/L [24]. |

| Polyvinylpyrrolidone (PVP) | Pore-forming agent, co-deposition polymer | Often used in casting solutions; can be co-deposited with PDA to enhance anti-fouling properties [25] [26]. |

| Polyethyleneimine (PEI) | Co-deposition polymer for enhanced adhesion | Improves PDA adhesion and enables introduction of additional nanoparticles (e.g., TiO₂) [12] [21]. |

Polydopamine demonstrates remarkable compatibility with diverse membrane substrates including PES, PVDF, PP, and PSf, confirming its status as a universal modification platform for membrane hydrophilicity enhancement. The experimental protocols and data summarized in this application note provide researchers with practical guidance for implementing PDA coating technologies across various membrane systems. While deposition parameters require optimization for specific applications, the fundamental adhesion mechanisms remain consistent across different substrates, making PDA an exceptionally versatile tool for membrane surface engineering. Future research directions should focus on further reducing processing times, enhancing coating durability under harsh operational conditions, and exploring synergistic effects of PDA with complementary modification agents for advanced membrane functionality.

The Role of Surface Energy and Wettability in Hydrophilic Performance

Surface energy and wettability are fundamental interfacial properties that directly dictate the performance of materials in aqueous environments. In fields ranging from water treatment to biomedical implants, achieving and controlling hydrophilicity is a critical design objective. Hydrophilic surfaces, characterized by high surface energy and low water contact angles, promote water spreading, enhance permeation, and mitigate fouling. Polydopamine (PDA), a bioinspired polymer, has emerged as a versatile and effective coating for rendering diverse material surfaces hydrophilic. This application note details the quantitative effects of PDA coatings on surface wettability and provides standardized protocols for implementing and characterizing these modifications within a research context focused on membrane science.

Quantitative Data on PDA-Induced Hydrophilicity

The following tables consolidate experimental data from recent studies on PDA-mediated hydrophilic modification of various polymeric substrates.

Table 1: Water Contact Angle (WCA) Reduction on Polymer Surfaces via PDA Coating

| Substrate Material | Original WCA (°) | PDA-Modified WCA (°) | Modification Conditions | Citation |

|---|---|---|---|---|

| Poly(vinylidene fluoride) (PVDF) Membrane | 118.0 ± 1.5 | 53.0 ± 2.3 | 2 g/L DA, Tris-HCl pH 8.5 [27] | |

| Poly(vinyl chloride) (PVC) Film | ~85 (est.) | 43.2 | Co-deposition with HBPL (DA/HBPL mass ratio 1:1) [11] | |

| Poly(dimethylsiloxane) (PDMS) | ~110 (est.) | ~60 (est.) | 2 mg/mL DA, 10 mM Tris-HCl, pH 8.0, 6 hr [28] | |

| Polytetrafluoroethylene (PTFE) Membrane | ~140 (est.) | ~40 (after 200-cycle TiO₂ ALD on PDA primer) | PDA priming followed by Atomic Layer Deposition [29] |

Table 2: Impact of Post-Treatment and Coating Parameters on Hydrophilicity

| Factor Studied | Impact on Water Contact Angle (WCA) & Hydrophilicity | Citation |

|---|---|---|

| Thermal Post-Treatment (121°C for 24 hr on PDA-coated Ti) | Increased WCA vs. pristine PDA, but enhanced cell proliferation. Associated with increased surface quinone groups. [30] | |

| Dopamine Concentration (for PVDF modification) | Optimized at 1.65 g/L via RSM, achieving a WCA of 33.9°. [27] | |

| Co-deposition with Additives (Hyperbranched Polylysine - HBPL) | Significantly enhanced deposition and stability; greatest WCA reduction achieved at a DA/HBPL mass ratio of 1:1. [11] |

Experimental Protocols

Standard Protocol for PDA Coating of Polymeric Membranes

This protocol is adapted for modifying PVDF membranes for enhanced hydrophilicity in water treatment applications [27].

Research Reagent Solutions:

| Reagent/Solution | Function |

|---|---|

| Dopamine Hydrochloride | Monomer for PDA formation. |

| Tris-Hydroxymethyl Aminomethane (Tris-HCl) Buffer (10 mM, pH 8.5) | Provides alkaline environment for dopamine oxidation and polymerization. |

| Isopropyl Alcohol (IPA) | Pre-treatment solvent to remove impurities and wet membrane pores. |

| Deionized (DI) Water | Solvent and rinsing agent. |

Step-by-Step Workflow:

Membrane Pre-treatment:

- Immerse the pristine PVDF membrane in isopropyl alcohol for 2 hours to remove impurities and wet the pores.

- Subsequently, soak the membrane in DI water for 12 hours. Store the hydrated membrane until use.

Dopamine Solution Preparation:

- Prepare a 10 mM Tris-HCl buffer solution at pH 8.5.

- Dissolve dopamine hydrochloride in the Tris-HCl buffer to a concentration of 1.65 g/L (optimized value). Filter the solution if necessary.

PDA Deposition Coating:

- Immerse the pre-treated and wetted PVDF membrane in the freshly prepared dopamine solution.

- Place the container on an orbital shaker and agitate at 120 rpm for 4.5 hours at room temperature (25°C). The solution will gradually darken, turning from clear to brown or black.

Post-Coating Processing:

- Remove the membrane from the dopamine solution and rinse thoroughly with DI water to remove loosely adhered PDA particles.

- Dry the modified membrane in a vacuum drying oven.

- The resulting product is the PVDF/PDA membrane, ready for characterization and use.

Protocol for Co-deposition of PDA with Hyperbranched Polylysine (HBPL)

This protocol enhances the stability and hydrophilicity of PVC surfaces [11].

Workflow Diagram: Co-deposition of PDA and HBPL

Key Steps:

- Synthesize HBPL via melt phase polycondensation of L-lysine hydrochloride [11].

- Prepare a co-deposition solution containing both dopamine hydrochloride and HBPL at a mass ratio of approximately 1:1 in a Tris-HCl buffer (pH 8.5).

- Immerse the PVC substrate in the mixed solution to allow simultaneous deposition and cross-linking.

- Proceed with rinsing and drying as in the standard protocol. The resulting PVC-pDA/HBPL film exhibits superior hydrophilicity and coating stability compared to PDA alone.

Protocol for Contact Angle Measurement: Sessile Drop vs. Captive Bubble

Accurate measurement of wettability is critical. The captive bubble method is recommended for reliable results on hydrophilic membranes [31].

Diagram: Contact Angle Measurement Methods

Procedure for Captive Bubble Method [31]:

- Sample Preparation: Mount the membrane sample with the active layer facing down in a custom-made cell filled with ultrapure water.

- Bubble Formation: Use a microsyringe to introduce a small air bubble (typically 1-2 µL) onto the membrane surface from below.

- Image Capture & Analysis: Capture an image of the captive bubble immediately after formation. Measure the contact angle formed between the membrane surface and the bubble's tangent using image analysis software. Report the average of multiple measurements.

Mechanisms of Hydrophilicity Enhancement

PDA enhances surface hydrophilicity through a combination of chemical and physical mechanisms. The following diagram illustrates the intermolecular interactions and subsequent nucleation behavior that underpin this performance enhancement.

Diagram: Mechanisms of PDA-Induced Hydrophilicity and Mineralization

- Chemical Composition: The abundant presence of catechol, amine, and imine functional groups on the polymerized PDA surface acts as sites for strong hydrogen bonding with water molecules, significantly increasing the surface's affinity for water [11] [7].

- Physical Microstructure: PDA deposition often increases surface roughness, which can further amplify hydrophilicity by increasing the effective surface area available for water contact, as characterized by techniques like Atomic Force Microscopy (AFM) [11] [27].

- Impact on Mineralization: The charged groups on PDA (e.g., catechol) strongly interact with calcium ions (Ca²⁺) in solutions like simulated body fluid (SBF). This interaction changes the nucleation mode of calcium phosphate from a pure "islanding" (Volmer-Weber) mode on uncoated surfaces to a mixed "islanding" and planar (Stranski-Krastanov) mode on PDA-coated surfaces, leading to a more bonded and uniform mineral layer [32].

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for PDA Coating

| Reagent / Material | Function / Role in Hydrophilic Modification |

|---|---|

| Dopamine Hydrochloride | The essential precursor monomer that undergoes oxidative self-polymerization to form the adherent polydopamine (PDA) coating. [11] [27] [28] |

| Tris-HCl Buffer (pH 8.5) | The standard alkaline buffer system that initiates and controls the oxidation and polymerization of dopamine. [27] [28] |

| Hyperbranched Polylysine (HBPL) | A polymeric additive that, when co-deposited with DA, enhances the deposition mass, stability, and hydrophilicity of the resulting coating via covalent and non-covalent interactions. [11] |

| Polyvinyl Alcohol (PVA) | A hydrophilic polymer often used in composite transition layers (e.g., with PDA and GO) to improve the adhesion and mechanical properties of subsequent coatings like hydroxyapatite. [33] |

| Graphene Oxide (GO) | A nanomaterial used in composite coatings; its oxygen-containing functional groups contribute to hydrophilicity and can be reinforced by PDA adhesion. [33] |

Practical Implementation: Coating Methods and Biomedical Applications of Polydopamine-Modified Membranes

In the broader context of research on polydopamine (PDA) coatings for membrane hydrophilicity enhancement, the dip-coating process stands out for its simplicity and effectiveness. This protocol details the optimization of two critical parameters—dopamine concentration and immersion time—to consistently produce high-performance PDA coatings on membrane substrates. PDA, a bioinspired polymer, can form uniform, adhesive coatings on virtually any substrate surface via a simple oxidative self-polymerization process in a weak alkaline aqueous environment [23] [34]. The primary goal of this hydrophilic modification is to mitigate membrane fouling by creating a highly hydrated layer that prevents the adhesion of organic contaminants, such as proteins, thereby improving flux and reducing cleaning frequency in applications like water treatment and biomedical separation [35] [23]. This document provides a standardized, optimized methodology for researchers and development professionals to achieve reproducible and effective PDA surface modifications.

Fundamental Principles of Polydopamine Coating

Polydopamine coating formation is inspired by the adhesive proteins found in mussels [34]. The process involves the oxidative self-polymerization of dopamine in a weak alkaline environment (typically pH = 8.5), leading to the formation of a thin, dark brown PDA film on the submerged substrate [23] [34]. The polymerization can proceed via two main pathways: covalent oxidative polymerization and physical self-assembly [36]. The former involves the oxidation of dopamine to dopaminequinone, followed by cyclization and polymerization to form 5,6-dihydroxyindole (DHI) units. The latter involves non-covalent interactions, such as hydrogen bonding and π-π stacking, among dopamine and its oxidized derivatives to form supramolecular assemblies [36]. The exceptional adhesive properties of PDA stem from the diverse interactions it can form with substrate surfaces, including hydrogen bonding, electrostatic interactions, π-π stacking, coordinative bonding, and covalent bonds [37]. Furthermore, the abundant catechol and amine functional groups on PDA provide active sites for further surface functionalization, allowing for the tailoring of membrane surface properties [36] [12].

Optimizing Coating Parameters: Key Data

The quality, thickness, and performance of the resulting PDA coating are highly dependent on the deposition conditions. The following tables summarize the effects and optimal ranges for key parameters, specifically dopamine hydrochloride (DA·HCl) concentration and immersion time, based on current literature.

Table 1: Effect of Dopamine Hydrochloride Concentration on Coating Properties

| DA·HCl Concentration (mg/mL) | Coating Characteristics | Impact on Membrane Hydrophilicity & Performance |

|---|---|---|

| 0.1 - 0.5 [12] | Thin, potentially uneven coating. | Moderate improvement in hydrophilicity; may be insufficient for long-term fouling resistance. |

| 1.0 - 2.0 [37] [35] | Standard Range: Robust and uniform films. Optimal for initiating hierarchical structures when combined with other agents (e.g., PAMAM) [37]. | Significant contact angle reduction; greatly enhanced protein fouling resistance and water flux [35]. |

| > 2.0 | Risk of excessive particle aggregation and pore blockage [35]. | Potential decline in pure water flux due to pore narrowing or sealing [35]. |

Table 2: Effect of Immersion Time on Coating Properties

| Immersion Time (Hours) | Coating Characteristics | Recommendation and Notes |

|---|---|---|

| 0.5 - 2 | Rapid initial growth; thin nanoscale film. | For a quick, base-layer coating. Film growth is most efficient in the first 2 hours [34]. |

| 4 - 6 | Increased thickness and surface coverage. | A balance between process time and coating robustness. |

| 12 - 24 [37] [35] [12] | Commonly Used Range: Ensures a thick, uniform, and stable coating. | Necessary for achieving superhydrophobic properties after post-modification [12]. Co-deposition with polymers like PEI can reduce required time [37]. |

| > 24 | Diminishing returns; possible instability from over-saturation [23] [34]. | Not typically recommended due to inefficiency and potential for heterogeneous coatings. |

Detailed Experimental Protocol

Reagent Setup and Solution Preparation

- Tris-HCl Buffer (10 mM, pH 8.5): Dissolve 1.57 g of tris(hydroxymethyl)aminomethane (TRIS, ≥99.8%) in 1 L of distilled water. Measure the pH with a calibrated pH meter. Adjust the pH to 8.5 ± 0.1 by adding drops of concentrated hydrochloric acid (HCl, 32%) under gentle stirring [34].

- Dopamine Hydrochloride Stock Solution (2 mg/mL): Weigh 200 mg of dopamine hydrochloride (DA·HCl, ≥98%) powder. Immediately before the coating process, dissolve the powder in 100 mL of the freshly prepared Tris-HCl buffer. Agitate gently until fully dissolved. Note: The solution will begin clear and gradually transition to light brown, indicating the start of polymerization.

Optimized Dip-Coating Procedure

- Substrate Pre-treatment: Cut the membrane substrate to the desired size. Clean the substrate by sonication in isopropyl alcohol (IPA) or ethanol for 10 minutes, followed by rinsing with copious amounts of distilled water to remove any organic residues [34]. Allow the substrate to air dry completely.

- Coating Initiation: Immerse the pre-treated substrate completely in the freshly prepared dopamine solution (2 mg/mL in Tris-Huffer, pH 8.5). Ensure the substrate is fully submerged and not trapped with air bubbles.

- Polymerization Reaction: Allow the reaction to proceed for a duration of 12-24 hours at room temperature with mild agitation (e.g., on a laboratory shaker or rocker). Agitation ensures uniform oxygen supply and prevents the settling of PDA aggregates on the membrane surface.

- Post-Coating Processing:

- Carefully remove the coated substrate from the solution using tweezers.

- Rinse the substrate thoroughly with distilled water to remove any loosely adhered PDA particles.

- Sonicate the coated membrane in distilled water for 10 minutes to further enhance coating uniformity and remove aggregates [34].

- Dry the modified membrane overnight at room temperature or in a vacuum oven at low temperature (e.g., 40°C).

Advanced Technique: O₂ Backflow for Ultrafiltration Membranes

For ultrafiltration (UF) membranes where pore penetration and narrowing are significant concerns, the following modified protocol is recommended to achieve a surface-selective coating [35]:

- Setup: Place the membrane in a specialized filtration cell. Introduce the aqueous dopamine solution from the active (selective) side of the membrane.

- Gas Supply: Simultaneously, supply pure oxygen (O₂) gas from the porous backside of the membrane. This creates a physical barrier that limits the penetration of dopamine monomers into the pore structure.

- Reaction: The O₂ backflow enhances the oxidation kinetics of dopamine at the membrane surface, promoting faster and more localized polymerization. This results in a PDA coating that primarily modifies the surface without severely compromising the membrane flux through pore blockage [35].

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagent Solutions

| Reagent / Material | Function in Protocol | Notes for Researchers |

|---|---|---|

| Dopamine Hydrochloride (DA·HCl) | The fundamental monomer for PDA film formation. | Critical: Hygroscopic and air-sensitive. Store in a desiccator at -20°C. Use immediately after weighing. |

| Tris(hydroxymethyl)aminomethane (TRIS) | Provides a weak alkaline buffer (pH 8.5) necessary for dopamine oxidation and self-polymerization [34]. | Ensure high purity (≥99.8%). Solution pH is critical and must be verified before adding dopamine. |

| Hydrochloric Acid (HCl, 32%) | Used for fine adjustment of the Tris buffer to the target pH of 8.5. | Handle with care using appropriate personal protective equipment (PPE) in a fume hood. |

| Polyamidoamine (PAMAM) Dendrimer | An additive for co-deposition to create thicker, more stable PDA coatings with increased surface roughness [37]. | A DA:PAMAM weight ratio of 1:1 has been shown to produce high-quality coatings [37]. |

| Oxygen (O₂) Gas Cylinder | Used in the advanced O₂ backflow technique to accelerate polymerization and prevent pore penetration in UF membranes [35]. | Provides a cleaner and faster alternative to chemical oxidants like CuSO₄/H₂O₂. |

Characterization and Performance Validation

To confirm the success of the dip-coating process, the following characterizations are recommended:

- Surface Hydrophilicity: Measure the static water contact angle. A successful coating will show a significant decrease (increase in hydrophilicity) compared to the unmodified membrane [35].

- Chemical Composition: Use X-ray Photoelectron Spectroscopy (XPS) to detect the presence of nitrogen (N), which is a key element in PDA and confirms surface deposition [35].

- Coating Morphology and Thickness: Analyze surface morphology using Atomic Force Microscopy (AFM) or Scanning Electron Microscopy (SEM). Determine coating thickness via ellipsometry or profilometry [34].

- Fouling Resistance Test: Conduct dynamic protein filtration tests using a model foulant like Bovine Serum Albumin (BSA). A successful PDA coating will demonstrate higher flux recovery ratios and lower irreversible fouling compared to the pristine membrane [35].

Achieving sustainable membrane hydrophilicity is a critical challenge in the design of advanced materials for biomedical and separation applications. Polydopamine (PDA), a bioinspired polymer mimicking mussel adhesion proteins, has emerged as a versatile tool for surface modification due to its strong adhesion properties and ability to enhance surface wettability [38]. Two principal methodological approaches—blending and surface polymerization—enable the integration of PDA and its composites onto various polymer substrates. The selection between these approaches significantly influences the structural integrity, functional performance, and operational stability of the modified membranes. This application note provides a detailed comparative analysis of these two strategies, supported by quantitative data and standardized experimental protocols, to guide researchers in selecting and implementing the optimal modification technique for specific research and development objectives.

Comparative Analysis of Modification Approaches

The fundamental distinction between blending and surface polymerization lies in the stage at which the modifier is introduced during membrane fabrication and modification.

Surface Polymerization is a post-fabrication technique where a pre-formed membrane is immersed in an aqueous dopamine solution. Under weak alkaline conditions (typically Tris-HCl buffer, pH = 8.5), dopamine undergoes oxidative self-polymerization, depositing a thin PDA coating onto the membrane surface and within its pores [39] [27] [38]. This method is renowned for its simplicity and substrate-independent adhesion, making it applicable to a wide range of materials including polyvinylidene fluoride (PVDF), polytetrafluoroethylene (PTFE), and polyvinyl chloride (PVC) [27] [11] [38]. A key advantage is the introduction of a rich surface chemistry that allows for further secondary reactions and functionalization [11] [38].

Blending involves the direct incorporation of PDA particles, its monomers, or co-deposition components into the polymer dope solution prior to membrane formation (e.g., via phase inversion) [11]. This method embeds the modifier within the membrane matrix, potentially leading to more uniform distribution and enhanced structural stability. Co-deposition blending, where dopamine is mixed with other polymers like hyperbranched polylysine (HBPL) in the coating solution, has been shown to significantly improve the deposition rate, stability, and final performance of the coating [11].

Table 1: Comparison of Blending and Surface Polymerization Approaches for Polydopamine Modification

| Feature | Surface Polymerization | Blending |

|---|---|---|

| Process Definition | Post-fabrication coating via immersion in dopamine solution [27] [38] | Pre-fabrication incorporation of modifier into polymer dope solution [11] |

| Key Mechanism | Oxidative self-polymerization and deposition on substrate surface [38] | Entrapment within the membrane matrix during formation |

| Typical Coating Thickness | Tunable nanoscale layers (e.g., ~18 nm in 15 min with microwave induction [38]) | Dependent on initial concentration in dope solution |

| Hydrophilicity Enhancement | Significant; contact angle reduction from >100° to ~53°–43° [27] [11] | Enhanced, with improved stability |

| Adhesion Stability | Good, though can be unstable in strong alkalis [11]; enhanced with co-deposition or oxidants [38] | Excellent, due to mechanical anchoring within the matrix |

| Experimental Scalability | Highly scalable for various shapes and sizes; simple equipment [38] | Scalable, tied to membrane fabrication process |

| Suitability for Secondary Reactions | Excellent; surface-rich catechol/amine groups allow for further grafting [11] [38] | Limited, as functional groups are less accessible |

Quantitative Performance Data

The efficacy of PDA modification is quantitatively assessed through metrics such as hydrophilicity (water contact angle), permeability (water flux), and antibacterial performance. The methodology, particularly the use of co-deposition in surface polymerization, directly impacts these outcomes.

Table 2: Quantitative Performance Metrics of Select PDA-Modified Membranes

| Substrate | Modification Approach & Details | Water Contact Angle (°) | Pure Water Flux | Key Performance Outcomes |

|---|---|---|---|---|

| PVDF [27] | Surface Polymerization (DA: 1.65 g/L, 4.5 h) | 69° → 33.9° | Higher than pristine membrane | Excellent antifouling ability; Enhanced biodiversity in MBR |

| PVC [11] | Surface Polymerization with Co-deposition (DA/HBPL mass ratio 1:1) | Reduced to 43.2° | Not Specified | Superior stability in strong acid/alkali vs. PDA alone |

| PTFE [39] | Surface Polymerization with ZnO-NPs (PDA as adhesive layer) | Not Specified | Superior fluid permeability | Robust antibacterial efficacy against E. faecalis and S. mutans |

| PLGA Nanoparticles [40] | Surface Polymerization (Prime-coating with PDA) | Not Applicable | Not Applicable | Functionalized with ligands; No cytotoxicity; Expected cellular interactions |

Detailed Experimental Protocols

Protocol 1: Surface Polymerization via Dip-Coating

This is the standard method for depositing a PDA coating on a pre-formed membrane [27] [38].

Materials:

- Dopamine hydrochloride

- Tris(hydroxymethyl)aminomethane (Tris)

- Hydrochloric acid (HCl)

- Deionized (DI) water

- Substrate membrane (e.g., PVDF, PTFE, PVC)

Procedure:

- Solution Preparation: Prepare a 10 mM Tris-HCl buffer solution (pH = 8.5) by dissolving Tris in DI water and adjusting the pH with HCl.

- Dopamine Solution: Dissolve dopamine hydrochloride in the Tris-HCl buffer to a concentration of 1.65 - 2.0 g/L [27]. The solution will appear clear initially.

- Substrate Pre-treatment: Immerse the substrate membrane in isopropyl alcohol for 2 hours to remove impurities, then soak in DI water for 12 hours [27].

- Polymerization Reaction: Immerse the pre-treated membrane in the dopamine solution. Keep the reaction vessel open to air and agitate on a shaker (e.g., 120 rpm) at room temperature for a specified duration (e.g., 4.5 hours [27]).

- Membrane Retrieval and Washing: After the reaction, remove the membrane from the solution and rinse thoroughly with DI water to remove any loosely adhered particles.

- Drying: Dry the modified membrane in a vacuum drying oven at room temperature or a specified low temperature (e.g., 25°C [27]) until constant weight is achieved.

Protocol 2: Co-deposition Blending for Enhanced Coating

This protocol details the simultaneous deposition of PDA with another polymer, such as hyperbranched polylysine (HBPL), to create a composite coating with enhanced properties [11].

Materials:

- Dopamine hydrochloride

- Hyperbranched polylysine (HBPL)

- Tris-HCl buffer (10 mM, pH = 8.5)

- DI water

- Substrate membrane (e.g., PVC)

Procedure:

- Coating Solution Preparation: Dissolve dopamine hydrochloride and HBPL in Tris-HCl buffer at a mass ratio of approximately 1:1 (DA/HBPL) [11].

- Substrate Immersion: Immerse the pre-cleaned substrate membrane into the co-deposition solution.

- Reaction and Deposition: Allow the reaction to proceed under agitation at room temperature for the desired coating time. The presence of HBPL accelerates deposition and increases the coating mass.

- Washing and Drying: Retrieve the membrane, rinse with DI water, and dry under vacuum.

Protocol 3: Characterization of Hydrophilicity and Permeability

Water Contact Angle Measurement: [27] [11]

- Use a contact angle goniometer for measurement.

- Cut the membrane sample into strips (approx. 5 cm x 1 cm).

- Place a deionized water droplet (~2 µL) on the membrane surface.

- Measure the static contact angle at at least five different locations on the sample surface and calculate the average value.

Pure Water Flux Measurement: [27]

- Assemble a membrane module with a known effective filtration area (e.g., 60.5 cm²).

- Pre-pressurize the membrane with deionized water at 0.10 MPa for 30 minutes to compact and wet it thoroughly.

- After the flux stabilizes, measure the volume of water permeated over a specific time under a constant applied pressure.

- Calculate the flux (J) using the formula: ( J = V / (A \times t) ), where ( V ) is the permeate volume (mL), ( A ) is the membrane area (cm²), and ( t ) is the collection time (hours).

Workflow and Performance Relationship Visualization

The following diagrams illustrate the procedural workflow for the two modification approaches and the logical relationship between process parameters and final membrane performance.

Diagram 1: Workflows for two modification approaches.

Diagram 2: Parameter effects on coating properties and performance.

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for Polydopamine-Based Membrane Modification

| Reagent/Material | Function/Application | Key Characteristics & Notes |

|---|---|---|

| Dopamine Hydrochloride [39] [27] [11] | Precursor for polydopamine coating. | Undergoes self-polymerization in weak alkaline conditions (pH ~8.5) to form adherent coatings. |

| Tris-HCl Buffer [39] [27] | Provides a stable alkaline environment (pH 8.5) for dopamine polymerization. | Standard concentration is 10 mM. |

| Hyperbranched Polylysine (HBPL) [11] | Co-deposition agent to enhance coating mass, stability, and hydrophilicity. | Used at ~1:1 mass ratio with dopamine; provides abundant amine groups. |

| Zinc Oxide Nanoparticles (ZnO-NPs) [39] | Functional nanomaterial for imparting antibacterial properties. | Adhered to membrane surface using PDA as an intermediate adhesive layer. |

| Polyvinylidene Fluoride (PVDF) Membrane [27] | Common hydrophobic substrate for modification. | Requires pre-treatment with alcohol to wet pores before PDA coating. |

| Ammonium Persulfate / Sodium Periodate [38] | Chemical oxidants to induce rapid dopamine polymerization. | Significantly reduces deposition time compared to air oxidation. |

Surface modification of polymeric membranes is a critical step in enhancing their performance for various separation and biomedical applications. Among the many coating materials, polydopamine (PDA) has emerged as a premier bio-inspired polymer for membrane surface engineering. Derived from the oxidative self-polymerization of dopamine, PDA exhibits exceptional adhesion properties across diverse substrates, high biocompatibility, and the ability to significantly improve membrane hydrophilicity and antifouling resistance [23]. Traditional immersion polymerization, while widely used, presents limitations including lengthy processing times, inconsistent coating morphology, and challenges in controlling deposition uniformity [41] [23].

To overcome these constraints, advanced deposition techniques such as spray coating and electropolymerization have been developed. These methods offer superior control over the PDA layer's thickness, uniformity, and structural properties, enabling more precise and efficient membrane modification [42] [41]. This article details the application notes and experimental protocols for these advanced deposition methods, providing researchers and development professionals with practical guidance for implementing these techniques in membrane hydrophilicity enhancement.

Table 1: Comparison of Polydopamine Deposition Methods for Membrane Modification

| Feature | Immersion Polymerization | Spray Coating | Electropolymerization |

|---|---|---|---|

| Process Principle | Spontaneous oxidative polymerization in solution [23] | Atomization and deposition of dopamine solution via nozzle [42] | Electrochemical oxidation of dopamine on a conductive substrate [41] [43] |

| Typical Coating Time | Several hours to days [41] [23] | Minutes to hours [42] | Minutes to hours (highly controllable) [41] |

| Coating Uniformity | Prone to PDA aggregation and rough surfaces [41] | High uniformity achievable with parameter optimization [42] | Can produce smooth, uniform films [41] |

| Key Advantages | Simple setup, universal adhesion [23] | Scalable, reduced material waste, suitable for patterned membranes [42] | Precise thickness control, rapid deposition, no chemical oxidants [41] [43] |

| Technical Challenges | Long duration, PDA aggregation, stability issues [41] [23] | Requires optimization of spray parameters [42] | Limited to conductive substrates [43] |

| Impact on Hydrophilicity | Significant improvement [23] | Enhanced hydrophilicity with improved flux [42] [41] | Enhances hydrophilicity [41] |

Spray Coating of Polydopamine

Principle and Application Advantages

Spray coating is a membrane fabrication and modification technique that involves atomizing a dopamine-containing solution and depositing it onto a substrate surface. This method stands out for its scalability and processing efficiency, using up to 50% less precursor material than traditional dip-coating without compromising performance [42]. The technique provides exceptional control over membrane thickness and morphology, which is crucial for producing uniform, defect-free, and ultrathin PDA layers [42]. Furthermore, spray coating can be adapted for patterning membrane surfaces, a feature shown to improve permeance by up to 50% by creating patterned selective layers without reducing pore size or porosity [42].

Detailed Experimental Protocol

Research Reagent Solutions

- Dopamine Hydrochloride Solution: Typically 2 mg/mL in Tris-HCl buffer (10 mM, pH 8.5). Functions as the PDA precursor [41].

- Tris-HCl Buffer (10 mM, pH 8.5): Provides the mildly alkaline environment necessary for dopamine oxidation and polymerization [41] [23].

- Polyethersulfone (PES) or Polyvinylidene Fluoride (PVDF) Membranes: Commonly used hydrophobic substrates for hydrophilic modification [41] [23].

Equipment Setup

- Spray Coating System: Consisting of an airbrush or ultrasonic spray nozzle, a solution reservoir, and a compressed air or nitrogen source.

- Motion Control System (Optional): A programmable stage to ensure consistent nozzle movement and coating uniformity.

- Fume Hood: To ensure safe handling of aerosols.

Step-by-Step Procedure

- Substrate Preparation: Clean the membrane substrate (e.g., PES UF membrane) with ethanol and deionized water to remove surface contaminants. Dry at room temperature.